Summary of Contents for VHF E4

- Page 1 ORIGINAL OPERATING INSTRUCTIONS Originalbetriebsanleitung Instrucciones de uso originales Mode d'emploi d'origine Istruzioni d'uso originali dentalportal.info https://stomshop.pro/...

- Page 2 https://stomshop.pro/...

-

Page 3: Table Of Contents

8 Maintenance 5.6 Lever for emergency release of the working chamber 8.1 Basic maintenance door 8.2 Preventive maintenance 5.7 Working chamber 8.3 Maintenance section 5.8 Cooling liquid tank and dry tank 8.4 Servicing Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 4 9.3 Emergency opening of the working chamber door 9.4 Loosening a fixed tool magazine 9.5 Removing broken tools from the collet chuck 10 Disposal 10.1 Disposing of the cooling liquid and machining residues Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 5: Welcome

Calls to action 1.4 Copyright Single or general calls to action Distribution or duplication of all content is only 1. Numbered action step allowed by written consent of vhf camfacture AG. This includes reproduction by presentation and broad- Result casting. Other symbols... -

Page 6: General Safety Instructions

Check the power cable for damage before every dentistry startup. Use machine / DENTALCNC Instructed persons In the following cases, disconnect the machine for cleaning and maintenance from the electrical source immediately and prevent it from being restarted: Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 7: Fire Hazard

Check the machine regularly for damage, espe- Damage due to poor maintenance cially the safety devices. Clean and exchange the collet chuck according to the maintenance table. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 8: Dentalcam & Dentalcnc Software

General safety instructions Damage caused by unsuitable tools process. Recommendation: Only use original tools from vhf. Ensure that your network is working without disrup- tions. WiFi connections are not as reliable as wired Use tools only within the maximum tool life shown networks. -

Page 9: Transportation And Storage

Ensure that the tank is completely dry. 3. Clean the working chamber. Ensure that the work- ing chamber is completely dry. 4. Install the transport lock. For this, follow the cor- responding steps on the supplement. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 10: Unpacking And Positioning Of The Machine

5. Pull the transport protection cover backwards over the machine and press it down on all sides until the top of the bottom cushion is exposed. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 11 . 11 B LUE AREA ORKSPACE Side view 11. Lift the machine out of the padding. a. Place the machine on a surface that can carry the machine weight. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 12 Tilt the upper part down and remove it. . 15 14. Close the working chamber door. Commissioning is only possible with the working chamber door closed. . 13 . 16 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 13 In case of emergencies: Emergency opening of the working chamber door – on page 82 15. Keep all parts of the transport lock and the packing set for possible service returns. . 17 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 14: Getting To Know Your Machine

Installing the air extraction system ( page 22 ) 3. Hose connection for the air extraction system Installing the air extraction system ( page 22 ) 4. Openings for the ventilation of the working chamber Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 15: Connection Panel

page 36 ) . 18 Cleaning or replacing the collet chuck of the spindle page 53 ) The Start button is used to start and interrupt a job. 2. Measuring key Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 16: Cooling Liquid Tank And Dry Tank

Exchanging the cooling liquid and cleaning the cooling liquid tank ( page 57 ) Your E4 uses the following interchangeable tanks: Cooling liquid tank for wet machining Dry tank for dry machining (extra equipment) Extra equipment can be obtained from your customer service provider. -

Page 17: Axes

The identification plate of the machine contains identi- fying information such as the serial number. You can find the identification plate and machine serial number at the following location: . 22 S ERIAL NUMBER ON THE IDENTIFICATION PLATE MARKED ORANGE Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 18: Technical Data

1 x 2.0 B Spindle Unit Value Model SFE 300E (synchronous) Maximum rotational speed 60.000 Nominal power under continuous operation (S1) Nominal power under unin- terrupted periodic operation (S6) Peak power (P Diameter collet chuck Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 19: Installation

Checking the scope of delivery ( page 20 ) Connecting the machine ( page 22 ) Commissioning ( page 26 ) Operating the machine ( page 29 ) Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

