Table of Contents

Advertisement

PUBLISHED 03/18

OPERATOR'S & PARTS MANUAL

This Operator's Manual is an integral part of the safe operation of this machine and must be main-

tained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety and Operation

Insrtuctions contained in this manual before operating the equipment. C01-Cover

RHINO

®

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

Email: parts@servis-rhino.com

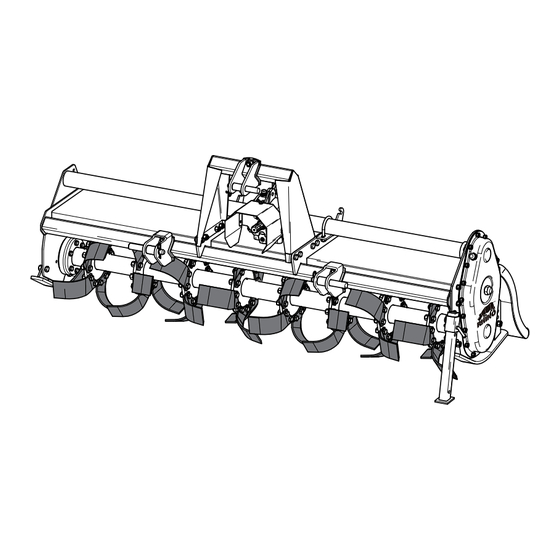

SRT, SRD, SRM

TILLER

PART NO. 00788293

903849001~01

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for RHINO SRT40

- Page 1 This Operator’s Manual is an integral part of the safe operation of this machine and must be main- tained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety and Operation Insrtuctions contained in this manual before operating the equipment. C01-Cover 903849001~01 RHINO ® 1020 S. Sangamon Ave. Gibson City, IL 60936 800-446-5158 Email: parts@servis-rhino.com...

- Page 2 To the Owner/Operator/Dealer All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance of accidents.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SAFETY SECTION ......................General Safety Instructions and Practices ....................Operator Safety Instructions and Practices ....................Equipment Operation Safety Instructions and Practices ................Transporting Safety Instructions and Practices ................... Maintenance and Service Safety Instructions and Practices ............... Storage and Parking Safety Instructions and Practices ................1-10 Concluding Safety Instructions and Practices ..................... - Page 4 SLIP CLUTCHES ............................SEASONAL CLUTCH MAINTENANCE ...................... OIL CHANGE ............................... REPLACEMENT OF LATERAL CHAIN TRANSMISSION ON SRT40 & SRT48 ........DISASSEMBLY OF GEARBOX ON SRT40 & STR48.................. REPLACEMENT OF LATERAL CHAIN TRANSMISSION ON STR55 ............DISASSEMBLY OF GEARBOX ON SRT55 .

-

Page 5: Safety Section

SAFETY SECTION Safety Section 1-1... -

Page 6: General Safety Instructions And Practices

SAFETY General Safety Instructions and Practices A careful operator is the best operator. Safety is of primary importance to the manufacturer and should be to the owner/operator. Most accidents can be avoided by being aware of your equipment, your surroundings, and observing certain precautions. - Page 7 SAFETY Never operate the Tractor or Implement until you have read and completely understand this Manual, the Tractor Operator’s Manual, and each of the Safety Messages found in the Manual or on the Tractor and Implement. Learn how to stop the tractor engine suddenly in an emergency.

-

Page 8: Operator Safety Instructions And Practices

SAFETY Operator Safety Instructions and Practices The operator and all support personnel should wear hard hats, safety shoes, safety glasses, and proper hearing protection at all times for protection from injury including injury from items that may be thrown by the equipment. -

Page 9: Equipment Operation Safety Instructions And Practices

SAFETY Extreme care should be taken when operating near loose objects such as gravel, rocks, wire, and other debris. Inspect the area before tilling. Foreign objects should be removed from the site to prevent machine damage and/or bodily injury or even death. Any objects that cannot be removed must be clearly marked and carefully avoided by the operator. -

Page 10: Transporting Safety Instructions And Practices

SAFETY Do not exceed the rated PTO speed for the Implement. Excessive PTO speeds can cause Implement driveline or blade failures resulting in serious injury or death. (SG-26) Operate the Tractor and/or Implement controls only while properly seated in the Tractor seat with the seat belt securely fastened around you. -

Page 11: Maintenance And Service Safety Instructions And Practices

SAFETY Maintenance and Service Safety Instructions and Practices The rotating parts of this machine continue to rotate even after the PTO has been turned off. The operator should remain in his seat for 60 seconds after the brake has been set, the PTO disengaged, the tractor turned off, and all evidence of rotation has ceased. - Page 12 Rhino products are designed utilizing specifically matched system components to ensure optimum equipment performance. These parts are made and tested to Rhino specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce equipment performance, void warranties, and present a safety hazard.

