Table of Contents

Advertisement

Quick Links

Rua Central da Vergada, 1280

4535 - 166 Mozelos VFR

PORTUGAL

Tel (+351) 227 471 120 ● Fax. (+351) 227 471 129

E-mail: info@egitron.pt ● URL: www.egitron.pt

TorsiLab

Cork and Bar Top

Torsion Force Measuring System

User Manual

Version 1.2.1

Valid for PC interface software version 1.2.0 or above

Valid for embedded software version 2.3.0 or above

Advertisement

Table of Contents

Summary of Contents for Egitron TorsiLab

- Page 1 Rua Central da Vergada, 1280 4535 - 166 Mozelos VFR PORTUGAL Tel (+351) 227 471 120 ● Fax. (+351) 227 471 129 E-mail: info@egitron.pt ● URL: www.egitron.pt TorsiLab Cork and Bar Top Torsion Force Measuring System User Manual Version 1.2.1 Valid for PC interface software version 1.2.0 or above...

- Page 2 TorsiLab – Cork and Bar Top Torsion Force Measuring System RESPONSIBILITY EXEMPTION This manual was written and revised to explain the TorsiLab functioning and characteristics the most correct way possible, particularly the PC interface and control software. However, this user manual and/or the equipment can be changed with previous notice. EGITRON is not responsible for any damage caused by any direct or indirect error, omission or discrepancies between the TorsiLab and the instructions of this user manual.

- Page 3 This is valid excepting for the first onsite displacement or equipment transport if required within the first month of the warranty period, which will be free. In this last case, EGITRON will decide the most appropriate option between the technician onsite displacement and the equipment transportation to EGITRON facilities and back to the client.

- Page 4 TorsiLab – Cork and Bar Top Torsion Force Measuring System To request for the warranty services contact EGITRON technical support. EGITRON can ask for the purchase proof / equipment invoice. This equipment is suitable only for the design purposes and EGITRON is not responsible for its improper use.

-

Page 5: Table Of Contents

TorsiLab – Cork and Bar Top Torsion Force Measuring System INDEX WELCOME NOTES ..............................7 1 - MANUAL CONTENTS ............................7 2 - CONVENTIONS ..............................8 3 - TORSILAB AND PC INTERFACE SOFTWARE SETUP ................. 9 3.1 - MACHINE SETUP ............................9 3.2 - PC INTERFACE SOFTWARE SETUP AND CONFIGURATION ............ - Page 6 TorsiLab – Cork and Bar Top Torsion Force Measuring System 7.2 - C ....................... 31 LAMPS FOR ORK STOPPERS ANNEX A ................................. 32 A-1 – TECNICAL CONSIDERATIONS ABOUT THE TORSIOMETER ............32 A-2 – CALCULATION OF CUT TENSION ......................32 ANNEX B .................................

-

Page 7: Welcome Notes

TorsiLab – Cork and Bar Top Torsion Force Measuring System WELCOME NOTES Congratulations for the purchase of TorsiLab – Cork and Bar Top Torsion Force Measuring System. With this excellent equipment it is possible to assess the flexibility and the resistance of cork stoppers, following the standards in practice, or to verify the gluing of Bar Top corks. -

Page 8: Conventions

• Calibration certificate from a credited laboratory (optional). This user manual starts with TorsiLab characteristics, the setup procedure, the connection to a PC and the interface control software setup. After the setup, the user manual describes the TorsiLab functioning, the test process and the data collect from the software. In the following chapters, you can find information regarding saving the tests, opening saved tests and printing reports. -

Page 9: Torsilab And Pc Interface Software Setup

3 - TORSILAB AND PC INTERFACE SOFTWARE SETUP 3.1 - MACHINE SETUP TorsiLab is supplied with one power cable which should be connected to a power plug with same voltage and frequency indicated on the equipment specifications. TorsiLab is also supplied with one serial communication cable to connect TorsiLab to a personal computer. -

Page 10: Pc Interface Software Setup And Configuration

D is the CD/DVD drive letter. To open the Run command you can also use the keyboard shortcut ‘Windows+R’. After software installation, start the control software from the shortcut “TorsiLab” on the menu programs (clicking with the mouse right button is possible to send a shortcut to Desktop). -

