Summary of Contents for Cannon Tools NEILSEN CT2594

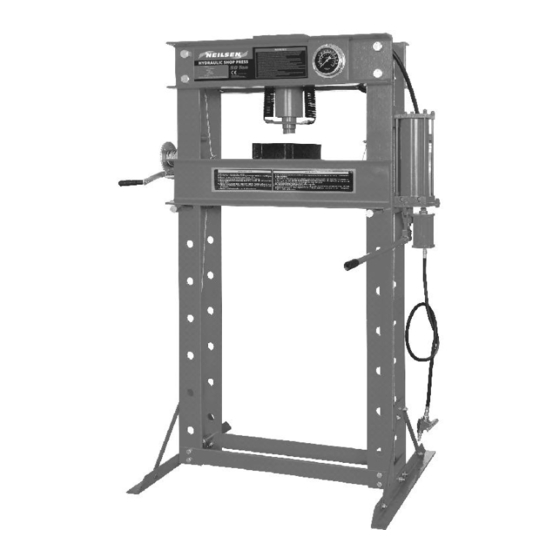

- Page 1 50 TON HYDRAULIC SHOP PRESS CT2594 Instruction & Assembly CANNON TOOLS LTD Add: 20 station road, Rowley Regis, west midlands,B65 0JU.U.K. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE...

-

Page 3: Ec Declaration Of Conformity

EC DECLARATION OF CONFORMITY We CANNON TOOLS LTD 20 Station road, Rowley Regis, West Midlands,B65 0JU.U.K. Declare that the following machine complies with the appropriate basic safety and health requirements of the EC Directive based on its design and type, as brought into circulation by us. -

Page 4: Specification

1. SPECIFICATION Model: CT2594 Capacity: 50Tons Working range: 0-1000mm Ram stroke: 185mm Air pressure: 110 -120PSI Air inlet: 1/4" NPT 2. IMPORTANT SAFETY INFORMATION You will need this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance, and cleaning procedures. Keep your invoice with this manual. - Page 5 regularly by a qualified technician. 11. Do not force the tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed. Do not force the tool and do not use the tool for a purpose for which it is not intended.

- Page 6 sprayed or spilled. Allow the hydraulic system to cool before conducting maintenance. 5. Hydraulic components require regular inspection. Release all pressure from the system before you inspect it. Replace damaged hydraulic parts with identical manufacturer's components. 6. Do not attempt makeshift repairs to a hydraulic system. Such repairs can fail suddenly and create a hazardous condition.

-

Page 7: Technical Description

3. TECHNICAL DESCRIPTION 4. UNPACKING AND CHECKING WARNING! Do not operate the tool if any part is missing. Replace the missing part before operating. Failure to do so could result in a malfunction and personal injury. Remove the parts and accessories from the packaging and inspect for damage. Make sure that all items in the parts list are included. -

Page 8: Operation

5. ASSEMBLY Secure the right and left Base Supports to the bottoms of the frame, using Screws, Spring Washers , and Nuts for each Base Support. Attach Seek help to set upright. Connect each of the four support bars to the post and base section with bolts , flat washers , lock washers and nuts . -

Page 9: Maintenance

7. MAINTENANCE Maintain the tool with care. A tool in good condition is efficient, easier to control and will have fewer problems. Inspect the tool components periodically. Repair or replace damaged or worn components. Only use identical replacement parts when servicing. Keep the tool handles clean, dry and free from oil/grease at all times. -

Page 10: Parts List

PARTS LIST Part No. Description Part No. Description Bolt Arbor plate Cross beam Pressure beam Damping nut M16 Jack Spring washer M22 Bole Washer M22 Washer M16 Damping nut M22 Gear Pole Gear seat Damping nut M10 Tighter the screws Bole Washer M12 Steel wire... - Page 12 CANNON TOOLS LTD 20 Station road, Rowley Regis, West Midlands,B65 0JU.U.K. Made in China...

Need help?

Do you have a question about the NEILSEN CT2594 and is the answer not in the manual?

Questions and answers