Table of Contents

Advertisement

Quick Links

MODELS

RFDU 22

RFDU 23

CAUTION:

WARNING for CA residents: go to www.dukemfg.com/prop65 for prop 65 warning

This manual is Copyright © 2021 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

U.S. and Foreign Patents Pending

Please read this manual completely before attempting

to install, operate or service this equipment

trademark of the Duke Manufacturing Co.

Installation and

Operation Manual

REV E 03/15/2022

P/N 229399

Advertisement

Table of Contents

Summary of Contents for Duke READYFLEX RFDU 22

- Page 1 WARNING for CA residents: go to www.dukemfg.com/prop65 for prop 65 warning This manual is Copyright © 2021 Duke Manufacturing Co. All rights reserved. Reproduction without written permission is prohibited. Duke is a registered P/N 229399 trademark of the Duke Manufacturing Co.

-

Page 2: Table Of Contents

RFDU Operator’s Manual TABLE OF CONTENTS TO BE UPDATED Manufacturer’s Introduction ............................3 Important Safety Instructions ..........................4-5 Installation ..................................6 RFDU Operating Instructions ............................8 Overview ......................................8 Preheating ......................................9 Faults ........................................9 RFDU Daypart Menu ..................................9 Settings ..................................10 Menu ........................................10 Temp Mode .......................................10 PHU Configurator ...................................10 RFDU Recipe Editor ..................................11... -

Page 3: Manufacturer's Introduction

The Duke ideal holding curve, the DNA of the RFDU, has been developed, improved, and refined since Duke introduced the first product holding unit in 1999. Utilizing the innovative top and bottom heat, extended hold times with improved food quality and consistency are achieved. -

Page 4: Important Safety Instructions

• This equipment should be serviced by qualified personnel only. Contact the nearest Duke authorized service facility for adjustment or repair. • Do not block or cover any openings on the unit. - Page 5 RFDU Operator’s Manual IMPORTANT SAFETY INSTRUCTIONS The following warnings and cautions appear throughout this manual and should be carefully observed. • Turn the unit off, disconnect the power source and allow unit to cool down before performing any service or maintenance on the unit. •...

-

Page 6: Installation

RFDU Operator’s Manual INSTALLATION UNPACKING UNIT Inspect the shipping carton and/or container, carefully noting any exterior damage on the delivery receipt; also note any damage not evident on the outside of the shipping container (concealed damage). Contact the carrier immediately and file a damage claim with them. Save all packing materials when filing a claim. Freight damage claims are the responsibility of the purchaser and are not covered by the warranty. - Page 7 RFDU Operator’s Manual INSTALLATION The following minimum clearances must be maintained between the warmer and any combustible or non- combustible substance: Unit Clearance Right Side 2” Left Side 2” Rear OPEN Floor 0” Proper airflow around unit will cool the electrical components. With restricted airflow, the unit may not operate properly and the life of the electrical components may be reduced.

-

Page 8: Rfdu Operating Instructions

After the RFDU has loaded the runtime screen will boot screen will appear first for 2 or 3 seconds. This load. Different types of information are found on will display the Duke Logo along with the firmware the runtime screen. Details below. version number of the RFDU. -

Page 9: Preheating

RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued 1. Bottom Heater High Temperature Fault PREHEATING 2. Bottom Heater Low Temperature Fault When the RFDU first boots each well will contain a 3. CAN Error Fault preheating icon. This indicates the well is heating to temperature. -

Page 10: Settings

RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued SETTINGS Several Settings are available on the RFDU. To enter the Settings menu click on the cog icon ( ) which is found in the lower right hand corner of the runtime screen. Menu PHU Configurator When the user loads the “RFDU Config”... -

Page 11: Rfdu Recipe Editor

RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued Use the left and right navigation buttons to scroll through the available recipes for this RFDU. To assign a new recipe to the well, simply select the desired recipe. Select to exit without making a change. Select to save and update the RFDU Configuration. -

Page 12: About

RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued About Network The “About” screen will detail specific settings The Network Config option will allow the RFDU available to the RFDU. network connection to be configured. After selecting “Network Config” the following screen will This will include the unit’s serial number, API key, load. - Page 13 RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued The current network selection will be highlighted, To connect to a WiFI SSID click on the SSID name. either Ethernet or WiFi. For example: The Wifi SSID password will then be required. Press anywhere within the “Enter Password”...

- Page 14 RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued Once entered select “OK” on the on-screen keyboard followed by the check button to attempt to join the WiFi SSID. If the WiFi password is incorrect the RFDU will not join the WiFi network. If the WiFI password is correct the RFDU will join the network and the RFDU will be connected.

-

Page 15: Phu Volume

RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued PHU Volume Manager Menu The PHU Volume option will either enable or disable The MANAGER menu is PIN code protected and sound on the RFDU. allows the 'manager' access to the ACCESS, TEMP OFFSET and IRDC Period functions. -

Page 16: Access

RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued Access Menu Temp Offset The Temperature Offset function will allow the The ACCESS menu allows a number of configuration options to be “locked” or unable to be changed. When temperature offset to be adjusted per ZONE on the selected the following screen will appear. -

Page 17: Irdc Period

RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued Temp Offset - Continued IRDC Period The edit icon ( ) will load the offset editor screen The IRDC Period is the total period time of the IR for either “Shelf 1 Temperature Offset” or “Shelf 2 in seconds. -

Page 18: Sous Chel Technology Programming

2x2 RFDU and well programming can also be updated via configuration appears below. Duke’s cloud solution – the Sous Chef Cloud. The Sous Chef Cloud requires the user’s Account Name to be defined along with a user login and password. -

Page 19: Usb Programming

RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued The “SHOW LEGEND” button can also be used to A list of local recipes found on the RFDU will appear display the full recipe list for the full account. here. These can be edited, added, or deleted using the appropriate function which will update the connected RFDU local recipe set in real-time. - Page 20 RFDU Operator’s Manual RFDU OPERATING INSTRUCTIONS - Continued For the user’s Account an “offline recipe set” will always be available to the user. This information will be saved and be readily available if a USB file is required to be created. The RFDU Configurator is available for well programming.

