Summary of Contents for MUDPUPPY 250

- Page 1 Mud Puppy 250 Installation, Operation & Maintenance Manual Mud Puppy 250 Pump Installation and Operation Manual www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055...

-

Page 2: Table Of Contents

Mud Puppy 250 Installation, Operation & Maintenance Manual TABLE OF CONTENTS FOREWORD GENERAL INSTRUCTIONS BEFORE SERVICING PUMPS INSTALLATION INTERCHANGEABILITY PUMP ASSEMBLY AND MOUNTING LOCATION FOUNDATION COUPLING ALIGNMENT PIPING PUMP SUCTION PUMP DISCHARGE PREPARATION FOR OPERATION INITIAL LUBRICATION MECHANICAL SEALS PRIMING THE PUMP... - Page 3 250 PUMP DIMENSIONS LONG BODy 250 PUMP DIMENSIONS SHORT BODY 250 PUMP Short Body Pump Assembly with Rope Packing – Base Selection 54 250 PUMP Short Body Pump Assembly with Mechanical Seal – Base Selection 55 250 PUMP Long Body Pump Assembly with Rope Packing –...

- Page 4 Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 3X2X13 PUMP CURVE 700-2500 RPM 250 PUMP 4X3X13 PUMPCURVE 970 RPM 250 PUMP 4X3X13 PUMP CURVE 1150 RPM 250 PUMP 4X3X13PUMP CURVE 1450 RPM 250 PUMP 4X3X13PUMP CURVE 1750 RPM...

-

Page 5: Foreword

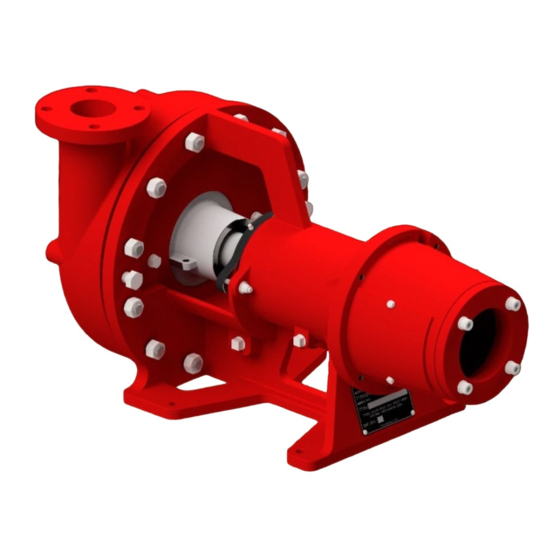

Mud Puppy Corp. distributor or Sales Representative in your area. The MUD PUPPY 250 pump generation is an improved version of older 2½ inch shaft pumps. The MUD PUPPY 250 pump is designed to give longer... -

Page 6: Before Servicing Pumps

PUMP ASSEMBLY AN D MOUNTING To install the Mud Puppy 250 pump, place the pump on the machine lining up the pump with the mounting holes. Mount using (4) 5/8” X 2 ¾” bolts, (8) 5/8” flat washers (4) 5/8” lock washers and (4) 5/8” nuts. -

Page 7: Location

There should be no more than a 1/64th of an inch in the gap between coupling halves. CAUTION! MISALIGNMENT BETWEEN THE MOTOR AND 250 PUMP COULD CAUSE FAILURE OF THE COUPLING, PUMP, MOTOR, BEARING OR EITHER SHAFT. ALIGNMENT MUST NOT BE ATTEMPTED UNTIL THE BASE IS IN POSITION AND THE MOUNTING AND FLANGE BOLTS HAVE BEEN TIGHTENED. - Page 8 Mud Puppy 250 Installation, Operation & Maintenance Manual The recommended procedure for coupling alignment is with the use of a dial indicator, as illustrated in Figures 1 and 2. The dial indicator is attached to one coupling half with the indicator button resting on the 0.0. of the other coupling half to measure offset misalignment.

