Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Pacmac 2015

- Page 1 Pacmac Model 2015 OPERATIONS MANUAL v1.7 ...

-

Page 2: Table Of Contents

2015 OPERATIONS MANUAL TABLE OF CONTENTS M3 SCREENS WARNING __________________________________3 RUN SCREEN __________________________________4 CHANGE SETTINGS __________________________________7 DISPLAY STATUS _________________________________19 MANUAL SCREEN _________________________________10 UTILITY MENU _________________________________11 o MACHINE PARAM _________________________________12 MACHINE PARAM _________________________________15 ... - Page 3 2015 OPERATIONS MANUAL THEORY OF BAG MAKING ORDER OF OPERATIONS _________________________________34 TIMING CONSIDERATIONS _________________________________35 TROUBLESHOOTING WRINKLES _________________________________38 FILM DRIVE _________________________________42 HEADER SEAL _________________________________43 ZIPPER SEAL _________________________________44 HORIZONTAL SEAL _________________________________44 ULTRASONICS _________________________________45 ...

-

Page 4: Warning

2015 OPERATIONS MANUAL WARNING THE WARNING SCREEN CONTAINS A BRIEF WARNING ABOUT OPERATING THE MACHINE. TOUCH OK TO AGREE. TOUCH THE LANGUAGE BUTTONS TO VIEW THE WARNING IN THAT LANGUAGE. THIS ALSO CHANGES LANGUAGE FOR THE MACHINE. -

Page 5: Run Screen

2015 OPERATIONS MANUAL RUN SCREEN THE RUN SCREEN IS USED TO MONITOR THE SELECTED PROGRAM SETTINGS. THE PROGRAM NAME, DATE, AND TIME ARE ALL DISPLAYED ON THIS SCREEN. THE RUN SCREEN ALSO DISPLAYS A SCALE SHOWING THE MACHINE CYCLE GRAPHICALLY, AND THE BAGGER INTERFACE MODE. - Page 6 2015 OPERATIONS MANUAL FROM THE RUN SCREEN, YOU MAY SELECT THE FOLLOWING. SELECT PROGRAM TO SELECT A PROGRAM, THE OPERATOR MUST FIRST TOUCH THE SELECT PROGRAM BUTTON, TO DISPLAY THE PROGRAM SELECTION SCREEN. THE OPERATOR CAN NOW CHOOSE A PROGRAM BY TOUCHING THE NAME OF THE DESIRED PROGRAM.

- Page 7 2015 OPERATIONS MANUAL HOME JAWS TOUCH THE HOME JAWS BUTTON TO HOME THE JAWS. THE JAWS MUST BE HOMED ANYTIME THE MACHINE IS TURNED OFF. THE BUTTON WILL FLASH RED WHEN THE MACHINE WANTS THE OPERATOR TO HOME THE JAWS.

-

Page 8: Change Settings

2015 OPERATIONS MANUAL CHANGE SETTINGS SCREEN THE CHANGE SETTINGS SCREEN IS A PASSWORD PROTECTED SCREEN USED TO MAKE CHANGES IN A SELECTED PROGRAM. ONLY FILM LENGTH WHEN RUNNING CLEAR BAGS, OR PRINT POSITION WHEN RUNNING PRINTED BAGS CAN BE CHANGED OUTSIDE THE CHANGE SETTINGS SCREEN. - Page 9 2015 OPERATIONS MANUAL THE CHANGE SCREEN FUNCTIONS ARE THE SAME AS THE RUN SCREEN IN ADDITION TO THE FOLLOWING. RENAME A PROGRAM TOUCHING THE PROGRAM NAME IN THE TOP LEFT-HAND CORNER OF THE SCREEN ALLOWS THE OPERATOR TO RENAME THE SELECTED PROGRAM.

