Summary of Contents for Enerpac CAT 3600 Series

- Page 1 CAT 3600 Series Engines L4163 Rev. C 06/17 Connecting Rod Tensioner • Part No. 498-6547 • Bolt Size M19 x 1.5 • 40 mm Bolt Centers NEHS1281 English (EN) Instruction Sheet...

-

Page 3: Table Of Contents

INSTRUCTIONS ....7 Troubleshooting Chart ... . . 14 Instruction Sheet © 2017 Enerpac, All Rights Reserved... -

Page 4: Safety

Please note that the • Immediately replace worn or damaged parts with genuine Safety Alert Symbol will not be used with this Enerpac parts. Enerpac parts are designed to fit properly and signal word. to withstand high loads. Non-Enerpac parts may break or cause the pump to malfunction. -

Page 5: Hydraulic Tensioner Safety Precautions - Cat 3600 Connecting

1.3 Hydraulic Tensioner Safety Precautions - • Never attempt to disconnect a hydraulic coupler while it is under pressure. CAT 3600 Connecting Rod Tensioner • Do not move or lift the hydraulic tensioners using the hydraulic hoses and fittings. WARNING •... -

Page 6: Product Data

2.0 PRODUCT DATA 2.2 Maximum Tensioner Force 2.1 Maximum System Pressure Maximum rated load that tensioner can Maximum rated working generate @ 1500 bar [21,750 psi] pressure of tool: 1500 21,750 59,350 (± 3 kN) (± 675 lbf) 2.3 Additional Specifications Puller Thread Hydraulic Area Maximum Stroke... -

Page 7: Product Description

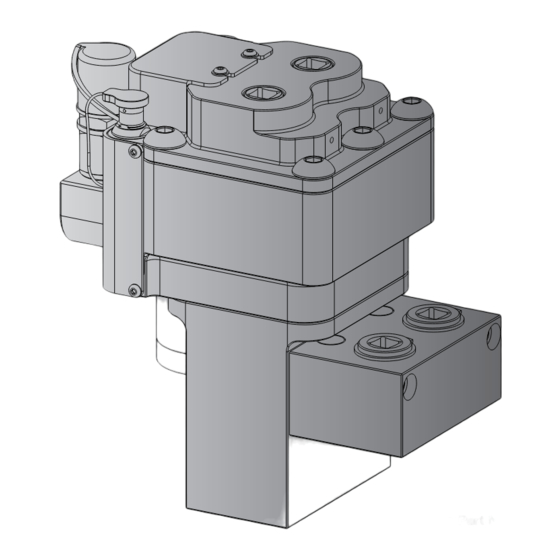

• The tensioner mounts and operates quickly, since it is 3.1 Overview especially designed for the CAT 3600 tensioning application. The Enerpac Model 498-6547 hydraulic tensioner is designed to • The puller sleeves and drive gears contain standard 3/8 precisely tension the connecting rod studs used on CAT 3600 inch female square drives. -

Page 8: Setting Up

Note: Chafe gear protective covering (three pieces) not shown. Key: 1. Socket Kit (service tool) 6. Hose Assy. - Pump to Flow Divider. 7. Flow Divider 2. Tensioner 3. Thumbwheel 8. Cable Assy. - Junction Box to Tensioner 4. Travel Case 9. -

Page 9: Tensioner Operational Checks

Figure 7, Checking Puller Sleeve Retraction If the tensioner is unable to successfully perform one or more of the operational checks, it should be inspected and repaired by an Enerpac Authorized Service Center before being placed into service. Figure 5, Checking Spring Return... -

Page 10: Hydraulic Oil

5.4 Hydraulic Oil To Connect Couplers: The hydraulic oil shown in the following table is approved for use See Figure 8. Loosen with the pump. Before making any connections, be sure that the pump pressure gauge and the touchscreen HMI pressure readout Temperature Range Approved Hydraulic Oil both indicate (0) psi/bar. -

Page 11: Hose And Cable Assemblies

5.6 Hose and Cable Assemblies NO GAP See Figure 10 for an overall view of the hoses, cables, flow- divider and junction box. For detailed hose and cable connection instructions, refer to the Smart Tensioning Pump instruction sheet (document L4186). Before connecting or disconnecting hydraulic couplers on hoses, tensioner, pump and other hydraulic devices: •... -

Page 12: Procedures

obvious damage or defects, and that they appear capable of Reaching maximum stroke is a possible indication of a problem withstanding the force that will be applied by the tensioners. with the connecting rod assembly. • Ensure that the connecting rod caps are correctly and firmly If the maximum stroke indicator appears before the desired seated, and that the nuts are fully threaded onto the studs hydraulic pressure is reached, always stop the pump and verify... -

Page 13: Cycle Counter

The puller assemblies are not user-serviceable and must hydraulic system or connected components are pressurized. be replaced by an Enerpac Service center or other qualified Escaping oil under pressure can penetrate the skin, causing hydraulic repair facility. Other internal wear items, such as seals, serious personal injury. -

Page 14: Troubleshooting Chart

Troubleshooting Chart Symptom Possible Cause Remedial Action Puller sleeves not moving when they Bad hydraulic connections. Check ALL hydraulic couplers for debris and should be moving. proper engagement. Pump not building pressure. Check if pressure is increasing, using: 1) mechanical pressure gauge, 2) touchscreen HMI readout, 3) amber LED on proportional relief valve driver. - Page 16 Connec�ng Rod Training Video CATU1269 (located on Caterpillar Channel 1) For service, warranty, or troubleshoo�ng, please use the following resources: Country/Region Enerpac Academy or Regional Office U.S./Canada Enerpac | 199 Gateway Court, Columbus, WI 53925 1‐800‐558‐0530 op�on #2 | techservices@enerpac.com La�n America Europe Northern Africa Enerpac B.V. | Galvanistraat 115 | 6716 AE Ede, The Netherlands Sub Sahara Africa Office +31 (0)318 535 911 | EAINFO@ENERPAC.COM ...

Need help?

Do you have a question about the CAT 3600 Series and is the answer not in the manual?

Questions and answers