Subscribe to Our Youtube Channel

Summary of Contents for maxilift 3300W

- Page 1 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com SERVICE CRANE Mod. 3300W Code MD.0.121 USE AND MAINTENANCE MANUAL Edition 07/09...

- Page 2 Outrigger beam - (mechanical jack) The table has to be filled carefully with the above option when purchased PRELIMINARY INFORMATION Operator’s and maintenance manual of MAXILIFT COBRA 3300W SERVICE CRANE Manual code: MD.0.121 This manual is valid starting from serial no: 9310 Manufacturer: NEXT HYDRAULICS S.r.l.

-

Page 3: Table Of Contents

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com INDEX FOREWORD ....................P Summary ................................ “ Remarks ................................. “ Manual revision ............................... “ HOW TO CONSULT THE MANUAL ..............“ Instructions ..............................“ CRANE IDENTIFICATION ..................“ Versions and optional available ........................ - Page 4 Performances ..............................Load chart table ............................... WIRING AND HYDRAULIC DIAGRAMS ..............“ 11.1 Wiring diagrams ............................. “ 11.1.1 Pendant and control wirings .......................... “ 11.1.2 3300 Wiring diagram ............................“ 11.2 Hydraulic diagrams ............................“ 11.2.1 Hydraulic diagram 3300W ..........................“...

-

Page 5: Age

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com FOREWORD 1.1 SUMMARY This manual is divided into chapters to make its consultation easier. Chapter 1: Includes summary and a short introduction. Chapter 2: Explains how to consult the manual. Chapter 3: Crane identification data. -

Page 6: Manual Revision

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com NOTE The table on the back of the front page has to be filled at customer’s care. It contains all the ne- cessary data required when calling our Technical Service. A copy of this manual is supplied along with every crane. -

Page 7: Crane Identification

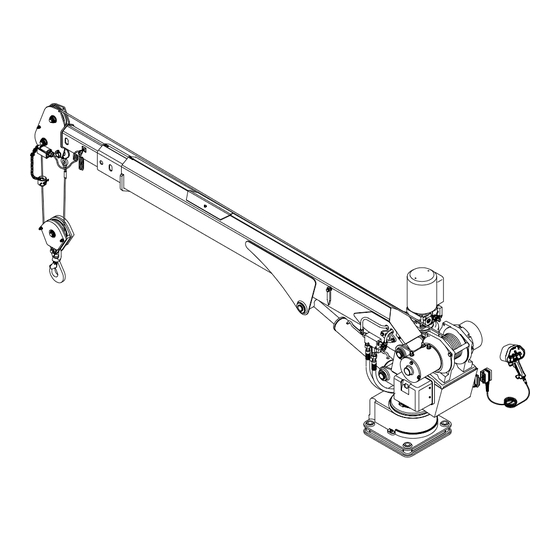

3.1 VERSIONS AND OPTIONS AVAILABLE The service instructions written on this manual are referred to the CRANE MAXILIFT COBRA 3300W. This model is supplied in one only version, the hydraulic circuit is fed by a DC hydraulic power pack connected to the truck battery. -

Page 8: Crane Usage And Limits Of Applications

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com CRANE USAGE AND LIMITS OF APPLICATIONS 4.1 CRANE CLASSIFICATION AND PROPER USAGE The machine is an hydraulic truck crane for hook service. It can also be used for the same purpose from a static mounting. - Page 9 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com • normal depth perception and field of vision (peripheral); • ability to distinguish colors if color recognition or differentiation is, required for safe operation; • adequate hearing, with or without a hearing aid; •...

-

Page 10: Safety Rules

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com SAFETY RULES 5.1 RULES CONCERNING PEOPLE • Always wear the prescribed personal safety devices • Always wear approved accident-prevention clothing such as: protective helmets, anti-slip shoes, protec tive gloves, antinoise headphones, protective glasses, reflective jackets with breathing apparatus. -

Page 11: Rules For The Correct Positioning Of The Crane

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 5.3 RULES FOR THE CORRECT POSITIONING OF THE CRANE 5.3.1Choice of crane operating place pressure on the ground • Carefully choose the place where lowering and put into action the stabilizers of the crane outriggers. The most important thing is the capacity of the ground to bear the pressure produced by the outriggers. -

Page 12: Safety Distance From Electrical Power Lines

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com • for brought-back or crumbling terrain safety distance (a) must be double of the slopes’ depth that is: a = 2 • b • for compacted, not crumbling terrain safety distance (a) must be equal to the slopes’ depth, that is: a = 1 •... - Page 13 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com Grounding is especially required when: • working close to electric power lines; • working nearby powerful broadcasting plants such as radio, T.V., an so on • working nearby electricity plants where high frequency is involved •...

