Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ACES SYSTEMS Viper II

- Page 1 User Manual ACES Viper II and Cobra II Analyzers ACES Systems/TEC Aviation Division Document Number 4041-OM-01 Revision 6.00 April 2020 Part Number 10-300-4041 10737 Lexington Drive – Knoxville, TN 37932-3294 USA – Telephone 865-671-2003– Fax 865-675-1241 – Web www.AcesSystems.com...

- Page 2 Copyright Notice Copyright by TEC, 2018. All rights reserved. No part of this document may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any form by any means without the express written permission of TEC. Disclaimer This documentation is provided for information purposes.

-

Page 3: Table Of Contents

Table of Contents (Rev 6.00, Apr 2020) Preface (Rev 2.01, Apr 2020) Contact ACES Systems Warranty Calibration and Certification Introduction (Rev 2.10, Apr 2020) Table 1.1 ACES Gen II Analyzer Function Comparison Chart Notes, Cautions, and Warnings Conventions Analyzer Description (Rev 2.10, Apr 2020) - Page 4 4.1.4 Connect Sensors 4-21 4.1.5 Start Aircraft 4-23 4.1.6 Acquiring Data 4-23 4.1.7 Review Job 4-25 4.1.8 Balance Solution 4-27 4.1.9 Vibration Summary 4-33 Resume Job 4-35 Manage Jobs 4-35 Manage Setups 4-36 Weight Calculator 4-36 Reserved (Rev 1.00, Dec 2014) Reserved (Rev 1.00, Dec 2014) Main Rotor Track &...

- Page 5 8-25 Analyzer Chart Forms 8-26 8.8.1 Regular Chart Forms 8-26 8.8.2 Irregular Chart Forms 8-28 Transient Balance (Viper II only) (Rev 2.10, Apr 2020) Create Setup 9.1.1 Transient Balance Setup 9.1.2 Sensor Information Screen 9.1.3 Transient Balance Speeds Screen 9.1.4...

- Page 6 Start Aircraft 10-28 10.2 Resume Job 10-29 10.3 Manage Jobs 10-29 10.4 Manage Setups 10-30 Fan Blade Mapper (Viper II only) (Rev 3.00, Apr 2020) 11.1 Fan Blade Mapper 11-1 11.1.1 Start Job 11-1 11.1.2 Select Setup List 11-2 11.1.3...

- Page 7 15-14 15.1.9 Storing Data 15-19 15.2 Resume Job 15-21 15.3 Manage Jobs 15-22 15.4 Exporting Time Trace Reports (Viper II only) 15-22 15.5 Manage Setups 15-24 Monitor Spectrum (Rev 2.10, Apr 2020) 16.1 Monitor Spectrum 16-1 16.1.1 Spectra Setup 16-1 16.1.2...

- Page 8 Monitor Overall (Rev 2.10, Apr 2020) 19.1 Monitor Overall 19-1 19.1.1 Overall Vibration Setup 19-1 19.1.2 Speeds (Viper II only) 19-4 19.1.3 Monitor Overall 19-5 19.1.4 Collecting Data with Spectra 19-7 Check Track (Rev 3.00, Apr 2020) 20.1 Check Track 20-1 Test Tach Power (Rev 2.01, Apr 2020)

- Page 9 Updated Rev level for Chapters 4, 7, 8, 11, 12, 13, 15, 17, 19, 20, 22, 23, and 24. 2/17/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This East chapter was updated with screenshots and corrections to minor typographical errors.

-

Page 10: Preface (Rev 2.01, Apr 2020)

RMA by completing the form found at https://www.acessystems.com/product-repair-service/. Feedback ACES Systems depends on information from our customers to continue the attributes of quality, dependability and simplicity associated with our products. We invite you to contact our Technical Support office by completing the online form found at: https://www.acessystems.com/contact-us/contact-support/... -

Page 11: Warranty

Gen II Warranty The ACES Systems’ Analyzer is warranted to be free of defects in material and workmanship for a period of 60 months (5 years) following the purchase date. Warranty does not cover the analyzer unless it is properly used, stored, and maintained in accordance with the provisions of this manual. -

Page 12: Calibration And Certification

5-year warranty. See “Warranty” in this section for details. Revision History 2/15/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. East 4/1/2020 2.01: Updated minor grammatical errors. Added note to Warranty section. Removed “login required” under Shively RMA request section. -

Page 13: Introduction (Rev 2.10, Apr 2020)

(Revision 2.1, April 2020) The ACES Systems’ Second Generation (Gen II) Analyzers are available in two versions – Cobra II and Viper II. The chart below shows the functions available in each analyzer. All analyzer features are discussed in this manual. -

Page 14: Notes, Cautions, And Warnings

The Viper II analyzer is capable of true, four-channel, simultaneous data acquisition while the Cobra II is capable of only two-channel, simultaneous data acquisition. Both analyzers provide full graphic-spectrum capabilities including on-screen display of limits and component identification using normal and harmonic cursors. -

Page 15: Conventions

User Manual Gen II 1.2. – Conventions The following are writing conventions used throughout the manual to describe certain concepts: This manual indicates keys/keystrokes in square brackets. For example: [OK], [HOME], [5], or [F1]. The term “select,” as used in this manual, means to highlight the item on the current menu by using the arrow keys, then pressing the [OK] key. - Page 16 “Facing the propeller Looking At it” when working on a pusher-type propeller installation. Revision History 2/15/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter was updated East with comparison chart for the two analyzers. 01/09/2020 2.1: Added Direct Connect Verbiage to Function Comparison Chart.

-

Page 17: Analyzer Description (Rev 2.10, Apr 2020)

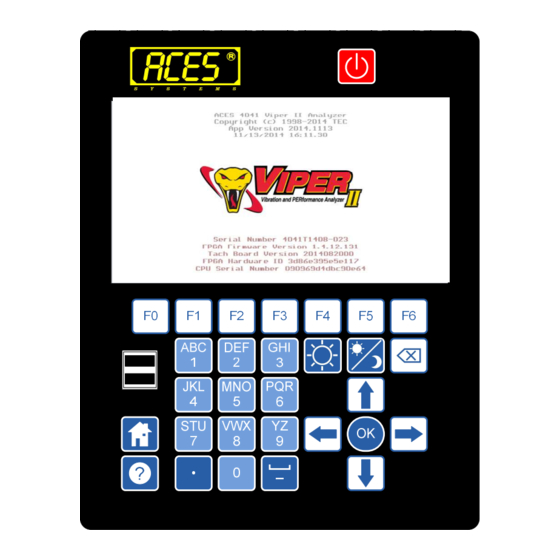

Chapter 2 Analyzer Description (Revision 2.1, April 2020) This chapter gives you a brief tour of the analyzer. It describes the various keys and their functions, the input and output ports, and the standard accessories supplied with the analyzer. Optional accessories are discussed later in the chapter. -

Page 18: Keypad

User Manual Gen II 2.1. – Keypad The analyzer keypad consists of 30 function keys. (See Chapter 3, “Using the Gen II Analyzer” for keypad operation.) Located at the top right of the analyzer keypad, the [ON/OFF] key, when pressed once and released, turns the analyzer power on or off. - Page 19 User Manual Gen II The brightness key is located below the [F4] key. This key is fully functional for all phases of operation when the analyzer is powered. There are eight levels of brightness. Each key press will produce an incremental increase in the screen’s brightness. Once the highest level of brightness has been reached, the next key press will return the screen to the first brightness level.