-

Page 10: Display Status

2015 OPERATIONS MANUAL DISPLAY STATUS THE DISPLAY STATUS SCREEN IS USED TO MONITOR THE MACHINE’S INPUTS. THE INPUT NUMBER AND FUNCTIONS ARE DISPLAYED TO THE LEFT OF THE FUNCTION AND CORRESPONDS TO THE NUMBER AND FUNCTION ON THE INPUT BOARD INSIDE THE ELECTRICAL CABINET. -

Page 11: Manual Screen

2015 OPERATIONS MANUAL MANUAL SCREEN THE MANUAL SCREEN IS USED TO OPERATE THE MACHINE FUNCTIONS INDEPENDENTLY. THE SCREEN CAN ALSO BE USED FOR TROUBLESHOOTING. THE MANUAL SCREEN ALSO DISPLAYS THE OUTPUT NUMBER NEXT TO THE FUNCTION NAME. THE OUTPUT NUMBERS AND FUNCTIONS ARE DISPLAYED AND CORRESPOND WITH THE NUMBERS AND FUNCTIONS ON THE OUTPUT BOARD. -

Page 12: Utility Menu

2015 OPERATIONS MANUAL UTILITY MENU THIS SCREEN IS USED TO SET PARAMETERS THAT ARE COMMON TO ALL PROGRAMS. THE SCREEN ALSO PROVIDES INFORMATION WINDOWS ABOUT MACHINE SOFTWARE. THE NEXT FEW PAGES WILL COVER ALL THE SCREENS ASSOCIATED WITH THE UTILITY MENU. -

Page 13: Machine Param

2015 OPERATIONS MANUAL MACHINE PARAM. THE MACHINE PARAM. SCREEN HAS 2 LEVELS. THE FIRST LEVEL GIVES YOU ACCESS TO INPUT, OUTPUT, SERVO AND ETHERNET PARAM. THE SECOND LEVEL ALLOWS THE OPERATOR TO CHANGE THE FOLLOWING. SCREEN SAVE o THE AMOUNT OF TIME BEFORE THE SCREEN SAVER IS SHOWN. - Page 14 COMPUTER WILL IGNORE A SCALE READY SIGNAL BETWEEN THIS DEGREE AND THE IGNORE STOP DEGREE UNLESS THEY ARE THE SAME. CUSHION LENGTH o CHANGEABLE BY PACMAC PERSONNEL ONLY. SPECIAL FUNCTION o CONFIGURES OUTPUT AUX 4. FOR SPECIAL FUNCTION. SEE PAGE 100 FOR MORE INFO.

- Page 15 2015 OPERATIONS MANUAL JAMMED JAW o SETS THE LENGTH OF TIME ALLOWED FOR THE JAWS TO BECOME FULLY CLOSED. 14 ...

-

Page 16: Input Param

2015 OPERATIONS MANUAL INPUT PARAM. THIS SCREEN ALLOWS THE OPERATOR TO CONFIGURE THE INPUTS THAT ARE CONFIGURABLE. INPUT # o THIS NUMBER CORRESPONDS WITH THE INPUT NUMBER ON THE INPUT BOARD. FUNCTION o LISTS THE FUNCTION OF THE INPUT TO BE CONFIGURED. -

Page 17: Output Param

2015 OPERATIONS MANUAL OUTPUT PARAM THIS SCREEN IS USED TO CONFIGURE THE DEGREE-TYPE OUTPUTS. OUTPUT # (O#) o THIS NUMBER CORRESPONDS WITH THE OUTPUT NUMBER ON THE OUTPUT BOARD. FUNCTION o LIST THE FUNCTION OF THE OUTPUT TO BE CONFIGURED. -

Page 18: Ethernet Param

2015 OPERATIONS MANUAL ETHERNET PARAM. THIS SCREEN ALLOWS YOU TO VIEW THE MACHINE’S ETHERNET SETTINGS. FROM THIS SCREEN YOU CAN CONFIGURE THE MACHINE IP ADDRESS, SUBNET MASK, DEFAULT GATEWAY, CONFIGURE WHETHER THE MACHINE WILL ALLOW REMOTE CONTROL, AND DISPLAYS HOW MANY DEVICES ARE CONNECTED TO THE COMPUTERS MODBUS SERVER. -

