Table of Contents

Advertisement

Quick Links

Tonkaflo Pumps

MANUAL

Installation, Operation, and Maintenance Manual

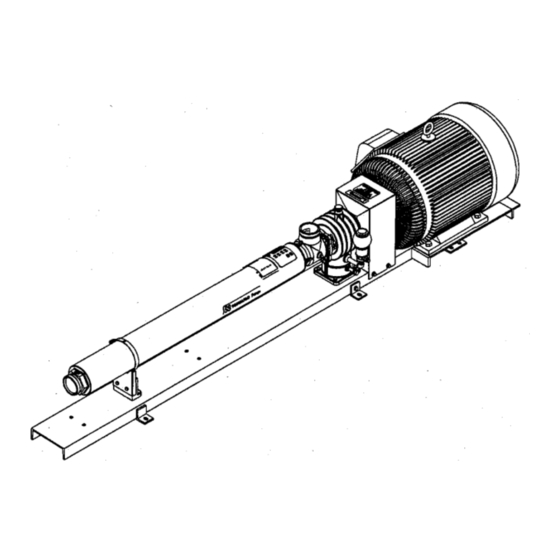

For SS5500, SS8500, SS12500, SS23000 and SS24000 Series

High-Pressure Tonkaflo Centrifugal Pumps

Note:The company referred to throughout is GE, as that was the name we operated under at the time of first release of

this manual.

Veolia Water Technologies

Please contact us via:

www.veoliawatertechnologies.com

Tonkaflo* Pumps SS Series

with E Bearing Frames

P/N 1115092 Rev. R

WATER TECHNOLOGIES

Advertisement

Table of Contents

Summary of Contents for Veolia SS Series

- Page 1 Tonkaflo Pumps MANUAL Tonkaflo* Pumps SS Series Installation, Operation, and Maintenance Manual For SS5500, SS8500, SS12500, SS23000 and SS24000 Series High-Pressure Tonkaflo Centrifugal Pumps with E Bearing Frames P/N 1115092 Rev. R Note:The company referred to throughout is GE, as that was the name we operated under at the time of first release of this manual.

-

Page 2: Table Of Contents

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL FOR SS5500, SS8500, SS12500, SS23000 AND SS24000 HIGH-PRESSURE TONKAFLO CENTRIFUGAL PUMPS WITH TYPE E-BEARING FRAME TABLE OF CONTENTS Page INTRODUCTION TONKAFLO SPECIFICATIONS Capacities Maximum Developed Boost Pressure for Standard Model Pumps (350 RPM) Maximum Recommended Operating Temperature Standard Materials of Construction Special Materials of Construction Pump Nomenclature... - Page 3 Page GENERAL TROUBLESHOOTING FOR TONKAFLO PUMPS Troubleshooting Chart Bearing Frame Temperature TONKAFLO FIELD MAINTENANCE Mechanical Seal Leakage Removal and Installation of Liquid End Assembly 6.2.1 Removal of Liquid End Assembly 6.2.2 Installation of Liquid End Assembly Mechanical Seal Replacement - SS5500, SS8500, SS12500, SS23000, and SS24000 Series Pumps High-Pressure Mechanical Seal Replacement Bearing Frame Maintenance on E-Bearing Frame Tonkaflo Pumps...

- Page 4 Page DIMENSIONAL DRAWINGS 10.0 REPLACEMENT PARTS 10.1 Pump Cutaway Drawing 10.2 Standard Model Parts List 10.3 Accessories 10.4 Recommended Spare Parts List 10.5 Complete Set of Bearing Frame Replacement Parts 10.6 Bearing Frame Overhaul Tools 10.7 Mechanical Seal Change-Out Tools 10.8 Ordering Parts 11.0...

-

Page 5: Introduction

INTRODUCTION This manual contains information important to the installation, operation, and maintenance ® of your Tonkaflo high-pressure multi-stage centrifugal pump. The Tonkaflo pump has been designed for reliable service in many types of pumping applications. Proper installation and normal maintenance will help insure extended pump life and prevent costly downtime. Before installing and operating your Tonkaflo pump, read these instructions carefully and keep the manual handy for future reference. -

Page 6: Tonkaflo Specifications

TONKAFLO SPECIFICATIONS The Tonkaflo pumps covered in this instruction manual are the higher capacity SS5500, SS8500, SS12500, SS23000, and SS24000 Series pumps. These five series of pumps cover a flow range of 20 - 300 gpm (4.5 - 68 m /h) with single-unit pressures up to 650 psig (44.8 barg). -