- Page 20 User Manual Gen II The ten alphanumeric keys (0 through 9 / A through Z) are used to input alphanumeric values into the analyzer. A single press followed by a two-second delay returns the first alpha character displayed on the key. Two or three rapid presses followed by a two second delay returns the second or third alpha character respectively.

-

Page 21: Screen

– Input and Output Ports 2.3.1. – Top Panel The Viper II has nine input/output ports on the top panel of the analyzer, as shown in the figure below: four “CHANNEL” (vibration channel) inputs, four “TACH” (tachometer) inputs, and one “AUX/COMM” (auxiliary/communication) input/output port. - Page 22 Table 2.1: ACES Gen II Analyzer Tach Inputs ACES Gen II Analyzer Tach Inputs Analyzer Versions Tach Input Cobra II Viper II Optical (Phototach or LaseTach) Mag Pickup (Mag P/U) ...

-

Page 23: Side Panel

STRB / JEDA / ACCY 18-28V DC IN 2.3.2.1. - STRB / JEDA / ACCY Port (Viper II) or STRB / ACCY Port (Cobra II – not pictured) This port is used for connection of a current and future accessories designed to work with the Gen II analyzers. -

Page 24: Front Face

User Manual Gen II The Viper II analyzer allows for the connection of the ACES Model 1752B JEDA or Direct EMS and is used in conjunction with the Honeywell Performance option (Chapter 12) to communicate with Honeywell’s TFE731 series of engines. -

Page 25: Carrying Case

User Manual Gen II WARNING The Gen II analyzers were not intended to be operated during the charging cycle. Individual power requirements must be examined on a case-by-case basis. Operation of the Gen II analyzers with the charger energized and connected may affect acquired readings. 2.4.3. -

Page 26: Optional Equipment

Even with the USB keyboard connected, the keypad on the front panel remains active. 2/16/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter was updated East with illustrations and corrections to minor typographical errors. -

Page 27: Using The Gen Ii Analyzer (Rev 2.10, Apr 2020)

Chapter 3 Using the Gen II Analyzer (Revision 2.10, April 2020) 3.1. – Entering Data Data is entered into the analyzer in one of three ways: (1) by typing data using the keypad; (2) by selecting from specific lists; or (3) by transferring data from a USB flash drive. The methods of inputting data are described in the following sections. -

Page 28: Filling In Fields

– Downloading E-Setups from the ACES Systems web site (Log-in required) Electronic versions of the setups (E-Setups) are stored on the ACES Systems web site and can be downloaded directly to the USB flash drive by following the instructions below: The following instructions describe the procedure using Internet Explorer. - Page 29 User Manual Gen II Once you are logged into the ACES website, hover the mouse over, but do NOT click, “Support”. In the dropdown menu, click on the “Technical Library” link as shown below. In the “Technical Library” page, you may use the “Filter Results” drop down lists. Simply click on the Bold Type headers and click in the checkbox(es) to narrow your search down until you see what you need in the results widow to the right.

- Page 30 User Manual Gen II Click the “Download” link to the right of the setup you wish to download. In the pop-up menu, you can select the “Save” button and the E-Setup will be saved in your “Downloads” folder by default. Alternatively, you can click the down arrow on the right side of the “Save”...

- Page 31 User Manual Gen II 3.1.3.2. – Exporting setups from the analyzer Setups can be exported from the analyzer, see paragraph 3.4.4.5 below. After exporting the setup, it will be saved in the “aces_export” folder. Remove the USB flash drive from the analyzer and insert it into a USB port on the computer.

- Page 32 User Manual Gen II From the Analyzer Management menu, select “Database Management.” Select “Import Setups from USB Drive” and press [OK]. If an existing setup with the same name as the setup you are importing exists, you will be asked if it is ok to overwrite this file.

-

Page 33: Main Menu

Your analyzer may not show all items displayed in the screen below. If you do not have a license for certain functions, contact your ACES Systems sales representative for information about optional Gen II functions and obtaining a license for them. -

Page 34: Status Pane

User Manual Gen II Viper II Cobra II The [F2] “Hide” and [F3] “Show All” keys allow you to control what is shown on the Main Menu. To hide a seldom used menu item, use the [] and [] keys to highlight the menu item and press the [F2] “Hide”... -

Page 35: Common Job Functions

User Manual Gen II 3.4. – Common Job Functions NOTE The functions listed below will apply to all job types listed on the Main Menu. The job types shown in the screenshots below (i.e. Propeller Balance) are for reference only. 3.4.1. -

Page 36: Manage Jobs

User Manual Gen II 3.4.3. – Manage Jobs Selecting “Manage Jobs” from within a Main Menu Job function presents several sub-menu choices as shown below. These choices allow you to “manage” previously completed job data you have stored in the analyzer. 3-10 –... - Page 37 User Manual Gen II 3.4.3.1. – Review Selecting the “Review” option presents a list of stored jobs on the “Job List” banner screen. You can select one job for on-screen viewing. Incomplete jobs will be preceded by an “I” inside a square.

- Page 38 User Manual Gen II Once you select a job and press [OK], a progress indicator will be displayed. During this process, the analyzer will display the “Creating Report” banner screen. As progress is made in completing the report, the page number and status bar will update. After the report is created, the screen will change to indicate that the process is complete.

- Page 39 User Manual Gen II 3.4.3.2.1. Transfer Reports Press the [HOME] key to return to the Main Menu. The Status Pane will show any pending reports, which will be transferred to the USB memory device then stored in the “aces_reports” folder of the USB memory device. Whenever reports are pending, the [F1] “Xfer Rpt” button is visible as shown below.

- Page 40 User Manual Gen II The analyzer will display the screen below when the transfer is complete. Press [F5] “Continue” to return to the Main Menu. At this time, it is safe to remove the USB device. After you move the USB memory device to a computer, you can open or print the reports on the computer without the need for any additional software (provided the computer has a PDF reader installed).

- Page 41 User Manual Gen II When deleting individual jobs, you will first be presented with a list of available jobs. After selecting the job you want to delete, or when selecting to “Delete All” jobs, you will be asked to confirm your selection. Press either [F1] “Yes” to continue with the deletion, or [F5] “No”...

- Page 42 User Manual Gen II Once the operation is complete, you will be returned to the applicable job function menu (“Main Rotor Track & Balance Jobs” in our example). 3.4.3.4. – Export Selecting the “Export” option presents a list of stored jobs on the “Export Job to USB” banner screen.

- Page 43 User Manual Gen II When the export is complete, the screen will display the “Operation Complete” message. Press the [F5] “Continue” key to return to the “Export Job to USB” menu to export another job. 3-17 – Using the Gen II Analyzer Chapter 3 Revision 2.10, April 20...

