Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Robert Kappel DSMH2-12V

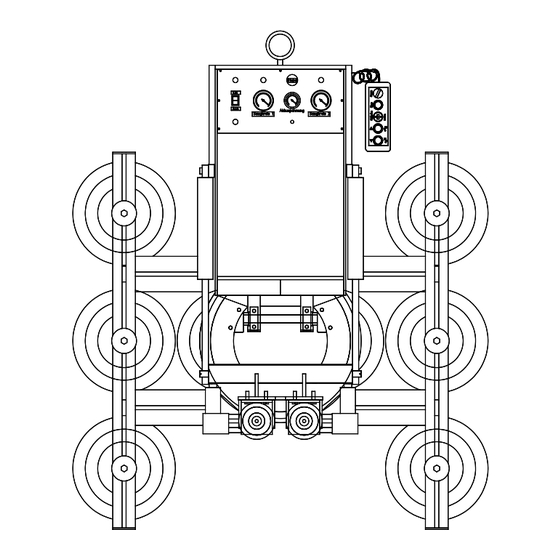

- Page 1 Operating Instructions DSMH2-12V...

-

Page 2: Table Of Contents

Safety instructions for special types of danger Electrical energy Oils, greases and other chemical substances Commissioning Charging the battery The remote control Attaching the suction pads to the DSMH2-12V Before transporting Operation Working cycle Switching off Charging the battery Kappel Flachglastechnik GmbH... - Page 3 The vacuum lines Leak check The geared motors The hydraulic pumps with cylinder The vacuum pump See appendix Technical data Performance data of the DSMH2-12V Options for the DSMH2-12V Wiring diagram of the DSMH2-12V Spare parts list Kappel Flachglastechnik GmbH...

-

Page 4: Foreward

DSMH2-12V and to use it as intended. These operating instructions contain important instructions about operating the DSMH2-12V safely, effectively, and economically. Observing them helps to avoid repair costs and down time and to increase the reliability and working life of the DSMH2-12V. -

Page 5: Technical Description

90 degrees hydraulically. The rotation and swivelling movement is operated by remote control with a cable. The DSMH2-12V is hung on a crane hook and is supplied with energy via the installed battery. In addition to easy installation on a... - Page 6 1-4 on the device. If there is a vacuum of –0.72 bar in each vacuum circuit, the load can be transported. To release the suckers from the load, set the suction switch to OFF and the release key must be operated. Caution The DSMH2-12V must NEVER be commissioned with only one functional vacuum circuit. Kappel Flachglastechnik...

-

Page 7: Basic Safety Information

Authorised use The DSMH2-12V has been constructed in accordance with the state of the art and recognised safety regulations. Nevertheless, its use may result in danger to life and limb of the operator or third parties and impairment of the machine or other property may occur. -

Page 8: Organisational Measures

DSMH2-12V Safety information Organisational measures Always keep the operating instructions within reach at the site of use. In addition to the operating instructions please observe and teach any other generally applicable statutory regulations concerning accident prevention. Such obligations can also include providing and wearing personal protective equipment. -

Page 9: Personnel Selection And Qualifications

DSMH2-12V Safety information Personnel selection and qualification Work on/with the machine may only be performed by reliable personnel. The legal minimum working age should be observed. Use only trained or instructed personnel; responsibilities among personnel should be clearly established for operation, equipping, maintenance, and repair. -

Page 10: Special Work

DSMH2-12V Safety information Special work The setting, maintenance, inspection activities and deadlines, including information on replacement of parts and modules stipulated in these operating instructions must be observed. These activities may only be performed by authorised specialists. Only perform maintenance and repair work when the machine is positioned on flat ground with sufficient bearing capacity and is secured so that it cannot roll away or collapse. -

Page 11: Commissioning

Assembly Commissioning Note Do not store the DSMH2-12V in a damp or very cold (frost) environment. Otherwise there is no guarantee that the installed pumps will function properly. Rotation and swivelling can only be carried out when the pumps in the two vacuum circuits are switched off. -

Page 12: Charging The Battery

(plug connection) with the necessary data for the vacuum pumps. If they do not correspond, the machine may not be operated. Connect the DSMH2-12V to the supply network using an extension cable. The charging procedure can be checked in the voltage display after pressing the test button. -

Page 13: The Remote Control

DSMH2-12V Assembly The remote control Kappel Flachglastechnik GmbH... - Page 14 Die Fernbedienung, Seite 3-3 Saugen (Wahlschalter) Suction (selector switch) Saugen AUS, Saugen EIN Suction OFF, Suction ON Lösen (Drucktaster rot) Release (push button red) Kippschalter für Drehen oder Schwenken Flip switch for rotation or swivelling Nach Links = Drehen To the left = rotate Nach Rechts = Schwenken To the right = swivel Bei Kippschalter auf Drehen...

