Table of Contents

Advertisement

Quick Links

600B637/02

INSTALLER GUIDE

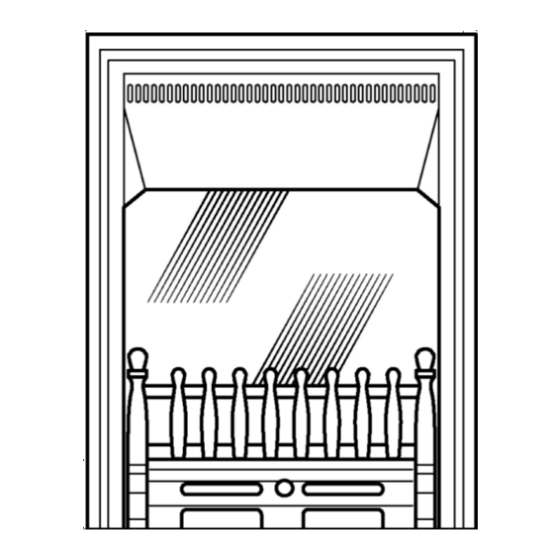

ETERNITY

MODEL 540C

(GC No. 32-032-19)

INSET

BALANCED FLUE

GAS FIRE

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20)

THIS APPLIANCE IS FOR USE IN THE UNITED KINGDOM (GB) AND THE

REPUBLIC OF IRELAND (IE) ONLY.

We trust that this Installer Guide gives sufficient details to enable the appliance to be installed

and maintained satisfactorily. However, if further information is required, the Valor

AdviceLine will be pleased to help.

Please telephone 0345 626341 (Local call rates apply).

INSTALLER: Please leave this guide with the owner

Advertisement

Table of Contents

Summary of Contents for Suncrest ETERNITY 540C

- Page 1 600B637/02 INSTALLER GUIDE ETERNITY MODEL 540C (GC No. 32-032-19) INSET BALANCED FLUE GAS FIRE THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20) THIS APPLIANCE IS FOR USE IN THE UNITED KINGDOM (GB) AND THE REPUBLIC OF IRELAND (IE) ONLY. We trust that this Installer Guide gives sufficient details to enable the appliance to be installed and maintained satisfactorily.

- Page 2 INSTALLER’S GUIDE Safety First. Suncrest fires are CE Approved and designed to meet the appropriate British Standards and Safety Marks. Quality and Excellence at the heart of every Suncrest fire. All Suncrest fires are manufactured to the highest standards of quality and excellence and are manufactured under a BS EN ISO 9001 quality system accepted by the British Standards Institute.

-

Page 3: Table Of Contents

INSTALLER’S GUIDE CONTENTS 1 APPLIANCE DATA ....................4 2 GENERAL INSTALLATION REQUIREMENTS ........... 5 3 UNPACKING & PRELIMINARY CHECKS............ 9 Unpacking......................9 Appliance Disassembly..................9 Ignition Spark Check..................10 4 GAS SUPPLY INSTALLATION............... 10 5 WALL PREPARATION ..................11 Select Appliance Position ................11 Constructing a Recessed Opening .............. -

Page 4: Appliance Data

INSTALLER’S GUIDE 1 A P P L I A N C E D A T A This product uses a burner compartment rear wall and gaskets containing Refractory Ceramic Fibres (RCF), which are man-made vitreous silicate fibres. Excessive exposure to these materials may cause temporary irritation to eyes, skin and respiratory tract. Consequently, it makes sense to take care when handling these articles to ensure that the release of dust is kept to a minimum. -

Page 5: General Installation Requirements

INSTALLER’S GUIDE 2 G E N E R A L I N S T A L L A T I O N R E Q U I R E M E N T S Figure 1 The appliance can be installed into the following :- a) A minimum 4.5in rebate surround or 5in. - Page 6 INSTALLER’S GUIDE Note that soft wall coverings (e.g. embossed vinyl etc.) are easily affected by heat. They may therefore, scorch or become discoloured when close to a heating appliance. Please bear this in mind when installing. Installation to a timber-framed building should be in accordance with the relevant sections of The Institute of Gas Engineers publication IGE/UP/7 “Gas installations in timber frame buildings”.

- Page 7 INSTALLER’S GUIDE The minimum height from the top surface of the hearth or finished floor to the underside of any shelf made from wood or other combustible materials is as follows:- • For a shelf up to 150mm deep Minimum height = 780mm. •...

- Page 8 INSTALLER’S GUIDE 2.12 Minimum allowable distances from the terminal are shown in figure 2 & table 1. TABLE 1 Terminal Position Minimum Distance (mm) Directly below an openable window or other opening e.g. air brick Below gutters, soil pipes or drain pipes Below eaves Below balconies or car port roof From vertical drain pipes and soil pipes...