- Page 13 SAFETY Transport only at speeds where you can maintain control of the equipment. Serious accidents and injuries can result from operating this equipment at high speeds. Understand the Tractor and Implement and how it handles before transporting on streets and highways. Make sure the Tractor steering and brakes are in good condition and operate properly.

-

Page 14: Storage And Parking Safety Instructions And Practices

SAFETY Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in such a way as to be clearly visible and legible. When transporting the Equipment use the Tractor flashing warning lights and follow all local traffic regulations. (SG-6) In wet conditions where there is a likelihood of material collecting on the Implement, make certain that this material is removed before traveling on public roadways. -

Page 15: Decal Location

Driveline shield missing Serial No code Serial N. plate RHINO tiller Operator’s 00762257 Danger manual inside Maintain 00756494 Warning shields and deflector Rhino - 00787001 Logo-name Rhino - SRT 40 Rhino - SRT 48 00787002 Logo-name 00787003 Logo-name Rhino - SRT 55... -

Page 16: Decal Description

SAFETY Decal Description DANGER! Failing to obey safety messages and operating instructions can cause serious bodily injury or even death to the operator and others in the area. P/N 00762257 DANGER! Guard Missing, Do Not Operate. If you see this decal, Do Not Operate the mower until the shield has been replaced. - Page 17 SAFETY Logo Product Name: Rhino P/N 49696 4782464 Model name:SRT40 SRT40 P/N 00787001 Model name:SRT48 SRT48 P/N 00787002 Model name:SRT55 SRT55 P/N 00787003 Model name:SRT65 P/N 00787982 SRT65 Model name:SRT73 P/N 00787983 SRT73 Model name:SRD63 P/N 00788091 SRD63 © 2009 Alamo Group Inc.

- Page 18 SAFETY Model name:SRD73 SRD73 P/N 00788092 Model name:SRD83 SRD83 P/N 00788093 Model name:SRM81V SRM81V P/N 00788126 Model name: RHINO P/N 00787010 Model name:SRM91V SRM91V P/N 00788123 © 2009 Alamo Group Inc.

- Page 19 SAFETY Read Operator’s Manual! The operator’s manual is located inside this canister. If the manual is missing order one from your dealer. TILLER 02/12 Safety Section 1-15 © 2010 Alamo Group Inc.

-

Page 20: Federal Laws And Regulations

SAFETY Federal Laws and Regulations This section is intended to explain in broad terms the concept and effect of federal laws and regulations concerning employer and employee equipment operators. This section is not intended as a legal interpretation of the law and should not be considered as such. Employer-Employee Operator Regulations U.S. -

Page 21: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1... - Page 22 INTRODUCTION These Tillers are designed with care and built with quality materials by skilled workers. Proper assembly, maintenance, and operating practices, as described in this manual, will help the owner/operator get years of satisfactory service from the machine. The purpose of this manual is to familiarize, instruct. The Assembly Section instructs the owner/operator in the correct assembly of the Tiller using standard and optional equipment.

- Page 23 INTRODUCTION The SRT40 requires between 10HP - 20 HP with adequate front end weight. The SRT48 requires between 10 HP - 20 HP with adequate front end weight. The SRT55 requires between 15 HP - 35 HP with adequate front end weight.

- Page 24 INTRODUCTION Attention Owner/Operator BEFORE OPERATING THIS MACHINE: 1. Carefully read the Operator’s Manual, completely understand the Safety Messages and instructions, and know how to operate correctly both the tractor and Tiller. 2. Fill out the Warranty Card in full. Be sure to answer all questions including the Serial Number of the Tiller. Mail promptly using the return envelope included with the Operator’s Manual.