-

Page 15: Attaching The Suction Pads To The Dsmh2-12V

DSMH2-12V Assembly Attaching the suction pads to the DSMH2-12V Caution -Blue hose lines = vacuum circuit1 = vacuum strip blue -Black hose lines vacuum circuit 2 = vacuum strip black There must always be the same amount of suction pads distributed as there are suction circuits, in order to ensure even load distribution in case one of the vacuum circuits fail. -

Page 16: Before Transporting

15 minutes later. If there is no discrepancy, the device is leak-tight and safe to operate. If a discrepancy of more than 5% occurs, the DSMH2-12V must be checked to find the leak. -

Page 17: Operation

Operation Operation Note Do not store the DSMH2-12V unit in a damp or very cold (frost) environment. Otherwise there is no guarantee that the installed pumps will function properly. Rotation and swivelling can only be carried out when the pumps in the two vacuum circuits are switched off. -

Page 18: Working Cycle

Swivelling can only be carried out if the pumps in both vacuum circuits are switched off. Swivelling can only be carried out if the DSMH2-12V is attached to the cross arm, i.e. the hydraulic pumps are in the vertical position. - Page 19 If this is not done, a vacuum cannot build up and the DSMH2-12V can therefore not lift the material. Set the rotary suction switch to ON.

- Page 20 DSMHQT2-24V Operation Check that all suckers on the surface are clean and have full contact and, if necessary, press on or align a sucker that is not making contact until it is in the correct position. If this is not done, a vacuum cannot build up and the DSMHQT2-24V can therefore not lift the material.

-

Page 21: Switching Off

DSMH2-12V Operation Note If the battery is drained, you can also use the DSMH2-12V in mains mode. You only have to ensure that the cable to the network supply line is run appropriately. Switching off After completing transport work, switch the machine off in order not to drain the battery unnecessarily. -

Page 22: Troubleshooting

DSMH2-12V Troubleshooting Troubleshooting Pumps no longer perform correctly The machine no longer reaches -0.72 bar vacuum. Please check whether all suckers contact the transported goods cleanly; align them if necessary. Check the suckers and hose lines for possible damage and replace them if necessary. -

Page 23: Leak Check

DSMH2-12V Troubleshooting Leak check Leak check for the entire system You can perform a leak check of the two independently functioning vacuum circuits to find the leak as follows. First of all, you should check the entire vacuum circuits with all suckers and the hose lines to both vacuum circuits. -

Page 24: Electrical Malfunction

DSMH2-12V Troubleshooting Electrical malfunction Vacuum pumps do not start when the device switch is actuated Vacuum supply sufficient. Device running correctly. Battery flat? Press button Test to check voltage display. Run machine in mains operation or charge battery. Vacuum monitor for switching point P2 defective? Replace Circuit board defect? Have circuit board checked by an expert. -

Page 25: Swivelling Cannot Be Carried Out

DSMH2-12V Troubleshooting Electrical malfunction Rotation movement cannot be carried out Pumps are active The 25A fuse in the junction plate of the geared motor is defect due to overloading Swivelling movement cannot be carried out Vacuum pumps are active Kappel Flachglastechnik GmbH... -

Page 26: Maintenance

DSMH2-12V Maintenance Maintenance Note Please note that the trades association requires an annual inspection of vacuum lifting devices by a specialist, in accordance with the accident prevent regulations (VbG 9a-prEN 13155:1998). If you do not have a suitable staff member, we offer a maintenance contract for our vacuum lifting devices which includes annual maintenance including testing and certification. -

Page 27: Leak Check

The leak must be corrected immediately or the porous material replaced. Caution Always check the operational safety of the pump and the other elements before starting work / commissioning. Caution The DSMH2-12V must NEVER be commissioned with only one functional vacuum circuit. Kappel Flachglastechnik GmbH... -

Page 28: The Geared Motors

DSMH2-12V Maintenance The Geared motor Maintenance free The Hydraulic pump with cylinder Maintenance free Kappel Flachglastechnik GmbH... -

Page 29: Technical Data

Manufacturer’s address: Kappel Flachglastechnik GmbH Schlachthofstraße 3-5 D-87700 Memmingen Phone: 08331/4487 Fax: 08331/82962 After-sales service: Phone: 08331/4487 Performance data for DSMH2-12V Maximum size of the plate material to be transported Height: approx. 2000 mm Width: approx. 3000 mm With extensions Height: approx. -

Page 30: Performance Data Of The Dsmh2-12V

All specifications relating to the load capacity refer to an even surface load. Furthermore, all suckers must also have sucked onto the goods to be transported. DSMH2-12V delivered with suckers type __________________ Number of suckers ____________________ Load capacity vertical: ____________________... -

Page 31: Options For The Dsmh2-12V

DSMH2-12V Description Options for the DSMH2-12V Removable extensions with support suckers via which greater stability in the case of larger panes is achieved. Kappel Flachglastechnik... -

Page 32: Wiring Diagram Of The Dsmh2-12V

DSMH2-12V Maintenance Wiring diagram DSMH2-12V Kappel Flachglastechnik GmbH... -

Page 33: Spare Parts List

DSMH2-12V Spare parts Spare parts list for DSMH2-12V Position Order no. Quantity Designation M16 / 1.2t , 135597 Suspension eye / articulared suspension LX98206 Vacuum meter 12V 63mm ¼“ 150K Suction pad 150 Kappel --------- Remote control 905708 Schuco plug...

Need help?

Do you have a question about the DSMH2-12V and is the answer not in the manual?

Questions and answers