Advertisement

Quick Links

LENGII

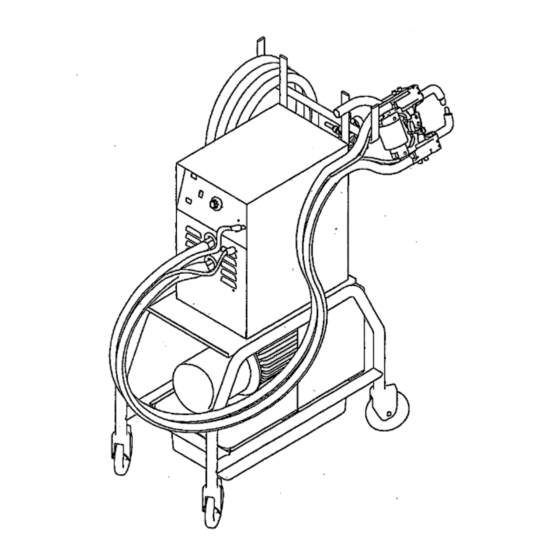

MARK III SPOT WELDER

L-6000

»WARNINGS AND SAFEGUARDS FOR WELDING AND CUTTING OPERATIONS

Important - Protect yourself and others ! _ Remember that -safety depends on you. The operator, supervisor, and '

helper must read and understand all warning and safety information provided in these instructions.'Serious injug

or death could result if welding equipment is not properly installed, used and maintained. Training and proper

supervision are most important for a safe work place. Installation, operation, repair work, and maintenance must be

preformed by qualified personnel. Retain these instructions for future use.

A

f

ELECTRICAL SHOCK CAN CAUSE INJURY OR DEATH

V

-;

' ; Install and maintain equipment in accordance with the National Electrical Code NFPA 70 and

a local codes. Do not service or repair equipment with power on. Do not operate equipment with

I

; protective insulators or covers removed. Service or repair to equipment must be done by qualified

'

" " e - '

and/or trained personnel only.

Maintain welding head, work clamps, welding cable, and welding machines and related equipment in good safe

operating condition. Replace all worn or damaged insulation. Occasionally, check all connections to determine if

they are mechanically strong and electrically adequate for the current required. Never immerse electrodes in water

for cooling.

-

.

I

g

V -

_

References; See Safety .and Operating References A, E H,

I.

. "

"

SMOKE, FUMES, AND GASES CAN BE DANGEROUS TO YOUR HEALTH .

__ »

Keep smoke,fumes, and gases from your breathing zone and the general area. Smoke, fumes, and

I

.

;

gases from the welding process are of various types and strengths, depending on the kind of metal

1 -

. .

being welded on. To ensure your safety, do not breathe these fumes or gases. Ventilation must be

adequate to remove smoke, fumes, and gases during the welding procedure to protect operators and others in the _

immediate area. Fumes produced by welding or cutting, especially in confined areas, can cause discomfort and

physical harm if inhaled over an extended period of time. Always provide adequate ventilation inthe welding and

cutting area to insure breathing air is safe. Use air-supplied. respirators if ventilation is not adequate to remove all

fumes and gases. Never ventilate with oxygen, because oxygen supports and vigorously accelerates fire.

V

References: See Safety and Operating References A, B, C, H, & I.

A

_

. .

_

HOT PARTS

_

. Hot parts can cause serious burns. The area at and near the work being welded should be handled

figs:

with proper gloves. Proper clothing should be worn to prevent spatter from causing bums. Never

pick up welded materral until 1t has been properly cooled.,References. See Safety and Operating

References A, B, H, &_I.

-

.

cnusnmc

_

,

1

-

I A

The electrode tips and arms can pinch hands or fingers when they are between them and the switch is

57. "

- activated. Hold the head by both handles when Positioning the head for welding. Disconnect air line

"/A '

from the welder before repairing or adjusting components on the welding head.

Advertisement

Need help?

Do you have a question about the L-6000 and is the answer not in the manual?

Questions and answers