-

Page 9: Piping

Connect the inlet hose from the tank to the front of the 250 pump. Connect the hose going to the Desander Manifold from the top of the 250 pump. There will also be a hose running from the Mix Hopper. -

Page 10: Pump Discharge

Mud Puppy 250 Installation, Operation & Maintenance Manual CAUTION! THE CAPACITY OF A CENTRIFUGAL PUMP SHOULD NEVER BE ADJUSTED BY THROTTLING THE SUCTION LINE. A positive shut-off valve of a type to cause minimal turbulence should be installed in the suction line to permit the closing of the line for removal of the pump for inspection and maintenance. -

Page 11: Preparation For Operation

Mud Puppy 250 Installation, Operation & Maintenance Manual CAUTION! THE PUMP MUST NOT SUPPORT THE WEIGHT OF THE PIPE OR COMPENSATE FOR MISALIGNMENT. If operating conditions are not known with sufficient accuracy, it will be necessary to provide a throttle valve in the discharge line to ensure that the pump operates at the design point. -

Page 12: Priming The Pump

The correct rotation can be found by an arrow on the casing. It is very important that the pump rotation is determined before starting the pump. If The Mud Puppy 250 is turned backwards the impeller may unscrew causing severe damage to the pump. -

Page 13: Packed Pumps

VALVE CLOSED AT ANY TIME! THERMAL SHOCK CAN CRACK THE STATIONARY SEAT IF THE TEMPERATURE IS RAISED FROM ROOM TEMPERATURE TO 250°F IN LESS THAN 30 SECONDS. RUN THE PUMP WITH THE DISCHARGE VALVES CLOSED ONLY FOR SHORT PERIODS OF TIME. THE ENERGY GOING INTO THE PUMP HEATS THE FLUID IN THE CASING. -

Page 14: Mechanical Seal Pumps

Mud Puppy 250 Installation, Operation & Maintenance Manual When adjusting the packing always adjust only ¼ turn on each nut at a time; waiting for the packing to heat before adjusting tighter. CAUTION! THE PACKING MUST LEAK 10-12 DROPS PER MINUTE TO REMAIN COOL. -

Page 15: Operation

Mud Puppy 250 Installation, Operation & Maintenance Manual OPERATION MAXIMUM OPERATIN G CONDITIONS PUMP RECO RDS Information to be included in these records should be: Pump size and serial number. Pump model number, impeller diameter, material of construction. Mechanical seal manufacturer, type, code and drawing number. -

Page 16: Lubrication Of Inboard Lip Seals

LUBRICATION OF INBOARD LIP SEALS The standard Mud Puppy 250 Pump is equipped with labyrinth seals that do not require lubrication. WARNING! FAILURE TO REMOVE THE GREASE RELIEF PORT PRIOR TO ADDING GREASE CAN FORCE OLD GREASE PAST THE LIP SEALS AND INTO THE BEARINGS, GREATLY SHORTENING THEIR LIFE. -

Page 17: Packing Appearance

Mud Puppy 250 Installation, Operation & Maintenance Manual should be avoided. Slight leakage approximately 10-12 drops per minute is desirable to act as a packing lubricant. A grease fitting has been installed in the ¼” tapped Lantern Ring connection. CAUTION! MOST EARLY PACKING FAILURES ARE CAUSED BY OVER TIGHTENING OR POOR INSTALLATION. -

Page 18: Grease

Mud Puppy 250 Installation, Operation & Maintenance Manual Wrap one piece around the shaft and push it into the stuffing box. Use the packing gland to push the piece as far in as possible, (Rotate the split 90 degrees from the last, each time a piece is... -

Page 19: Re-Packing The Pump (Rope Packing Seal Option)

Mud Puppy 250 Installation, Operation & Maintenance Manual PACKING AND SHAFT LIFE WILL BE INCREASED UP TO 500%. Also, water leakage from the packing will not be as objectionable as mud. If water cannot be used, the next best addition to the packing would be grease from an automatic spring-loaded grease cup. - Page 20 Mud Puppy 250 Installation, Operation & Maintenance Manual Install the Grease Ring so that the two halves encompass the pump shaft. Slide the Grease Ring halves into the pump pedestal packing box until they meet the third Rope Packing Ring.

