Summary of Contents for Müller-Elektronik TRAIL-Control II

- Page 1 Installation and User´s Guide TRAIL-Control II Version: V5.20131113 30293001-02-EN Read and follow these operating instructions. Keep these operating instructions in a safe place for later reference.

- Page 2 Imprint Document Installation and User´s Guide Product: TRAIL-Control II Document number: 30293001-02-EN From software version: 1.01.0a Original language: German Copyright © Müller-Elektronik GmbH & Co.KG Franz-Kleine-Straße 18 33154 Salzkotten Germany Phone: ++49 (0) 5258 / 9834 - 0 Fax: ++49 (0) 5258 / 9834 - 90 Email: info@mueller-elektronik.de...

-

Page 3: Table Of Contents

Mounting the terminal Connecting the cable Connecting the battery connection cable Mounting the gyroscope 3.5.1 Mounting the bracket for the gyroscope 3.5.2 Connecting the gyroscope to TRAIL-Control II 3.5.3 Using the gyroscope Instructions on retrofitting Product description Performance description Minimal preconditions... - Page 4 Manually entering the number of pulses for the wheel sensor Calibrate steering 5.6.1 Teaching-in the central position and end stops 5.6.2 Calibrating the hydraulics of the proportional valve Using TRAIL-Control II in the field Activating TRAIL-Control II Steering the trailed implement 6.2.1 Steering in manual mode 6.2.2 Steering in automatic mode 6.2.3...

-

Page 5: For Your Safety

▪ Before charging the tractor battery, always disconnect the connection between the tractor and the terminal TRAIL-Control II. ▪ Before welding on the tractor or implement, always disconnect the power supply to the terminal. ▪ Before maintenance or repair to the tractor, always disconnect the connection between the tractor and the terminal. -

Page 6: Safety Signs On The Machine

For your safety Safety signs on the machine Safety signs on the machine You receive a safety sign adhesive label together with the product. This label must be attached near the bend area with drawbar steering. When attaching safety signs, observe the following: ▪... -

Page 7: User Requirements

Müller-Elektronik's Customer Services department will be happy to assist you. Intended use TRAIL-Control II is used exclusively for the steering of agricultural trailed implements during work in fields. TRAIL-Control II is intended exclusively for use in agriculture as well as in wine-growing, fruit- cultivating, and hop-growing operations. -

Page 8: About These Operating Instructions

Target group of these Operating Instructions About these Operating Instructions Target group of these Operating Instructions This operating manual is aimed at users of TRAIL-Control II. Layout of operating instructions The operating instructions explain step by step how you can perform certain operations with the product. -

Page 9: Mounting And Installation

Mounting and installation System overview Mounting and installation System overview TRAIL-Control II - system overview Copyright © Müller-Elektronik GmbH & Co.KG... -

Page 10: Mounting The Terminal

Mounting and installation Mounting the terminal Terminal / On-board computer Cable glands for connecting sections, bypass, Included in delivery regulation, sensors Power connection cable Locking sensor Included in delivery Can be ordered. Item no.: 312586 Bracket for computer Wheel sensor Included in delivery Can be ordered. -

Page 11: Connecting The Cable

Mounting the gyroscope The gyroscope is a measuring device to determine the directional changes of the tractor. You must mount the gyroscope to use the TRAIL-Control II. To mount the gyroscope you must carry out the following: ▪ Mount the bracket on the tractor. -

Page 12: Mounting The Bracket For The Gyroscope

The bracket must be fastened securely to prevent shaking while driving. 3.5.2 Connecting the gyroscope to TRAIL-Control II Procedure 1. Connect the gyroscope cable with the connection cable. 2. Insert the connection cable into the 8-pin socket of TRAIL-Control II. Copyright © Müller-Elektronik GmbH & Co.KG... -

Page 13: Using The Gyroscope

Mounting and installation Instructions on retrofitting 3.5.3 Using the gyroscope Procedure 1. Fasten the gyroscope into the bracket on the tractor and screw tight with the wing screw. The side with the TOP-OBEN label must be on the top: 2. After work, fasten the gyroscope into the bracket on the trailed implement and screw tight with the wing screw. - Page 14 Mounting and installation Instructions on retrofitting ▪ The transmitting part must be spatially separated from the vehicle's electronic system. ▪ When attaching the antenna, pay attention to proper installation, including a sound ground connection between the antenna and the vehicle's ground wire. For information on wiring and installation as well as the maximum allowable current consumption, please also refer to the installation guide provided by the machine manufacturer.