Page 7: Maximum Developed Boost Pressure For Standard Model

Maximum Developed Boost Pressure for Standard Model Pumps (3500 rpm) Table 2.2 Tonkaflo Standard Model Pump Boost Pressure Centrifugal SS Series Stages Standard 5500 Up to 650 psig (44.8 barg) 8500 Up to 640 psig (44.1 barg) 12500 Up to 640 psig (44.1 barg) 23000 Up to 380 psig (26.2 barg) -

Page 8: Special Materials Of Construction

Special Materials of Construction Optional ethylene propylene (EPDM), Viton*, and Teflon* elastomers are available, contact the factory. Pump Nomenclature M o d e l S S 5 5 1 8 E M o d e l S S 5 5 2 7 E - 5 0 H z Materials of Construction Materials of Construction Series 5500... -

Page 9: Pump Installation

PUMP INSTALLATION Check Upon Arrival Your pump was inspected at the factory prior to shipment to assure meeting the requirements of your order. It is suggested the pump be checked upon receipt for possible damage due to shipping. Any damage should be reported immediately to the carrier. -

Page 10: Bedplate Installation

Bedplate Installation NOTE: The bedplate must be level and securely mounted for proper pump operation. Figure 3.1 Bedplate Installation... -

Page 11: Motor, Pump, And Coupling Alignment

Motor, Pump, and Coupling Alignment (Applicable for Direct Drive) Accurate alignment of the motor, pump and coupling is a "MUST." The final alignment of the motor, pump and coupling is to be done after the bedplate is rigidly mounted (Section 3.3, Foundation), with the unit in its final operating position. Shipment, as well as handling in the field, may have changed the alignment, and it is essential that the alignment be checked before operating the pump. -

Page 12: Coupling Alignment

Figure 3.2 Coupling Alignment... -

Page 13: Coupling Guard

Coupling Guard Coupling guards are available for all Tonkaflo pumps. GE recommends a coupling guard. Check your plant safety requirements. G a p Coupling inch Size 22.2 25.4 1-1/8 28.6 1-7/16 36.5 Figure 3.3 Gap Between Flanges Piping The pump inlet housing has been designed for either upright or left or right horizontal positioning. -

Page 14: Bypass Piping For Multi-Stage Pumps

The discharge piping should be sized to properly handle the maximum flow and pressure developed by the pump. When the pump operates with a suction lift, the suction pipe should slope upward to the pump from the source of supply (Figure 3.4, Suction Lift Piping). Provision must be made for priming the pump. -

Page 15: Suction Screen (Strainer)

A bypass pipe, (a pipe from the discharge piping back to the source of liquid supply or suction line), may be needed for your installation to ensure that the pump operation is within the specified flow range. It is recommended that the connection of a bypass pipe to the suction line be at least 24-inches (61 cm) away from the pump inlet. -

Page 16: Pump Piping Connections

3.11 Pump Piping Connections The standard model Tonkaflo SS5500, SS8500, SS12500, SS23000 and SS24000 Series Pumps have grooved ends as shown in Figure 3.5 (Installation of Discharge Screen) to accept Victaulic-type couplings. The couplings with 1000 psi (69 bar) working pressure rating are available as an accessory and include a Buna-N gasket (standard). -

Page 17: Installation Of Oiler

An oil sight gauge is provided on the bearing frame so the oil level may be viewed before start-up as a check on proper installation of the oiler. Figure 3.6 Figure 3.7 Installation of Oiler Initial Cold Setting for Constant Level Oiler To install the oiler, remove the 1/4-inch pipe plug in either side of the bearing frame. -

Page 18: Tonkaflo Pump Start-Up

TONKAFLO PUMP START-UP Pump Priming THE INLET PIPING AND PUMP MUST BE FILLED WITH LIQUID (i.e., PRIMED) BEFORE START-UP. If the pump is below the liquid source or connected to a positive pressure source, the pump may be primed from that source. If the pump is above the liquid source, fill the pump and supply line with liquid from an external source. -

Page 19: Initial Operation

Initial Operation With the oiler installed and filled, oil level set, pump primed, and pump rotation checked, your pump is ready to operate. Upon start-up, check to see that the correct boost pressure level is obtained at design flow and that oil droplets form in the oil eye (Section 3.12, Lubrication of Pump Bearings). -