Page 19: Machine Statistics

2015 OPERATIONS MANUAL MACHINE STATISTICS THE SCREEN ALLOWS YOU TO TRACK THE PERFORMANCE OF THE MACHINE ON A DAILY BASIS AND HAS A LIFETIME COUNT. THE DAILY VALUES ARE RESETABLE VIA THE RESET BUTTON AT THE BOTTOM OF THE SCREEN. -

Page 20: Touch Screen Doc

2015 OPERATIONS MANUAL TOUCH SCREEN DOCTOR THIS SCREEN IS USED TO TEST THE OPERATION OF THE COMPUTER TOUCH SCREEN. THE SCREEN USES INFRARED BEAMS ACROSS THE SCREEN TO READ AN INPUT AND HIGHLIGHTS THE ASSOCIATED NUMBER ON THE SCREEN. IF A BEAM FAILS TO HIGHLIGHT GREEN THE BEAM IS BAD, AND THE COMPUTER WILL NEED TO BE REPAIRED. -

Page 21: Diag

2015 OPERATIONS MANUAL DIAG. THIS SCREEN IS USED TO TEST SERIAL AND ETHERNET COMMUNICATIONS BETWEEN VARIOUS DEVICES. TOUCH THE BUTTON FOR THE APPROPRIATE CONNECTION AND DEVICE TO TEST ITS CONNECTION. YOU WILL THEN BE BROUGHT TO THIS SCREEN WHICH WILL GIVE YOU THE IP... -

Page 22: Change Password

2015 OPERATIONS MANUAL CHANGE PASSWORD TO CHANGE THE MACHINE PASSWORD, TOUCH THIS BUTTON AND ENTER THE MACHINE AUTHORIZATION CODE. YOU WILL THEN BE SHOWN THE MACHINES CURRENT PASSWORD, THEN BE PROMPTED TO ENTER THE NEW PASSWORD. FACTORY DEFAULT USE THIS BUTTON TO RETURN THE MACHINE TO FACTORY SETTINGS. -

Page 23: Servo Param

2015 OPERATIONS MANUAL SERVO PARAM. THIS MENU PROVIDES ACCESS TO SERVO OPERATION. DISCOVER SERVOS o THIS BUTTON CAUSES THE COMPUTER TO ATTEMPT COMMUNICATION WITH SUPPORTED SERVO CONTROLLERS AT ALL ADDRESSES. SERVO LOG o DISPLAYS THE SERVO ERROR LOG IF IT IS SUPPORTED. -

Page 24: Servo Utility

2015 OPERATIONS MANUAL SERVO UTILITY/DISCOVER SERVOS THIS SCREEN ATTEMPTS TO DISCOVER EACH SUPPORTED SERVO CONTROLLER AT ALL ADDRESSES. YOU CAN RECONFIGURE THE AUXILIARY PORT FOR A SERVO CONTROLLER ONLY FROM THE SERVO UTILITY SCREEN. 23 ... -

Page 25: Comm Errors

2015 OPERATIONS MANUAL SERVO STATUS THIS SCREEN IS USED TO TROUBLESHOOT THE SERVO SYSTEM ON THE MACHINE. WE WILL BRIEFLY COVER EACH SCREEN. COMM ERRORS. THIS SCREEN LOGS ERRORS REPORTED FROM THE SERVO CONTROLLERS. THE ERROR IS LISTED WITH A TIME/DATE STAMP AND THE ERROR. - Page 26 2015 OPERATIONS MANUAL SERVO STATUS THIS SCREEN SHOWS THE I/O STATUS OF EACH SERVO CONTROLLER, ALONG WITH SOME INTERNAL VALUES ADJUSTED FROM THE COMPUTER. I.E FILM SPEED, LENGTH, JAW OPENING AND SO ON. CYCLE BETWEEN EACH SERVO CONTROLLER VIA THE BUTTONS AT THE BOTTOM OF THE SCREEN.

