Summary of Contents for SABROE SAB 283

- Page 1 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit Operation Guide Form Number: 004059 en 2023.09 Issue Date: 2023-09-21 Supersedes: 004059 en 2019.11...

- Page 2 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 3: Table Of Contents

Purging a refrigeration plant......................32 F-gas regulation (fluorinated greenhouse gases)................32 Bans on GWP.............................. 33 Labelling..............................33 Leakage test..............................33 Recovery of refrigerant..........................33 Certification of personnel..........................33 Record keeping............................33 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 4 Liquid injection............................54 Suction check valve by-pass....................... 54 Balance piston pressure regulator....................55 Low ambient temperature operation....................57 Heating element..........................57 ATEX................................57 Start-up..............................57 Preparations before start-up........................57 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

- Page 5 Charging the compressor with lubricating oil................. 71 Sampling the oil........................... 73 Motor..............................75 Motor lubrication............................75 Replacing the motor bearings........................75 Final disposal..............................76 Safety precautions..........................76 Waste disposal............................. 76 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

- Page 6 Machine parts.............................76 Oil and refrigerant............................. 76 Electric components..........................76 Batteries..............................76 Compliance..............................77 Declaration of conformity........................77 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 7: Manual For Sab 283 And 355 Screw Compressors

Anti-condensation heater Drive type r Fixed speed r Variable speed (VSD) Coalescer filter r pcs. Unisab setting values Separator velocity ref. _______________ Separator velocity ref. CR________________ SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 8 Economiser Other Pressure loss, if any, from safety valve to customer connection (based on design pressure) [bar] ______________________________________________________ Safety valve type: r Back-pressure dependent r Back-pressure independent SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 9: Introduction To Operating Manual

OHU 6042 in this manual, and the OHU 7650/6050 which is a bigger compressor, referred as the OHU 7650 in this manual. Both the SAB 283 and the SAB 355 compressors can use either oil separators depending on the operating conditions. -

Page 10: Compressor Name, Sabroe And Frick

Compressor name, SABROE and Frick The compressor in a SABROE SAB 283 and 355 screw compressor unit is manufactured by Frick ® The following table and image indicates how the SABROE and Frick compressor names are made and how they correspond to each other. -

Page 11: Amendments To The Manual

‘Requirements for competent persons’ section has been added. • ‘Noise data’ section has been updated. • Declarations of conformity, unit and ATEX, have been added. • And more. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 12 The original version of this manual is the English language version. If there are any discrepancies or conflicts between the English and any other version that has been translated into another language, the English version will prevail. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 13: Safety Precaution Definitions Used In This Manual

Assign only competent personnel instructed in safety and all machine functions to operate or service the compressor/unit according to EN 13313. • Operators and maintenance personnel must carefully read, understand, and fully comply with all alarms and instructions. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 14: Areas Of Application Of The Screw Compressor

(separate) and react on the increased temperature and pressure by creating acids, which will destroy the pumps. However, check with the local authorities as exemptions to this rule may be granted. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 15 Johnson Controls Denmark is not liable for injuries to personnel or damage to equipment resulting from using the equipment for other purposes than the ones stated previously. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 16: Identification

All Johnson Controls Denmark equipment can be identified by one or several name plates as shown in the following sections. Unit and pipe name plate Figure 2: Name plate for standard unit, with CE mark SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 17 Figure 3: Name plate for ATEX unit Figure 4: Name plate for standard unit, without CE mark SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

- Page 18 For EC PED approval: Refrigerant - Group Fluid group 1 or 2 according to the PED directive. Supply voltage - Control Supply voltage and frequency of the control system. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

- Page 19 TheEurAsian Conformity mark (EAC) indicates that the unit is in compliance with all relevant technical regulations of the Eurasian Customs Union. Note: Locate the main supply voltage on the motor and/or electrical name plate. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 20: Compressor Name Plate