-

Page 44: Manage Setups

User Manual Gen II 3.4.4. – Manage Setups Selecting “Manage Setups” presents several sub-menu choices as shown below. These choices allow you to “manage” setups that have been previously stored in the analyzer. 3.4.4.1. – Edit Selecting the “Edit” function displays the “Setup List” screen. Select the setup you wish to edit and press OK. - Page 45 User Manual Gen II the configuration may be slightly different (i.e. tach or sensor position). Making a copy preserves the integrity of the original setup. NOTE When copying a setup, the setup name must be changed. The change can be as simple as adding a “2”...

- Page 46 User Manual Gen II Once you select a setup and press [OK], a progress indicator will be displayed as shown below. When the report creation is complete, the message “Report created” will appear. In addition, the “Pending Reports” value will increase by one indicating there is another report ready for transfer to the USB flash drive.

- Page 47 User Manual Gen II 3.4.4.4. – Delete The “Delete” option presents you with a list of stored setups. From the list, you may select an individual setup for deletion. After making your selection, you will be asked to verify your intent to delete the selected setup by pressing the [F1] key for “Yes,” or the [F5] key for “No.”...

- Page 48 User Manual Gen II 3.4.4.5. – Export The “Export” option presents a list of stored setups on the “Export Setup to USB” banner screen. From the list you may choose a setup to be exported directly to a USB flash drive. The exported setup file is saved in a “.tgz”...

-

Page 49: Data Management On The Usb Drive

User Manual Gen II 3.5. – Data Management on the USB Drive Your analyzer will come with a USB flash drive intended for transferring data to or from the analyzer. This device is formatted with a FAT32 file system to insure proper operation with the analyzer’s file system. -

Page 50: Aces_Export

User Manual Gen II 3.5.2. – aces_export This location contains exported jobs and setups. Data is stored here when you use the “Export” function found inside the Manage Jobs or Manage Setups menu items described above in paragraphs 3.4.3.4 and 3.4.4.5 respectively. 3.5.3. -

Page 51: Aces_Setups

Added new screen captures and process for downloading eSetups from the web. 2/15/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter was updated East with screenshots from the new website. -

Page 52: Propeller Balance (Rev 2.20, Apr 2020)

Viper II Cobra II Because most propeller balancing applications use common accessories, ACES Systems has assembled a propeller balancing kit, described below, which can be purchased with the Gen II Analyzers. -

Page 53: Propeller Balancing Kit

The three-pin MS female connector on one end of the cable mates to the 991D -1 sensor. The six-pin MS male connector mates to one of the four (CHANNEL A, B, C, or D) vibration-input ports available on the analyzer. Contact ACES Systems for other sensor, cable, or adapter options. - Page 54 The connectors are constructed of aluminum alloy with olive drab chromate coating for corrosion resistance. The male end connects to the tach input of any ACES Systems’ analyzer/balancer or to the female end of another cable of the same type. The opposite (female, bulkhead) end will accept another 10-320-0126 cable for extension or connect to an aircraft or sensor interface.

- Page 55 User Manual Gen II Propeller Protractor The propeller protractor is designed to measure angles in a typical propeller/spinner assembly. The propeller protractor pictured below is a complete circle. It is divided into five-degree increments. Every 15 degrees, the angle is identified by a tick mark. Every 45 degrees, the angle is printed in a circular identifier.

- Page 56 User Manual Gen II Place the protractor over the spinner with the Rotation indicator pointing in the direction of rotation (forward looking aft) and the 360-degree points aligned with the position of the reflective tape. Read the numbers in the circles, and then interpolate values of the unmarked incremental lines to locate the desired angle.

- Page 57 The tape is manufactured by the 3M Company and is the only tape we recommend for use with the system. Contact ACES Systems for replacement tape. (See Chapter 23, “Equipment and Accessory Setup and Troubleshooting” for additional information for high RPM.) ACES Systems Balance Placard Placards similar to the one shown below are included in the propeller balancing kit.

-

Page 58: Start Job

User Manual Gen II 4.1. – Start Job Selecting “Start Job” from the “Propeller Balance” banner screen allows you to begin a new propeller balance job. When you select this option, one of three screens will appear depending on whether you are: 1) Starting a new job with no setups previously defined in the analyzer’s memory;... - Page 59 User Manual Gen II If you are starting a new job with previously defined setups available in the analyzer’s memory, the screen will automatically display the Select Setup List banner screen similar to the one shown below. The actual setup names will be those, which you have entered into your analyzer. If you are resuming an incomplete job being held in the analyzer’s memory, the opportunity to do so is presented immediately following the “Start Job”...

-

Page 60: Prop Balance Setup

User Manual Gen II 4.1.1. – Prop Balance Setup The “Prop Balance Setup” banner screen allows you to define and store a propeller balance Setup. The “Prop Balance Setup” banner screen displays fill-in and selection type fields. The fill- in fields have squared off ends ([ ]). These fields are filled in using inputs from the analyzer keypad. - Page 61 Using the [] key, move to the “Max Wts” field. Enter the maximum total trim balance weight (in grams) allowed for this installation. If the manufacturer does not specify a maximum weight, refer to the ACES Systems Guide to Propeller Balancing. The valid range of values for this field is 1 to 9999.

- Page 62 User Manual Gen II (Root Mean Square). Typically, you will use Peak if using IPS in the “Vib:” field above. 4.1.1.1.11. Move to the “FSR” field and use the [] key to select the Full-Scale Range for the vibration amplitude you reasonably expect to encounter on this job. For a propeller balance conducted using IPS, a normal selection would be 1.

- Page 63 CAUTION Sensors connected to Channel A and Channel B (or Channel C and Channel D in the Viper II) must be of the same type. Using different sensors during the same job will cause erroneous readings and problems achieving good balance results.

- Page 64 User Manual Gen II The “Edit ICF” (which corresponds to the [F1] key) selection appears at the bottom left of the “Prop Balance Setup” banner screen. Press the [F1] key if you wish to define the Influence Coefficients for this setup. The following “Edit ICF” banner screen is displayed. If you have selected a two (2) engine balance, the screen will contain individual ICF fields for each engine.

- Page 65 User Manual Gen II 4.1.1.2.3. A successful balance job (one that has updated the setup’s ICF) will toggle the “Edit” menu item above the [F3] key. Pressing the [F3] key will display additional function key options giving you the option to press [F1] “Avg=Def” to set the averaged ICF to the default ICF, pressing [F2] “Def by HP”...

- Page 66 User Manual Gen II 4.1.1.3. – Sensor Setup Pressing the [F5] “Sensor” key from the “Prop Balance Setup” banner screen displays the “Sensor Setup” banner screen shown below. The information on this screen should correspond to the sensor you selected for this setup in paragraph 4.1.1.1.199 above. 4.1.1.3.1.

- Page 67 User Manual Gen II 4.1.1.3.2. When all fields are completed to your satisfaction, press the [OK] key to accept the inputs and continue to the “Prop Hole Layout Setup”. 4.1.1.4. – Prop Hole Layout Setup If “Yes” was selected under the “Holes:” entry in paragraph 4.1.1.1.7 the “Prop Hole Layout Setup”...