Page 11: Operation Statement And Features Of The Equipment

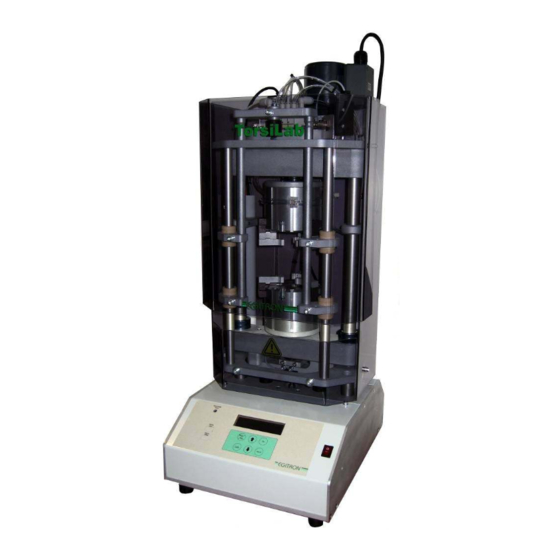

4 - OPERATION STATEMENT AND FEATURES OF THE EQUIPMENT On this chapter we will explain the functionalities of the TorsiLab system including the control by the command box and the control by the interface software, thus enabling the user to operate the equipment correctly for performing the tests. - Page 12 TorsiLab – Cork and Bar Top Torsion Force Measuring System Electric Motor Pneumatic valves Encoder Door security switch Upper group Security door Top Gripprer B Pneumatic Grippers Lower Gripper A Range Selector Power indicator led Gain and zero adjustment Command Box...

- Page 13 TorsiLab – Cork and Bar Top Torsion Force Measuring System Generally, the pressure should be between 2 and 2.5 bar, in order to prevent the sliding of the cork stopper during the test and, secondly, to prevent high pressures that could damage the cork. The operator should adjust the gripper’s pressure whenever this value is not in the correct range, i.e.:...

-

Page 14: Controling Thru Command Box

4.2.2 - Range Selection TorsiLab allows the range selection in accordance with the cork stopper length. The user can change between Range A and Range B. By default Range A is suitable for cork stoppers with length equal or inferior to 38mm and Range B to lengths superior to 38mm. -

Page 15: Discs For Cork Position

TorsiLab – Cork and Bar Top Torsion Force Measuring System 4.2.3 - Discs for cork position TorsiLab is supplied with two aluminium discs, one with thickness of 3mm and the other with 4mm. These discs allow raising the cork stopper on the Lower Gripper (A) with the objective of achieving a more appropriate placement for the type of cork or capsulated cork Figure 13 –... -

Page 16: Check Information On Display

TorsiLab – Cork and Bar Top Torsion Force Measuring System “Start Test: xxx” | “Confirm/ Cancel”, where xxx is the new test number. Press “OK” to confirm the beginning of the test (or “Abort” to cancel). ii) “Check initial position?” this means one of the movable parts (upper gripper B or vertical actuator) is not at its home position. -

Page 17: Calibration

TorsiLab – Cork and Bar Top Torsion Force Measuring System 4.2.8 – Calibration TorsiLab has a calibration mode, which can be started using the keypad or the PC interface software (for further details please read the 4.3.9 - Calibration ADC: 0691 Torque = 056.5 daNcm... -

Page 18: Data Tables

This information appears in the form of a picture (fixed or intermittent) and text. The main area of this window displays information related with test results, including values and graphics of the present test (acquired from TorsiLab or opened from the database). Main menu... -

Page 19: Report Configuration

TorsiLab – Cork and Bar Top Torsion Force Measuring System • Client/Supplier • Cork type • Size • Treatment • Washing • Cork grades • Observations Figure 17 – Cork type table To open the tables, go to “Configuration” - “Tables” and select the table to open. All tables look similar and work the same way. -

Page 20: Range Configuration

Equal or More than X Equal or Less than X mm To send the range selection the TorsiLab (according to the configuration described above), click on the Configure Range button at the PC interface software main window. - Page 21 TorsiLab – Cork and Bar Top Torsion Force Measuring System To collect the values press the “Acquire Tests” button. The PC interface software main window is composed by three tabs: • Maximum Values (figure 20): here it is possible to see the maximum torque...

-

Page 22: Saving Reports

TorsiLab – Cork and Bar Top Torsion Force Measuring System • Identification: On this tab the user can fill in information required to identify the report. The same information can be entered on the “Save Report” window which will be explained in the next chapter. -

Page 23: Opening Saved Reports

TorsiLab – Cork and Bar Top Torsion Force Measuring System 4.3.6 - Opening saved reports After saving a report into the “BDTorsiLab.mdb” database, it is possible to open the saved reports. For this, select the “Open” option from the “Report” menu to open de “Open Report” window (figure 23) with the list of the reports saved on the Database. -

Page 24: Data Export To Microsoft Excel

TorsiLab – Cork and Bar Top Torsion Force Measuring System values, and then, according to the option “Individual Reports”, a page for each test corresponding to each individual test. Language list Zoom Page Navigation Individual Reports option Print Figure 24 – Printing Report preview window The reports can only be printed if previously saved into the database. -

Page 25: Calibration

Excel Language list allows configuring for the installed Excel idiom. 4.3.9 - Calibration Like any laboratory equipment, TorsiLab is subject to calibrations in order to verify and attest the values acquired. If required, EGITRON can supply a Calibration Kit for TorsiLab force reading, as referred in 7.1 - Calibration Kit... - Page 26 – ADC) into daN.cm (decaNewton.centimeter). The first function represents the function stored on TorsiLab’s memory. The coefficients of this function are imported directly from the TorsiLab every time the calibration window is opened or after pressing the “Cancel” button when editing.

