Daikin FDXS35E7VMB Installation Manual

Hide thumbs

Also See for FDXS35E7VMB:

- Operation manual (28 pages) ,

- Service manual (267 pages) ,

- Service manual (462 pages)

Summary of Contents for Daikin FDXS35E7VMB

- Page 1 INSTALLATION MANUAL R410A Split Series FDXS25E7VMB FDKS25E7VMB FDXS35E7VMB FDKS35E7VMB FDXS50C7VMB FDKS50C7VMB FDXS60C7VMB FDKS60C7VMB...

- Page 2 3PW60063-2A...

-

Page 3: Safety Precautions

SAFETY PRECAUTIONS The original instructions are written in English. All other languages are translations of the original instructions. • Read these Safety Precautions carefully to ensure correct installation. • This manual classifies the precautions into WARNING and CAUTION. Be sure to follow all the precautions below: they are all important for ensuring safety. WARNING....Failure to follow any of WARNING is likely to result in such grave consequences as death or serious injury. -

Page 4: Choosing A Site

ACCESSORIES Insulation Washer for Sealing Washer Screws for Clamp metal Sealing pad Drain hose Clamp for fitting hanging bracket material fixing plate duct flanges Large and small 3 pcs. 1 pc. 1 each 1 pc. 1 pc. 8 pcs. 2 pcs. 6 pcs. -

Page 5: Preparations Before Installation

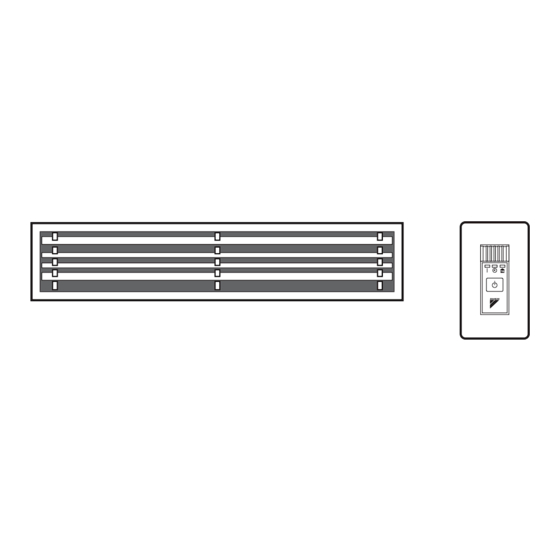

CHOOSING A SITE Select the signal receiver mounting location according to the following conditions: • Install the signal receiver, which has a built-in temperature sensor, near the intake vent where there is convection of air and it can get an accurate reading of the room’s temperature. If the Air discharge grille: intake vent is in another room or the unit cannot be installed near the intake vent for any Wooden or plastic grille is recommended... - Page 6 Mount chamber lid and air filter (accessory). Air inlet In case of bottom suction. (1)Remove the chamber lid. (7 locations) (2)Reattach the removed chamber lid in the orientation shown in Fig.(7 locations) Chamber lid Chamber lid (3)Attach sealing pad as shown in the figure below.

-

Page 7: Indoor Unit Installation

PREPARATIONS BEFORE INSTALLATION When two indoor units are installed in one room, one of the two wireless remote controllers can be easily set for another addresses. PCB in the indoor unit Wireless remote controller • Cut the jumper J4. • Cut the jumper JA on PCB. -

Page 8: Outdoor Unit Installation

For heat pump: If your feet feel cold when using the heating function, it is recommended that the air discharge grille shown at below be attached. 45° (Adjustable angle) OUTDOOR UNIT INSTALLATION Install as described in the installation manual supplied with the outdoor unit. REFRIGERANT PIPING WORK See the installation manual supplied with the outdoor unit. -

Page 9: Refrigerant Piping Work

REFRIGERANT PIPING WORK 3) After the work is finished, make sure to check that there is no Coat here with refrigeration Torque wrench gas leak. machine oil Spanner Flare nut Piping union 4) After checking for gas leaks, be sure to insulate the pipe connections. •... -

Page 10: Drain Piping Work

DRAIN PIPING WORK Caution Make sure all water is out before making the duct connection. Install the drain piping. Drain pipe connection hole • Make sure the drain works properly. • The diameter of the drain pipe should be greater than or equal to the diameter of the connecting pipe (vinyl tube;... -

Page 11: Installing The Duct

INSTALLING THE DUCT Connect the duct supplied in the field. Air inlet side • Attach the duct and intake-side flange (field supply). • Connect the flange to the main unit with accessory screws (in 16, 20 or 24 positions). • Wrap the intake-side flange and duct connection area with aluminum tape or something similar to prevent air escaping. Caution When attaching a duct to the intake side, be sure also to attach an air filter inside the air passage on the intake side. - Page 12 WIRING See the installation manual supplied with the outdoor unit. HOW TO CONNECT WIRINGS. • Wire only after removing the control box lid as shown in the Fig. Control box lid • Make sure to let a wire go through a wire penetration area. Power supply wiring •...

-

Page 13: Trial Operation And Testing

TRIAL OPERATION AND TESTING Trial operation and testing (1) Measure the supply voltage and make sure that it falls in the specified range. (2) Trial operation should be carried out in either cooling or heating mode. Trial operation from remote controller (1) Press ON/OFF button to turn on the system. - Page 14 NOTES...

- Page 15 NOTES...

- Page 16 4PW54864-1A...

Need help?

Do you have a question about the FDXS35E7VMB and is the answer not in the manual?

Questions and answers