-

Page 15: Product Description

Minimal preconditions The following minimal preconditions must be met for working of the TRAIL-Control II: ▪ Minimal speed = 3 km/h. Steering is not possible with lower speeds. ▪ Minimal oil throughput for the hydraulic system of the tractor = 25 l/min. -

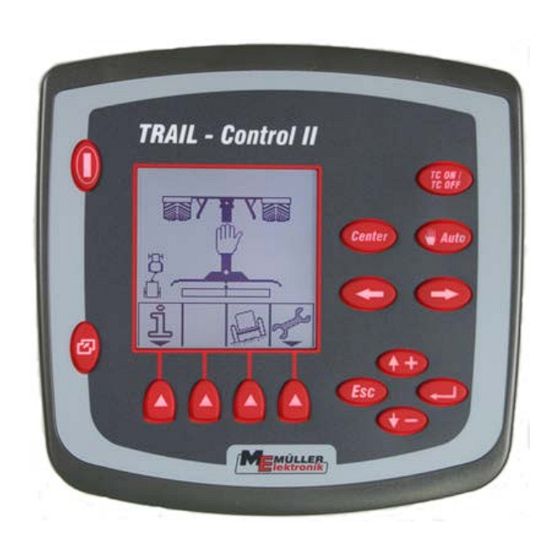

Page 16: Screen Structure

Product description Screen structure In the menus – move the cursor up one line Increase the value by one during data input In the menus – move the cursor down one line Reduce the value by one during data input Exit screen Cancel data input Close a pop-up window... -

Page 17: Main Area Of Work Screen

Drawbar was locked with the locking sensor Function icons section The lower area of the work screen shows the function symbols. The lower area of the work screen shows the function symbols. With TRAIL-Control II, four function symbols can be shown simultaneously here. Controls... - Page 18 Product description Screen structure Screen structure Header area Function symbol area contains the designation of the displayed Icons that can be pressed on this screen. screen Screen content Copyright © Müller-Elektronik GmbH & Co.KG...

-

Page 19: Configuring Trail-Control

Configuring TRAIL-Control II When should you configure what? Configuring TRAIL-Control II After you have connected all components of the system, you must configure TRAIL-Control II and the connected components. To configure the system, you must carry out the following: ▪ Configure the on-board computer. -

Page 20: Setting Date / Time

5.2.1 Setting date / time ▪ Prior to initial startup. When to enter? ▪ When TRAIL-Control II has had no power supply for more than two weeks. Procedure 1. Change to the Date/time screen: ⇨ The following screen will appear: ⇨... -

Page 21: Selecting Language

⇨ The on-board computer language is modified. - Restart the on-board computer. Entering the trailed implement parameters Before you use TRAIL-Control II, you must enter the parameters for the connected trailed implement. Procedure 1. Change to Parameters 2 screen Copyright © Müller-Elektronik GmbH & Co.KG... - Page 22 Configuring TRAIL-Control II Entering the trailed implement parameters ⇨ The following screen will appear: - Mark the line with the required parameter. - Enter the required parameter. - Change to Parameters 3 screen 5. Enter the required parameter in the Parameters 3 screen.

-

Page 23: Configuring Trail-Control Ii After Tire Change

Configuring TRAIL-Control II Configuring TRAIL-Control II after tire change Parameter Description manually. Track width Track width of the machine Configuring TRAIL-Control II after tire change The following machine parameters change after any tire or wheel replacement: ▪ Wheel.pls ▪ Track width You can configure up to three wheel sets to prevent having to re-enter these parameters after each tire or wheel change. -

Page 24: Determining Pulses Per 100 Meters

100 meters. When you know the amount of impulses, the TRAIL-Control II can calculate the current speed. In order for the wheel sensor to function correctly, it must receive at least 250 pulses over a distance of 100 metres. -

Page 25: Manually Entering The Number Of Pulses For The Wheel Sensor

Configuring TRAIL-Control II Calibrate steering ⇨ You have calibrated the wheel sensor. - Exit the screen. 5.5.2 Manually entering the number of pulses for the wheel sensor If you know the number of pulses for the wheel sensor you can enter this number manually as well. - Page 26 Configuring TRAIL-Control II Calibrate steering 2. Change to the TRAIL-Control screen: or when the angle sensor is mounted to the swivel pin: ⇨ The following screen will appear: ⇨ The following screen will appear: - Call up the calibration of the central position.

- Page 27 Configuring TRAIL-Control II Calibrate steering ⇨ ⇨ The following screen will appear: - Start calibration. ⇨ Calibration is initiated. - Confirm within three seconds. ⇨ The following screen will appear: ⇨ The following screen will appear: 4. Wait until the message 'Left maximum position: calibration runs' is no longer displayed.