-

Page 21: Pump Inspection

Mud Puppy 250 Installation, Operation & Maintenance Manual CAUTION! TIGHTEN THE GLAND AGAINST THE PACKING FINGER TIGHT ONLY. IF PACKING IS OVER-TIGHTENED IT MAY BE BURNED WHEN THE PUMP IS STARTED. PUMP INSPECTION IMPELLER Replace if impeller shows excessive erosion (especially on the pump-out vanes on the back of the impeller), corrosion, extreme wear, or vane breakage. -

Page 22: Seals

Mud Puppy 250 Installation, Operation & Maintenance Manual When greasing these bearings, we recommend the grease listed above, Chevron SRJ-2 or equivalent. When using a standard sized grease gun 5 shots of grease every 2-3 months should be sufficient for a 24 hour operation. - Page 23 Mud Puppy 250 Installation, Operation & Maintenance Manual Install the Shaft Assembly into the Pump Pedestal. Install Item 10 O-Ring against Item 2 Seal Sleeve. Install Item 2 Seal Sleeve into Item 1 Mechanical Seal Stuffing Box. Install Item 4 Mechanical Seal into Item 1 Mechanical Seal Stuffing Box.

- Page 24 Mud Puppy 250 Installation, Operation & Maintenance Manual Bolts threaded into the sleeve, with a lock down nut. When tightened pulls the impeller towards the stuffing box. Bolts threaded into the pedestal. When tightened moves the impeller towards the wear plate. Ensure the shaft still turns, and check the gap between the impeller and the wear plate, this gap can be no more than 1/32”.

- Page 25 Mud Puppy 250 Installation, Operation & Maintenance Manual Install the housing, with housing in place bolt down using (10) ¾” Nylock nuts, (10) ¾” lock washers as shown 10. Rope Packing Backup Option: Some pumps include emergency rope packing backup which is to be used only if the mechanical seal fails.

-

Page 26: Excessive Packing Leakage And Rapid Packing Wear

Mud Puppy 250 Installation, Operation & Maintenance Manual EXCESSIVE PACKING LEAKAGE AND RAPID PACKING WEAR GENERAL Most early packing failures are caused by over-tightening or poor installation. PACKING APPEARAN CE If the packing being removed is hard and brittle, it has been run dry some time in its life. -

Page 27: Bearing Failures And How To Improve Bearing Life

Mud Puppy 250 Installation, Operation & Maintenance Manual water (a few drops per minute) which gets into the mud while the pump is running should not be objectionable to the oil companies. BEARING FAILURES AND HOW TO IMPROVE BEARING LIFE... -

Page 28: Identification Of Bearing Failure

Mud Puppy 250 Installation, Operation & Maintenance Manual IDENTIFICATION OF BEARING FAILURE ABNORMALLY HIGH TEMPERATURES Normal operational temperature is less than 180ºF. If you can hold your hand on the bearing housing for five seconds or longer the bearing temperature is running in a normal range (suitable for most pumps). -

Page 29: Dirty Lubrication

Mud Puppy 250 Installation, Operation & Maintenance Manual DIRTY LU BRICATION Contaminates found in lubricants often act as an abrasive compound, which will lap or polish ball and race surfaces, increasing the probability of failure. Always be sure to use clean lubricant from a tube and NOT from an open bucket. -

Page 30: Capacity Requirements Of Equipment In Rig Applications

Mud Puppy 250 Installation, Operation & Maintenance Manual It appears that most installations do not have enough NPSH to run a 5x6 pump at flows above 1400GPM even with an 8-inch suction. (This does not mean that no one has enough NPSH). The result of inadequate NPSH is cavitation and early pump failure. -

Page 31: Installation Of Replacement Parts

Mud Puppy 250 Installation, Operation & Maintenance Manual If the pumps are to be stored outdoors, the pump suction and discharge openings should be sealed to prevent any water from entering the pump housing. This will prevent rust and corrosion. -