-

Page 27: Common Equipment And Software Operations

“Cancel” button, and continue using the existing conversion function in the TorsiLab. If necessary, EGITRON can provide a prepared file (Microsoft Excel), to calculate the new conversion function. Pressing “Exit” will close the PC interface software calibration window. The calibration mode will only end after exiting the calibration mode at the equipment. -

Page 28: Acquire Tests

Excel, print reports on different languages, etc. 4.4.4 - Deleting test The TorsiLab equipment can save 99 tests in memory, and even if powered off, the tests remain in memory until being erased by the operator. Deleting all tests in memory can be done by two different ways: a. -

Page 29: Safety And Protection

TorsiLab – Cork and Bar Top Torsion Force Measuring System 4.4.6 - Safety and Protection The TorsiLab has built-in protections, avoiding damages to the user or the equipment. The PC software is permanently checking the equipment status and warns the user if any anomaly occurs. -

Page 30: Troubleshoot

Resolution: Turn off, let it rest for some seconds, and turn on again the equipment. If the problem persists, check the error messages that appear on the screen of the equipment or on the interface application. If the problem persists, please contact EGITRON for help on this problem. -

Page 31: Optional Devices

TorsiLab – Cork and Bar Top Torsion Force Measuring System 7 - OPTIONAL DEVICES 7.1 - Calibration Kit This kit is used to check/calibrate the torque readings of TorsiLab. It can be acquired separately and is composed by: Calibrated masses with 1kg, 2kg, 3kg e 5kg (optional);... -

Page 32: Annex A

EGITRON TorsiLab applies an axial torsion to the cork stopper in test. The values obtained will depend on how the cork stoppers are gripped, and on a lesser degree, the speed at which the test is performed. -

Page 33: Annex B

TorsiLab – Cork and Bar Top Torsion Force Measuring System ANNEX B B-1 – Communication Cable TorsiLab Connector DB- Connector DB- 9 Female 9 Female B-2 – “Dip-Switch” Configuration 19.200 Bits/Second Communication SW1.1 Speed 9.600 Bits/Second Portuguese SW1.2 Language English Without security port SW1.3... -

Page 34: Annex C - Calibration

1. The equipment must be turned on thirty minutes before initializing this procedure. 2. The calibration kit supplied by EGITRON, was designed for a maximum load of 10kg, which represents a load 100daN.cm on TorsiLab. Not respecting this limit can overload the system and therefore damage the installed load cell. - Page 35 Apply the measurement arm using the screws provided. The application force point is 100mm distant from the axis center. Apply pulley support and tighten it on the TorsiLab’s right shaft. Apply the stainless steel cable. After stretched, the cable must be parallel to the support plan.

- Page 36 TorsiLab – Cork and Bar Top Torsion Force Measuring System Take off the seal label that is down the indication “Gain” on the frontal panel (see figure 6). ii. Use a small screw driver to access the potentiometer, which is inside the command box, towards the hole below the indication ‘Gain’.

- Page 37 Connect the security door micro-switch cable. Install the back and frontal lower shield. Test TorsiLab, by doing one or more tests and checking the correct operation of the equipment. If there is any doubt when following this procedure do not hesitate to contact EGITRON, for support.

-

Page 38: Annex D - Technical Specifications

Save the tests into a database for later consult; Export to Microsoft Excel; Possible to integrate with the following applications: EGITRON CorkLab / ControLab (Cork Quality Control) e EGITRON SPC (Statistic Process Control); Available in Portuguese and English; Compatible with Windows 9x/2000/XP and Vista. -

Page 39: Notes

TorsiLab – Cork and Bar Top Torsion Force Measuring System NOTES EGITRON Page 39 of 40... - Page 40 TorsiLab – Cork and Bar Top Torsion Force Measuring System Rua Central da Vergada, 1280 4535 - 166 Mozelos VFR PORTUGAL Tel (+351) 227 471 120 ● Fax. (+351) 227 471 129 E-mail: info@egitron.pt ● URL: www.egitron.pt EGITRON Page 40 of 40...

Need help?

Do you have a question about the TorsiLab and is the answer not in the manual?

Questions and answers