Summary of Contents for Ampco ZP3 Series

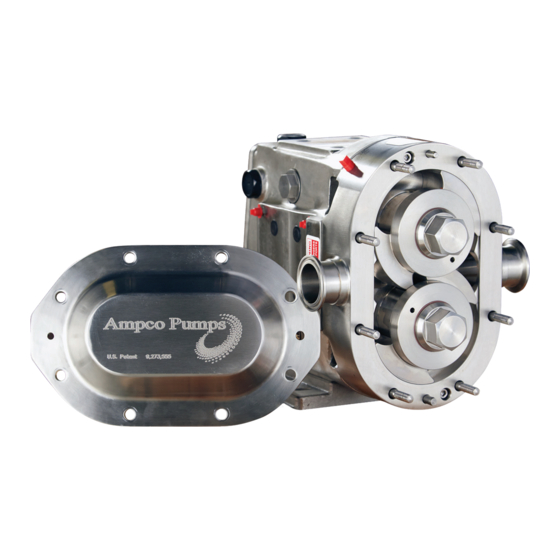

- Page 1 Ampco ZP3 Series Positive Displacement Pumps Installation and Maintenance Manual Original Instructions M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 2: Safety Notices

Safety Notices General Safety Instructions IMPORTANT: Read and understand this manual Warning BEFORE installation, operation, or maintenance of the • Do not remove safety labels; doing so may result in pump. Improper installation, operation, or maintenance injury to users. may result in severe injury or death. Equipment damage •... -

Page 3: Table Of Contents

Single Mechanical Seal ....................24 Double Mechanical Seal ....................28 Seal Cutaways ........................ 29 Gear Case Maintenance ....................30 Disassembly ........................30 Assembly ........................32 Pump Assembly ....................... 37 Pump Clearances ......................41 M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... - Page 4 Table of Contents (continued) Ampco Pumps Available Options ..................42 Vented Cover (Pressure Relief) ..................42 Jacketed Cover ......................42 Section 5 Troubleshooting Troubleshooting ......................43 Section 6 Appendix PD Pump Remanufacturing Program ................45 ATEX Certification Information ..................45 Terms and Conditions ......................

-

Page 5: General Information

Introduction Pump Receiving To ensure the best results and service, please read and Ampco covers the pump inlet and discharge ports prior fully understand this manual prior to putting this pump to shipping, ensuring that foreign matter does not enter into service. -

Page 6: Label Information

The customer should be aware of the pump’s serial number and model number prior to Do not remove these labels; doing so may result in contacting Ampco with any concerns. These labels can injury. be seen in Figure 1. -

Page 7: Pump Information

ZP3 60 20.4 15.0 0.568 200° 93° ZP3 130 34.1 25.0 0.946 ZP3 180 52.2 38.0 1.450 ZP3 210 68.1 50.0 1.900 ZP3 220 70.4 52.0 1.980 ZP3 320 75.2 2.847 M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... - Page 8 • For operating parameters that fall outside the standard values defined in Table 1 and Table 2, Noisy pump operation may result from cavitation, air/ please contact the Engineering Department at Ampco gas in product, rotor to body contact, rotor to rotor Pumps Company (414-643-1852).

-

Page 9: Installation

To ensure safety, protective guards must be properly installed over all external rotating parts and components. Failure to do so may result in injury. Ampco provides protective guards for complete base packages (pump and drive unit). M-004 Rev G 5.23... -

Page 10: Piping And Connections

Figure 7. Correct Piping (Supply Below) Figure 6. Correct Piping (Supply Above) Always verify all electrical devices connected to the equipment are properly grounded to avoid risk of potential corrosion from stray current. M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... -

Page 11: Check/Isolation/Relief Valves

(Figure 9). product. Notice Check Valve Ampco’s ZP positive displacement pumps are designed with extremely tight tolerances allowing only low slip internally between rotors and pump housing. DAMAGE will occur if the pump is operated with discharge or inlet lines closed. DO NOT operate pump with lines closed. -

Page 12: Strainers And Gauges

Strainers and Gauges Base Alignment Strainers and magnetic traps should be used to prevent Pump and base assemblies sent directly from Ampco’s foreign matter from entering the pump. It is essential factory are aligned prior to shipment. Assemblies to service strainers and traps regularly to prevent must be checked once they are installed and prior to restriction of flow. -

Page 13: Pump Rotation

Figure 14). Also check that the pump turns freely and is free of any foreign contaminates. Connect the pump and check to make certain all guards are in place. Figure 13. Top Drive Shaft Figure 14. Bottom Drive Shaft M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... -

