Table of Contents

Advertisement

Quick Links

I

M

nstallation,

aintenance and

O

I

peration

nstruction

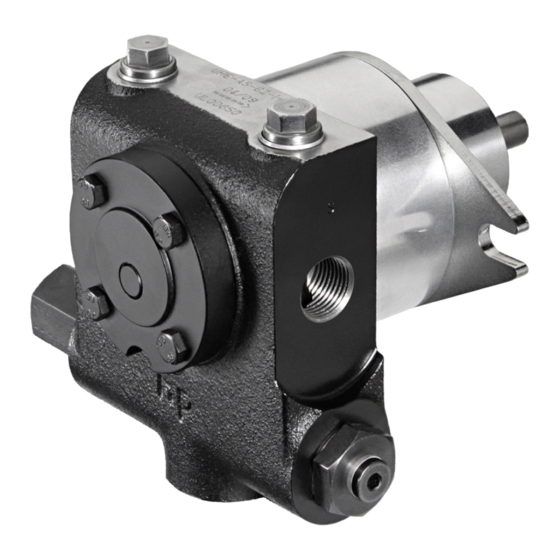

Internal Gear Pump Series UHE-WH3

hp-TE CHNIK GmbH Indus t ri epu mpen -För deragg re gate un d Anl agenb au

Gablonzer Straße 21

D-76185 Karlsruhe Germany

Tel.: 0721/ 9 56 18 – 0

Postfach 21 10 10

D-76160 Karlsruhe Germany

FAX: 0721/ 9 56 18 – 28

info@hptechnik.com

home:

http://www.hptechnik.com

š:

Advertisement

Table of Contents

Summary of Contents for hp-TECHNIK UHE-WH3 Series

- Page 1 nstallation, aintenance and peration nstruction Internal Gear Pump Series UHE-WH3 hp-TE CHNIK GmbH Indus t ri epu mpen -För deragg re gate un d Anl agenb au Gablonzer Straße 21 D-76185 Karlsruhe Germany Tel.: 0721/ 9 56 18 – 0 Postfach 21 10 10 D-76160 Karlsruhe Germany FAX: 0721/ 9 56 18 –...

-

Page 2: Table Of Contents

Contents 1. General Safety Notes ........................3 1.1 Intended Use ..........................3 2. General Information ........................3 2.1 Operational Limits ......................... 4 2.2 Materials used ..........................4 2.3 Mechanical Seal ..........................5 3. Installation ............................5 3.1 The Following must be Observed for Installation and before Commissioning: ......5 4. -

Page 3: General Safety Notes

---- 1. General Safety Notes Indicates a potentially dangerous situation. If this is not avoided, small or light injury may result. Indicates general information on a danger of property damage. Indicates general information on a danger of personal injury. The notes for installation and maintenance are intended for a specialist! Pursuant to DIN EN 12514-1 section 4.3.3., the operator of the complete system must provide a pressure controller, e.g. -

Page 4: Operational Limits

---- Fig. 1 2.1 Operational Limits Capacity 600 l/h at 30 bar Max. pressure (adjustable on the integrated overflow valve) up to 40 bar Min. inlet pressure - 0,4 bar Max. inlet pressure 5,0 bar Max. valid rotation speed of the pump 2800 min at 50 Hz Initial pump breakaway torqu e... -

Page 5: Mechanical Seal

---- 2.3 Mechanical Seal 1. Pump housing 2. Union nut 3a. O-Ring 3. Tapet 4a. O-Ring 4. Counter ring 5. Spring Installation size* * - In case of replacement can be found in the documents accompanying the valid installation dimension Article-number: 0190015 Fig. - Page 6 ---- · Before switching on the pump, check that all locking valves in the pipes and check whether the pump has sufficient medium is available. · Ensure that the pump is operated in the intended rotational direction (engraved arrow). Connect the motor according to the information on the type place and switch it on.

-

Page 7: Commissioning

---- Never use water as purging liquid! Danger of corrosion! 4. Commissioning Ensure that the pump does not start up dry. It must be filled with oil. Mechanically abrasive and chemically aggressive components in the medium reduce the pump service life. Clear your pipe lines from any dirt or metal particles before connecting it to the pump. -

Page 8: Preservation

---- 5.2 Preservation After the test run, testing oil remains in the pump to preserve it. The parts not treated ex works must be re- treated by the operator according to the local conditions. If the pump is inactive for an extended period or stored, it must be preserved with acid-free non-resinous oil and stored dryly. -

Page 9: Environment

---- 6. Environment Of course, hp-TECHNIK focuses on Environmental protection for its development work! To ensure that the environment does not take damage from our products - caused, e.g. by environmentally harmful media escaping unnoticed - we will even increase our efforts for the further development of our hp- Program. -

Page 10: Dimensional Drawing Uhe-Wh3

---- 8. Dimensional drawing UHE-WH3 Fig. 4 9. Flow characteristics for hp-pumps series UHE-WH3 Flow characteristics UHE-WH3 Characteristics Characteristics hp-Pump Series UHE-WH3 hp-Pump Series UHE-WH3 at 2800 min^-1 at 3600 min^-1 Pressure (bar) Pressure (bar) 1900 1900 1700 1700 1500 1500 1300 1300...

Need help?

Do you have a question about the UHE-WH3 Series and is the answer not in the manual?

Questions and answers