- Page 68 User Manual Gen II indicate the direction of increasing hole numbers as viewed from forward looking aft. 4.1.1.4.5. Move to the “Max H. Wt” field using the [] key. Using the keypad, enter the maximum allowable weight (in grams) for any single hole. If you do not know this value, refer to the aircraft maintenance manual or the ACES Guide to Propeller Balancing.

- Page 69 User Manual Gen II If you selected “Uneven” in paragraph 4.1.1.4.3 – Multiple angle/hole number fields are displayed. Each hole number (“No.”) is automatically populated and its corresponding angle must be defined individually. Using the keypad, complete each field by entering an angular (“Ang”) location as measured opposite the direction of propeller rotation.

-

Page 70: Job Identification

User Manual Gen II [OK] to accept the settings. The analyzer will return you to the “Propeller Balance Setups” menu. 4.1.2. – Job Identification At this point in the “Propeller Balance” process, you should have completed the following steps: (1) selected “Propeller Balance” from the Main Menu; (2) selected “Start Job;” and (3) completed the “Prop Balance Setup”... -

Page 71: Engine Information

User Manual Gen II 4.1.3. – Engine Selection / Engine Information The “Engine Selection” banner screen is displayed. If you have selected a two (2) engine balance setup, the first screen above will be displayed. In that setup you may select to run either, or both the engines within the setup. -

Page 72: Connect Sensors

User Manual Gen II 4.1.4. – Connect Sensors The “Connect Sensors” banner screen will be displayed as shown above. Messages that appear on this screen prompt you to perform the physical installation and connection of the tach and vibration sensors to the input ports you specified in the setup. 4.1.4.1. - Page 73 Alternatively, all trim balance weights can be removed before proceeding beyond this point. Refer to the ACES Systems’ Guide to Propeller Balancing (included with your propeller balancing kit) for a full list of FAA-approved inspection requirements.

-

Page 74: Start Aircraft

User Manual Gen II 4.1.5. – Start Aircraft Prior to performing any dynamic balancing, it is advised to follow the instructions in the ACES Systems’ Guide to Propeller Balancing included with your analyzer for inspections prior to balancing. The document is FAA approved and provides guidelines for the selection and installation of balance weights. - Page 75 User Manual Gen II “Current Vib:” – The current vibration reading. This value is for monitoring purposes only and is not being recorded. NOTE The Difference between the Desired and Current RPM should not exceed the values outlined in Chapter 24, paragraph 24.2.5 “RPM Warnings”...

-

Page 76: Review Job

User Manual Gen II percentage of error (Error) in the averaging. If you wish to reset the averaging and take new data, press the [F1] “Reset” key. The data can be viewed in a polar chart format by pressing the [F2] “Polar”... - Page 77 User Manual Gen II If you are satisfied with the results of the run and are ready for a solution, press [OK] to accept the data and continue. If you want to retake data for this run, press the [F1] “Retake #1” key, [F2] “Retake #2”, or [F3] “Retake All”...

-

Page 78: Balance Solution

User Manual Gen II 4.1.8. – Balance Solution The “Run 1 Existing Weights” screen will appear based on the selection made in step 4.1.1.1.7 above, ONLY after Run #1 andIF the “Holes:” field was set to “Yes”. This is a feature that will allow the existing trim balance weights to remain on for the data collection phase of the job on the first run. - Page 79 User Manual Gen II If you do NOT have existing trim balance weights installed press the [F5] “No” key to proceed to the next step. The solution screen displayed will depend on the selection made in 4.1.1.1.7 above. If the “Holes:”...

- Page 80 If the solution exceeds the single location limits of the propeller or spinner assembly (refer to ACES Systems’ Guide to Propeller Balancing included with your analyzer), you may split the weight across two locations.

- Page 81 User Manual Gen II The single location solution (in this case 32.4 g @ 270 degrees) is displayed at the top of the screen. The next line states: “Enter New Location.” Use the keypad to complete the next two fields, “Angle 1” and “Angle 2.” Locate the two available weight installation locations (one on each side of the 270-degree location) and enter them in the two fields.

- Page 82 User Manual Gen II If you discover a problem with the split weight locations you specified, press the [F1] “Re-split” or [F0] “Back Up” key and enter the two new angles. When the “Actual Installed Weight” fields are completed, press [OK] to continue. The screen will return to the “Balance Solution”...

- Page 83 User Manual Gen II In the lower portion of the screen you see an information line stating: “Remove old weights; install and enter new weights.” If the previous dynamic balance trim weights were left installed, as explained in step 4.1.8 above, at this point the existing weights will be removed and replaced with the new solution.

-

Page 84: Vibration Summary

Then repeat the procedures described above starting with paragraph 4.1.5 until the level of vibration is at or better than an acceptable level. See the ACES Systems Guide to Propeller Balancing for details of vibration levels and weight installation procedures. - Page 85 User Manual Gen II The “Vibration Summary” banner screen will display run number at which the current vibration level was recorded. It will give a brief description of the current engine vibration level. The screen will show the starting vibration magnitude and phase angle on any channels defined in the setup.

-

Page 86: Resume Job

User Manual Gen II 4.2. – Resume Job The features in this section are common among all jobs. Because of this, they are contained in “Chapter 3, Using the Gen II Analyzer”. 4.3. – Manage Jobs The features in this section are common among all jobs. Because of this, they are contained in “Chapter 3, Using the Gen II Analyzer”. -

Page 87: Manage Setups

User Manual Gen II 4.4. – Manage Setups The features in this section are common among all jobs. Because of this, they are contained in “Chapter 3, Using the Gen II Analyzer”. 4.5. – Weight Calculator CAUTION If test weights were used on the spinner, they must be removed before installing any permanent weights. - Page 88 User Manual Gen II The weight calculator, as shown below, can be used for placement of the final balance weights. This function can be accessed by using the [F3] “WtCalc” function key from the “Balance Summary” screen shown in paragraph 4.1.9 above . For your convenience, this function can also be accessed at any time from the “Propeller Balance Jobs”...

- Page 89 User Manual Gen II The “Split Angle” toggle field allows you to split the weight across two locations. Selecting “No”, the final weight solution will be installed at a single weight location as shown below. By selecting “Yes” in the “Split Angle” field, the “Set Split Weight” screen is displayed as shown below.

- Page 90 1.02: Added text about the Polar Chart view. Main Polar view explanation in Chapter 24. Lucas 2/17/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter was updated East with screenshots and corrections to minor typographical errors.

-

Page 91: Reserved (Rev 1.00, Dec 2014)

Chapter 5 RESERVED (Revision 1.00, Dec 2014) -

Page 92: Reserved (Rev 1.00, Dec 2014)

Chapter 6 RESERVED (Revision 1.00, Dec 2014) -

Page 93: Main Rotor Track & Balance (Rev 3.00, Apr 2020)

Chapter 7 Main Rotor Track & Balance (Revision 3.00, April 2020) This section is intended to familiarize you with the various electronic chart forms and setup screens used with the Gen II Analyzer–first by looking at each of the chart forms found in the main rotor section, then by using these forms to create an actual setup. - Page 94 20 alphanumeric characters. CAUTION Sensors connected to Channel A, Channel B, (or Channel C and Channel D in the Viper II) must be of the same type. Using different sensors during the same job will cause erroneous readings and problems achieving good balance results.

