Summary of Contents for BRINKMANN PUMPS BBV1

- Page 1 Operating instructions (Translation) BBV1, BBV2 100 bar and higher Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher BBV1-2 100 bar and higher Englisch 2018-11-26...

-

Page 2: Table Of Contents

3.2 Basic design 4 Technical data 4.1 General 4.2 Permissible pressure range 4.2.1 Operating pressure 4.2.2 Layout pressure setting range - flow rate BBV1, 2 4.3 Permissible temperature range 4.4 Material data 4.5 Dimensions 5 Transport and storage 5.1 General 5.2 Storage... - Page 3 8 Removal 8.1 Safety instructions for removal 8.2 General 9 Maintenance 9.1 Safety instructions for maintenance 9.2 Maintenance work 9.3 Maintenance instructions 10 Repairs 10.1 Safety instructions for repair 10.2 General 10.3 Detecting and eliminating failures...

-

Page 4: General

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 1 General 1.1 About the documentation These operating instructions describe the installation, operation and maintenance of the following device: Pressure relief valve BBV1-2 100 bar and higher, The device is manufactured in different versions. Information about the version concerned in the individual case can be found on the device's type plate. -

Page 5: Symbolism

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 1.3 Symbolism DANGER Identification of an immediate hazard, which would result in death or severe bod- ily injury if not avoided. WARNING Identification of a potential medium risk hazard, which would lead to death or se- vere bodily injury if not avoided. -

Page 6: Safety

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 2 Safety 2.1 Intended use The device has been designed for operation with fluid. The device may be operated in filled condition only. The medium must be compatible with the materials used in the device. The chemical competence is necessary for this. -

Page 7: Basic Hazards

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 2.4 Basic hazards DANGER Hazardous fluids! Danger of death when handling hazardous fluids. Comply with the safety data sheets and regulations on handling hazardous fluids. Collect and dispose of hazardous fluids so that no hazards arise for people or the environment. -

Page 8: Device Description

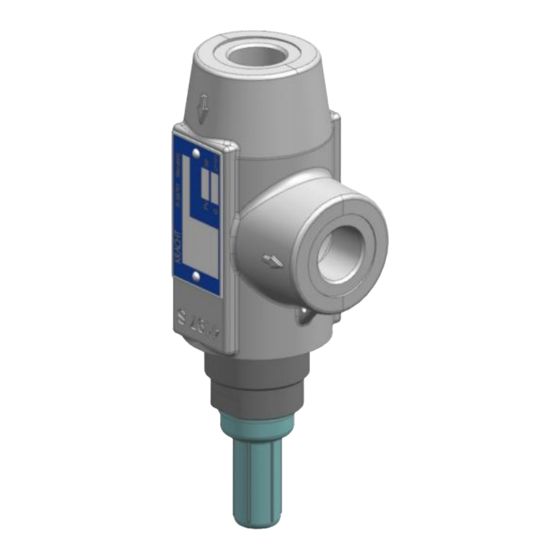

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 3 Device description 3.1 Functional principle Pressure relief valves of the BBV1-2 series are directly operated seat valves and are used to safeguard low-pressure hydraulic circuits. Explanation 1 Housing 2 Valve cone... -

Page 9: Basic Design

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 3.2 Basic design EBV1, 2 BBV1, 2 Explanation Explanation 1. Damping plugs 1. Housing 2. Valve seat 2. Damping plugs 3. O-Ring 3. Valve seat 4. Valve cone 4. O-Ring 5. O-Ring 5. - Page 10 Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher BBVH1, 2 Explanation 1. Housing 10. O-Ring 2. Damping plugs 11. Support ring 3. Valve seat (only NG 20) 4. O-Ring 12. Check nut 5. Valve cone 13. Adjustment screw 6. O-Ring 14.

-

Page 11: Technical Data

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 4 Technical data 4.1 General General information BBV1, 2 Design Seat valve, directly operated Screw-in valve / Pipeline installation Fixing type Connection KP 1 (BBV1, 2) BBV1, 2 R 5 Whitworth pipe thread G ¾... -

Page 12: Permissible Pressure Range

Inlet pressure Outlet pressure [bar] [bar] [bar] [bar] e min. e max R max 4.2.2 Layout pressure setting range - flow rate BBV1, 2 Pressure stage Pressure setting ranges [bar] Flow [l/min] v min. v max. max. at p v max. -

Page 13: Transport And Storage

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 5 Transport and storage 5.1 General ● After receipt, check the device for transport damages. ● If transport damage is noticed, report this immediately to the manufacturer and the carrier. The device must then be replaced or repaired. - Page 14 Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher Recommended storage conditions Storage temperature: 5 °C - 25 °C Relative air humidity: < 70 % Protect elastomer parts from light, especially direct sunlight. Protect elastomer parts from oxygen and ozone.