-

Page 25: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1 © 2010 Alamo Group Inc. -

Page 26: Driveline Attachment

ASSEMBLY DRIVELINE ATTACHMENT Before starting assembly, make certain that all paint, dirt, and grease are removed from gearbox shaft . To ease assembly apply a light coat of grease to splines and assemble. Do not assemble a driveline without a shield. -

Page 27: Operation Section

OPERATION SECTION Operation Section 4-1 © 2010 Alamo Group Inc. - Page 28 OPERATION RHINO SRT, SRD, SRM OPERATION INSTRUCTIONS The Tiller is manufactured with quality material by skilled workers. This implement is ideal in horticultural, agricultural, or commercial applications, especially for landscapers, rental yards, vineyards, vegetable farms, and nurseries. The implement is equipped with protective deflectors to prevent objects being thrown from the implement by the blades, however, no shielding is 100% effective.

-

Page 29: Standard Equipment And Specifications

OPERATION Standard Equipment and Specifications SRT Series SRT40 SRT48 SRT55 SRT65 SRT73 65” 73” Tilling Width 40” 48” 55” 66” 77” Overall Width 45” 53” 62” Type of Knives “c” “c” “c” “c” “c” Knives Per Flange Number of Flanges 6”... - Page 30 OPERATION SRM Series SRM81V SRM91V Tilling Width 91” 81” Overall Width 87” 96” Type of Knives “c” “c” Knives Per Flange Number of Flanges Tilling Depth (Max.) 7” 7” Skid Shoe Settings 20” implement Swing Diameter 20” 185-208-235-266 Rated Rotor Speed(RPM) 185-208-235-266 Gearbox Housing Cast...

-

Page 31: Operator Requirements

OPERATION 2. OPERATOR REQUIREMENTS Safe operation of the unit is the responsibility of a qualified operator. A qualified operator has read and understands the implement and tractor Operator’s Manuals and is experienced in implement and tractor operation and all associated safety practices. In addition to the safety messages contained in this manual, safety signs are affixed to the implement and tractor. -

Page 32: Rops And Seat Belt

ASAE approved Roll-Over Protective Structure (ROPS) or ROPS cab and seat belt. • Slow Moving Vehicle (SMV) emblem, lighting, PTO master shield • Tractor Horsepower: -SRT Series: SRT40, SRT48 ..10-20 HP SRT55 ....15-35 HP SRT65, SRT73 ..30-50 HP -SRD Series ...... -

Page 33: Tractor Horsepower

OPERATION 2.3 Tractor Horsepower The power required to operate an implement is determined by the tractor PTO horsepower. For most operating conditions, implement requires a tractor with at least 10 HP. Operating the implement with a tractor that does not have adequate power may damage the tractor engine. Exceeding required HP may cause implement damage by overpowering the unit in heavy cutting conditions. -

Page 34: Getting On And Off The Tractor

OPERATION DO NOT use a PTO adapter to attach a non-matching Implement driveline to a Tractor PTO. Use of an adapter can double the operating speed of the Implement resulting in excessive vibration, thrown objects, and blade and implement failure. Adapter use will also change the working length of the driveline exposing unshielded driveline areas. -

Page 35: Dismounting The Tractor

OPERATION 3.2 Dismounting the Tractor Before dismounting, park the tractor and implement on a reasonably level surface, apply the parking brake, idle the engine down, disengage the PTO, and lower the implement to the ground. Shut down the tractor engine according to the operator’s manual, remove the key, and wait for all motion to completely stop. Never leave the seat until the tractor, its engine and all moving parts have come to a complete stop. -

Page 36: Connecting The Implement To The Tractor

OPERATION Never run the Tractor engine in a closed building or without adequate ventilation. The exhaust fumes can be hazardous to your health. (SG-23) Start tractor only when properly seated in the Tractor seat. Starting a tractor in gear can result in injury or death. Read the Tractor operators manual for proper starting instructions. -

Page 37: Setting Implement Height

OPERATION 4. Turn off the tractor engine and dismount. 5. One lift arm at a time, align arm end hole between the set of A-frame lift lugs. Insert hitch pin through the lug and arm holes and insert retaining pin into hitch pin. 6. -

Page 38: Rotation Speed Change Srm 80V-90V

OPERATION 5.3 ROTATION SPEED CHANGE SRM 81V-91V To modify the rotation speed of the rotor, the positions relative to the straight gears contained in the gear box must be exchanged. Before making the replacement, wait for the gear box to have cooled down and wear the relevant PPE, in particular gloves as there is a hands burning hazard present. - Page 39 OPERATION “Bottoming Out” Check Procedure • Disconnect driveline from the tractor and slide the profiles together until fully compressed. • Place a mark on the inner shield 1/8” from the end of the outer shield. • Reattach the driveline to the PTO Shaft. •...