Page 20: General Troubleshooting For Tonkaflo Pumps

GENERAL TROUBLESHOOTING FOR TONKAFLO PUMPS Troubleshooting Chart LOW FLOW MOTOR RUNS HOT OR STOPS Restrictions in inlet or discharge 1. Motor wired improperly Foot valve operating improperly 2. Bad connection Air leak in inlet piping 3. Motor exceeded rated amp draw Air leak in mechanical seal 4. -

Page 21: Tonkaflo Field Maintenance

TONKAFLO FIELD MAINTENANCE Mechanical Seal Leakage If liquid is leaking from the hole on the bottom or the holes on either side of the bearing frame near the inlet, the mechanical seal may need to be replaced. With new pumps, pumps with new mechanical seals, or pumps which have been dormant for long periods, the seal faces may not be completely seated and a slight leakage will occur. -

Page 22: Installation Of Liquid End Assembly

Figure 6.8 Separation of Liquid End from Bearing Frame 6.2.2 Installation of Liquid End Assembly STEPS Place the shaft key in the pump shaft key way and be sure it is fully seated. Check to see that anti-seize compound is on the exposed pump shaft where it engages with the bearing frame shaft. -

Page 23: Mechanical Seal Replacement - Ss5500, Ss8500, Ss12500, Ss23000, And Ss24000 Series Pumps

Mechanical Seal Replacement - SS5500, SS8500, SS12500, SS23000, and SS24000 Series Pumps STEPS Remove the liquid end assembly (Section 6.2, Removal and Installation of Liquid End Assembly). Remove the pump shaft key and slide the mechanical seal holder off the pump shaft (Figure 6.9, Removal of Mechanical Seal). Remove the rotary portion (spring, washer, and face assembly) of the seal assembly from the pump shaft by rotating and pulling the rotary portion until it slides off the pump shaft. -

Page 24: High-Pressure Mechanical Seal Replacement

Lubricate the O-ring on the outside of the new stationary seat. Lubricate with petroleum or silicone grease. Install the stationary portion into the seal holder cavity. Make sure the stationary portion is fully seated. Lightly lubricate the ground surface of the stationary seat with grease or oil. -

Page 25: Bearing Frame Overhaul

Remove retaining ring #1 from the bearing frame as shown on Figure 6.10 (Bearing Frame Overhaul). Remove the lock nut, lock washer and flat washer from the bearing frame shaft. Place the bearing frame in a press. Simultaneously press out the oil seal holder and remove bearing cone #2 from the shaft by pressing on the motor end of the bearing frame shaft. -

Page 26: Assembly Of Pumps With Type E-Bearing Frame

To remove the bearing cup(s) from the bearing frame, use a brass or soft steel rod and hammer to knock them out. Inspect both oil seals and replace if the seals are no longer pliable or if they were leaking (Section 6.5.2, Assembly of Pumps with Type E-Bearing Frame). -

Page 27: Setting Bearing Frame Shaft End Play

Figure 6.11 Setting Bearing Shaft End Play Tighten or loosen the lock nut as required. Advancement of the nut until the next lock washer tang is aligned results in 0.0008-inch (0.02 mm) less end play. Advancing the lock nut until the same notch lines up with the next lock washer tang results in 0.003-inch (0.08 mm) less end play. -

Page 28: Install The Liquid End And Remount The Pump

WARNING: TO PREVENT OIL LEAKAGE, DO NOT TO DAMAGE THE SEAL LIP. The oil seal rubber must be lubricated with grease or oil and the shaft key way must be covered to protect the oil seal from damage. A thin metal sleeve placed over the end of the shaft will suffice. Taper the sleeve on the end so the seal can be easily slipped on the end. -

Page 29: Replacement Of Oil Seal #1

Remove the constant level oiler bottle and drain about 1/2 cup or 120 cubic centimeters (cc) of oil from the bearing frame. Remove the three bolts and lock washers that fasten the bearing frame cap to the bearing frame. Separate the bearing frame cap from the bearing frame. -

Page 30: Replacement Of Oil Chamber O-Ring Seal

STEPS Use two 5/16-18NC bolts and a flat plate (not provided) to bridge across the end of the bearing frame to pull out the seal holder. Drill two holes, 3/8-inch (9.5 mm) diameter, through the flat plate, spacing the holes 3.25 inch (82 mm) apart. Insert two 5/16-18NC bolts through the plate and turn them into the seal holder's two coupling nuts provided. -

Page 31: Lubrication

Lubrication 6.7.1 Adding Oil Add oil to the oiler bottle; do not fill directly into the oiler reservoir. After filling, allow at least fifteen minutes to elapse before measuring the oil level (Figure 3.6, Initial Cold Setting for Constant Level Oiler). Fill the oiler bottle approximately 2/3 to 3/4 full, and not completely full, for best operation of the Trico Oiler. -

