Summary of Contents for Grunbeck DE200

- Page 1 We understand water. Accessories | Communication module DE200 Profibus for Delta-p as of software V3.04 Operation manual...

- Page 2 General Contact Germany International Sales Phone +49 9074 41-145 Technical Service Phone +49 9074 41-333 Fax +49 9074 41-120 Availability Monday to Thursday 7:00 am - 6:00 pm Friday 7:00 am - 4:00 pm Copyright The manufacturer reserves the copyright to this operation manual. Without the written consent of Grünbeck Wasseraufbereitung GmbH, no part of this manual may be reproduced in any way, nor may any part be processed, duplicated or distributed using electronic systems.

-

Page 3: Table Of Contents

Table of contents Table of contents Requirements for the installation site......10 Table of contents ..............3 Checking the scope of supply ........10 Installing the product ..........11 About this manual ............. 4 Other applicable documents ........4 Start-up/commissioning ..........15 Target group .............. 4 Storage of documents .......... -

Page 4: About This Manual

About this manual About this manual Other applicable documents The following documents shall be considered as applicable documents for communication module DE200 Profibus Delta-p: ● For Grünbeck's technical service/authorised service company: Technical service manual Water softener Delta-p Order no.: 185 951 Target group This manual is intended for qualified specialists and owners/operators/operating companies. -

Page 5: Typographical Conventions

Lists ● Listed item • Listed sub-item Status level>Menu level>Submenu Menu paths Display texts Display text Control elements Button/key Validity of the manual This manual applies to the products below: ● Communication module DE200 Profibus for Delta-p/Delta-p-I 5 | 28... -

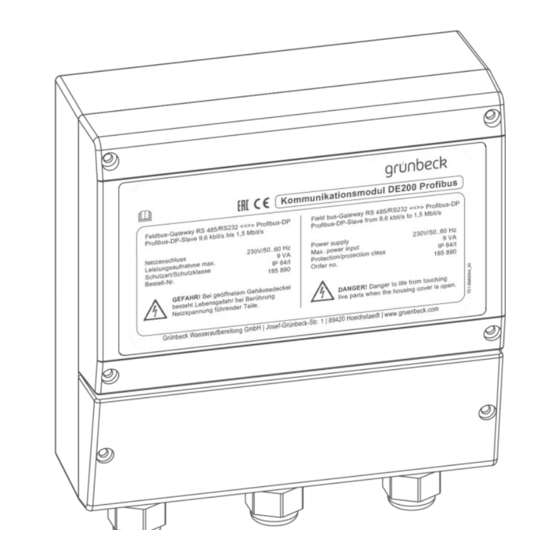

Page 6: Type Plate

Fieldbus gateway RS 485/RS 232 Profibus DP slave Rated voltage range/frequency Max. power input Protection/protection class Order no. ● Product designation: Communication module DE200 Profibus ● Order no.: 185 890 ● Serial no.: ________________ ● Software version ________________ 6 | 28... -

Page 7: Safety

Safety Safety Safety measures ● Carefully read this manual before operating your product. ● Only operate the product if all components are installed properly. ● Only have persons working on your product that have read and understood the present manual and that are qualified to do such work due to their vocational training. -

Page 8: Responsibilities Of The Qualified Specialist

Safety Responsibilities of the qualified specialist Comply with the instructions below to ensure the proper and safe functioning of the product: ● Only perform activities described in this manual. ● Perform all activities in accordance with all applicable standards and regulations. ●... -

Page 9: Product Description

Interface Schuko mains plug Functional description The communication module DE200 Profibus is suitable for water softeners Delta-p and Delta-p-I. The assignment of the input and output data is specified by the respective control software. The measured values and status information indicated on the display of the control unit are available at the PROFIBUS DP interface for collection and further processing by a PROFIBUS DP master on site. -

Page 10: Installation

● The ambient temperature must not fall below -5 °C and not exceed +55 °C. Checking the scope of supply The components below are included in the scope of supply: ● Communication module DE200 Profibus ● Operation manual ● CD (GSD file, A list) Check the scope of supply for completeness and damage. -

Page 11: Installing The Product

Installation Installing the product 4.3.1 Opening the housing 1. Open the lid of terminal compartment – loosen 2x screws. 2. Open the housing lid – loosen 4x screws. 4.3.2 Fastening the housing The client is responsible for firmly installing the communication module according to the wall situation on site. - Page 12 Installation 1. Position the communication module near the water softener Delta-p – pay attention to the length of the cables for power supply and interfaces when doing so. 2. Fasten the housing smoothly and evenly using the fastening material provided by the client on site (aligned horizontally and vertically) 4.3.3 Electrical installation...