-

Page 27: Servo Log

2015 OPERATIONS MANUAL SERVO LOG THIS SCREEN DISPLAYS THE ERROR LOG FROM EACH SERVO CONTROLLER. WHEN THE OPERATOR TOUCHES THE SCREEN, IT WILL DISPLAY THE NEXT SERVO LOG SCREEN. AFTER THE LAST LOG IT WILL RETURN TO THE SERVO PARAM SCREEN. -

Page 28: Servo Setup

2015 OPERATIONS MANUAL SERVO SETUP THE SERVO SETUP SCREEN IS USED TO CHANGE CONFIGURATIONS FOR THE SERVO CONTROLLERS. FILM DRIVE OUTPUT 4 ENABLE: o ENABLES OUTPUT 4 OF SERVO CONTROLLER TO RUN A PRINTER. OUTPUT 4 DELAY TO START: o MILLISECOND DELAY TO START ... -

Page 29: How To

2015 OPERATIONS MANUAL HOW TO ADJUST THE FILM AND ZIPPER BRAKES 1. DISENGAGE HANDLE A 2. LOOSEN BOTTOM JAM NUT B 3. TIGHTEN NUT C TO COMPRESS SPRING D TO A LENGTH OF APPROX. 2 3/4”. 4. TIGHTEN JAM NUT B WHILE IN THIS POSITION. -

Page 30: Copy Program

2015 OPERATIONS MANUAL HOW TO COPY A PROGRAM TO COPY A PROGRAM, YOU MUST HAVE THE PROGRAM YOU WANT COPIED LOADED. SEE SELECT PROGRAM ON PG 5. ONCE THE PROGRAM YOU WISH TO COPY IS SELECTED DO THE FOLLOWING:... - Page 31 HOW TO COPY FILES TO AND FROM USB TO COPY FILES, INSERT A PACMAC FORMATTED USB INTO THE BACK OF THE COMPUTER. TOUCH THE COPY FILES BUTTON IN THE UTILITY MENU AND TOUCH THE BUTTON THAT REFLECTS WHAT YOU WANT TO DO.

-

Page 32: Adjust Side Belts

2015 OPERATIONS MANUAL HOW TO ADJUST SIDE BELTS 1. LOOSEN THE BOLTS CONNECTING THE MAYME LEVERS TO THE SLIDE BLOCKS. 2. SLIDE PULL BELTS ALL THE WAY OUT AWAY FROM THE TUBE. 3. MANUALLY CLOSE THE PULL BELTS VIA THE HAND WHEEL ON THE ACTUATOR. -

Page 33: Adjust Nip Roller

2015 OPERATIONS MANUAL HOW TO ADJUST NIP ROLLER 1. LOCATE THE 2 TENSIONING SPRINGS ON THE LEFT AND RIGHT SIDE OF THE NIP ROLLER. 2. THE SPRINGS CAN BE LOOSENED OR TIGHTENED VIA THE 1/2” NUTS ON THE TENSIONING EYE BOLTS. -

Page 34: Order Of Operations

ARRIVE JUST AFTER THE JAW CLOSES AND MUST FULLY ACCUMULATE ON THE JAW BEFORE THE JAW REOPENS. THE PACMAC VFFS RELIES ON PROPER SETUP TO ACHIEVE MAXIMUM PERFORMANCE. PLEASE REFER TO THE PACMAC VFFS START UP PROCEDURE FOR MORE INFORMATION ON MACHINE START... -

Page 35: Timing Considerations

TIMED TO START AFTER THE JAW BECOMES FULLY OPEN. FILM SPEED ADJUSTS HOW FAST THE FILM DRIVES. SHOULD BE SET TO 2600 UNLESS ADVISED OTHERWISE BY A PACMAC REP. FILM DRIVE, FILM SPEED, AND BAGS PER MINUTE SETS THE FILM DRIVE END DEGREE IN THE DISPLAY STATUS SCREEN. - Page 36 ZIPPER PINCH START TIME = ZIPPER WELD START TIME. ZIPPER WELD START TIME PLUS 100 + ZIPPER WELD END TIME. GAP SHOULD BE SET TO .001, REFER TO THE PACMAC VFFS START UP PROCEDURE FOR MORE INFORMATION ON SETUP.