-

Page 40: Pre-Operation Inspection And Service

OPERATION 7. PRE-OPERATION INSPECTION AND SERVICE Before each use, a pre-operation inspection and service of the implement and tractor must be performed. This includes routine maintenance and scheduled lubrication, inspecting that all safety devices are equipped and functional, and performing needed repairs. DO NOT operate the unit if the pre-operation inspection reveals any condition affecting safe operation. -

Page 41: Tractor Pre-Operation Inspection/Service

OPERATION 7.1 Tractor Pre-Operation Inspection/Service Refer to the tractor operator’s manual to ensure a complete pre-operation inspection and scheduled service performed according manufacturers recommendations. The following are some of the items that require daily service and inspection: • Tire condition/air pressure •... - Page 42 OPERATION Tractor PRE-OPERATION Inspection Tractor ID# Make Date: Shift Before conducting the inspection, make sure the tractor engine is off, all rotation has stopped and the tractor is in park with the parking brake engaged. Make sure the mower is resting on the ground or securely blocked up and all hydraulic pressure has been relieved.

- Page 43 OPERATION Tiller PRE-OPERATION Inspection Tiller ID# Make Date: Shift Before conducting the inspection, make sure the tractor engine is off, all rotation has stopped and the tractor is in park with the parking brake engaged. Make sure the blade is resting on the ground or securely blocked up and all hydraulic pressure has been relieved.

-

Page 44: Operating The Tractor And Implement

OPERATION 8. OPERATING THE TRACTOR AND IMPLEMENT THE OPERATOR MUST COMPLETELY UNDERSTAND HOW TO OPERATE THE TRACTOR AND IMPLEMENT AND ALL CONTROLS BEFORE ATTEMPTING TO OPERATE. The operator must read and understand the Safety and Operation Sections of the implement and tractor operator’s manuals. These manuals must be read and explained to any operator who cannot read. -

Page 45: Bystanders/Passersby Precautions

OPERATION Extreme care should be taken when operating near loose objects such as gravel, rocks, wire, and other debris. Inspect the area before tilling. Foreign objects should be removed from the site to prevent machine damage and/or bodily injury or even death. Any objects that cannot be removed must be clearly marked and carefully avoided by the operator. -

Page 46: Operating The Implement

OPERATION 8.5 Operating the Implement Only operate the implement from the tractor operator’s seat with the seatbelt securely fastened. The tractor must be equipped with a ROPS in the raised position or a ROPS cab. The implement is designed for horticultural, agricultural, or commercial applications cultivation. Maintained knives will produce a better cultivation and require less power. -

Page 47: Implement Storage

OPERATION Always shut the Tractor completely down, place the transmission in park, and set the parking brake before you or anyone else attempts to connect or disconnect the Implement and Tractor hitches. (S3PT-15) To disconnect the implement, first extend the tractor 3-point hitch top link to remove tension on the top link hitch pin. -

Page 48: Transporting The Tractor And Implement

OPERATION 11. TRANSPORTING THE TRACTOR AND IMPLEMENT Inherent hazards of operating the tractor and implement and the possibility of accidents are not left behind when you finish working in an area. Therefore, the operator must employ good judgement and safe operation practices when transporting the tractor and implement between locations. - Page 49 OPERATION Transport only at speeds where you can maintain control of the equipment. Serious accidents and injuries can result from operating this equipment at high speeds. Understand the Tractor and Implement and how it handles before transporting on streets and highways. Make sure the Tractor steering and brakes are in good condition and operate properly.