-

Page 21: Cleaning Guide

RFDU Operator’s Manual CLEANING GUIDE Electrical shock hazard. Do not wash with water jet or hose. DO NOT USE CAUSTIC CLEANERS, ACIDS, AMMONIA PRODUCTS OR ABRASIVE CLEANERS OR ABRASIVE CLOTHS. THESE CAN DAMAGE THE STAINLESS STEEL AND PLASTIC SURFACES. Bottom and sides of warmer wells are very hot and cool slowly. DAILY CLEANING NEVER USE AN ACID BASED CLEANING SOLUTION! MANY... - Page 22 RFDU Operator’s Manual CLEANING GUIDE - continued RECOMMENDED SUPPLIES Cleaning Towels Non-Scratch Scrub Pad KAY™ Degreaser KAY® SINK SANITIZER, KAYQUAT™ Sanitizer, or compatible sanitizer PROCEDURE 1. Turn unit off, unplug, and allow to cool for 30 minutes. 2. Remove all holding pans. Wash, rinse, and sanitize at the 3 compartment sink. 3.

-

Page 23: Temperature Check Procedure

RFDU Operator’s Manual RFDU Operator’s Manual TEMPERATURE CHECK PROCEDURE 1. A digital temperature meter that has been 5. All temperature controls exhibit a swing in calibrated must be used to get an accurate temperature as the control cycles on and off temperature reading. -

Page 24: Rfdu Specification

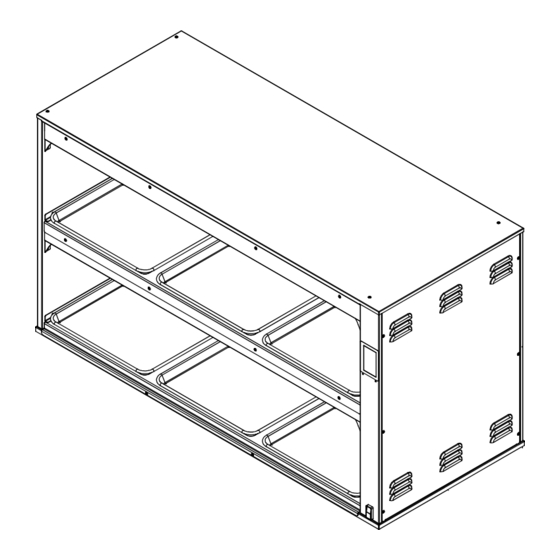

RFDU Operator’s Manual RFDU SPECIFICATIONS 34.02 26.53 62.00 RFDU-23 Shown Above ELECTRICAL SPECIFICATION DIMENSIONS: (TOP AND BOTTOM HEAT) 208/240 V - 400V - Height Width Depth (body only) 60Hz-3~ 50/60Hz-3N~ Model Amps Amps 15.5/17.3 34.0 86.4 42.9 108.9 26.5 67.3 RFDU-22 RFDU-23 15.5/17.3... -

Page 25: Wire Diagrams

RFDU Operator’s Manual RFDU 22 WIRE DIAGRAM - Domestic Light Ballast FILTER LINE N.C. Light Ballast N.O. Interlock Interlock Relay Relay N.C. N.C. N.0. N.0. N.C. N.C. N.0. N.0. N.C. N.O. 2 2 1-6 1 5 2 2 1-6 1 5 2 2 1-6 1 5 2 2 1-6 1 5... - Page 26 RFDU Operator’s Manual RFDU 22 WIRE DIAGRAM - International Light Ballast FILTER LINE N.C. Light Ballast N.O. Interlock Interlock Relay Relay N.C. N.C. N.0. N.0. N.C. N.C. N.0. N.0. N.C. N.O. 2 2 1-6 1 5 2 2 1-6 1 5 2 2 1-6 1 5 2 2 1-6 1 5...

- Page 27 RFDU Operator’s Manual RFDU 23 WIRE DIAGRAM - Domestic Light Ballast Light Ballast FILTER FILTER LINE LINE N.C. N.C. N.C. Light Ballast Light Ballast N.O. N.O. N.O. Interlock Interlock Relay Relay N.C. N.C. N.C. N.C. N.0. N.0. N.0. N.0. N.C. N.C.

- Page 28 N.0. N.0. N.0. N.0. N.C. N.C. N.C. N.O. N.O. N.O. 221-615 221-615 221-615 221-615 221-615 221-615 221-615 221-615 221-615 221-615 221-615 221-615 Phone: 314-231-1130 Duke Manufacturing Co. Toll Free: 1-800-735-3853 2305 N. Broadway www.dukemfg.com Fax: 314-231-5074 St. Louis, MO 63102...

Need help?

Do you have a question about the READYFLEX RFDU 22 and is the answer not in the manual?

Questions and answers