- Page 37 2015 OPERATIONS MANUAL BAG STRETCHER TIMED TO GO IN BEFORE THE FILM DRIVE STARTS AND RETRACT AFTER IT ENDS. USED TO REMOVE END SEAL WRINKLES. CONTAINS THE ZIPPER WHEELS. TYPICAL TIMING.______________________________________0-125 JAW CLOSE TIMED TO CLOSE IMMEDIATELY AFTER THE BAG STRETCHER RETRACTS.

-

Page 38: Troubleshooting Wrinkles

2015 OPERATIONS MANUAL TROUBLESHOOTING WRINKLES BAG LAYOUT ULTRASONIC WELD HEADER SEAL ZIPPER BEAD GUSSET FOLD VERTICAL SEAL WRINKLES DIAGONAL WRINKLES BETWEEN HEADER SEAL AND ZIPPER SEAL. WRINKLES POSSIBLE CAUSE o ZIPPER WHEELS OVER PULLING. IF WHEELS ARE BRAND NEW THEY WILL NEED TO “WEAR IN”... - Page 39 2015 OPERATIONS MANUAL HORIZONTAL FOLDS BETWEEN HEADER SEAL AND ZIPPER. BIG FOLDS POSSIBLE CAUSES o ZIPPER WHEELS ARE NOT GRIPPING CAUSING THE ZIPPER TO SLIP BACK AND DRAW UP THE FILM. o CHECK MECHANICAL OPERATION, TIMING, AND CONDITION OF WHEELS.

- Page 40 2015 OPERATIONS MANUAL END SEAL WRINKLES POSSIBLE CAUSES o LACK OF TENSIONING BETWEEN BAG STRETCHER AND GUSSET. o SET GUSSET DEPTH TO 1.5” o SET BAG STRETCHER TO PULL TIGHT. TOO TIGHT TOO LOOSE GOOD 39 ...

- Page 41 2015 OPERATIONS MANUAL END SEAL WRINKLES POSSIBLE CAUSES o GUSSET TUCKING TOO DEEP. o BAG STRETCHER STRETCHING TOO TIGHT. 40 ...

- Page 42 2015 OPERATIONS MANUAL TROUBLESHOOTING FILM DRIVE (MECHANICAL) FOR ALL CLEAR FILM LENGTH RELATED ISSUES, FIRST ENSURE THAT THE COMPUTER IS SET TO CLEAR FILM AND THAT THE FILM LENGTH IS SET CORRECTLY. SHORT BAGS ON CLEAR FILM POSSIBLE CAUSES ...

- Page 43 2015 OPERATIONS MANUAL LONG BAGS PRINTED FILM. POSSIBLE CAUSES MISSED EYE MARK o CHECK THAT EYE IS CENTERED OVER THE EYE MARK ON THE FILM. o CHECK THAT THE EYE IS SEEING THE EYE MARK AS IT PASSES THROUGH.

-

Page 44: Horizontal Seal

2015 OPERATIONS MANUAL TROUBLESHOOTING VERTICAL ZIPPER SEAL LOSS OF PRESSURE o CHECK THE CONDITION OF THE SPRINGS ON THE HEADER HEATER BAR. o CHECK ALIGNMENT WITH ZIPPER GUIDE. o ENSURE THAT THE ACTUATOR IS ADJUSTED PROPERLY AND IS COMPLETELY LOCKED OVER WHEN THE ACTUATOR IS IN THE CLOSED POSITION. - Page 45 2015 OPERATIONS MANUAL TROUBLESHOOTING ULTRASONICS NO SMASH o SET ULTRASONICS GAP TO .010. o ENSURE CYLINDER IS WORKING PROPERLY. o CHECK ULTRASONICS TIMING. o ENSURE ULTRASONICS POWER SUPPLY IS TURNED ON. o REFER TO THE 2015PM UL WIRING DIAGRAM AND CHECK WIRING.

