Summary of Contents for HOWIN 9600i

- Page 1 SILENT DIESEL INVERTER GENERATOR 9600i V201708 OPERATION MANUAL PLEASE READ THIS MANUAL CAREFULLY. IT CONTAINS IMPORTANT SAFETY INFORMATION.

- Page 2 Do not charge the battery connected. The diodes will be damaged by the high voltage. the 9600i generator sets. This manual is primarily concerned Connect the (+) lead of the charger to the (+) terminal of the with the generator specifications, function, troubleshooting and battery, and the (–) lead to the (–) terminal.

- Page 3 9. LONG TERM STORAGE CONTENT BEFORE YOU PLACE THE GENERATOR IN LONG TERM 1. SAFETY INFORMATION …………….…………………. 1 STORAGE 2. COMPONENT IDENTIFICATION …………………...…… 5 EXPLOSION HAZARD! NEVER check the remaining battery charge by shorting out the 3. PREPARATION FOR STARTING ……………………..10 terminals.

- Page 4 Black exhaust smoke 1. SAFETY INFORMATION Trouble Diagnose Correction Engine overloaded Reduce load Clogged air cleaner element Clean element or replace Failure to properly follow these precautions can result in property Replace with recommended Improper diesel fuel damage, serious injury or DEATH! diesel fuel Faulty spraying of fuel ...

- Page 5 8. TROUBLESHOOTING If a problem occurs, stop the engine immediately. TO PREVENT FIRE Refer to the SYMPTOM column in the Troubleshooting Chart to Never add fuel to the fuel tank while the engine is running. identify the problem. Wipe off any overflow of diesel fuel with a clean cloth. Keep explosives and other flammable products away from the ...

- Page 6 Do not hook up tools or other appliances to the generator before it 1) Clean the area around the fuel cap. has been started. If equipment is plugged in and the circuit 2) Remove the fuel cap from the fuel tank. breakers are on, the generator starting motion may cause sudden 3) Lift out the inlet fuel screen.

- Page 7 1) Remove the wing nut. MAIN TECHNICAL SPECIFICATIONS AND DATA 2) Remove the air cleaner cover. Model LG9600i 3) Remove the air cleaner element and outer foam element. Item 4) Blow air through both elements using 42-71psi (0.29−0.49 MPa, Rated frequency (Hz) 3.0−5.0kgf/cm2) compressed air to remove the particulates.

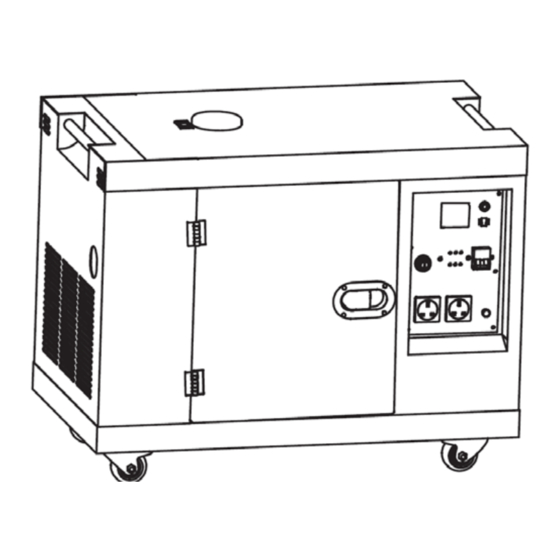

- Page 8 2. COMPONENT IDENTIFICATION 2.1 Component Location ○ ○ 10) Recheck the engine oil level by fully inserting, but not screwing in the oil filler cap. 11) Add engine oil as needed until the level is between the upper and lower lines on the oil filler cap. 12) Replace the oil filler cap and tighten by hand.

- Page 9 7.2 Clean / Inspect Engine Oil Filter * Every 6 months or 500 hours ○ Clean / inspect the engine oil filter as follows: 1) Remove the oil filter retaining bolt. 2) Pull the oil filter cap out and remove the oil filter. ○...

- Page 10 2.2 Control Panel 7.1 Changing the engine oil The engine oil on a new engine becomes contaminated from the initial ○ ○ break-in of internal parts. The initial 20 hour oil change and filter cleaning is very important. Drain the engine oil as follows: ○...

- Page 11 2.3 Indicator 7. PERIODIC MAINTENANCE RUN INDICATOR: Periodic maintenance is very important to keep the generator in After the engine is started, the run lamp will light and remain ON during normal optimum running condition. The chart below indicates what checks operating conditions.

- Page 12 6. STOPPING THE GENERATOR For maximum engine life, we recommend that when shutting the engine down, you allow the engine to run, without load, for five 1. Turn the OUTPUT SWITCH off. minutes. This will allow the engine components that operate at high temperatures, such as the exhaust system, to cool slightly before the engine itself is shut down.

- Page 13 3. PREPARATION FOR STARTING Low oil alarm system The oil alarm system is designed to prevent engine damage caused by an insufficient amount of oil in the crankcase. Before the 3.1 Diesel Fuel Specifications oil level in the crankcase fails below a safe limit, the Low oil alarm Diesel fuel should comply with the following specifications.

- Page 14 The engine may be damaged if operated with insufficient engine oil; it is also dangerous to overfill the oil level. RUN INDICATOR HOWIN 9600i generators are equipped with a low oil pressure In case of overload operation or short circuit: warning and shutdown system. This system stops the engine automatically when the oil pressure falls below a safe level and prevents catastrophic engine failure.

- Page 15 3) Switch on the OUTPUT SWITCH. 4) Remove oil filler cap. The oil level should be between upper lines on the oil filler cap. 5) Fully reinsert oil filler cap and hand tighten. Over-tightening the oil filler cap will damage it. OUTPUT SWITCH 4) Switch on the equipment to be used.

- Page 16 3.3 Connect the Battery 5. OPERATING THE GENERATOR To connect the battery, first connect the positive (red) cable to the positive (+) post of the battery. Use the fasteners provided and ensure 5.1 Operate the generator the connection is secure. Next connect the negative (black) cable Warm up the engine without load for three minutes.

- Page 17 Do not wash the element with detergent. NEVER hold the key in the START position for longer than 15 When the engine is operated in dusty conditions, clean the air seconds or the starter motor will overheat. cleaner element more frequently.

- Page 18 HIGH-PRESSURE HAZARD! 4. STARTING THE GENERATOR Avoid skin contact with the high-pressure diesel fuel spray caused by a fuel system leak such as a broken fuel injection line. High-pressure fuel can penetrate your skin and result in serious injury. If you are exposed to high-pressure fuel spray, obtain prompt medical ...

Need help?

Do you have a question about the 9600i and is the answer not in the manual?

Questions and answers