Page 14: Seal Flushing

9. Discharge side valves should be open and free of obstructions. 10. Check the pump and drive rotation to verify the correct product flow at start-up. See “Pump Rotation” on page 13. M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... -

Page 15: Start-Up Procedure

2. When the pumphead is filled with product, stop the pump and allow the pump’s fluid components to thermally adjust to the product temperature for 15 minutes. 3. Re-start the pump. M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... - Page 16 Installation Section 3 THIS PAGE INTENTIONALLY LEFT BLANK M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 17: Maintenance

Caution Only trained personnel should perform maintenance. The Ampco ZP3 pump is designed to be easily disassembled for cleaning and maintenance purposes. When performing maintenance on the pump it is important to inspect all wetted parts for standard wear and damage. -

Page 18: Preventive Maintenance/Inspection

ISO Grade 320, SAE 140 or AGMA Number 6EP Shaft Shoulder Grease Specifications: Shaft Keyway Halo-Guard FG-2, NSF H1 FOOD-GRADE, NLGI Grade No. 2 *Replacement oil and grease is available from Ampco. Preventive Maintenance/Inspection Caution Figure 18. Shaft Inspection Points Handle rotors,... -

Page 19: Gear And Bearing Inspection

If evidence of gear teeth wear is present, replacement is recommended. If gear(s) are loose, check the shaft key and keyway, either may require replacement. Figure 21. Check for Bearing Movement Figure 20. Check for Gear Backlash M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... -

Page 20: Annual Maintenance

Figure 22, C. Replace, if necessary. • Check the pump clearances detailed on page 41 to determine pump wear. Pump wear can be Check Rotors compensated by increasing pump speed. Figure 22. Annual Maintenance Checks M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... -

Page 21: Cleaning

For models which cannot achieve the aforementioned requirements, a booster pump and/or bypass loop must be used during CIP. For additional support, please contact the Engineering Department at Ampco Pumps Company (414-643-1852). M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... - Page 22 2. Remove the rotor nut assembly using the appropriate size wrench and a non-metallic wedge to keep the rotors from moving (Figure 24). Unthread each nut and disassembly the nut assembly (rotor nut, Bellville washer, and retaining o-rings. M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 23 Description Rotor Nut O-Ring, Rotor Nut Rotor O-Ring, Rotor Seal Face Rotor Seal Face Body Seal Face O-Ring, Body Seal Face Inner Wave Spring Seal Sleeve Figure 26. Removing Pump Body M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 24: Seal Maintenance

(Figure 28). Align the slot and pin Wave Spring Stationary Seal O-Ring Figure 27. Inserting Figure 28. Stationary Seal Assembly M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... - Page 25 Press the seal down until it seats inside of the rotor. Rotating Seal O-Ring Rotating Seal Align Figure 29. Installing the Rotating O-Ring Figure 30. Inserting Rotating O-Ring M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 26 (Figure 32). Install a rotor nut o-ring before threading the nut onto the shaft. Retaining O-Ring Shoulder Rotor Nut Bellville Washer Rotor Nut O-Ring Figure 32. Rotor Nut Assembly Figure 31. Rotor Assembly M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 27 Figure 34, so that the cover is evenly tightened to the body. Wedge Overlap Figure 33. Rotor Assembly Figure 34. Cover Assembly M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 28: Double Mechanical Seal

Check that the seal stop pins are aligned with the Seal Seat notches on the outer stationary seal. Outer Seal O-Ring, Outer Seal Outer Seal Wave Spring Figure 37. Installing Stationary Seals M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... -

Page 29: Seal Cutaways

Body Seal Face O-Ring, Body Seal Face Inner Wave Spring O-Ring, Rotor Hub Outer Seal Wave Spring O-Ring, Outer Seal Outer Seal Seal Seat Shaft O-Ring Specific parts for Double Mechanical Seals (61-65) M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... -

Page 30: Gear Case Maintenance

(Figure 40). start-up and injury. Using a spanner wrench or the nut removal tool (available from Ampco), remove the gear lock nuts. Caution Slowly remove the gears from the shafts. Remove the gear keys and gear spacers from the shafts. - Page 31 Figure 42. Pressing Shafts from Gear Case ends are protected (Figure 44). Reference Table 5 for the required force (in tons) needed to press the bearings off the shafts. M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 32: Assembly

