Table of Contents

Advertisement

Quick Links

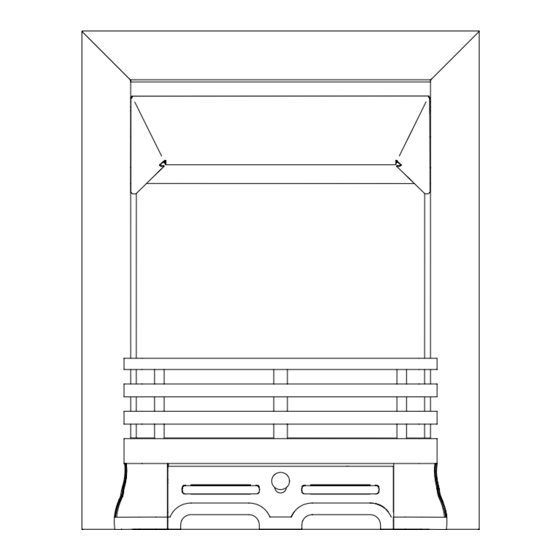

Caribbean Glow

INSET FLUELESS

HIGH EFFICIENCY GAS FIRE

MODEL : PI27

INSTALLATION AND USER INSTRUCTIONS

All instructions must be handed to user for safekeeping

Revision A - 10/08

Country(s) of destination - GB/IE

Valley Forge Limited, Ravensdale, Dundalk, Co. Louth, Ireland

Tel: (042) 9371586 • Fax: (042) 9380018 • International code : 00+353+42

Advertisement

Table of Contents

Summary of Contents for VALLEY FORGE Caribbean Glow PI27

- Page 1 INSTALLATION AND USER INSTRUCTIONS All instructions must be handed to user for safekeeping Revision A - 10/08 Country(s) of destination - GB/IE Valley Forge Limited, Ravensdale, Dundalk, Co. Louth, Ireland Tel: (042) 9371586 • Fax: (042) 9380018 • International code : 00+353+42...

- Page 2 The products covered by this booklet are protected under booklet is owned by Valley Forge Limited. You are not per- patent GB2275331B. mitted to copy or adapt any of the content without the prior written permission of Valley Forge Limited.

-

Page 3: Table Of Contents

During this period the appliance may cause smoke alarms to sound. If this happens, reset the alarms, but do not remove the batteries. Consult ALL instructions before installation and use of this appliance. This appliance is free from any asbestos material. © Valley Forge Limited 2008... -

Page 4: Appliance Data

It is recommended that the appliance should not be installed within 1 metre of any air vent. © Valley Forge Limited 2008... -

Page 5: Installation Method

In this situation the thickness of the hearth or ledge may be as desired, but it must have the strength to support the weight of the appliance and the facia. © Valley Forge Limited 2008... -

Page 6: Installation Method

It is important in these circumstances that any vapour control barrier is not damaged, and that any structural members of the house frame are not dam- aged - refer to section 6.5. © Valley Forge Limited 2008... -

Page 7: Ventilation

A small incision can now be made in the rub- ber to slip snugly around the outside of the supply pipe and sleeving. Warning : Do not install or use the appliance without this seal in place. © Valley Forge Limited 2008... -

Page 8: Gas Supply Routes

75mm air gap at the sides and rear and 100mm air gap above the firebox. Alternatively the firebox may be insu- lated with 75mm of fibre glass wool or rock wool to the sides, rear and 100 mm to the top. © Valley Forge Limited 2008... - Page 9 The hearth may now be put in place (If fitted). Again this should not bridge the cavity where it projects into the wall space. Finally install the fireplace or fire surround and back panel/marble to its finished location. © Valley Forge Limited 2008...

- Page 10 It is also a good idea to enable as much airflow as possible, into and out of the area behind the fire without causing excessive heat loss from the room when the fire is off. © Valley Forge Limited 2008...

-

Page 11: Installation Method 4

Visually inspect and repeat if necessary to achieve a good fit. Note: Surplus cable MUST NOT be cut off, as this will prevent proper re-installation after servicing. Coil up the surplus cable and tuck the coils out of the way. © Valley Forge Limited 2008... -

Page 12: Checking The Burner & Spark Gap

Re-fit the glass panel using 4 M6 screws. The fire is designed to operate correctly with the supplied components according to the instructions. Never add coals. Never put combustible or non-combustible materials, rubbish or other matter into the fire. © Valley Forge Limited 2008... -

Page 13: Fitting Decorative Hood/Frame

To turn to the PILOT position from the HIGH or LOW positions, press the control knob in, and return to the pilot position and release. To turn the fire off, keep the knob pressed in, return to the OFF position and release. © Valley Forge Limited 2008... -

Page 14: Setting Pressure

15. Check any purpose provided ventilation is un-obstructed. 16. Light the fire and check setting pressures. 17. Carry out combustion check as per section 9.4. 17. Check safe operation of the appliance. For specific servicing instructions, see relevant sections. © Valley Forge Limited 2008... -

Page 15: Cleaning The Coals

MUST not be done. Replacements must be original manufacturers parts. Re-assemble in the reverse of removal. Ensure setting pressures are as stated in Section 2; Appliance Data. © Valley Forge Limited 2008... -

Page 16: Catalyst

It is important to note that the appliance can never be expected to be 100% smoke tight and small quantities of smoke may be seen in corners of joints and gasket faces etc without affecting safety when the fire is in operation. © Valley Forge Limited 2008... -

Page 17: Troubleshooting Guide

Fire smells when first lit or in use Newness smell from brand new appliance. Leakage occurring - Carry out leakage test and rectify any problems. Low temperature sealants or combustible materials used in incor- rect positions. © Valley Forge Limited 2008... - Page 18 This appliance is only suitable for the gas type for which it is supplied. WARNING: Due to the nature of this product the area around the top of the appliance (i.e. the grille) gets very hot. Care should be taken when operating the appliance. © Valley Forge Limited 2008...

- Page 19 It should be established that any mirrors or picture frames etc. to be positioned on the wall above the appliance are able to withstand prolonged exposure to moderate heat and moisture before proceeding with their installa- tion. © Valley Forge Limited 2008...

- Page 20 NOT allow the appliance to be used until the appliance and installation is passed as safe. If the pilot continues to be extinguished you must call your installer to check the operation of the complete appliance. © Valley Forge Limited 2008...

- Page 21 Seal kit for Catalyst F860599 © As our policy is one of continuous improvement and development , we hope therefore you will understand we must retain the Valley Forge Limited 2008 right to amend details and/or specifications without prior notice.