-

Page 15: Installation

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 6 Installation 6.1 Safety instructions for installation DANGER Hazardous fluids! Danger of death when handling hazardous fluids. Comply with the safety data sheets and regulations on handling hazardous fluids. Collect and dispose of hazardous fluids so that no hazards arise for people or the environment. -

Page 16: Mechanical Installation

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 6.2 Mechanical installation 6.2.1 Preparation ● Check the device for transport damage and dirt. ● Remove existing preservatives. ○ Use only those cleaning agents that are compatible with the materials used in the device. -

Page 17: Connection Lines

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 6.3 Connection lines 6.3.1 General WARNING Failure of load-carrying parts due to overload! Danger of injury from flying parts. Danger of injury from spurting fluids. Use only connections and lines approved for the expected pressure range. -

Page 18: Operation Start-Up

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 7 Operation start-up 7.1 Safety instructions for start-up DANGER Hazardous fluids! Danger of death when handling hazardous fluids. Comply with the safety data sheets and regulations on handling hazardous fluids. Collect and dispose of hazardous fluids so that no hazards arise for people or the environment. -

Page 19: Pressure Setting

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 7.2 Pressure setting The response pressure of the device is factory set to the mean value of each pres- sure stage. If applicable, the pressure setting must be adapted during commission- ing. - Page 20 Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher Pressure setting for actuation type: B with knob 1 Check nut 2 Twist grip ● Loosen the lock nut ● Set the response pressure with the adjusting screw ○ clockwise = Higher response pressure ○...

-

Page 21: Further Operation Start-Up

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 7.3 Further operation start-up ● Open existing shut-off elements upstream and downstream of the device. ● Vent the system at the highest possible point. ● Check the operating data such as: ○... -

Page 22: Removal

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 8 Removal 8.1 Safety instructions for removal DANGER Hazardous fluids! Danger of death when handling hazardous fluids. Comply with the safety data sheets and regulations on handling hazardous fluids. Collect and dispose of hazardous fluids so that no hazards arise for people or the environment. -

Page 23: General

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 8.2 General ● Depressurise and de-energize the system. ● Close existing shut-off elements upstream and downstream of the device. ● Open existing drain elements and loosen connection lines. Collect and dis- pose of discharging medium so that no hazard arises for persons or environ- ment. -

Page 24: Maintenance

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 9 Maintenance 9.1 Safety instructions for maintenance DANGER Hazardous fluids! Danger of death when handling hazardous fluids. Comply with the safety data sheets and regulations on handling hazardous fluids. Collect and dispose of hazardous fluids so that no hazards arise for people or the environment. -

Page 25: Maintenance Work

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 9.2 Maintenance work Checking and documentation of the operating data Regular checking and documentation of all operating data such as pressure, tem- perature, current consumption, degree of filter soiling, etc. contributes to early problem detection. - Page 26 Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher Maintenance recommendations Pressure relief valve Interval Maintenance work Employees Duration approx. [h] Inspection: Valve function Inspection: Response pressure Inspection: System pressure Firstly: Inspection: Fluid temperature after max. 24 h Inspection: Device temperature...

-

Page 27: Repairs

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 10 Repairs 10.1 Safety instructions for repair DANGER Hazardous fluids! Danger of death when handling hazardous fluids. Comply with the safety data sheets and regulations on handling hazardous fluids. Collect and dispose of hazardous fluids so that no hazards arise for people or the environment. -

Page 28: General

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 10.2 General The repairs covers: Troubleshooting Determination of damage, pinpointing and localisation of the damage cause. Elimination of damage Elimination of the primary causes and replacement or repair of defective com- ponents. -

Page 29: Detecting And Eliminating Failures

Pressure relief valve BBV1-2, BBVH1-2 100 bar and higher 10.3 Detecting and eliminating failures Failure Potential causes Possible measures Increased noise Air in the spring chamber Bleed system Mechanical vibrations Response pressure too Valve cone tight or jammed Clean the device...

Need help?

Do you have a question about the BBV1 and is the answer not in the manual?

Questions and answers