- Page 46 2015 OPERATIONS MANUAL TROUBLESHOOTING FILM DRIVE NO ENABLE LIGHT PULL E-STOP BUTTON OUT CHECK THAT PLC S02 IS LIT GREEN IF NOT SEE PAGE 100 CHECK THAT MOTOR CONTACTORS ARE ENERGIZED CHECK FOR 24VDC BEWEEN J1 PIN 4 AND J2 PIN 12...

- Page 47 2015 OPERATIONS MANUAL NO FILM DRIVE ENSURE THAT THE OUTPUT IS WORKING PROPERLY BY TESTING THE FILM DRIVE FROM THE MANUAL SCREEN. IF NOT SEE PG 100 WHEN THE OUTPUT IS ON YOU SHOULD READ 24VDC FROM J1 PIN 5 TO J2 PIN 12...

- Page 48 2015 OPERATIONS MANUAL ONLY PULLING 8” OR 15” BAG INSPECT THE OUTPUT BOARD TO ENSURE THAT SELECT LINE 1 IS ON FOR CLEAR SELECT LINE 2 IS ON FOR PRINTED CHECK FOR 24VDC BETWEEN J1 PIN 14 - J2 PIN 12 FOR...

- Page 49 2015 OPERATIONS MANUAL SERVO NOT IN POSITION WITH THE MACHINE RESET CHECK FOR 24VDC BETWEEN J2 PIN 12 AND J2 PIN 10 IF VOLTAGE IS PRESENT, SEE PAGE 100 IF VOLTAGE IS NOT PRESENT YOU CAN BYPASS THE INPUT BOARD...

-

Page 50: Startup-Guide

CLEAN NIP/DRIVE ROLLERS AND PULL BELTS. CLEAN WITH ALCOHOL BASED CLEANERS. ALL DISCOLORATION SHOULD COME OFF. TURN ON MAIN AIR. PACMAC SPECIFICATIONS REQUIRE THAT THE MACHINE AIR PRESSURE BE 100 PSI WITH 50 CFM FOR OPTIMUM PERFORMANCE. - Page 51 2015 OPERATIONS MANUAL INSTALL THE DESIRED TUBE THE TUBE MOUNTS TO THE TOP PLATE OF THE MACHINE AND SECURES WITH 2, 5/16-18 BOLTS. ADJUST THE PULL BELTS LOOSEN THE 2, 3/8-16 BOLTS ON THE BACK OF THE PULL BELTS.

- Page 52 2015 OPERATIONS MANUAL SET THE VERTICAL HEATER WITH THE TUBE SLIDE ALL THE WAY IN AND IN THE PROPER POSITION, CLOSE THE VERTICAL HEATER AND SECURE LATCH. LOOSEN THE HEATERS VIA THE 2 HANDLES ON EACH BAR.

- Page 53 2015 OPERATIONS MANUAL INSTALL HORIZONTAL HEATER BARS HEATER BARS SHOULD BE CLEANED AND ASSESSED FOR PROPER FUNCTION BEFORE INSTALLING. THE RIGHTHAND HEATER BAR HAS A DEEPER GROOVE FOR THE CUTTER BLADE. CORD GRIP SHOULD BE TOWARD THE BACK OF MACHINE WHEN INSTALLED.

- Page 54 2015 OPERATIONS MANUAL INSTALL GUSSETS SLIDE TOP GUSSET MOUNT OVER EXPOSED ALL THREAD. SLIDE LOWER GUSSET INTO SLOT ON BOTTOM. SCREW KNOB BACK ON BUT DON’T TIGHTEN. SET GUSSET DEPTH EXTEND THE CYLINDER FORWARD TO EXTEND THE GUSSET IN BETWEEN THE SPREADER RODS.

- Page 55 2015 OPERATIONS MANUAL ADJUST THE BAG STRETCHER THE BAG STRETCHER SHOULD BE SET TO PUT TENSION ON THE BAG WITHOUT OVER PULLING. THIS WILL BE DETERMINED BY THE TUBE SIZE INSTALLED. WITH GUSSET MANUALLY EXTENDED, ADJUST BAG...