Compressor name plate Figure 6: Compressor name plate SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 21 Compressor manufacturing number. Max. driver speed - rpm Maximum number of revolutions allowed. Max. allowable pressure - psig/bar Maximum working pressure of compressor (psig/bar). Assembled in Manufacturing country. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 22: Compressor Name Plate - Atex

Compressor manufacturing number. Max. driver speed - rpm Maximum number of revolutions allowed. Max. allowable pressure - psig/bar Maximum working pressure of compressor (psig/ bar). Assembled in Manufacturing country. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 23: Labelling Of Explosion-Proof Equipment

Min. ignition oil to shaft seal temperature of oil 450°C 380°C 500°C 300°C 230°C 350°C 200°C 130°C 250°C 135°C 65°C 185°C 100°C 30°C 150°C 85°C 15°C 135°C SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 24: Geometrical Swept Volume

1.12154 0.031739 5618 SGCH/B 3519 355 1000 3600 1.42748 0.040398 7150 SGCB 3524 1000 3600 1.80328 0.051033 9033 Vessel name plate Figure 9: Name plate for vessel SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 25 (Group 1 or 2) according to the PED directive. The minimum and the maximum pressures (pressure relative to Allowable pressure, PS atmospheric pressure) that the vessel or vessel part has been designed for. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

- Page 26 Note: Depending on the supplier of the pressure vessel or heat exchanger, the layout and content of the vessel name plate may differ from the previous SABROE name plate. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 27: Safety Precautions

Internal overpressure Hazardous substance Cold surfaces hearing protectors Do not step The unit IS filled Flammable gas No open flame on surface with refrigerant R290 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 28: General

All safety features, disengagement and interlocks must be in place and function correctly before the equipment is put in operation. Never by-pass or wire around any safety device. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 29: Ventilation

Ensure that the motor cannot start up inadvertently. • Ensure that there is no over-pressure and no refrigerant in the part to be dismantled. Close all necessary stop valves. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 30: Atex

For equipment not supplied by Johnson Controls Denmark, it is the contractor who is responsible for ensuring that the equipment is in conformity with the ATEX directive. Specifically, the contractor is responsible for equalising potential differences on the compressor. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 31: Power Supply

It is not recommended to reuse oil. Refrigerants Use caution when dealing with refrigerants. For safe handling, refer to the safety data sheets and other relevant material delivered by the refrigerant supplier. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 32: Purging A Refrigeration Plant

GWP (Global Warming Potential) R134a 1300 R407C 1650 R404A 3785 R507 3850 Requirements of the F-gas regulation include: • Bans and limitations • Labelling • Leakage test SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 33: Bans On Gwp

Important: For further information, refer to the F-gas regulation in full. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 34: Sound And Noise Data

SWL comparable values. • Be aware of local and national requirements for the use of ear protection. Generally, it is recommended to use ear protection in machine rooms. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 35: Installation

12. Setup the control system settings including calibration according to the control system manual. 13. Check the direction of rotation of the compressor motor and oil pump (optional). 14. Mount the coupling. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 36: Atex

Controls Denmark, it is the contractor who is responsible for ensuring that the equipment is in conformity with the ATEX directive. Specifically, the contractor is responsible for equalising potential differences on the compressor. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

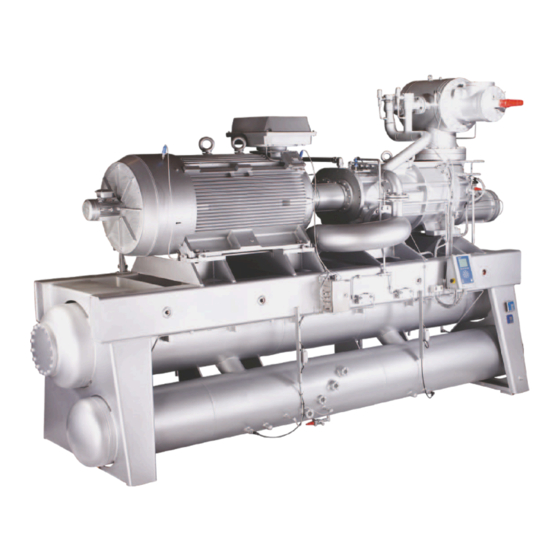

Page 37: Operating Instructions

The compressor unit is controlled by an electronic control system. The control system is described in a separate manual, delivered with the unit. Principle drawing Figure 11: SAB 283 with oil separator, OHU 7650, viewed from the back SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 38 Figure 12: SAB 283 with oil separator, OHU 7650, viewed from the front Figure 13: SAB 355 with oil separator, OHU 7650, viewed from the back SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

