Advertisement

Quick Links

1/2-INCH, SOLENOID OPERATED, 24 VDC

NOTICE: PROPRIETARY INFORMATION OF WHITTAKER CONTROLS, INC., A BUSINESS UNIT OF MEGGITT PLC.

THE INFORMATION CONTAINED IN THIS DOCUMENT IS DISCLOSED IN CONFIDENCE. IT IS THE PROPERTY OF

WHITTAKER CONTROLS, AND SHALL NOT BE USED, DISCLOSED TO OTHERS, OR REPRODUCED IN WHOLE

OR IN PART WITHOUT THE EXPRESS WRITTEN CONSENT OF WHITTAKER CONTROLS. IF CONSENT IS GIVEN

THIS NOTICE SHALL APPEAR IN ANY SUCH REPRODUCTION.

Maintenance Manual

GAS VENT VALVE

PART NUMBERS:

REVISION 1.1 – 10/15/2004

C422425

C422685

C422695

C422705

C423095

C423155

Advertisement

Summary of Contents for Whittaker C422425

- Page 1 THE INFORMATION CONTAINED IN THIS DOCUMENT IS DISCLOSED IN CONFIDENCE. IT IS THE PROPERTY OF WHITTAKER CONTROLS, AND SHALL NOT BE USED, DISCLOSED TO OTHERS, OR REPRODUCED IN WHOLE OR IN PART WITHOUT THE EXPRESS WRITTEN CONSENT OF WHITTAKER CONTROLS. IF CONSENT IS GIVEN THIS NOTICE SHALL APPEAR IN ANY SUCH REPRODUCTION.

-

Page 2: Table Of Contents

MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 LIST OF EFFECTIVE PAGES On a revised page, the portion of text or illustrations affected by the change is indicated by a vertical line in the outer margin of the page. - Page 3 WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 LIST OF TABLES TABLE PAGE General Characteristics/Specifications ......... . 6 Detailed Characteristics/Specifications .

- Page 4 A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 WEAR PROTECTIVE CLOTHING ! Wear protective clothing (gloves, apron, etc.) approved for the materials and tools being used. USE APPROVED SAFETY EQUIPMENT ! When cleaners are being used, approved explosion-proof lights, blowers, and other equipment must be used.

- Page 5 A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 VALVE MAINTENANCE PRECAUTIONS ! Do not loosen any fasteners or attempt to removal the valve from the line until all pressure is isolated and released from the system, with valve halfway closed to release the body cavity pressure.

-

Page 6: Introduction

WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 INTRODUCTION Purpose of Manual This technical manual contains instructions for operation and shop maintenance of the Gas Vent Valve (valve). - Page 7 WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 Symbols and Abbreviations Symbols and abbreviations used in this technical manual are as follows: American Wire Gage...

- Page 8 MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 Table 1. General Characteristics/Specifications Application ........Gas Turbine Engine Fuel Gas Systems Service Fluid .

-

Page 9: Description And Operation

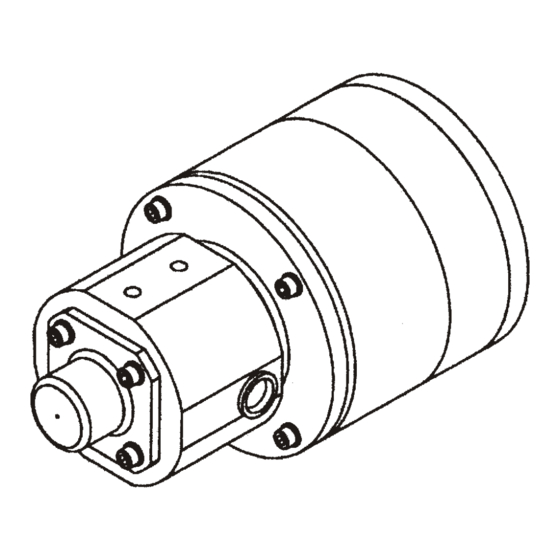

WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 DESCRIPTION AND OPERATION Description and Operation (See Figure 1) Part Numbers C422425 and C422685 The Gas Vent Valve is a solenoid operated poppet shutoff valve. The valve is normally spring- loaded to its open position. -

Page 10: 2-Inch Gas Vent Valve

WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 Figure 1. 1/2-Inch Gas Vent Valve INDUSTRIAL PRODUCTS GROUP Revision 1.1 10/15/2004 Page 8... -

Page 11: Electrical Schematic Diagram

WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 Figure 2. Electrical Schematic Diagram INDUSTRIAL PRODUCTS GROUP Revision 1.1 10/15/2004 Page 9... - Page 12 MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 Table 2. Detailed Specifications Valve Type ..........Gas Vent, Solenoid Operated Service Fluid .

-

Page 13: Installation

WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 INSTALLATION General This section contains information on installation and interfacing of the gas vent valve. Refer to Figure 3 for key dimensions. - Page 14 MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 Connect the field wiring for the solenoid and position indicating switch (when applicable) to their assigned terminals on the terminal block. Torque the wire terminal screws to 7 to 10 pound- inches (0,8 to 1,1 Nm).

-

Page 15: Key Dimensions

WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 Figure 3. Key Dimensions (Sheet 1 of 2) INDUSTRIAL PRODUCTS GROUP Revision 1.1 10/15/2004 Page 13... - Page 16 WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 Figure 3. Key Dimensions (Sheet 2 of 2) INDUSTRIAL PRODUCTS GROUP Revision 1.1 10/15/2004 Page 14...

-

Page 17: Fault Isolation

WHITTAKER CONTROLS, INC. A MEGGITT PLC COMPANY MAINTENANCE MANUAL GAS VENT VALVE C422425 • C422685 • C422695 • C422705 • C423095 • C423155 FAULT ISOLATION General Make sure that the electrical power is off before removing the terminal cover or touching the electrical wires. - Page 18 Figure 2). If possible, verify that the valve position and flow status are correct. If operation is not normal, return the faulty valve to Whittaker Controls for failure analysis, over- haul and proper testing to certification. If operation is correct, proceed with the following steps.

Need help?

Do you have a question about the C422425 and is the answer not in the manual?

Questions and answers