Page 32: Information Required To Orderparts

G. When the repacking is finished and operational, follow the instructions on Initial Checks at startup. NOTE: NEW GASKETS SHOULD BE USED THROUGHOUT. USE THE PROPER GASKETS FOR THE 250 PUMP AS LISTED IN THE PARTS LIST. INFORMATION REQUIRED TO O RDERPARTS: Pump Type Pump Size Impeller diameter. -

Page 33: Packing Burned

Mud Puppy 250 Installation, Operation & Maintenance Manual tip bent 90 degrees across the shaft to detect damage on the shaft. If there are deep grooves in the shaft you will need to replace the shaft. PACKING BURN ED If the packing is burned and hard when removed the packing was over tightened and the lack of leakage and/or lack of proper greasing caused the packing to burn. -

Page 34: Mud Puppy 250 Mud Pump And Wet End Kit Order Sheet

Mud Puppy 250 Installation, Operation & Maintenance Manual MUD PUPPY 250 MUD PUMP AND WET END KIT ORDER SHEET www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 35: 250 Pump Motor Mount Shaft Kit Long Body

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP MOTOR MOUNT SHAFT KIT LONG BODY www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 36: 250 Pump Motor Mount Shaft Kit Short Body

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP MOTOR MOUNT SHAFT KIT SHORT BODY www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 37: 250 Pump Wet End Kit 4X3X13 Ductile Iron Mechanical Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 4X3X1 3 DUCTILE IRON MECHANICAL SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 38: 250 Pump Wet End Kit 4X3X13 Ductile Iron Packed Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 4X3X1 3 DUCTILE IRON PACKED SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 39: 250 Pump Wet End Kit 4X3X13 Chrome Mechanical Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 4X3X1 3 CHROME MECHANICAL SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 40: 250 Pump Wet End Kit 4X3X13 Chrome Packed Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 4X3X1 3 CHROME PACKED SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 41: 250 Pump Wet End Kit 6X5X11 Ductile Iron Mechanical Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 6X5X1 1 DUCTILE IRON MECHANICAL SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 42: 250 Pump Wet End Kit 6X5X14 Ductile Iron Mechanical Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 6X5X1 4 DUCTILE IRON MECHANICAL SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 43: 250 Pump Wet End Kit 6X5X11 Ductile Iron Packed Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 6X5X1 1 DUCTILE IRON PACKED SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 44: 250 Pump Wet End Kit 6X5X14 Ductile Iron Packed Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 6X5X1 4 DUCTILE IRON PACKED SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 45: 250 Pump Wet End Kit 6X5X11 Chrome Mechanical Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 6X5X1 1 CHROME MECHANICAL SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 46: 250 Pump Wet End Kit 6X5X14 Chrome Mechanical Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 6X5X1 4 CHROME MECHANICAL SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 47: 250 Pump Wet End Kit 6X5X11 Chrome Packed Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 6X5X1 1 CHROME PACKED SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 48: 250 Pump Wet End Kit 6X5X14 Chrome Packed Seal

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP WET END KIT 6X5X1 4 CHROME PACKED SEAL www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 49: Piping Recommendations

Mud Puppy 250 Installation, Operation & Maintenance Manual PIPING RECOMMENDATIONS www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 50: Piping Recommendations (Continued)

Mud Puppy 250 Installation, Operation & Maintenance Manual PIPING RECOMMENDATIONS (CONTINUED) www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 51: Piping Recommendations (Continued)

Mud Puppy 250 Installation, Operation & Maintenance Manual PIPING RECOMMENDATIONS (CONTINUED) www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 52: 250 Pump Dimensions Long Body

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP DIMENSIONS LONG BODY www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 53: 250 Pump Dimensions Short Body

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP DIMENSIONS SHORT BODY www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 54: 250 Pump Short Body Pump Assembly With Rope Packing - Base Selection

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP SHORT BODY PUMP ASSEMBLY WITH ROPE PACKING – BASE SELECTION www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 55: 250 Pump Short Body Pump Assembly With Mechanical Seal - Base Selection

