Subscribe to Our Youtube Channel

Summary of Contents for Krupp HM 1000

- Page 1 Repair manual Krupp hydraulic hammers ® HM 1000 / 1000 Marathon Pt.-Id.-No. 3071017 Valid from:11/98 GB...

-

Page 2: Table Of Contents

3.3.5 Press-out aid for wear bushes................Dismantling the hydraulic hammer..........11/98....Removing the working tool................... Removing the percussion mechanism of the HM 1000 from the hammer box..Removing the high-pressure accumulator............. Removing the control slide valve................Removing the AutoControl - valve................ - Page 3 Chapter Title Version Page Assembling the hydraulic hammer............11/98... Tightening torques for screws and screw couplings on the HM 1000..... Fitting the cylinder....................Fitting the percussion piston and sealing bush............Fitting the cylinder cover..................Fitting the AutoControl – valve................Fitting the perforated disk..................

-

Page 4: General

Repair manual HM 1000 / 1000 Marathon General In order to maintain the operational safety of all versions of the HM 1000 hydraulic hammer, repair work should only be carried out by Krupp trained specialists using genuine Krupp spare parts. Krupp trained specialists know which parts need replacing and when. -

Page 5: Explanation Of The Symbols In The Repair Manual

® Repair manual HM 1000 / 1000 Marathon Explanation of the symbols in the repair manual To emphasise their importance, certain points in the repair manual are marked with symbols, which are described below. Theses passages contain information on the... -

Page 6: Operational Safety

® Repair manual HM 1000 / 1000 Marathon Operational safety Caution! General In order to maintain the operational safety of the hydraulic hammer, repair work should only be The hammer's integrated piston accumulator is carried out by trained specialists using genuine pressurised. -

Page 7: Tools, Measuring And Testing Equipment

Repair manual HM 1000 / 1000 Marathon Tools, measuring and testing equipment tools required dismantling reassembling the HM 1000 are to be provided by the user (see Chapter 3.1). The special accessories used in this section are listed in Chapter 3.3 Operating media / consumables... -

Page 8: Tools

® Repair manual HM 1000 / 1000 Marathon Tools General tools The tools required for repair work are listed below: Designation Part ID no. Qty. Sledgehammer 2 kg 1031811 Sledgehammer 4 kg 1146433 Grease gun cpl. 3034567 Slugging ring spanner... -

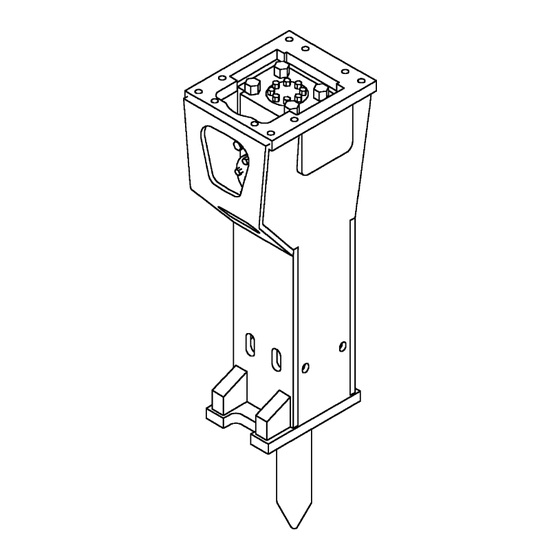

Page 9: Toolbox 3

® Repair manual HM 1000 / 1000 Marathon Toolbox 3 The tools required for service work on the hammers are contained in Toolbox 3 Fig. 1 Toolbox 3 Dimensions Length 760 mm Width 215 mm Height 250 mm Toolbox contents ordered under part ident. -

Page 10: Special Accessories

® Repair manual HM 1000 / 1000 Marathon Special accessories This chapter lists the special tools and apparatus which can be purchased from Krupp Berco Bautechnik to equip the workshop. 3.3.1 Accumulator filling device The tools listed in the table below are used to fill the high-pressure accumulator. -

Page 11: Power Wrench

® Repair manual HM 1000 / 1000 Marathon 3.3.2 Power wrench You can choose between an electronic or a hydraulic power wrench. 3.3.3 Heli-Coil tools The tools listed in the table below are used to Fig. 4 replace the Heli-Coil inserts. -

Page 12: Fitting Aid For Percussion Piston

® Repair manual HM 1000 / 1000 Marathon 3.3.4 Fitting aid for percussion piston Designation Pt. Id No. Eye bolt 0206700 Fig. 7 Fitting aid 3.3.5 Press-out aid for wear bushes Item Designation Pt. Id No. Press-out tool, compl. Grip... -

Page 13: Dismantling The Hydraulic Hammer

® Repair manual HM 1000 / 1000 Marathon Dismantling the hydraulic hammer Removing the working tool • Lay the hydraulic hammer on a suitable base. • Remove the plugs (1/5) and (1/9) from the hammer box. • Using the pin punch from Toolbox 3 (1/7), and... -

Page 14: Removing The Percussion Mechanism Of The Hm 1000 From The Hammer Box

• Using hoist/crane, lift percussion mechanism of the HM 1000 out of the hammer box (Fig. 4). Caution! • If the percussion mechanism has jammed in hammer box, e.g. -

Page 15: Removing The High-Pressure Accumulator

(e.g. on a stand similar to Fig. 5), or lay flat. Caution! If the HM 1000 is still attached to the carrier, the Fig. 6 hydraulic system must be depressurised prior to Releasing and unscrewing the Allen screws removing the high-pressure accumulator. - Page 16 Download the full PDF manual instantly. Our customer service e-mail: aservicemanualpdf@yahoo.com...

Need help?

Do you have a question about the HM 1000 and is the answer not in the manual?

Questions and answers