- Page 56 2015 OPERATIONS MANUAL CHECK THE ZIPPER WHEELS THE ZIPPER WHEELS SHOULD GRIP THE FILM DURING A FILM DRIVE AND RELEASE TENSION AFTER THE DRIVE ENDS. THE ZIPPER WHEELS OVERRIDE LEVER NEEDS TO BE IN THE OFF POSITION.

- Page 57 2015 OPERATIONS MANUAL ATTACH SKIRT TO THE TUBE SLIDE THE SKIRT ON THE BOTTOM OF THE TUBE. SKIRT NEEDS TO BE SLIT UP THE BACK TO ALLOW THE GUSSET TO OPERATE IN AND OUT. USE THE BAND PLIERS TO SECURE THE SKIRT.

- Page 58 STOP BUTTON IS PRESSED WHILE FINISHING SETUP. IT IS IMPORTANT TO FOLLOW YOUR COMPANY’S LOCK OUT/TAG OUT PROCEDURES WHILE WORKING ON A PACMAC VFFS BAGGING MACHINE. TURN ON ALL HEATERS THE HEATER SWITCHES ARE LOCATED ON THE FRONT OF THE MACHINE UNDER THE COMPUTER TOUCH SCREEN.

- Page 59 2015 OPERATIONS MANUAL LOAD THE FILM SLIDE THE FILM ROLL SHAFT THROUGH THE FILM CORE AND TIGHTEN DOWN USING A ¼” ALLEN WRENCH. ENSURE THE ROLL IS UNWINDING TOWARDS THE FRONT OF THE MACHINE. TIGHTEN BY TURNING ALLEN WRENCH A ¼”...

- Page 60 2015 OPERATIONS MANUAL FILM THREAD DIAGRAM THREAD THE FILM ALL THE WAY THROUGH TO THE PULL BELTS. 59 ...

- Page 61 2015 OPERATIONS MANUAL CLOSE THE NIP ROLLER DOWN IS (CLOSED) SET THE BRAKE ROLL THE FILM ROLL BACKWARDS TO RELEASE THE TENSION ON THE BRAKE. SET THE BRAKE BY PUSHING THE RED HANDLE DOWN. o UP IS...

- Page 62 2015 OPERATIONS MANUAL PRINTED SETUP POSITION THE EYE ABOVE THE EYE MARK AND RUN PRINTED SETUP. FOR MORE INFORMATION ABOUT PRINTED SETUP SEE PG. 30. LOAD THE ZIPPER SLIDE THE SHAFT THROUGH THE ROLL OF FILM SO THAT THE ZIPPER FLANGES ARE TOWARDS THE FRONT OF THE MACHINE.

- Page 63 2015 OPERATIONS MANUAL THREAD THE ZIPPER 62 ...

- Page 64 2015 OPERATIONS MANUAL MAKE A VERTICAL SEAL SEAL THE ZIPPER TO THE FILM BY MANUALLY CLOSING THE VERTICAL HEATERS VIA THE HAND WHEEL. ROTATE UNTIL THE BARS TOUCH AND LOCK OVER. HOLD FOR 2 SECONDS AND THEN OPEN.

- Page 65 2015 OPERATIONS MANUAL CLOSE DOORS AND RESET ALL DOORS AND COVERS MUST BE IN PLACE BEFORE THE MACHINE CAN BE RESET. RESET THE MACHINE BY PRESSING AND HOLDING THE GREEN RESET/START BUTTON. MAKE 5 BAGS ONCE THE DOORS ARE CLOSED SELECT EMPTY SINGLE AT THE BOTTOM OF THE SCREEN.

- Page 66 2015 OPERATIONS MANUAL PRINTED SETUP SELECT PRINTED FILM ENSURE THAT THE PROGRAM SELECTED IS SET TO “PRINTED FILM”, THIS CAN BE FOUND ON THE RIGHT HAND SIDE OF THE CHANGE SETTINGS SCREEN. PRINTED FILM CENTER THE EYE OVER ...

