Summary of Contents for MIHM-VOGT HTS-2/METAL GLOW 120

- Page 1 Operating manual (translated from the original German operating manual) Annealing oven HTS-2/METAL GLOW 120 Friedrich-List-Straße 8 D-76297 Stutensee-Blankenloch Tel.: +49 (0) 7244 70871-0 www.mihm-vogt.de...

-

Page 2: Table Of Contents

Starting/stopping a heating program ............... 28 Programming heating levels ................29 Programming levels S2 to S4 ................30 Saving the heating program ................30 Saving the heating program with a name ............31 Page 2 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... - Page 3 Care and maintenance ..............49 Checking the argon system ............49 Faults and error messages ............50 Safety ..................50 Faults ...................51 Error messages in the electronics ..........52 Decommissioning..............53 Disposal..................53 Safety ..................53 Disposal ..................53 Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 3...

-

Page 4: General Information

The operator must provide personnel with the necessary protective equipment. The operator must have all safety devices checked regularly for operability and completeness. Page 4 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 5: Documentation

Indicates a potentially dangerous situation that may cause minor physical injury. Note Indicates a potentially harmful situation in which the product or an object in its vicinity may be damaged. Note Information or tips for easier operation. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 5... -

Page 6: Formatting And Symbols

indicates a list indicates a button Service address Friedrich-List-Straße 8 76297 Stutensee-Blankenloch, Germany Tel.: +49 (0) 7244 70871-0 www.mihm-vogt.de Page 6 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 7: Safety

Use of inflammable and explosive materials near the oven. h Do not operate the annealing oven near highly flammable sources. h Do not install the annealing oven on highly flammable supporting surfaces. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 7... - Page 8 This operating manual must be read and understood by each user before working on and with the unit. The operating manual must be kept for the specified service life of the annealing oven. Page 8 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021...

-

Page 9: Transport, Packaging And Storage

The goods must be inspected for damage and loss immediately upon receipt. Defects must be documented by the freight carrier on the letter of consignment in order to lodge claims. Mihm-Vogt GmbH & Co.KG assumes no liability for any damage and loss that is only found subsequently. -

Page 10: Packaging

Store the unit only at temperatures between +5 and +40 °C. h Always store the unit in dry and dust-free conditions. h Avoid exposure to direct sunlight. h Avoid mechanical vibrations. Page 10 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 11: Technical Description

A temperature sensor integrated into the heating chamber measures the temperature of the chamber close to the product. A thermocouple fail-safe prevents the annealing ovens from overheating if the temperature sensor becomes defective. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 11... -

Page 12: Conformity

Folgende nationale oder internationale Normen (oder Teile/Klauseln daraus) und Spezifikationen wurden angewandt: - Name und Anschrift der Person, die bevollmächtigt ist, die technischen Unterlagen zusammenzustellen: Gillen, Tobias Ort: Stutensee / Datum: 18.05.2021 _______________________________ (Unterschrift) Dietmar Gräbe Page 12 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 13: Certification

Risk assessment and risk reduction EN ISO 12100:2010 RoHS Conformity This symbol indicates that this product contains no poisonous or dangerous substances and can be recycled after disposal, and should not be thoughtlessly discarded. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 13... -

Page 14: Intended Use

Only aids/accessories/wearing parts as well as spare parts approved by Mihm-Vogt may be used. You can find an overview of the approved media and equipment on the supplementary sheet in your unit packaging. Page 14 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 15: Annealing And Sintering With Argon

At a flowrate of 1.4 l/min (bell system 120 mm), the consumption per process is approx. 380 litres. With a 50 litre compressed gas bottle, approx. 26 NEM processes are possible. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 15... -

Page 16: Technical Data

+5 to +40 °C Relative air humidity Up to 31 °C: 80 % Maximum air humidity Up to 40 °C: 50% no condensation Height Max. 2000 m Pollution degree Page 16 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 17: Installation

Have at least two persons carry/move the annealing oven together (max. 30 kg load bearing capacity/person). Caution Risk of overheating! Overheating due to blocked air inlets. h Make sure that the air vents remain clear on all sides. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 17... -

Page 18: Electrical Connection

Do not touch live cables and components with wet hands. h Observe the accident-prevention regulations when working with electric current. h Only connect the unit to a voltage supply that matches the specifications on the rating plate. Page 18 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 19: Rating Plate

Danger due to escaping gas! Potential risk of explosion or fire as well as suffocation. h During all work on the HTS-2/Metal GLOW 120, the argon and voltage supply must be shut off, and the gas bottle must be closed. - Page 20 A ventilation in the floor area is recommended (argon is heavier than air and settles on the floor). Protect the ducts and shafts against penetration by gas. Page 20 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021...