- Page 95 User Manual Gen II 7.1.1.7. Press the [] key to move to the “Number of Weight Positions” field. Using the [] key, select the total number of lateral balance weight positions as determined from the lateral balance chart. The maximum number of positions equals 6. 7.1.1.8.

-

Page 96: Tracking Setup Screen

User Manual Gen II “Both” = measurement and storage of both vibration and track for the listed condition “Vib” = measurement and storage of vibration only for the listed condition “Trk” = measurement and storage of track only for the listed condition When all conditions and measurement types desired have been input to your satisfaction, press [OK] to continue. - Page 97 User Manual Gen II device. Use the keypad to enter a number between -180 to 180 degrees. For more information on Blade 1 Offset see the paragraph 2.4 of the Model 550 Aces TraX Operational Supplement. 7.1.2.5. Use the [] key to move to the “In. from Mast CL” block. This will define the linear distance, as measured in the same plane as the tracker is mounted, from the tracker to the extended centerline of the mast.

-

Page 98: Main Rotor Condition Setup Screen

User Manual Gen II 7.1.3. – Main Rotor Condition Setup Screen English Metric The “Main Rotor Condition. Setup” screen appears. The purpose of this screen is to allow the user to enter an “ID” number for each polar chart or tracking influence to be used by the analyzer when determining if a solution is required. - Page 99 User Manual Gen II Looking at the example main rotor conditions setup screen above, three charts will be used, two vertical and one lateral. One tracking influence definition will also need to be created. The first chart is for vertical measurements at hover only. The second chart is for the averaged vertical measurements from both FLT 80 and FLT 120.

-

Page 100: Main Rotor Adjustment Symbol And Solution Logic Screen

User Manual Gen II The last example shows one lateral chart and two track adjustment ID entries. The lateral measurements for both Ground and Hover will be averaged, with the solution based on this average. The recorded track split for Ground and Hover will be averaged with one solution based on this average. - Page 101 User Manual Gen II The “M/R Adj Symbol & Soln Logic” screen appears as shown. This screen is used to establish the direction of move for a positive adjustment as determined by the charts. For example, if the selection of “Sweep (AFT)” is made, when the analyzer gives an adjustment for blade sweep to move a blade “4 flats”, the actual movement of the blade is 4 flats aft.

-

Page 102: Chart Definition

User Manual Gen II “All”, the analyzer will present all of the available solutions for vertical, lateral and track readings. Analyzers with App Version Service Pack 5 and subsequent* The two solution options are “Max” and “Avg”. “Max”, Unchanged from Service pack 1-4. the analyzer will present the solution for the highest vibration reading attained for the vertical and lateral sensors. - Page 103 User Manual Gen II Rotor diameter: 37.0 Feet. Lead/lag units are read in inches. Rotor speed: 385 RPM/ 7-11 – Main Rotor Track & Balance Chapter 7 Revision 3.00, Apr 2020...

- Page 104 User Manual Gen II 7.1.6.1. – Main Rotor Setup Screen The name of the setup has been labeled as “EXAMPLE 1”. Vertical vibration will be measured on channel “A”. Lateral vibration will be measured on channel “B”. ...

- Page 105 User Manual Gen II Tab Adj Decimal set to “3” Rotors, a single rotor is chosen. Four conditions have been entered for this job, “GROUND”, “HOVER”, “80 KTS”, and “120KTS”. Both track and vibration will be measured and recorded for this setup. Press [OK] to proceed to the next screen.

- Page 106 User Manual Gen II 7.1.6.3. – Main Rotor Conditions Setup Use the sample polar charts in paragraph 7.1.6. In the “Main Rotor Conditions Setup” screen above, two vertical charts and one lateral chart have been identified. The first vertical chart, ID number “1”, will be used for a vertical measurement in hover only, while the second vertical chart, ID number “2”, is for the average vertical measurement of both “FLT 80”...

- Page 107 User Manual Gen II In the “Main Rotor Adj Symbol & Soln Logic” setup screen above, the positive numeric value in a solution screen has been identified as ADDING weight, sweeping a blade FWD , moving a blade UP using either pitch change links or tabs. The solution logic has been set to “MAX” and will present the solution related to the highest vibration readings attained for the vertical and lateral sensors.

- Page 108 User Manual Gen II The name of the chart, “Vert: HOVER”, has been automatically entered from the “Main Rotor Conditions Setup” screen and is non-editable. The chart type is “Regular”. This chart uses no sweep adjustments, and is therefore left as “No”. ...

- Page 109 User Manual Gen II The “Vert: 80 KTS – 120KTS ” chart setup screen appears next. Use the vertical vibration chart in paragraph 7.1.6, to complete the steps below and properly define this chart. The name of the chart, “Vert: 80 KTS – 120KTS ”, has been automatically entered from the “Main Rotor Conditions Setup”...

- Page 110 User Manual Gen II 7.1.6.7. – Lateral Hover Chart The last chart defined will be “Lat: HOVER”. Use the lateral vibration chart in paragraph 7.1.6, to complete the steps below and properly define this chart. The name has been automatically entered as “Lat: HOVER” from the “Main Rotor Conditions Setup”...

-

Page 111: Main Rotor Balance Process

User Manual Gen II The third Bld/Pos name entered is “BLANK”, utilizing an adjustment unit of “GMS” weight. The influence co-efficient for this point is “200.00” grams adjustment per “1.0” IPS vibration. The Move line for this position is “2:30”. ... -

Page 112: Starting A New Job

User Manual Gen II 7.2.1. – Starting a New Job Selecting “Start Job” from the “Main Rotor Track & Balance” banner screen allows you to begin a main rotor balance job. When you select this option, one of three screens will appear next depending on whether you are using the main rotor function for the first time, have previously defined main rotor setups, or have a previously started job stored in the analyzer. -

Page 113: Setup List

User Manual Gen II 7.2.2. – Setup List The setup list presents the stored main rotor setups in analyzer memory. Select the setup you wish to use by highlighting the name of the setup using the [] key and pressing [OK]. If the setup you need is not present, press the [F1] “New”... -

Page 114: Connect Sensors

User Manual Gen II If the analyzer has been used previously, a list of customer names and/or A/C Reg numbers will have been stored and are accessed by pressing the [F1] “Cust” or [F2] “A/C Reg” keys respectively. A name can then be selected from this list for use with this job. When finished, press [OK]. - Page 115 – Optical Tachometer Setup (Optional) To install the optical tachometer, do the following: If not specifically provided by an ACES Systems Application Note or manufacturer’s directions, locate a position that allows the Phototach to be installed not more than 18 inches away or closer than 4 inches from a rotating main rotor component.