- Page 39 Figure 14: SAB 355 with oil separator, OHU 7650, viewed from the front SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 40: General P&I Diagram

General P&I diagram Figure 15: General P&I diagram, SAB 355 with oil cooler, dual oil filters and oil pump SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 41 Figure 16: General P&I diagram, SAB 283, OHU 6042 or 7650 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

- Page 42 Temperature probes indicate: Suction pressure TE-1 Suction gas temperature Strainer TE-2 Discharge gas temperature High temperature alarm TE-3 Lubricating oil temperature TAHH High temperature TE-4 Separator oil temperature shutdown SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 43: P&I Diagram - Liquid Injection

Solenoid valve Temperature switch YY-9 Dual-port liquid injection solenoid Temperature switch high – – alarm P&I diagram - liquid injection Figure 17: P&I diagram - liquid injection SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 44: Valve Positions During Operation

123 / 138 Stop valve after oil filter Oil filter 2: Open 123 - 135 Close: 138 - 136 Service valve - oil filter Closed Oil sample valve Closed SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 45: Descriptions Of Main Components And Systems

SGX 3524, VI 2.4 to 4.5 • A hydraulic unloader cylinder to operate the slide stop and slide valve. • Bearing and casing design for 28 bar [400 psi] discharge pressure. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 46: Compressor Lubrication System

Water-cooled or thermosyphon oil cooler for compressor oil cooling. The rotors are constructed with an asymmetrical profile. The male rotor has four lobes, and the female rotor has six, see Figure SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 47: No Pump Oil System

If the oil level rises and remains in the sight glass, there is a problem in the oil return separation system or compressor operation. For information on how to correct the problem, see Maintenance instructions. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 48: Automatic Oil Return Valve

7, is unable to move the piston, position 7. However,the pressure loss of the oil flow through the nozzle, position 7, is able to move the piston, position 7. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 49: Cold-Start System

A bleed valve on the side of the check valve is used to vent the space between the check valve and the stop valve. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 50: High-Stage Units

For operation, see Suction check valve by-pass. Note: For alarm descriptions and shutdown or cut-out parameters, refer to the separate control system manual. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 51: Compressor Hydraulic System

Both sections are controlled by double-acting, four-way solenoid valves which are actuated when a signal from the appropriate microprocessor output energizes the solenoid valve. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 52: Single-Acting Mode, High-Stage (> 10 Bar Pressure Differential)

Double-acting mode, booster (< 10 bar pressure differential) • Open the valve at SC1 • Open the valve at SC2 • Close the valve at BP (by-pass) SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 53: Booster Compressor Loading

On SAB 355 the SC4 port does not exist. The inboard side of the slide stop piston is at suction pressure. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 54: Compressor Vi Decrease

NV-2 should be closed slightly. If the separator takes more than 20 to 30 minutes to equalise to suction pressure after shutdown, you can open NV-2 slightly, see Figure SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 55: Balance Piston Pressure Regulator

SB-2 is needed by a Balance Piston Regulator (BPR). On the SAB 355 compressors the oil is fed separately through the SB-2 port. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 56 Orifice: The orifice ensures oil supply to the inlet end bearings during upset conditions such as • start-up. Figure 26: Balance piston regulator principle diagram. For SAB 355 H and some SGCs that require controlled oil pressure to the balance piston SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 57: Low Ambient Temperature Operation

5. Check on the control display that the compressor capacity control system is in minimum slide position 0 to 4%. WARNING On ATEX-executions, you must always respect the limits in Table Table SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 58: Initial Start-Up Procedure