-

Page 67: Pm Schedule

2015 OPERATIONS MANUAL PM SCHEDULE DAILY CHANGE HORIZONTAL HEATER BAR TAPE CLEAN THE KNIFE BLADE GROOVES CLEAN THE KNIFE BLADE CHECK WIRE CONNECTIONS CHANGE GRIPPER CORDS WEEKLY CHANGE VERTICAL HEATER BAR TAPE GREASE ALL GREASE ZERKS WIPING OFF EXCESS GREASE REPLACE 2”... -

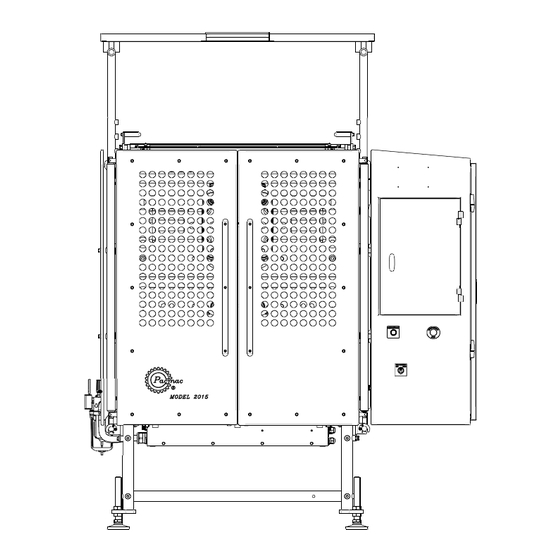

Page 68: Machine Installation

MACHINE INSTALLATION MACHINE PLACEMENT THE PACMAC MUST BE SET CENTERED UNDERNEITH THE FILLER (I.E. SCALE/CONVEYOR) SO THAT THE PRODUCT DROPPING OUT FALLS DOWN THE CENTER OF THE FORMING TUBE ASSEMBLY. ALLOW ADEQUATE SPACE AROUND THE MACHINE SO THAT THE DOORS CAN BE OPENED FULLY AND THE FILM AND ZIPPER CAN BE LOADED. ... -

Page 69: Machine Interface Mode

2015 OPERATIONS MANUAL MACHINE INTERFACE MODES THE PACMAC HAS THE ABILITY TO INTERFACE WITH A NUMBER OF DIFFERENT SCALES AND VOLUMETRIC FILLERS. MASTER: USED PRIMARILY WITH AN OVERHEAD SCALE. ALLOWS THE OPERATOR TO HAVE AN ADJUSTABLE OUTPUT PULSE. SLAVE: USED PIMARILY WITH AN INCLINE CONVEYOR. -

Page 70: Interface Wiring

2015 OPERATIONS MANUAL INTERFACE WIRING 69 ... -

Page 71: Safety Plc

2015 OPERATIONS MANUAL SAFETY PLC WHEN THE MACHINE IS IN ANY E-STOP CONDITION, THE FILM DRIVE AND JAW DRIVE SERVO CONTROLLERS ARE DISABLED BY REMOVING THE COMMON FROM THE ENABLE CIRCUIT THROUGH THE SAFETY PLC. TO ACTIVATE THE FILM DRIVE SERVO CONTROLLER THE OPERATOR MUST ACTIVATE (S02) ON THE SAFETY PLC. - Page 72 2015 OPERATIONS MANUAL 71 ...

- Page 73 2015 OPERATIONS MANUAL 72 ...

-

Page 74: Washdown

2015 OPERATIONS MANUAL WASHDOWN POWER DOWN THE MACHINE VIA THE MAIN POWER DISCONNECT ON THE BACKSIDE OF THE CABINET. ENSURE THAT ELECTRICAL CABINET DOORS ARE CLOSED FULLY AND LOCKED. . FULLY OPEN UP MACHINE SIDE PANELS AS SHOWN REMOVE HORIZONTAL HEATER BARS AND KNIFE BLADE. WASHDOWN AVOIDING HIGH PRESSURE WATER AROUND ELECTRICAL CONNECTIONS. FULLY CLOSE MACHINE AFTER DRYING. 73 ...

Need help?

Do you have a question about the 2015 and is the answer not in the manual?

Questions and answers