-

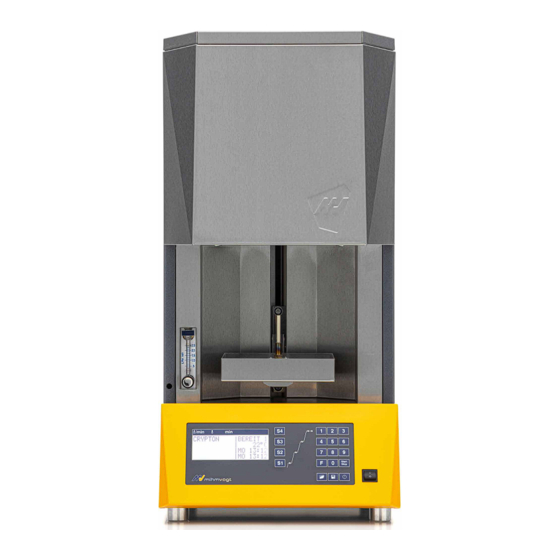

Page 21: Operation

7 Save button 3 Numeric keypad 8 Load button 4 Start/Stop button 9 Function button 5 Finishing time button 10 Heating phase LEDs 11 Additional function: Open oven door Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 21... -

Page 22: Switches And Button Functions

Function button for setting the parameters (see graphic “Parameter settings” on page 38) Additional function: Open oven door This additional function is active only if the current oven temperature is less than the set temperature in level 4. Page 22 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 23: Standby Screen

Danger from escaping argon gas! h Close the compressed gas bottle after each annealing process. h Ensure sufficient ventilation in the laboratory after using argon. h Check the argon system regularly for leaks. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 23... -

Page 24: Setting The Argon Flow Rate

Sinter bell system Ø 120 mm As delivered, the flow rate is pre-set at the factory to 1.4 l/min. Here, the lower edge of the suspended body indicates the flow rate in litres/minute. Page 24 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 25: Initial Commissioning

Using the door insulation Place the base support (3) in the door. Insert the connecting pins (2) in the base support (3). Place the support stone (1) on the connecting pins (2). Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 25... -

Page 26: Door Insulation Assembled

Initial commissioning Door insulation assembled Page 26 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 27: Annealing And Sintering Aids

Initial commissioning Annealing and sintering aids Note Only use sintering aids approved by Mihm-Vogt. You can find application notes in the information flyer for the relevant aid. Annealing process Selecting and loading a heating program Load Press the button. The LOAD PROGRAM menu opens. -

Page 28: Starting/Stopping A Heating Program

Start Stop The heating program is stopped. Â The status display changes from SEQUENCE to READY. Â Start/Stop Press the button again to continue the heating Start Stop program. Page 28 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 29: Programming Heating Levels

After entering the temperature value, the cursor skips to the next  input field. If the entry is below a four-digit value, the cursor must be moved over  the relevant level button to the next input field. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 29... -

Page 30: Programming Levels S2 To S4

° Press the button. The SAVE menu is displayed. Â Press the S2 button for “YES” to save the heating program. Page 30 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 31: Saving The Heating Program With A Name

A memory name with up to four lines can now be saved in the left field. You can use the button to move the cursor incrementally to the  right. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 31... -

Page 32: Starting A Heating Program Automatically

The finishing time as well as the calculated switch-on time are shown  in the display. Page 32 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 33: Annealing Without Protective Gas

Make sure that no one reaches between the oven door and heating chamber while the oven door is closing. Removing the product from the annealing oven Remove the annealing material with suitable tongs and place it on a heat-resistant surface. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 33... -