-

Page 116: Select Aircraft Condition

User Manual Gen II 7.2.4. – Select Aircraft Condition Once the aircraft is started and at operating speed, use the “Select Condition” screen to view and chose the conditions that were defined in the setup; each preceded by a set of brackets. To measure a condition, highlight it using the [] key and press [OK]. -

Page 117: Data Acquisition

User Manual Gen II 7.2.5. – Data Acquisition Upon selecting to acquire a measurement, the data acquisition screen appears. The screen banner will contain the run number as well as the condition being measured. At this point vibration and track data will be collected simultaneously. Within the screen, the analyzer will present the “Average”... -

Page 118: Review Prior Runs Data

User Manual Gen II 7.2.6. – Review Prior Runs Data The “Review Prior Runs Data” screen will now appear presenting the Vibration data and Track data for the current run and condition. The data will be displayed in the order of the current run and first condition measured. From this first screen, press the [] key to proceed to the next condition measured for the current run. -

Page 119: Solution Screens

User Manual Gen II When you have completed reviewing the data, and all conditions data has been collected press [OK] to continue to the solution screens. 7.2.7. – Solution Screens The number and type of solutions presented will depend upon the data gathered and the targets that were set for each of the measurement types in the “Conditions Setup”... - Page 120 User Manual Gen II performed, or skipped. If the analyzer presents a solution and you choose not to apply it on the current run, you are required to zero out the adjustment entries in the recording screen for that particular adjustment. If you believe that the current ICFs are correct and the impact of one adjustment on another will be minimal, it is possible to make multiple adjustments during a single run by pressing the [F1] “All Adj”...

- Page 121 User Manual Gen II [F2] “Inst=None” key will delete all “Installed” field entries. This function is used when a particular adjustment is to be skipped on the current run. [F3] “Collected” – Displays the “Review Prior Run(s) Data” screen ...

- Page 122 User Manual Gen II – Example Solution Screen #3 The last correction given for our sample job is for the Track adjustment using trim tabs. The solution type for this adjustment is degrees on the trim tab. NOTE The analyzer will attempt to give solutions that “resolve to zero” in all cases. This may nullify the ability to make some adjustments with any degree of accuracy.

-

Page 123: Main Rotor Manage Data Functions

User Manual Gen II 7.3. – Main Rotor Manage Data Functions The main rotor “Review Job” function presents chart information, correction history, and influence co-efficient for the job. The following paragraphs will describe these new screens and how to navigate through them to review this information. 7.3.1. -

Page 124: View Main Rotor Track And Balance

User Manual Gen II To review different conditions within the same run, press either the [] or [] key. To review data for a different run, press either the [] or [] key. To view adjustments made for the current run, press the [F1] “ViewAdj” key. See paragraph 7.3.2. -

Page 125: View Main Rotor Chart

User Manual Gen II 7.3.3. – View Main Rotor Chart The “View M/R Chart” screen gives the chart name, chart type, default magnitude of adjustment, name and adjustment ratio of each blade position. Pressing the [] or [] keys will toggle between multiple chart types if more than one is defined for the setup. -

Page 126: View Main Rotor Chart Icfs

User Manual Gen II 7.3.4. – View Main Rotor Chart ICFs The “View M/R Chart ICFs” screen shows how the influence coefficient magnitude and rotation was changed as a result of the correction made on each run. Because the analyzer continues to learn between runs, it is very important to ensure accurate data entry for the actual correction made during each run. -

Page 127: Resume Job

User Manual Gen II 7.4. – Resume Job The features in this section are common among all jobs. Because of this, they are contained in Chapter 3, “Using the Gen II Analyzer”. 7.5. – Manage Jobs The features in this section are common among all jobs. Because of this, they are contained in Chapter 3, “Using the Gen II Analyzer”. -

Page 128: Manage Setups

User Manual Gen II 7.6. – Manage Setups The features in this section are common among all jobs. Because of this, they are contained in Chapter 3, “Using the Gen II Analyzer”. 7.7. – Analyzer Chart Forms Just as in the case with polar balance charts, there are two types of analyzer chart “forms” used with the Analyzer and one tracking influence setup screen. - Page 129 User Manual Gen II 7.7.1.1. – Regular Main Rotor Chart Setup The main rotor balance chart shown to the right depicts three weight positions, Red, Yellow, and Blue. The move line for each position has been indicated with an arrow, the type of adjustment given below the chart is “Plates”.

- Page 130 User Manual Gen II No Adjustment Bld/Pos.: This field is used to designate a main rotor blade as a “no adjustment blade”. This feature is used when the OEM suggests that no adjustments be applied to a particular blade during a track and balance job. An optimized solution is provided by the analyzer that requires no adjustments to the designated “No Adjustment Blade”.

-

Page 131: Irregular Chart Forms

User Manual Gen II NOTE Blade position names must be entered sequentially in either clockwise or counter clockwise order. It does not matter what direction is chosen. 7.7.2. – Irregular Chart Forms Any polar chart that does not fit the “Regular”... - Page 132 User Manual Gen II Chart Type: Press either the [] or [] keys to select the chart type. For this example, select “Irregular”. Sweep Only: This field is used when defining a chart that incorporates sweeping of the blades as the only means of adjustment.

-

Page 133: Tracking Influence Setup

User Manual Gen II angle is 30. Perform this for each adjustment point shown on the chart and the setup is complete. The move line for the T AFT position will be 5:30. The move line for the BLANK position will be 8:30. B AFT will have the move line at 11:30. NOTE Blade position names must be entered sequentially in either clockwise or counter clockwise order. - Page 134 1.02: Added text about the Polar Chart view. Main Polar view explanation in Chapter 24. Lucas 2/12/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter was East updated with screenshots and corrections to minor typographical errors.

-

Page 135: Tail Rotor Balance (Rev 3.00, Apr 2020)

Chapter 8 Tail Rotor Balance (Revision 3.00, April 2020) This section is intended to familiarize you with the various electronic chart forms and setup screens used with the Gen II Analyzer, first by looking at each of the chart forms found in the tail rotor section, then by using these forms to create an actual setup. - Page 136 User Manual Gen II In the “Name” field, enter a name for the setup using the keypad. Press [] to move to the “Sensor Channel” field. Use the [] key to select the vibration sensor channel for this setup. ...

-

Page 137: Tail Rotor Chart Setup

User Manual Gen II choose “Dont Care” regardless of the actual direction of rotation of the tail rotor. For further guidance contact Aces Support at support@acesystems.com. Press the [] key to move to the “Number of Blades” field. Using the keypad, enter the number of blades on the tail rotor. - Page 138 User Manual Gen II Press the [] key and select the chart type by pressing the [] key. The type of chart for this example is “Irregular”. See paragraph 8.8.1 for more information on chart type “Regular” and paragraph 8.8.2 for chart type “Irregular”. ...

-

Page 139: Tail Rotor Setup Screen

User Manual Gen II 8.2.1. – Tail Rotor Setup Screen Using the instructions outlined in paragraph 8.1.1 to complete the “Tail Rotor Setup” screen as shown in the screenshot above. When finished with the main setup screen, press [OK]. 8.2.2. –... - Page 140 User Manual Gen II Press the [] key to move to the name field for the second condition. Press the [] key to assign the next chart ID. If the tail rotor requires different charts as shown above, the ID’s will be 1 and 2. If all conditions use the same chart all of the ID numbers will be 1.