-

Page 14: Influence Of The Wind On The Crane Operation

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com DANGER electrocution hazard Always connect in a perfect way the load and the ground Before touching the load with your hands, always ground the load by touching it with the insulated rod. DANGER electrocution hazard Always hold the rod by its insulated handle. -

Page 15: General Rules On Winch Operations

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 5.5 GENERAL RULES ON WINCH OPERATIONS 5.5.1 Winch system operation The Winch is mounted at the rear of the first section boom.It has capacities totally indipendent of the rest of the crane and can normally pull more than the crane itself can withstand.Therefore,care must be taken to insure that the load being lifted is within boom rating.To lift some of the heavier loads on the capacity chart,it will be necessary to multiple-part reeve the winch block to increase the lifting capacity of the winch (the... -

Page 16: General Rules When Operating Winch

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 5.5.5 General rules when operating winch 1 - Always operate the winch control to payout the loadline while extending the boom. This will maintain clearance between the boom tip and loading hook. 2 - Do not pull load block into boom tip. -

Page 17: Description Of The Crane

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com DESCRIPTION OF THE CRANE 6.1 MODEL 3300W Item Description Slewing system Slewing motor Column Main boom Boom hoist cylinder First boom section (hydraulic) Second boom section (mechanical) -

Page 18: Controls Description

View thousands of Crane Specifications on FreeCraneSpecs.com SAFETY DEVICES 6.3.1 Safety devices installed All the safety devices,installed on MAXILIFT COBRA 3300 crane, are listed and described in the following pages. description of safety functions The crane is fitted with 4 standard electro-hydraulic safety limitations:... -

Page 19: Relief Valve

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 6.3.3 Relief valve The main relief valve is on the electro-hydraulic unit and limits the maximum working pressure. 6.3.4 Pilot operated holding valves These valves are installed on every cylinder and will stop and lock every motion of the cylinder should any pressure loss occur. -

Page 20: Controls Description

The electrovalves (EV3B-EV2B-EV1B-EV1A) are fitted with manual controls, to be used only in case of emergency (remote control box or electronic power unit breakdown). Model 3300W - E For emergency manoeuvres, fully turn counter-clockwise the manual control of the electrovalve coupled to... -

Page 21: Remote Control Box

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 6.4.2 Remote Control Box The remote control box for single-hand use was designed to give the operator an ergonomic, practical remote control device, and to optimize the several crane functions. It is essentially consisting of a plastic container with protected control panel completely connected to an ergonomic handgrip. -

Page 22: Operating Instructions

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com OPERATING INSTRUCTIONS 7.1 GENERAL ATTENTIONS The crane must be used exclusively by qualified and skilled operators. They must know location and func- tion of every control, instruments, indicators, lights, plate and sticker. DANGER Before starting operations make sure that nobody is in the working area of the crane. -

Page 23: Stabilizing The Truck

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com • Check every month the state and correct functioning of all the parts subject to wear: pins, valves, hoses, sliding pads and bushings, etc. If necessary replace with genuine spare parts. •... - Page 24 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com Mechanical jack (Pict. 11) Lower to the ground the pads (4) of the outrigger jack, by pulling the locking pin (5) out of its housing. The telescope and the pad will come down because of gravity.

-

Page 25: Opening The Crane

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 7.3 OPENING THE CRANE • Starting from the crane in rest position, operate the switch of „boom hoist up“ on remote control. When the boom is roughly horizontal or in any case, higher than vehicle sides or other existing obstacles. •... -

Page 26: Standard Hand Signals

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com • A sudden stop when lowering a load. This creates high forces of inertia on the crane structure with relevant dangerous overload. • Hitting the rope where the load is suspended, overload is generated. •... -

Page 27: Putting The Crane Into Service

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 8 PUTTING THE CRANE INTO SERVICE 8.1 TEN RULES FOR THE PERFECT CRANE OPERATOR Always comply with the following ten basic rules: 1 - When approaching the crane for the first time, become on familiar terms with it, executing all the manoeuvres the crane can perform during working. -

Page 28: Long Shutdowns

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 8.3.2 Long shutdowns Same precautions as above and, moreover: • apply protective oil on the entire crane surface • cover the crane using a plastic curtain against rain etc. •... -

Page 29: Maintenance

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 9 MAINTENANCE 9.1 WARNINGS • Do not wear rings, wristwatches, jewelry, loose-fitting or hanging clothing such as ties, torn garments, ordinary shoes, unbut toned jackets or un-zipped overalls, which could get caught up in the moving parts of the crane. -

Page 30: Maintenance Schedule

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com DANGER of fire or scald It is forbidden to use naked flame as lighting device when carrying out checks or looking for le- aks in the machine. •... -