Page 34: Annealing With Protective Gas

Press the S1 button. The SAVE menu is displayed. Â Follow the action steps of the saving of heating programmes in the general part (see “Programming the heating levels” on page 29). Page 34 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 35: Loading The Annealing Oven

Place the annealing material on the annealing disc (5). Place the bell (6) on the base plate (4). Start the heating program by pressing the Start/Stop button. Start Stop The oven door closes automatically. Â Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 35... -

Page 36: Removing The Product From The Annealing Oven

Removing the product from the annealing oven Remove the bell with suitable tongs and place it on a heat-resistant surface. Remove the product with suitable tongs and place it on a heat- resistant surface. Page 36 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 37: Sintering With Protective Gas

Press the S1 button. The SAVE menu is displayed. Â Follow the action steps of the saving of heating programmes in the general part (see “Programming the heating levels” on page 29). Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 37... -

Page 38: Basic Settings

Switch the annealing oven on at the mains switch. Function Press the button. The Parameters menu opens. Â Parameter-Menü Sprache Tonsignal Ein/Aus Datum weiter Lift Temperatur Zeitschema 12/24h Temperaturskala °C/F weiter Page 38 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... - Page 39 Set the days of the week using buttons 1–7 (1 = Mon, 2 = Tue, 3 = Wed, etc.). Press the button to change to the hours display. Set the hours using buttons 0–9. Press the button to change to the minutes display. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 39...

-

Page 40: Switching Off The Annealing Oven

Make sure the annealing oven has cooled down sufficiently before carrying out any work on it. It takes at least four hours for the annealing oven to cool down from the maximum temperature to around room temperature. Page 40 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 41: Rs-232 Interface

Note If the computer used has no RS-232 connection option, a USB adapter with installation CD can be ordered from the manufacturer. In this case, contact Mihm-Vogt customer service. Connect the annealing oven to the computer using the connecting cable. - Page 42 If the “Com Port” is not known, select a suitable one with “Portscan”. Confirm your entry with “OK”. Save your port configuration in the “File” menu and “Save as...”. Page 42 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021...

- Page 43 Confirm with “OK”. Start the program at the annealing oven. The sent data is displayed. Â The target temperature appears in the left column, the actual temperature in the right column. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 43...

- Page 44 Click on the X button to write the data to the known TXT file (here Test1.txt). The logging is terminated by clicking on the button. Call up Microsoft Excel to create a graphic. Import the generated text file. Page 44 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021...

- Page 45 RS-232 interface The Text Conversion Assistant opens. Â Click on “Next” and make the following settings: Set the checkmark at “Space”. Click on the “Next” button. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 45...

- Page 46 RS-232 interface Click on the “More...” button. Transpose the point and comma for both settings and confirm with “OK”. Click on the “Finish” button and “OK”. Page 46 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021...

- Page 47 RS-232 interface The data series are displayed. Select the Diagram Assistant and choose a diagram type (e.g. line). Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 47...

- Page 48 RS-232 interface Click on “Next” three times and then “Finish”. The finished diagram is displayed. Page 48 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021...

-

Page 49: Care And Maintenance

This could damage the heater. Note Check the sealing face of the annealing oven. Check argon system Check the argon supply (supply hoses, couplings, connections, etc.) regularly for functioning and leaks. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 49... -

Page 50: Faults And Error Messages

Note Material damage due to incorrect repair of electric cables! This may cause malfunctions and make electric components defective. h Do not repair defective cables or plugs. Page 50 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 51: Faults

Defective display Replace controller Service LEDs light up briefly Department when switching on Level LED flashes, but Defective heater Check heater for continuity Service oven does not heat Department Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 51... -

Page 52: Error Messages In The Electronics

Department Long acoustic signal Calibration of the door Call Customer Service Service without LCD display, switch not correct Department oven door does not close, program does not start Page 52 Annealing oven HTS-2/Metal GLOW 120 Version 1.1 – 08/2021... -

Page 53: Decommissioning

Sort the component parts of the annealing ovens into recyclable materials, hazardous substances and operating materials. Dispose of the component parts of the annealing ovens or take them to be recycled. Version 1.1 – 08/2021 Annealing oven HTS-2/Metal GLOW 120 Page 53...

Need help?

Do you have a question about the HTS-2/METAL GLOW 120 and is the answer not in the manual?

Questions and answers