-

Page 50: Brake And Differential Lock Setting

OPERATION 12.1 Brake and Differential Lock Setting Make sure the tractor brakes are in good operating condition. Tractor brakes can be set to operate independently allowing single rear wheel braking action or locked together to provide simultaneous rear wheel braking. FOR MOST DRIVING AND OPERATING CONDITIONS, THE BRAKE PEDALS... -

Page 51: Transporting On Public Roadways

OPERATION 12.2 Transporting on Public Roadways Extreme caution should be used when transporting the tractor and implement on public roadways. The tractor must be equipped with all required safety warning features including a SMV emblem and flashing warning lights to alert drivers of the tractor’s presence. Remember that roadways primarily... -

Page 52: Hauling The Tractor And Implement

OPERATION When operating on public roads, have consideration for other road users. Pull to the side of the road occasionally to allow all following traffic to pass. Do not exceed the legal speed limit set in your country for agricultural tractors. Always stay alert when transporting the tractor and implement on public roads. Use caution and reduce speed if other vehicles or pedestrians are in the area. -

Page 53: Troubleshooting Guide

OPERATION 13. TROUBLESHOOTING GUIDE PROBLEM POSSIBLE CAUSE POSSIBLE REMEDY Machine makes intermittent Loose knives Tighten knives clicking noise Gear tooth damaged Replace damaged gear Chain damaged Replace damaged chain link PTO Vibrates Worn universal joint Replace universal joint Machine lifted too high Lower machine and readjust tractor lift stop Excessive trash wrapped... - Page 54 © 2010 Alamo Group Inc.

-

Page 55: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1 © 2010 Alamo Group Inc. -

Page 56: Lubrication Information

MAINTENANCE Before operating your Tiller, make sure it is properly lubricated and thoroughly inspected. Only a minimum of time and effort is required to regularly lubricate and maintain this machine to provide long life and trouble free operation. Always disengage the PTO before raising the Tiller for transporting or making adjustments. LUBRICATION INFORMATION Do not let excess grease collect on or around parts, particularly when operating in sandy areas. -

Page 57: Driveline Lubrication

MAINTENANCE DRIVELINE LUBRICATION Grease Fittings are located on the Cross Assembly of each U-Joint and on the telescoping tubes. Grease the U-Joint after each 8 hours of use. Do not force grease through the Needle Cup Assemblies. Grease the telescoping tubes after every hours use. -

Page 58: Slip Clutches

MAINTENANCE SLIP CLUTCHES A Slip Clutch is incorporated in the PTO driveline. It is designed to slip, absorb the shock load, and protect the driveline. Clutch torque setting is factory set. If clutch slips excessively, check friction discs for excessive wear. Discs are 1/8"... -

Page 59: Oil Change

MAINTENANCE OIL CHANGE After about 500 hours of work the oil should be changed in both the central drive unit and side pan. Figure 5. Refill Central Drive and Side Pan with 90 EP Gear Oil to proper levels. TILLER 02/12 Maintenance Section 5-5 ©... -

Page 60: Replacement Of Lateral Chain Transmission On Srt40 & Srt48

MAINTENANCE REPLACEMENT OF LATERAL CHAIN TRASMISSION ON SRT 40 & SRT 48 INSTRUCTIONS FOR THE REPLACEMENT OF THE LATERAL CHAIN TRANSMISSION ON THE SRT40 & SRT48 TILLERS: 1. Drain the oil from the Gearbox by removing the Drain plug located under the Gearbox. -

Page 61: Replacement Of Lateral Chain Transmission On Str55

MAINTENANCE REPLACEMENT OF LATERAL CHAIN TRANSMISSION ON SRT55 INSTRUCTIONS FOR THE REPLACEMENT OF THE LATERAL CHAIN TRANSMISSION ON THE STR55 TILLERS: Drain the oil from the Gearbox by removing the Drain plug located under the Gearbox. Remove the support, located on the right side, from the Tiller and Gearbox by removing all the hardware. Remove the bolt that attaches the Gearbox to the support on the left side. -

Page 62: Replacement Of Lateral Chain Transmission On Srt65 & Srt73

MAINTENANCE REPLACEMENT OF LATERAL CHAIN TRANSMISSION ON SRT65 & SRT 73 INSTRUCTIONS FOR THE REPLACEMENT OF THE LATERAL CHAIN TRANSMISSION ON THE SRT65 & SRT73 TILLERS: 1. Drain oil from Lateral Cover. 2. Remove all bolts from the lateral cover. 3. -

Page 63: Proper Torque For Fasteners

MAINTENANCE PROPER TORQUE FOR FASTENERS The chart lists the correct tightening torque for fasteners. When bolts are to be tightened or replaced, refer to this chart to determine the grade of bolts and the proper torque except when specific torque values are assigned in manual text. - Page 64 © 2010 Alamo Group Inc.