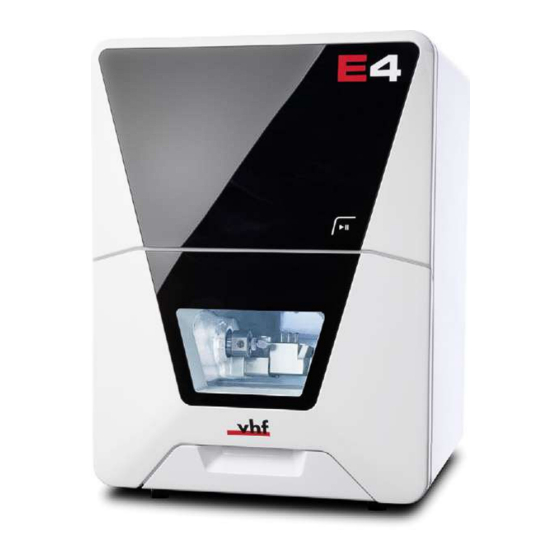

Page 20: Checking The Scope Of Delivery

Installation 6.1 Checking the scope of delivery Unpack the machine and ensure that you have received the following items: 1. 1 x Machine E4 2. 1 x Cooling liquid tank 3. 1 x Drain insert 4. 1 x Ethernet network cable 5. 1 x Power cable 6. - Page 21 2 x Accessory box Packing set 1 x Transport carton including floor insert 1 x Upper and lower padding 1 x Support pad 1 x Transport protection cover 1 x Housing protection cover Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 22: Connecting The Machine

⚠ WARNING! Always use an air extraction system that meets the requirements of the chapter Tech- 6.2.2 Connecting the CAM computer nical data. You connect the CAM computer via Ethernet network cable. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 23 3. If the diameter is different, adjust either the hose or the hose adapter supplied with the suction unit. Alternative: Use the optional hose connection of vhf. . 25 E XAMPLE UCTION HOSE WITH HOSE ADAPTER Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 24: Establishing The Electric Connection

3. Insert the plug of the cable into a socket that is pro- tected by a Residual Current Device / Ground Fault Circuit Interrupter. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 25 EN 25 Installation . 31 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 26: Commissioning

Select the correct machine model. 3. Approve the device driver installation. During the installation, CNC-Interface-Proxy will be installed. CNC-Interface-Proxy establishes the . 35 connection between the machine and DENTALCNC. 6. The CNC-Interface-Proxy window displays. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 27 EN 27 Installation <machine model>ID<serial number>(<IP address>) Example: FOX-I E4ID300000000 (10.0.21.33) E4 is the machine model 300000000 is the serial number 10.0.21.33 is the IP address . 36 7. If you want to change the language, do the following: a. Select the following icon on the right side of the window’s title bar:...

-

Page 28: Warming The Spindle

Use the warm-up process in DENTALCNC. The DENTALCAM & DENTALCNC user Information provides instructions on how to do this. 6.3.4 Drill tool magazine inserts For detailed information, please refer to the user information on DENTALCNC. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 29: Operating The Machine

page 31 ) Mounting & removing blanks ( page 34 ) Inserting and exchanging tools ( page 36 ) Starting, interrupting, canceling jobs ( page 39 ) Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 30: Starting The Machine

DENTALCNC displays that there is a tool in the col- let chuck. 2. Open the working chamber door. 3. ⚠ CAUTION! Wear gloves. 4. Hold the tool in the collet chuck in place. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 31: Switching Between Wet And Dry Machining

Filling the cooling liquid – on page 33 Exchanging the cooling liquid and cleaning the cooling liquid tank – on page 57 6. Push the cooling liquid tank into the compartment until it clicks into place. . 44 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 32 EN 32 Operating the machine . 46 . 47 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 33: Filling The Cooling Liquid

. 50 . 48 6. Fill the cooling liquid tank with cooling liquid until it reaches the max mark. 7. Push the cooling liquid tank into the machine until it clicks into place. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 34: Mounting & Removing Blanks