- Page 13 Installation RS 485 interface The serial connection between the “Communication module DE200 Profibus” and the GENO-IONO-matic is done via the RS 485 interface or the RS 232 interface. Item Designation Item Designation Plug-in screw-type terminal MC1,5/3-ST-3,81, 3-pin Connecting line to be provided by the client on site (max.

- Page 14 Not assigned Not assigned Profibus Signal B Profibus RTS Send request Ground 5 V supply (fed by communication module DE200 Profibus) Not assigned Profibus Signal A Not assigned 3. Establish a connection line to the GENO-IONO-matic on site. 14 | 28...

-

Page 15: Start-Up/Commissioning

If the length of the line between the control unit GENO-IONO-matic and the communication module DE200 Profibus is long, the terminating resistors for the COM1 interface must be activated. If the line is short, activation is not necessary. The interface COM2 (J3 and J4) is not used. The setting of J3 and J4 is not to be taken into consideration. -

Page 16: Setting The Profibus Address

Start-up/commissioning Setting the Profibus address The Profibus address is set using two rotary switches that are located on the Profibus plug- in module. The address is set as a hexadecimal number in the range from 01h ... FEh. Rotary switch 1 sets the higher-value and rotary switch 2 the lower-value hexadecimal digit. -

Page 17: Activating The Data Transfer In The Geno-Iono-Matic

Start-up/commissioning Hexadecimal Decimal Rotary switch 1 Rotary switch 2 address address 5.2.1 Data transfer The Profibus input and output data is allocated by the respective control software and is each recorded in a separate document (A list) – refer to chapter 6 “Operation”. The A list and the GSD file are located on the CD. -

Page 18: Diagnostics

WARNING: Life-threatening voltage when the housing lid is open. ● Severe burns, cardiovascular failure, fatal electric shock. ► Do not touch live components. The communication module DE200 Profibus features 3 SMD light-emitting diodes. Via these SMD light-emitting diodes, the module’s operating state can be read. Description... -

Page 19: Dip Switches

Start-up/commissioning DIP switches The DIP switches located under the Profibus plug-in module have reserved functions and must not be changed. Closing the housing 1. Close the housing lid – tighten 4x screws. 2. Close the lid of the terminal compartment – tighten 2x screws. 3. -

Page 20: Operation

Operation Operation Data range – Profibus (A list) GENO-IONO-matic 6.1.1 Data from Profibus to GENO-IONO-matic Byte Comments 0 Byte Bit 0: Manual regeneration (Exchanger* regenerates) Bit 1: Regeneration lock Bit 2: Free Bit 3: Free Bit 4: Free Bit 5: Free Bit 6: Free... - Page 21 Operation Byte Comments Bit 3: Er 8a (Error Water meter – Exchanger 3) Bit 4: Er C Bit 5: Er d Bit 6: Reserved Bit 7: Maintenance due 2. Byte Bit 0: Exchanger 1 in operation Bit 1: Exchanger 2 in operation Bit 2: Exchanger 3 in operation Bit 3:...

- Page 22 Operation Byte Comments 61. Byte Bit 0: Free Bit 1: Free Bit 2: Free Communication status Bit 3: Free between Bit 4: Free GENO-IONO-matic Bit 5: Free and Profibus modules Bit 6: Free Bit 7: Communi- cation OK 22 | 28...

-

Page 23: Troubleshooting

Troubleshooting Troubleshooting Troubleshooting. Refer to operation manual of water softener Delta-p/Delta-p-I (BA-TD3-BM001) and technical service manual of Delta-p/Delta-p-I (BA-185 951). 23 | 28... -

Page 24: Disposal

Disposal Disposal Obey the applicable national regulations. Packaging Dispose of the packaging in an environmentally sound manner. Product If this symbol (crossed out wheelie bin) is on the product, this product is subject to the European Directive 2012/19/EU. This means that this product and the electrical and electronic components must not be disposed of as household waste. -

Page 25: Technical Specifications

Technical specifications Technical specifications Dimensions and weight Communication module DE200 Profibus Width x height x depth [mm] 180 x 180 x 74 Operating weight, approx. [kg] Shipping weight, approx. [kg] Connection data Rated voltage range 50 – 60 Rated frequency [Hz] Max. - Page 26 European guidelines in terms of its design, construction and execution. This certificate becomes void if the system is modified in any way not approved by us. Communication module DE200 Profibus Serial no.: Refer to type plate The aforementioned system also complies with the following directives and provisions: •...

- Page 28 Grünbeck Wasseraufbereitung GmbH Josef-Grünbeck-Str. 1 89420 Hoechstaedt/Germany +49 9074 41-0 +49 9074 41-100 info@gruenbeck.com For more information go www.gruenbeck.com to www.gruenbeck.com...

Need help?

Do you have a question about the DE200 and is the answer not in the manual?

Questions and answers