-

Page 65: Spare Parts Section

SPARE PARTS SECTION Spare parts section 6-1 © 2010 Alamo Group Inc. - Page 67 Part Number when ordering Replacement Safety Decals. For maximum safety and to guarantee optimum product reliability, always use genuine Servis-Rhino Parts. The use of inferior replacement parts may cause premature or catastrophic failure which could result in serious injury or death.

-

Page 68: Srt40 & Srt48

SRT 40 & SRT 48 PARTS LISTING Parts Section 6-4 TILLER 02/12 © 2010 Alamo Group Inc. - Page 69 SRT 40 & SRT 48 PARTS LISTING ITEM PART. NO. DESCRIPTION 37107B13 HAI PIN, COTTER 00762333 PIN, A FRAME 00786568 BRACKET 61361168 SCREW UNI 5739 M10X35 8.8 00786569 T-40 00786570 T-48 REAR BOARD SRT-40 00786571 00786577 REAR BOARD SRT-48 00765550 00765549 COTTER PIN 3 00765676...

- Page 70 SRT 40 & SRT 48 PARTS LISTING Parts Section 6-6 TILLER 02/12 © 2010 Alamo Group Inc.

- Page 71 SRT 40 & SRT 48 PARTS LISTING ITEM PART. NO. DESCRIPTION 001465 GREASE NIPPLE M6 UNI 7663-A 00786591 RIGHT SKID 00762342 OIL SEAL 40X62X10 PP 00762298 BEARING SUPPORT GASKET 00786598 BEARING SUPPORT 00786599 ROTOR SRT-40 00786600 ROTOR SRT-48 00762315 DRIVEN GEAR Z19 00786648 32 (SRT-40) BLADE BOLT M12X30 8.8...

- Page 72 SRT 55 PARTS LISTING Parts Section 6-8 TILLER 02/12 © 2010 Alamo Group Inc.

-

Page 73: Srt55

SRT 55 PARTS LISTING ITEM PART. NO. DESCRIPTION 00786601 A. FRAME 61377C8 SCREW UNI 5739 M12X30 8.8 00772648 STOP NUT M12X1.75 DIN 980 8 701513C WASHER FIAT 10188 M12 00762333 PIN, TOP HITCH (CAT. I) 37107B13 COTTER PIN 00763207 CIRCLIP EXTERNAL 00762492 DRIVING GEAR Z11 3686002... - Page 74 SRT 55 PARTS LISTING Parts Section 6-10 TILLER 02/12 © 2010 Alamo Group Inc.

- Page 75 SRT 55 PARTS LISTING ITEM PART. NO. DESCRIPTION 00762465 LOCKNUT M35 GUP TYPE 00762490 DRIVEN SPROKET Z17 61379C8 SCREW UNI 5739 M12X40 8.8 00762468 SKID 00786621 END PLATE, IDLER SIDE 00762514 CHAIN (ASA 80-S TYPE, 40 LINKS) 00762498 CHAIN ADJUSTER 00762352 SPRING 00786622...

-

Page 76: Srt65 & Srt73

SRT 65 & SRT 73 PARTS LISTING Parts Section 6-12 TILLER 02/12 © 2010 Alamo Group Inc. - Page 77 SRT 65 & SRT 73 PARTS LISTING ITEM PART. NO. DESCRIPTION 00787984 RH A-FRAME 00787985 LH A-FRAME 00754518 SCREW M12X90 UNI 5739 00786633 SPACER, TOP HITCH 00762333 PIN, TOP HITCH (CAT.1) 37107B13 COTTER PIN Ø4 00772648 SELF LOCKING METAL NUT M12 DIN 980 70093C SELF LOCKING METAL NUT M8 DIN 980 00786575...

- Page 78 SRT 65 & SRT 73 PARTS LISTING Parts Section 6-14 TILLER 02/12 © 2010 Alamo Group Inc.

- Page 79 SRT 65 & SRT 73 PARTS LISTING ITEM PART. NO. DESCRIPTION 00777924 HOOK Ø10 00788003 ROTOR COVER OUTER SIDE 00762511 INTERNAL CIRCLIP Ø90 DIN 472 00762293 EXTERNAL CIRCLIP Ø40 DIN 471 00788004 BEARING 6208 00788005 ROTOR BEARING MOUNT, EXTERNAL SIDE 00788006 ROTOR SHAFT (4/6 BLADES) SRT/65 00788007...