TX10 to fix the selecting the depicted icon in the Machin- block with the fixing screw. ing view in DENTALCNC. 7.4.4 Mounting & removing blocks 1. Open the working chamber door. 2. ⚠ CAUTION! Wear gloves. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 35 EN 35 Operating the machine . 54 . 55 . 56 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 36: Inserting And Exchanging Tools

This option takes more time, but might be more convenient for some. It is described in the documentation for the man- ufacturing software. . 58 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 37 NOTICE! Tool breakage and defective with the suffix -T in position C1. machining results due to incorrect tool assignment Ensure that the positions of the tools in the tool magazine match the tool positions in DENTALCNC. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 38: Removing Tools From The Tool Magazine

4. Pull the tool upward out of the tool magazine. 5. Depending on whether you place the tool back in your inventory or no longer use the tool type, configure DENTALCNC accordingly: Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 39: Starting, Interrupting, Canceling Jobs

2. Recommendation: Leave the blank in the holder. Continuing the machining process 1. Close the working chamber door. 2. DENTALCNC: Confirm the current . 67 message. 9. Close the working chamber door. 10. Confirm the current message. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 40 EN 40 Operating the machine The following happens: a. The collet chuck closes. b. The spindle moves to its default position. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 41: Switching Off The Machine

3. Exit DENTALCNC. 4. ⚠ DANGER! Switch off the machine at the main power switch. 5. (Optional) Unplug the power cable. 6. (Optional) Switch off the main power switch of your workstation / facility. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 42: Maintenance

When your machine is delivered or installed, ask the service technician for contact details for the cus- tomer service team. We also recommend schedul- ing the first preventive maintenance appointment Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 43: Maintenance Table

Contact customer service. 2000operating hours 8.6.4 When necessary Action Recommended interval Procedure / Tools Updating the software and firmware When an update is available Updating the software and firmware – on page 79 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 44: Spare Parts And Wear Parts

If defective Exchange tool magazine inserts and associated holders – on page 62 Holder for tool magazine insert If defective Exchange tool magazine inserts and associated holders – on page 62 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 45 72 Tool magazine If defective Exchange tool magazine inserts and associated holders – on page 62 Top cover If defective Disassembling and assembling the machine housing – on page 73 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 46: Cleaning The Machine

Use a mild cleaning agent if necessary. 7. Clean the working chamber door seal thoroughly . 68 with the damp cloth. Use a mild cleaning agent if necessary. 1 x Mild cleaning agent (optional) Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 47 Reattach the measuring key cover: The measuring key cover is attached magnetically. The measuring key cover must be flush with the underlying surface and must not be twisted. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 48 Apply a bit of collet chuck grease to the bolts of the tool magazine holder. g. Place the tool magazine on the tool magazine holder. . 78 11. Close the working chamber door. . 75 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 49 . 82 1 x Cleaning cloth . 83 1 x Mild cleaning agent (optional) 14. Open the Maintenance section window with the fol- lowing icon in the main icon bar: Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 50 First of all, clean the opening of the blank holder. 9. Clean the measuring key: a. Remove the measuring key cover. b. Suck the machining residues from the meas- uring key. . 84 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 51 Place the tool magazine on the tool magazine holder. . 87 . 90 . 88 . 91 . 89 10. Clean the tool magazine and the tool magazine holder: Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 52 15. Select the icon shown for the Weekly machine cleaning entry. . 94 13. Clean the housing: NOTICE! Housing damage caused by . 95 incorrect aids and cleaning a. Clean the surface with a dry microfiber cloth. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 53: Cleaning Or Replacing The Collet Chuck Of The Spindle

The spindle moves into the position for collet chuck removal. 4. Open the working chamber door. 5. ⚠ CAUTION! Wear gloves. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 54: Cleaning The Collet Chuck

. 104 collet chuck with a clean and dry cloth. 8.9.4 Inserting the collet chuck 1. Insert the collet chuck into the spindle. Screw in the collet chuck by twisting it clockwise with your Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 55 . 106 c. Turn the knurled nut clockwise until the collet chuck fits tightly in the spindle. . 107 3. Store the spindle service set in a safe place. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 56: Cleaning The Nozzle Plate