Page 32: Tonkaflo Service Policy - Liquid End

TONKAFLO SERVICE POLICY - LIQUID END Section 6.0 (Tonkaflo Field Maintenance) in the Tonkaflo Installation, Operation, and Maintenance Manual was written to assist our customers in performing minor maintenance in the field on Tonkaflo pumps. Proper maintenance will ensure longer pump life and minimize downtime. -

Page 33: Tonkaflo Pump Return Goods Authorization (Rga) Procedure

TONKAFLO PUMP RETURN GOODS AUTHORIZATION (RGA) PROCEDURE If you wish to return goods for repair, warranty evaluation and/or credit, please have your original sales order or invoice available when you call GE . Call (800) 848-1750 and ask to speak with Customer Service. A GE Customer Service representative will provide instructions and a Return Goods Authorization (RGA) number which needs to be clearly written on the outside of the box used to ship your materials. -

Page 34: Dimensional Drawings

DIMENSIONAL DRAWING Figure 9.12 Dimensions (Pump Only) -

Page 35: Replacement Parts

10.0 REPLACEMENT PARTS 10.1 Pump Cutaway Drawing Figure 10.13 Pump Cutaway Drawing... -

Page 36: Standard Model Parts List

10.2 Standard Model Parts List Item Part Item Part Number Part Description Number Number Part Description Number 1114375 Screw Cap, 5/16-18NC x 1/2-inch 1110471 Clamp, HD Nut Lock 1113768 Liquid End Assembly 1110984 Discharge Support Assembly 1120600 Screw, Cap, 3/8-16NPC x (Includes items 10 &... - Page 37 Item Part Item Part Number Part Description Number Number Part Description Number Lock Washer Mechanical Seal 1/2-inch 1113104 Standard, Type 21, 200 psi 5/8-inch 1111650 (13.8 bar), ceramic seat 1121167 Screw, Cap High-Pressure, Type 1, 300 psi 3/8-16NC x 1-1/2-inch 1112250 (20.7 bar), ceramic seat 1116127...

-

Page 38: Accessories

10.3 Accessories Part Description Part Number Retaining ring pliers for mechanical seal retaining ring 1120717 Set screw pump shaft, D-, E, G- & H-Bearing frame 1113769 Allen wrench, 3/16-inch, for set screw (P/N 1113679) 1113770 Pump discharge screen 1120501 316SS Trico Oiler 2 cap screws, 5/16 x 18NC x 2-1/2-inch long U.S. -

Page 39: Recommended Spare Parts List

Part Description Part Number Victaulic adapters 3-inch Victaulic x 3-inch MNPT 304SS 1120589 3-inch Victaulic x 3-inch MNPT 316SS 1120590 3-inch Victaulic x 2-inch FNPT 304SS 1120586 3-inch Victaulic x 2-inch FNPT 316SS 1120587 1120588 3-inch Victaulic x 1-1/2-inch FNPT 316SS 4-inch Victaulic x 4-inch MNPT 304SS 1122066 4-inch Victaulic x 4-inch MNPT 316SS... -

Page 40: Complete Set Of Bearing Frame Replacement Parts

10.5 Complete Set of Bearing Frame Replacement Parts Part Part Description Number Quantity Bearing frame oil seal, motor side 1121049 (replaces P/N 1113997) Bearing frame oil seal, pump side 1113996 O-ring for bearing frame 1113998 Bearing cup and cone 1120603 Retaining ring for bearing frame house 1114280 Retaining ring for frame shaft... -

Page 41: Bearing Frame Overhaul Tools

10.6 Bearing Frame Overhaul Tools Two 5/16-inch x 18 UNC x 2-1/2-inch-long bolts for removal of grease seal holder (E-Bearing frame pumps). One 3/8-inch bolt for E-Bearing frame pumps to hold bearing frame shaft when removing lock nut. One 3/16-inch Allen (hex) wrench for removal of bearing frame shaft set screw. Bearing press (arbor press). -

Page 42: Warranty

11.0 WARRANTY TONKAFLO PUMP WARRANTY GE, warrants its pumps to be free from defects in design, material or workmanship for a period of 15 months from receipt or 12 months from installation of the product, whichever occurs first, when said products are operated in accordance with written instructions and are installed properly.

Need help?

Do you have a question about the SS Series and is the answer not in the manual?

Questions and answers