-

Page 28: Calibrating The Hydraulics Of The Proportional Valve

Configuring TRAIL-Control II Calibrate steering ⇨ ⇨ The following screen will appear: - Start calibration. ⇨ Calibration is initiated. - Confirm within three seconds. ⇨ The following screen will appear: ⇨ The following screen will appear: 8. Wait until the message 'Right maximum position: calibration runs' is no longer displayed. - Page 29 Configuring TRAIL-Control II Calibrate steering WARNING Danger of injury from machine movements When calibrating the proportional valve, the machine moves automatically in the bend area. This may cause danger for you and for persons in direct proximity to the machine.

-

Page 30: Using Trail-Control Ii In The Field

Only in this way can the implement remain in the tracks of the tractor. Minimum work speed The minimum work speed for TRAIL-Control II is 3 km/h. Speeds lower than this mean the system does not function optimally. -

Page 31: Steering In Manual Mode

6.2.2 Steering in automatic mode When you work in automatic mode the trailed implement is steered automatically. The gyroscope measures the directional change of the tractor and TRAIL-Control II calculates the required angle for steering the trailed implement. 6.2.3 Steering the trailed implement against the slope For work on a slope you can use the 'slope counter-steering' function. - Page 32 When the slope inclines to the right of the vehicle you must steer the trailer device to the right. - Deactivate 'slope counter-steering' function. Using slope counter-steering in automatic mode In automatic mode the TRAIL-Control II determines itself how far the machine must be steered against the slope. Procedure ...

-

Page 33: Documenting Work Results

The Counter screen has the following information: ▪ Time – time period of TRAIL-Control II in automatic mode. ▪ Distance – distance driven in automatic mode. ▪ Serv hours– time period in which TRAIL-Control II was switched on. Controls Delete day meter time Delete day meter distance Copyright ©... -

Page 34: Locking Trail-Control Ii For Road Driving

- Steer the trailed implement into the central position. 3. If you have locking bolts: Lock drawbar steering with the locking bolts. ⇨ A blue screen appears with the text 'TRAIL-Control II'. - Disable all functions of TRAIL-Control II. ⇨ TRAIL-Control II is ready for road traffic. -

Page 35: Maintenance And Servicing

Maintenance and servicing Checking the software version Maintenance and servicing NOTICE This product does not contain any components which require maintenance or repair! Never unscrew the casing! Checking the software version Procedure 1. Change to Diagnostic Info screen ⇨ The following screen will appear: ⇨... -

Page 36: Activating And Deactivating Hydraulic Valves

Maintenance and servicing Activating and deactivating hydraulic valves ⇨ The following screen will appear: Depending on the system's configuration, different sensors may be displayed here: Sensor displayed Displayed sensor value Meaning Gyroscope current measurement value current voltage in mV Potent.: current measurement value current voltage in mV (angle sensor) -

Page 37: Maintaining And Cleaning Device

- Exit Outputs 1 screen. Maintaining and cleaning device ▪ Only clean TRAIL-Control II with a soft damp cloth wet with clear water or glass cleaner. Disposing of the unit When it has reached the end of its service life, please dispose of this product as electronic scrap in accordance with applicable EU legislation. -

Page 38: Plug Assignment - 8-Pin Flange Socket

Maintenance and servicing Plug assignment - 8-pin flange socket Parameter Value ESD protection In accordance with ISO 10605 Level 3 Power input 5 Watt (no valves connected) Display 160 x 160 pixel LCD display, transflective with white LED backlighting; software-controlled contrast, brightness and temperature compensation Processor 60 MHz ARM7 LPC2214 with internal 256k flash disk and 16k RAM... -

Page 39: Pin Connection Of Gyroscope Connector

Maintenance and servicing Pin connection of gyroscope connector 39-pin connector Signal 39-pin connector Signal 39-pin connector Signal Pin no.: Pin no.: Pin no.: TC ON / OFF Magnetic valve, right 1 TC OFF / ON Bypass out Magnetic valve, left Free Magnetic valve, left Hand operation... -

Page 40: Troubleshooting

Troubleshooting Table with possible error messages Troubleshooting Table with possible error messages It may occur that a warning message or warning symbol appears on the terminal screen during work. ▪ Warning symbols appear in the header of the work screen. ▪... -

Page 41: Procedure With Faults

Troubleshooting Procedure with faults Error message Possible cause Help was exceeded. TRAIL-Control II. Sensors faulty Short signal interruptions with Check cabling of the sensors. all sensors. Procedure with faults Fault description Possible cause Help The device does not switch on Incorrect power supply polarity Check the battery connector cable.

Need help?

Do you have a question about the TRAIL-Control II and is the answer not in the manual?

Questions and answers