Page 31: Monthly Checking

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 9.3.2 Monthly checking • Check the setting of the pressures in the hydraulic system, and integrity of the seals. • Check the absence of oil leaks. •... -

Page 32: Crane Servicing

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 9.4 CRANE SERVICING 9.4.1 Oil level checking The oil level must be checked daily, with the crane in rest position and the truck on flat ground If necessary top up with hydraulic oil. -

Page 33: Wormgear Assembly Control

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 9.4.3 Wormgear assembly control (Pict. 14) It is important to check that the worm gear reducer has a correct axial backlash. This can be made, with the crane at standstill, the boom in horizontal position. -

Page 34: Greases And Oils Reference Table

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 9.5 Greases and oils reference table BRAND TOTAL MOBIL ESSO AGIP GREASE MULTIS MOBILGREASE BEACON GR MU ATHESIA ENEGREASE LR MP GREASE MULTIS MOBILGREASE BEACOM GR MU ATHESIA ENERGREASE LR MP... -

Page 35: Wire Rope

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com WIRE ROPE 9.6.1 WIRE ROPE INSPECTION Each day and before use, inspect the wire rope for the following conditions: 1 - Kinking (Sharp bends) 6 - Rope diameter loss 2 - Crushing 7 - Rope strand uneveness 3 - Unstranding... - Page 36 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com Wire rope is lubricated during manufacturing so the strands, and individual wires in strands, may move and adjust as the rope meves and bends. A wire rope cannot be lubrificated sifficiently during manufacture to last its entire life.

-

Page 37: Possible Faults And Relevant Remedies

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 9.7 POSSIBLE FAULTS AND RELEVANT REMEDIE Fault Cause Remedy Vibrations in hydraulic cylinder and jerkin- The temperature of the hydraulic oil is Perform manoeuvres without loads for gs at the first manoeuvres. - Page 38 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com Fault Cause Remedy Tension lack in the control box (green led Discharged battery. Recharge the battery. out). Burned fuses. Replace the fuses. Disconnected electric coupling Join correctly the connection. Replace the electric coupling.* A manoeuvre does not work.

- Page 39 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com...

-

Page 40: Technical Data

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 10 TECHNICAL DATA - WINCH SPECIFICATIONS SERIES 3300W STANDARD EQUIPMENT Electric winch Remote control with connection and 8 m. - 26’ ft. of cable Negativ brake for winch... - Page 41 Working pressure 2300 Crane weight WINCH SPECIFICATION 3303W Winch pull line 1600 Pull line speed E 12V ft/min Rope diameter inch 1/4” Wire rope length Cable breaking strength minimum 8000 Technical data not binding LOAD CAPACITIES COBRA 3300W Pict. 18...

-

Page 42: Wiring And Hydraulic Diagrams

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com WIRING AND HYDRAULIC DIAGRAMS 11 WIRING AND HYDRAULIC DIAGRAMS 11.1 WIRING DIAGRAMS 11.1.1 Pendant and control wirings Pict. 19... - Page 43 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com - Remote control box - Clockwise rotation magnet - Electronic power unit - Counter clockwise rotation magnet - Limit switch wiring - Boom raising magnet - Solenoid wiring - Boom lowering magnet - Crane rotation selector - Boom extension magnet...

-

Page 44: 3300 Wiring Diagram

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 11.1.2 3300W - wiring diagram 1 Battery 2 Starting Key 3 Fuse protection 4 Electronic power unit 5 Electro-hydraulic power pack 6 Power pack switch 7 Electric winch’s contactor pack... -

Page 45: Hydraulic Diagrams

View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com 11.2 HYDRAULIC DIAGRAMS 11.2.1 HYDRAULIC DIAGRAM FOR E 12V VERSION 1 Pump 2 Electrohydraulic unit 3 Rotation motor 4 Lifting cylinder 5 Overcenter valve 6 Pressure switch 8 Cylinder 9 Overcenter valve 11 Oil filter... - Page 46 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com...

- Page 47 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com NOTES Name of the installer (person) Name of the authorized installer workshop Address NEXT HYDRAULICS S.r.l. City Province State Via della Costituzione, 25 Poviglio (RE) - ITALY Tel number.

- Page 48 View thousands of Crane Specifications on FreeCraneSpecs.com View thousands of Crane Specifications on FreeCraneSpecs.com NEXT HYDRAULIC S.r.l. Via Mediterraneo 6 42022 BORETTO (Reggio E.) -Italy Tel. 0522 / 96 30 08 - Fax 0522 / 96 30 39...

Need help?

Do you have a question about the 3300W and is the answer not in the manual?

Questions and answers