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP SHORT BODY PUMP ASSEMBLY WITH MECHANICAL SEAL – BASE SELECTION www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 56: Base Selection

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP LONG BODY PUMP ASSEMBLY WITH ROPE PACKING – BASE SELECTION www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 57: 250 Pump Long Body Pump Assembly With Mechanical Seal - Base Selection

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP LONG BODY PUMP ASSEMBLY WITH MECHANICAL SEAL – BASE SELECTION www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 58: 250 Pump Housing, Impeller, Stuffing Box And Flange Gasket Selection

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP HOUSING, IMPELLER, STUFFING BOX AND FLANGE GASKET SELECTION www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 59: 250 Pump 3X2X13 Pump Curve 970 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 3X2X13 PUMP CURVE 970 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 60: 250 Pump 3X2X13 Pump Curve 1150 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 3X2X13 PUMP CURVE 1150 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 61: 250 Pump 3X2X13 Pump Curve 1450 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 3X2X13 PUMP CURVE 1450 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 62: 250 Pump 3X2X13 Pump Curve 1750 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 3X2X13 PUMP CURVE 1750 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 63: 250 Pump 3X2X13 Pump Curve 2900 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 3X2X13 PUMP CURVE 2900 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 64: 250 Pump 3X2X13 Pump Curve 3500 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 3X2X13 PUMP CURVE 3500 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 65: 250 Pump 3X2X13 Pump Curve 700-2500 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 3X2X13 PUMP CURVE 700-250 0 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 66: 250 Pump 4X3X13 Pumpcurve 970 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 4X3X13 PUMPCURVE 970 RPM (Please see www.MudPuppyInc.com for The Mud Puppy 250 Pump Long Body 3x4 and Short and Long Body 2X3 and 4X5) www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 67: 250 Pump 4X3X13 Pump Curve 1150 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 4X3X13 PUMP CURVE 1150 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 68: 250 Pump 4X3X13Pump Curve 1450 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 4X3X13PUMP CURVE 1450 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 69: 250 Pump 4X3X13Pump Curve 1750 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 4X3X13PUMP CURVE 1750 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 70: 250 Pump 4X3X13 Pumpcurve 2900 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 4X3X13 PUMPCURVE 2900 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 71: 250 Pump 4X3X13 Pumpcurve 3500 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 4X3X13 PUMPCURVE 3500 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 72: 250 Pump 4X3X13 Pump Curve 1000-2400 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 4X3X13 PUMP CURVE 1000-24 00 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 73: 250 Pump 6X5X11 Pump Curve 970 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X11 PUMP CURVE 970 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 74: 250 Pump 6X5X11 Pump Curve 1450 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X11 PUMP CURVE 1450 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 75: 250 Pump 6X5X11 Pump Curve 1750 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X11 PUMP CURVE 1750 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 76: 250 Pump 6X5X11 Pump Curve 800-1800 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X11 PUMP CURVE 800-180 0 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 77: 250 Pump 6X5X14 Pump Curve 970 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X14 PUMP CURVE 970 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 78: 250 Pump 6X5X14 Pump Curve 1150 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X14 PUMP CURVE 1150 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 79: 250 Pump 6X5X14 Pump Curve 1450 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X14 PUMP CURVE 1450 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 80: 250 Pump 6X5X14 Pump Curve 1750 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X14 PUMP CURVE 1750 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 81: 250 Pump 6X5X14 Pump Curve 800-1800 Rpm

Mud Puppy 250 Installation, Operation & Maintenance Manual 250 PUMP 6X5X14 PUMP CURVE 800-180 0 RPM www.mudpuppyinc.com orders@mudpuppyinc.com 530-662-5055... -

Page 82: Back Cover

And Mudpuppy Corp. expressly disclaims liability under any theory, including without limitation, contract negligence, misrepresentation or breach of any obligation relating to the recommendation, data, or information.

Need help?

Do you have a question about the 250 and is the answer not in the manual?

Questions and answers