4. Clean the 2 opposite openings (marked orange) in the nozzle plate. For this, move the interdental brush up and down. If necessary, apply some water with a cleaning agent and let it sit for some minutes. . 108 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 57: Exchanging The Cooling Liquid And Cleaning The Cooling Liquid Tank

2. Open the working chamber door. 3. Pull the cooling liquid tank out of the machine. 4. Remove the strainer basket from the cooling liquid tank. 5. Clean the strainer basket under running water. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 58 11. If you have used a cleaning agent, make sure that there is no residue of it in the cooling liquid tank. The cooling liquid tank is completely void of liquid, machining and cleaning agent residues. . 112 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 59 EN 59 Maintenance . 117 . 115 . 116 . 118 12. Place the filter or spare filter in the cooling liquid tank. 13. Insert the strainer basket. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 60 EN 60 Maintenance . 119 . 120 14. Fill cooling liquid into the cooling liquid tank. Filling the cooling liquid – on page 33 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 61: Cleaning The Cooling Liquid System

DENTALCNC‘s main machine, blanks and tools will be damaged. application window. Only use Tec Powder from vhf to clean the cooling 14. Wait until the process is finished. liquid system. 15. Empty the cooling liquid tank. Fill it with drinking Carefully follow the instructions below. -

Page 62: Exchange Tool Magazine Inserts And Associated Holders

OOL INSERT MARKED ORANGE If you want to exchange at least one of the 1. Have ready: holders: 1 x Torque screwdriver 1.5 Nm with TX20 1 x Holder for tool magazine insert Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 63 11. Get the required spare parts. 12. Press the AirTool insert into the rectangular opening of the holder. Ensure that the top of the insert is flush with the . 128 surface of the holder. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 64 15. Unscrew the 2 screws of the tool magazine insert holder on the underside of the tool magazine. The tool magazine holder and the screws slide into your hand. 16. Press the tool magazine insert down out of the opening. . 132 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 65 When doing so, make sure that the top of the tool magazine insert is flush with the surface of the tool magazine. If this is not the case, correct the position of the insert. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 66 21. Place the tool magazine on the tool magazine holder. . 142 . 143 22. Close the working chamber door. 23. Switch on the machine at the main power switch. 24. Start DENTALCNC. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 67 25. Select the following icon of the Exchange tool magazine inserts entry: 26. Follow the instructions in the documentation for DENTALCNC and drill the tool positions using the provided drill bit. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 68: Exchanging The Blank Holder

17. Switch on the machine at the main power switch. 18. Start DENTALCNC. 19. Mill a test specimen and calibrate the machine as necessary. Calibrating the axes – on page 78 . 145 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 69: Exchanging The Measuring Key

9. Carefully pull off the measuring key. Pay attention to the plugged-in measuring key cable. 10. Push in the side clip on the connector of the meas- uring key cable and pull the connector out of the socket. . 156 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 70 18. Switch on the machine at the main power switch. 19. Start DENTALCNC. 20. In DENTALCNC, do the following: a. Measure the measuring key. b. Drill the tool positions. c. Calibrate the axes. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 71: Exchanging The Gasket Of The Working Chamber Door

Place the profile on the back of the gasket on the outside of the working chamber and press the corners into the recess. b. Press the gasket firmly. Make sure that the entire gasket is firmly seated in the recess. . 162 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 72: Exchanging The Tank Cover

(marked in blue) on the top of the tank. 6. Use the wrench to tighten the 2 screws (marked orange) that secure the tank cover to the bottom of the tank. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 73: Disassembling And Assembling The Machine Housing

2. Slide the top cover completely to the front of the machine. . 172 3. Use the TX20 angle screwdriver to screw the back 1 x TX20 angle screwdriver panel to the machine with 6 screws (marked orange). Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 74: Removing And Installing The Service Cover

1. Using the TX20 offset screwdriver, unscrew the 2 screws (marked orange) that secure the service cover. 2. Hold the cover on the left and right side. 3. Move the cover upwards. 4. Remove the cover. . 181 . 178 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 75: Removing And Installing Side Panels