-

Page 141: First Condition Tail Rotor Chart Setup Screen

User Manual Gen II 8.2.3. – First Condition Tail Rotor Chart Setup Screen 80% Balance Chart The “Tail Rotor Chart Setup” screen for the first condition (80%) appears next. Using the tail rotor polar chart above, fill in the appropriate information as follows: ... -

Page 142: Second Condition Tail Rotor Chart Setup Screen

User Manual Gen II Press the [] key to enter the grams per IPS influence for the tail rotor. This example uses “100.00” grams. Press the [] key and enter the first weight position name as “TARGET”. Press the [] key and enter the “Add @”... - Page 143 User Manual Gen II 100% Balance Chart + Target The name for the chart, “100%”, has already been inserted from the “Tail Rotor Condition Setup” screen. Press the [] key and select the chart type by pressing the [] key. The type of chart for this example is “Regular”.

-

Page 144: Tail Rotor Balance Process

User Manual Gen II 8.3. – Tail Rotor Balance Process The following paragraphs present the tail rotor balance process and its associated screens. It is intended to familiarize the user with the data acquisition and correction capabilities of the Gen II analyzers. Prior to starting a new tail rotor balance job, you must first select the “Tail Rotor Balance”... -

Page 145: Setup List

[] key and pressing [OK]. If the setup you need is not present, you can download a setup from the ACES Systems Website Technical Library. Alternatively, you can create the setup by pressing the [F1] “New” key to proceed to the “Tail Rotor Setup”... -

Page 146: Job Identification

User Manual Gen II 8.3.3. – Job Identification The “Job Identification” banner screen appears next allowing entry of the customer name, A/C registration, and A/C total time. This information is optional, but it is suggested that at least a customer name be entered, as it will aid in identifying the job for future use. If the analyzer has been used previously, a list of customer names and/or A/C Reg numbers will have been stored and are accessed by pressing the [F1] “Cust”... -

Page 147: Start Aircraft

User Manual Gen II The “Connect Sensors” banner screen will be displayed next. Messages that appear on this screen prompt you to perform the physical installation and connection of the tachometer and vibration sensors to the input ports you specified in the applicable setup. ... -

Page 148: Select Tail Rotor Condition Screen

User Manual Gen II 8.3.6. – Select Tail Rotor Condition Screen If multiple conditions were configured in the setup, the “Select Tail Rotor Condition” screen will be displayed allowing the user to select the applicable condition to acquire data. This screen will only appear in “Multiple Condition”... - Page 149 User Manual Gen II error indication associated with the averaged measurement. The numeric error value will typically lower rapidly when the amplitude of vibration is high. The top line of this screen can display three different status messages. The messages are: “Waiting for Data”...

-

Page 150: Review Prior Run(S) Data

User Manual Gen II If performing a tail rotor balance job consisting of more than one condition, the “Select Aircraft Condition” screen will appear. Select the condition desired and press [OK]. When data has been collected at all of the conditions, the condition boxes will have “X’s”... -

Page 151: Shut Down Engines

User Manual Gen II If the setup has more than one condition, press the [F2] “Next Cond” key to view the data for the second condition. Pressing the [F3] “Polar” key will display the data in a polar chart format. When finished reviewing, press [OK] to continue to the solution process. -

Page 152: Tail Rotor Suggested/Installed Weights Screen

User Manual Gen II 8.3.11. – Tail Rotor Suggested/Installed Weights Screen The “T/R Suggested / Installed Weights” screen appears displaying the suggested adjustments and providing for input of the actual changes made to the tail rotor prior to the next run. It is extremely important that these changes are entered, as they will be used to update the influence co-efficient for the next run. -

Page 153: Tail Rotor Re-Solve Feature

User Manual Gen II Pressing the [F2] “None” key will delete all “Installed” entries. This function is used when an adjustment is to be skipped on the current run. Pressing the [F3] “Re-Solve” key will allow you to find an alternate solution. This may be used when weight is already attached to the tail rotor or the suggested weights are smaller than the minimum hole weight. - Page 154 User Manual Gen II In the example above, the suggested weight is smaller than the minimum weight; a bolt and nut, which are required to attach hardware (attach hdw). The weight of this hardware must be included in the final weight installation. In this case, press the [F3] “Re-Solve” key to find an alternate solution.

- Page 155 User Manual Gen II enter the negative sign before the removed weight value. When all weights have been weighed, removed from the tail rotor, and entered into the appropriated field, press the [OK] key to re-solve the balance solution. Now the solution presented on the top half of the “T/R Suggested/Installed Weights” screen below “Run 1 Suggestion:”...

-

Page 156: Tail Rotor Manage Data Functions

User Manual Gen II Once the solution has been applied, press [OK] to return to the “Start Aircraft” screen for the next run. Repeat the data acquisition and solution application process to verify the adjustments have brought vibration readings below limits. Once you have decreased vibration levels to below the Limit / Target entered in the setup, you will be presented with the Balance Status screen shown below. -

Page 157: View Tail Rotor Balance

User Manual Gen II 8.4.1. – View Tail Rotor Balance After selecting to review a job, the “View T/R Balance” screen appears showing the run number, RPM at which the data was acquired, amplitude and clock angle of the vibration, and suggested, as well as the installed, corrections to the rotor. -

Page 158: Resume Job

User Manual Gen II (below top). The second gives the influence co-efficient and phase angle rotation changes for each run (below bottom). Any additional charts will have similar screens to view. Pressing [F5] “Continue” will progress through all available screens for all conditions. When returned to the “View T/R Balance”... -

Page 159: Manage Jobs

User Manual Gen II 8.6. – Manage Jobs The features in this section are common among all jobs. Because of this, they are contained in Chapter 3, “Using the Gen II Analyzer”. 8.7. – Manage Setups The features in this section are common among all jobs. Because of this, they are contained in Chapter 3, “Using the Gen II Analyzer”. -

Page 160: Analyzer Chart Forms

User Manual Gen II 8.8. –Analyzer Chart Forms Just as in the case with polar balance charts, there are two types of analyzer chart “forms” used with the analyzer. The chart forms are also categorized as either “Regular” or “Irregular”. The selection of setup type is made within the chart form itself by using either the [] or [] keys to toggle between “Regular”... - Page 161 User Manual Gen II Name: The name of the chart will be automatically inserted from the “Tail Rotor Setup Screen” name field and is not editable. Chart Type: Use [] or [] key to select the chart type. For this example, the type is “Regular”.

-

Page 162: Irregular Chart Forms

User Manual Gen II NOTE Weight position names must be entered sequentially in either clockwise or counterclockwise order. It does not matter what direction is chosen. 8.8.2. – Irregular Chart Forms The tail rotor balance chart shown to the right represents four adjustment points, all of which utilize the addition of weight as a correction type. - Page 163 1.02: Added text about the Polar Chart view. Main Polar view explanation in Chapter 24. Lucas 2/12/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter was East updated with screenshots and corrections to minor typographical errors.