Once you set the value, you do not need to change it again unless the compressor should run at completely different operating conditions. To determine the necessary discharge temperature, see the following method. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 59: Method Selection

If the unit has water-cooled oil cooling, adjust the water control valve to cooler. • The compressor slide valve and slide stop linear transmitters should be calibrated. • Perform a vibration analysis, if the necessary equipment is available. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 60: Normal Start-Up Procedure

Synthetic components in the compressor may deteriorate over time even if they are kept flooded with oil. A warm and dry environment is essential to minimise environmental and corrosive damage. For further information, contact Johnson Controls Denmark. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 61: Secondary System

ComPAC evaporators and condensers are fully welded heat exchangers and you cannot mechanically clean them. For more information about chemical cleaning, contact a Johnson Controls representative. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 62: Temperature And Flow Control

Secondary refrigerant, for example, glycol in case of leakage. Leak detectors should be selected, installed, and maintained in cooperation and accordance with the recommendations of the detector supplier. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 63: Troubleshooting

Control manual Oil level too low Charge oil Compressor starts but Oil system failure (temperature, Check oil level and check the immediately stops pressure, level) valve positions SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 64 Suction pressure high and valve insufficient refrigeration capacity Adjust the regulating valve Oil return valve fully open according to manual Suction strainer clogged Clean the strainer SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 65: Compressor Unit - Oil Separation

Slide valve or slide stop out of calibration (over or under Calibrate compression) Tighten coupling. Replace if Coupling loose on shaft damaged Refrigerant flood back (Liquid Correct system problem slugging) SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 66: Demand Oil Pump System, Optional

Main filter pressure difference Oil is too cold Allow the oil to warm up is too high Service valve on filter outlet is Open valves fully partially closed SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 67: Maintenance Instructions

Motor lubrication and other routine maintenance tasks are usually based on running time. See Table Major overhaul For major maintenance tasks such as compressor overhauls, contact Johnson Controls Denmark. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 68 M22 x 2.5 M24 x 3.0 SAB 355 S SGC 3511 M24 x 3.0 M30 x 3.5 SAB 355 L SGC 3515 M24 x 3.0 M30 x 3.5 SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 69: Monitoring Of Operation

Keep the filled-in checklist, and send a copy to SABROE Factory as documentation that the unit has been installed and commissioned correctly. The checklist will be required in case of a warranty issue. - Page 70 Figure 27: Checklist SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 71: Oil

Connect the high-pressure hose, position 7, to the service valve, position 106, on the unit through the non-return valve, position 12. Use the correct reduction nipple. See Figure SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 72 Loosen the non-return valve carefully to equalise the remaining pressure. Remember to mount the cap nut on the charge valve and to seal the oil barrel if there is any oil left. Figure 28: Oil charging SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 73: Sampling The Oil

Do not unthread the valve from the filter housing or uncontrolled release of oil will result. Unthread the oil sampling valve cap and the locknut, see Figure SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 74 Figure 31: Sampling oil from high pressure application SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

-

Page 75: Motor

In connection with electric motors, it is absolutely essential to lubricate the bearings correctly and use the appropriate type of grease. Refer to the motor manual and the motor name plate. Replacing the motor bearings Contact Johnson Controls Denmark’s service organisation. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... -

Page 76: Final Disposal

Batteries Used batteries, for example from the control system backup, must be disposed of in accordance with prevailing national rules and regulations. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit... - Page 77 If more than one declaration of conformity is required, all relevant individual declarations will be contained in a dossier in accordance with the EU Blue Guide. Dossiers are uploaded with the other order specific documentation. SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit...

- Page 78 © Johnson Controls. All rights reserved. Subject to change without notice. Johnson Controls Denmark ApS. SABROE Factory. Christian X's Vej 201 8270 Højbjerg Denmark. Phone +45 87 36 70 00. www.sabroe.com...

Need help?

Do you have a question about the SAB 283 and is the answer not in the manual?

Questions and answers