-

Page 9: Unpacking & Preliminary Checks

INSTALLER’S GUIDE 3 U N P A C K I N G & P R E L I M I N A R Y C H E C K S 3.1 Unpacking The carton contains the following :- 1 Main fire assembly fitted with front 2 Eyebolts surround 2 Fibre wall plugs... -

Page 10: Ignition Spark Check

INSTALLER’S GUIDE 3.3 Ignition Spark Check See figure 5. The pilot burner and electrode unit is at the left front corner of the burner. Push in the right hand control knob and turn anticlockwise through the ignition position marked and up to the pilot position marked . -

Page 11: Wall Preparation

INSTALLER’S GUIDE 5 W A L L P R E P A R A T I O N 5.1 Select Appliance Position The flue must be installed so that it is at right angles to the back panel of the fire all round the flue circumference. - Page 12 INSTALLER’S GUIDE 5.2.1 Fitting a lintel Whenever a lintel is required to support the recess in the inner leaf of a brick/blockwork building, follow the method outlined below. See figures 7 & The lintel should be either steel (Catnic) or reinforced precast concrete. It should be 750mm long x 75mm deep x inner leaf thickness.

-

Page 13: Combustible Wall Materials

INSTALLER’S GUIDE equivalent to at least 100mm above and each side of the recess opening. See figure 9. • An alternative to rockwool above the opening is to seal across the top of the cavity with superlux board or equivalent. The board should slope downwards to the back so that any moisture will be channelled to the outside. -

Page 14: Cut The Flue Hole -Timber Frame Buildings

INSTALLER’S GUIDE 5.4.2 Hammer & Chisel Cutting • Mark a 152mm (6in) diameter circle for the flue hole. Chisel out the area marked. • It may be necessary to make good both the internal and external wall faces. To achieve a neat finish and to make any future removal of the flue unit easier, it is recommended that a cardboard cylinder is formed around the flue unit and inserted in the hole while making good. -

Page 15: Prepare Appliance Fixing Holes

INSTALLER’S GUIDE • Cut a hole through the inner leaf to accommodate a non-combustible sleeve 203mm (8in.) outside diameter. To minimise the effect of breaking through the vapour control layer (VCL), if possible, cut the hole approximately 10mm undersize in so that the sleeve will be forced through the layer. -

Page 16: Flue Terminal Installation

INSTALLER’S GUIDE 6 F L U E T E R M I N A L I N S T A L L A T I O N Fig. 10 Flue Unit Installation – Brick Fig. 10a Flue Unit Installation – Timber etc. -

Page 17: Fitting To Wall

INSTALLER’S GUIDE • Insert the polystyrene ring between the inner and outer tubes to support them. Cut both tubes squarely at the marked distance. Important: Remove all polystyrene from the flue unit after cutting. 6.2 Fitting to Wall • Fit the flue tubes firmly over the spigots at the rear of the fire. -

Page 18: Fitting Terminal Guard

INSTALLER’S GUIDE 6.3 Fitting Terminal Guard • Fold the terminal guard as shown in figure 12. • Place the guard centrally over the flue terminal. • Holding the guard in position and using it as a template, mark on the wall the positions of the four fixing holes. •... -

Page 19: Full Operational Checks

INSTALLER’S GUIDE 8 F U L L O P E R A T I O N A L C H E C K S 8.1 Check for Leaks • Turn on the gas supply and check all joints up to the appliance gas tap for gas soundness using a soap solution or leak detection fluid. -

Page 20: Check Reference Pressure

INSTALLER’S GUIDE 8.3 Check Reference Pressure The burner aeration is non-adjustable. The appliance is preset to give the correct heat input on Natural Gas at 20 mbar (8in w.g) inlet pressure and no further adjustment is necessary. The burner pressure should be checked at the pressure test point located on the pipe connecting the gas tap to the main burner (See figure 16). -

Page 21: Final Review

INSTALLER’S GUIDE F I N A L R E V I E W • Recheck the pilot ignition and operation of the fire through the range of settings. • Visually inspect the appliance. Clean off any marks incurred during installation •... -

Page 22: Servicing & Parts Replacement

INSTALLER’S GUIDE S E R V I C I N G & P A R T S R E P L A C E M E N T • Always turn off the gas and make sure that the appliance is cool before commencing any servicing. -

Page 23: To Remove The Ceramic Fuel Bed & Rear Wall

INSTALLER’S GUIDE 11.3 To Remove The Ceramic Fuel Bed & Rear Wall • Remove the front unit. See section 11.1. • Remove the window unit. See section 11.2 • Lift out the ceramic fuel bed. • Remove the rear wall by Carefully sliding it upwards to clear the retaining channel and then swinging the top slightly forwards. -

Page 24: To Remove Burner Can And Plaque Unit

INSTALLER’S GUIDE 11.5 To Remove Burner Can and Plaque Unit • Remove the front unit. See section 11.1. • Remove the window unit. See section 11.2. • Lift out the ceramic fuel bed & rear wall. See section 11.3. • The front plaque clamp has two cutouts. Below these cutouts are two screws. -

Page 25: To Remove The Pilot Unit

INSTALLER’S GUIDE 11.8 To Remove the Pilot Unit See figure 23. Note: The Pilot unit must be replaced as a whole assembly. Its individual components are not separately replaceable. • Remove the front unit. See section 11.1. • Remove the window unit. See section 11.2. •... -

Page 26: Short List Of Spares

INSTALLER’S GUIDE 11.10 Short List of Spares Description No. Off Part No. Ceramic rear wall 571789 Injector-Main burner – Bray Cat.960 Size 270 571799 Pilot Unit SIT Ref. OP9706 571809 Pilot Gasket 571819 Control valve 571829 Burner plaque & gasket set 569439 Ceramic fuel bed 571839...

Need help?

Do you have a question about the ETERNITY 540C and is the answer not in the manual?

Questions and answers