-

Page 80: Srd 63, Srd 73 & Srd 83

SRD 63, SRD 73 & SRD 83 PARTS LISTING Parts Section 6-16 TILLER 02/12 © 2010 Alamo Group Inc. - Page 81 SRD 63, SRD 73 & SRD 83 PARTS LISTING ITEM PART. NO. DESCRIPTION 00788018 SCREW M8X16 UNI 5449 DIN 316 701611C WASHER FIAT 10188 Ø8 ZNB LW, M8 00762480 SHIELD 00777905 U SCREW 613510C8 SCREW TE UNI5739 PG 8.8 M8X30 ZNB 701511C WASHER UNI6592 140HV DI.08 ZNB 00788019...

- Page 82 SRD 63, SRD 73 & SRD 83 PARTS LISTING Parts Section 6-18 TILLER 02/12 © 2010 Alamo Group Inc.

- Page 83 SRD 63, SRD 73 & SRD 83 PARTS LISTING ITEM PART. NO. DESCRIPTION 00777916 COVER PIN SRD/63 00785980 COVER PIN SRD/73 00777917 COVER PIN SRD/83 00765681 72 (SRD/63) SCREW DIN960 PF 8.8 M14X40FIL.20 ZNB 00765681 84 (SRD/73) SCREW DIN960 PF 8.8 M14X40FIL.20 ZNB 00765681 96 (SRD/83) SCREW DIN960 PF 8.8 M14X40FIL.20 ZNB...

- Page 84 SRD 63, SRD 73 & SRD 83 PARTS LISTING Parts Section 6-20 TILLER 02/12 © 2010 Alamo Group Inc.

- Page 85 SRD 63, SRD 73 & SRD 83 PARTS LISTING ITEM PART. NO. DESCRIPTION 00762398 SCREW M10X30 UNI 5739 00755954 GROWER M10 UNI 1751 00788055 SUPPORT LAP 00788056 GASKET 00756644 OILSEAL D45XD80X10 DIN3760 50053364 BEARING 30309 6320045 EXTERNAL CIRCLIP Ø45 DIN 472 00788057 PINION SHAF T 00788288...

-

Page 89: Srm 81V & Srm 91V

SRM 81V & SRM 91V PARTS LISTING Parts Section 6-25 TILLER 02/12 © 2010 Alamo Group Inc. - Page 90 SRM 81V & SRM 91V PARTS LISTING ITEM PART. NO. DESCRIPTION 00762332 SPLIT PIN Ø 4X80 00785969 00788019 PROTECTION SUPPORT 3038445 SELF LOCKING NUT M16 DIN 980 701511C WASHER Ø 8 UNI 6592 00785970 PLATE 00766906 "U" SCREW 00765530 PLATE 00765557 CHAIN 00785971...

- Page 91 SRM 81V & SRM 91V PARTS LISTING Parts Section 6-27 TILLER 02/12 © 2010 Alamo Group Inc.

- Page 92 SRM 81V & SRM 91V PARTS LISTING ITEM PART. NO. DESCRIPTION 00762465 SELF LOOKING NUT Ø 35X1,5 GUP 00762465 GEAR Z32 00762294 CIRCLIP I Ø 100 00787067 BEARING 21309 00762301 GASKET 00787068 SUPPORT 70816C8 SCREW TCEI M12X1,75X25 UNI 5931 00765647 OIL SEAL GNL 5470 00765564 00762296...

- Page 93 SRM 81V & SRM 91V PARTS LISTING Parts Section 6-29 TILLER 02/12 © 2010 Alamo Group Inc.

- Page 94 SRM 81V & SRM 91V PARTS LISTING ITEM PART. NO. DESCRIPTION 00763210 INTERNAL CIRCLIP Ø80 DIN 472 50053364 BEARING 32209 00777095 BEARING 32212 00788102 EXTENSION TUBE SRM/80V 00788103 EXTENSION TUBE SRM/90V 00788104 SHAFT SRM/80V 00788105 SHAFT SRM/90V 00762463 PLUG M14X1.5 00788106 DRIVING GEAR Z21 00788067...

- Page 99 SRT, SRD, SRM TILLER TILLER-SOM-02/12 Printed U.S.A.

Need help?

Do you have a question about the SRT40 and is the answer not in the manual?

Questions and answers