(Figure 45, Drawing 3). Bearing Spacer Drawing 1 Drawing 2 Drawing 3 Front Bearing Check Seat With Shim Figure 45. Pressing Front Bearing onto Shaft M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... - Page 33 • Backface Clearance+C+A-D-B = Shim Thickness A. Body Width B. Depth of Rotor Bore C. Distance from gear case pads to bottom of front bearing pocket D. Distance from shaft shoulder to back of bearing race M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 34 (Figure 51). Once the silicone sealant is applied, install the bearing retainers onto the gear Bearing case. Figure 49. Bearing Retainer Clearance M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 35 To time the gears, align so that the single punch mark falls between the two punch marks on the opposite gear (Figure 53, B). Figure 53. Installing Gears with Correct Timing M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 36 Table 3 on page 18. 180, 184, 220, 224 210, 214, 320, 324 Silicone Seal Placement Oil Seal (Spring faces towards gears) Figure 56. Installing Gear Casing Back Cover M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 37: Pump Assembly

(Figure 58, C). See Table 7 for required torque values. Repeat with the second rotor. M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... - Page 38 Maintenance Section 4 Figure 59. Installing Cover Assembly M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 39 Section 4 Maintenance 25 26 20 21 REAR SEAL SEE DETAIL FRONT SEAL SEE DETAIL M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 40 Maintenance Section 4 Table 9. ZP3 SERIES PARTS BREAKDOWN Item No. Description Item No. Description Body Retaining Screws Gear Case Cover Bolt Rotor Gear Case Cover Washer O-Ring, Rotor Nut Gear Case Cover Oil Seal O-Ring, Retainer Gear Case Cover...

-

Page 41: Pump Clearances

0.13 0.008 0.20 130, 134 0.004 0.10 0.005 0.13 0.008 0.20 180, 184, 220, 224 0.005 0.13 0.006 0.15 0.008 0.20 210, 214, 320, 324 0.005 0.13 0.010 0.25 0.011 0.28 M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual... -

Page 42: Ampco Pumps Available Options

The vented cover option is an internal pressure and Notice flow control which works independent of flow (rotational Ampco Pumps does not recommend using a vented direction). The complete assembly can be seen in cover on liquids over 5000Cp. Figure 61. The relief pressure is set with the adjustment screw and may require in-line pressure gauges for calibration. -

Page 43: Troubleshooting

Troubleshooting Each Ampco ZP3 is assembled and tested at the factory and is designed to have trouble-free operation. Problems may occur over the life of the pump due to system variations, standard wear, or user error. The following table has information that may help identify and solve a problem. - Page 44 Water build up in gear case Check that all gear case plugs are in place Misalignment in system (piping or pump Check and modify system to eliminate drive) alignment issues M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 45: Appendix

Section 6 Appendix PD Pump Remanufacturing Program ATEX Certification Information With the purchase of each new ZP pump, Ampco 1. Ampco pumps DOC (declaration of conformity) guarantees two full remanufactures. Depending must be included with the pump. The declarations on wear, the ZP pumps (and equivalents) can be starting on page 46 are provided for example remanufactured up to four times. - Page 46 Appendix Section 6 M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 47 Section 6 Appendix M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 48 Appendix Section 6 M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 49: Terms And Conditions

TERMS AND CONDITIONS OF SALE 1. ENTIRE AGREEMENT. This document contains all of the terms and conditions of the agreement (“the agreement”) between Ampco Pumps Company, Inc. (“Seller”) and the purchaser (“Purchaser”) of the Products (“Products”) to be sold to Purchaser, to the exclusion of any other statements and agreements, and to the exclusion of any terms and conditions incorporated in Purchaser’s order or other documents of... - Page 50 Seller of the purchase price in U.S. dollars upon presentation by Seller of Seller’s certification and/or such other documents as shall be required by the letter of credit. All banking and other charges for such letter of credit shall be for the account of Purchaser. M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

-

Page 51: Return Policy

“as new” condition. Any ordered, customer canceled order, etc. Before returning labor required by Ampco to return the parts to “as new” any product, contact us for a Returned Material condition will be deducted from the credit. - Page 52 Appendix Section 6 THIS PAGE INTENTIONALLY LEFT BLANK M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 53 Section 6 Appendix THIS PAGE INTENTIONALLY LEFT BLANK M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 54 Appendix Section 6 THIS PAGE INTENTIONALLY LEFT BLANK M-004 Rev G 5.23 Ampco Pumps Company ZP3 Manual...

- Page 56 2045 W. Mill Road Glendale, WI 53209 Phone: (800) 737-8671 or (414) 643-1852 Fax: (414) 643-4452 Email: ampcocs@ampcopumps.com For additional information on the ZP3 series and other Ampco Pumps products, please visit our website: www.ampcopumps.com ©2022 M-004 Rev G 5.23...

Need help?

Do you have a question about the ZP3 Series and is the answer not in the manual?

Questions and answers