2. Tilt the side panel cover outward. 3. Slide the side panel cover backwards out of the machine. . 186 4. Remove the cover. . 187 . 184 . 188 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 76 EN 76 Maintenance . 189 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 77: Exchanging The Main Fuse

5. If you do not have a replacement fuse ready, take the replacement fuse from the right side of the fuse cover and put it into the left side of the fuse cover. 6. Remount the fuse cover. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 78: Calibrating The Axes

3. Manufacture and measure a calibration specimen and enter the measuring values into DENTALCNC This data is used to calculate the required calib- ration. 4. Check if calibration was successful with another test specimen Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 79: Updating The Software And Firmware

The firmware is the internal control software of your machine. New versions may introduce new functions and improve existing ones. New firmware versions come as part of new versions of DENTALCNC. For more information, see the DENTALCAM & DENTALCNC user information. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 80: Troubleshooting

9.2.4 How to proceed in the event of a 1. Record the error message and error code that is dis- played. pow er failure Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 81 After a short power failure, restart the machine and the CAM computer. If you need to access the working chamber in case of a longer power failure, perform an emergency opening of the working chamber door. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 82: Emergency Opening Of The Working Chamber Door

4. Open the working chamber door. 5. Let go of the lever. 6. ⚠ CAUTION! Wear gloves. 7. Carry out your work in the working chamber. Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 83: Loosening A Fixed Tool Magazine

5. Pull the tool magazine off the tool magazine holder. 2. Open the working chamber door. 3. Use the flat blunt tool to remove the protective cap and put the cap aside within reach. . 195 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 84 7. Cover the screw opening with the cover cap. If the cap is damaged, use a provided spare cap (7.5 mm). . 197 . 198 8. Clean and grease the tool magazine and the tool magazine holder as described in the instructions for Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

-

Page 85: Removing Broken Tools From The Collet Chuck

Error code -24 – Abgebrochenes . 202 Werkzeug in der Spannzange . 199 . 203 6. Clean and grease the collet chuck and reinstall it: Cleaning the collet chuck – on page 54 . 200 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 86: General

/ or external devices. If necessary, have the machine disposed of by an approved disposal company. 10.3 Dismantling, transport and packaging Transportation and storage – on page 9 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... -

Page 87: Index

Spare part ..44 Start button ..15 Starting jobs ..39 Identification plate ..17 Starting the machine with a tool in the collet chuck ..30 Installation location ..10 Suction unit ..22-23 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/... - Page 88 Tool breakage ..80 Tool magazine inserts ..62 Top cover ..73 Warranty ..42 Wear part ..44 Working chamber ..15, 46 Emergency opening ..82 Working chamber door ..15, 73 Original Operating Instructions: E4 Version: 4/4/2023 https://stomshop.pro/...

- Page 89 Original EC Declaration of Conformity according to EC directive for machinery 2006/42/EC Annex II A vhf camfacture AG Lettenstraße 10 72119 Ammerbuch Germany hereby declare expressly that the Machine: CNC milling machine Type: Serial No.: E4ID300000000 – E4ID399999999 fulfills all the relevant provisions of the following directives:...

- Page 90 Original Declaration of Conformity according to Supply of Machinery (Safety) Regulations 2008 vhf camfacture AG Lettenstraße 10 72119 Ammerbuch Germany hereby declare expressly that the Machine: CNC milling machine Type: Serial No.: E4ID300000000 – E4ID399999999 fulfills all the relevant provisions of the following directives:...

- Page 91 Made Germany vhf camfacture AG https://stomshop.pro/...

Need help?

Do you have a question about the E4 and is the answer not in the manual?

Questions and answers

can you test if water is working without running a job

To test if water is working on a VHF E4 without running a job:

1. Open the working chamber door.

2. Ensure the cooling liquid tank is properly filled and inserted until it clicks into place.

3. Check that the cooling liquid tank is connected and not defective.

4. Observe for any water flow or leakage when the machine is powered on (but not running a job).

There is no specific test function mentioned, but ensuring proper setup and looking for water movement or flow can help confirm functionality.

This answer is automatically generated