-

Page 164: Transient Balance (Viper Ii Only) (Rev 2.10, Apr 2020)

(Viper II only) (Revision 2.10, Apr 2020) “Transient Balance” is an analyzer function that is only available in the Viper II analyzer. It is accessed from the analyzer’s Main Menu banner screen as shown in the illustration below. Selecting this function from the Main Menu produces the “Transient Balance” banner screen menu (also shown below). - Page 165 User Manual Gen II If another job was in progress but was not completed, the “Incomplete Job” banner screen will be displayed to inform you of this. The displayed message will give you the details of the last incomplete job and provide the opportunity to resume it. Pressing the [F1] “Yes” key will return you to the last logical in-progress step of the job.

-

Page 166: Transient Balance Setup

User Manual Gen II “Transient Balance Setup” Screen. If you are starting a new job with no setups previously defined in the analyzer’s memory, the screen will automatically display the Transient Balance Setup banner screen shown below. See paragraph 9.1.1 below for step-by-step instructions on completing the Transient Balance Setup. - Page 167 User Manual Gen II or optional USB keyboard. The selection fields have pointed ends (< >). These fields have two or more preset values that are selected by using the [] and [] keys. Navigate between the fields on this screen using the [] and [] keys. (Refer to Chapter 3, “Using the Gen II Analyzer”...

- Page 168 User Manual Gen II by noting the direction the fan rotates as viewed from behind the fan looking forward out of the intake. 9.1.1.6. Using the [] key, move to the “Num Baln Planes” field. Use the [] key to select the total number of rotational balance planes on this engine type.

- Page 169 User Manual Gen II 9.1.1.11. Use the [] key to move to the “Baln Weight Unit:” field. Use the [] key to select “g” for grams or “oz” for ounces. You will use this unit of measurement to define your class weight set. If using Actual Weights, this defines the units of measure in which the balance solution will be presented.

-

Page 170: Sensor Information Screen

User Manual Gen II 9.1.2. – Sensor Information Screen 9.1.2.1. In the “Eng ID:” (engine identification) field use the numeric keypad to enter the number of the engine. Press the [] key to move to the next field. 9.1.2.2. Use the [] to select the “Tach Chan” (tachometer channel) you will use for this job. -

Page 171: Transient Balance Speeds Screen

User Manual Gen II 9.1.2.6. Use the [] key to select the “Tach Filter Type”. The options are for a Single pole filter, a Double pole filter or None. 9.1.2.7. Use the keypad to enter the “Tach Filter Frequency”. Enter a numeric value equal to the lowest frequency of interest. - Page 172 User Manual Gen II 9.1.3.1. In the “Num Balance Speed Bands:” field, use the [] key to select the number of separate speed ranges you wish to configure for the balance run. The default is “1” This would be appropriate for performing an acceleration balance on an engine with no “Cautionary Ranges”...

-

Page 173: Define Class Wts Screen

User Manual Gen II greater than 20% of the value entered in the “Actual RPM @ 100%” field (Para 9.1.1.15 above). 9.1.3.6. Press the [] key to move the cursor to the next speed field under the “Speeds” columns. Use the keypad to enter a maximum speed for the first speed band. The speed may be entered as N1% or actual RPM. - Page 174 User Manual Gen II 9.1.4.1. In the “Set ID” field, use the keypad to enter a name or part number for the class weight set you are about to define. The Set ID should be one that is recognizable and commonly used by everyone who will be using this setup to balance.

- Page 175 User Manual Gen II 9.1.4.5. Use the [] key to move to the “Add/Remove” field. The possible selections are “Add/Remove” which allows you to 1) add and remove weights to implement a balance solution, 2) Free Form, which allows you to add, remove and even reassign weights as necessary to implement a balance solution, 3) Remove then Add, which requires that the previously installed weights be removed completely before installing a new set of weights to implement a balance solution and 4) Add Only, which dictates...

-

Page 176: Balance Plane Information Screen

User Manual Gen II 9.1.5. – Balance Plane Information Screen 9.1.5.1. The “Plane ID:” field displays the identifying number for the first balance plane information. You will complete one of these information screens for each balance plane as defined in paragraph 9.1.1.6 or 9.1.1.7 above. If you defined only one balance plane, you will only complete one Balance Plane Information screen. - Page 177 User Manual Gen II 9.1.5.3. Use the [] key to move to the “Num Positions:” (number of weight positions) field. Use the numeric keypad to enter a number equal to the total number of positions where balance weights may be attached for this balance plane only. 9.1.5.4.

- Page 178 User Manual Gen II angle to each position number based on the other information you provide in this screen. Any unequal spacing of even a single position dictates that you use the Uneven setting. If using the Uneven setting, an additional screen displaying a table will be displayed when you leave this screen.

- Page 179 User Manual Gen II However, if multiple complete weight sets are allowed on the balance plane, you can switch between these sets inside the job during the solution process. 9.1.5.15. Use the [] key to move to the “Trial Wt” field. Use the numeric keypad to enter a weight in grams or ounces (as defined in paragraph 9.1.1.11 above) for the analyzer to use as a trial weight in the first balance run.

-

Page 180: Label Detail Wt Holes Screen

User Manual Gen II (“Ang”) location and its corresponding position number (“No.”) as measured opposite the direction of fan rotation as viewed from the perspective selected in paragraph 9.1.5.11 above. Use the [] and [] keys to move between these fields. To determine these values, do the following. -

Page 181: Define Transient Balance Icfs Screen

User Manual Gen II hole number and an <-X->. The X symbolizes that a Detail Weight is located in this hole and it is not available for trim balancing. 9.1.7. – Define Transient Balance ICFs Screen 9.1.7.1. The “Plane ID:” field displays the identifying number for the balance plane being configured. -

Page 182: Start Job

User Manual Gen II 9.1.7.6. The “N1%” field identifies the N1 speed for which the ICF is configured. At least one ICF speed must be identified. If no known ICF speeds are available, this value will typically be “20” or “100”. 9.1.7.7. - Page 183 User Manual Gen II 9.2.2. – Engine Information Screen 9.2.2.1. The Engine Information screen will be displayed where you may enter the optional information of Position, Engine S/N, Type, TSO, TSN, and Cyc. Complete each field as necessary using the analyzer keypad. If Engine Serial Numbers have previously been entered in this analyzer, you may optionally press the [F3] “Eng S/N”...

- Page 184 User Manual Gen II 9.2.3. – Label Detail Wt Holes Screen 9.2.3.1. If you selected to label detail weights in the Job in paragraph 9.1.1.10 above, the “Label Detail Wt Holes” screen will appear. Complete as shown in paragraph 9.1.6 above.

- Page 185 User Manual Gen II 9.2.5. – Start Aircraft for Acceleration (Run 1) 9.2.5.1. The “Start Aircraft” banner screen, shown below, will be displayed with several informational messages. The Run number indicates which run of the balance job is currently being collected. The second line states “Perform FOD check, start engine per flight manual and set engine(s) to idle.”...

- Page 186 User Manual Gen II 9.2.5.3. Begin the acceleration or deceleration at such a rate to maintain a green ribbon in the scale. The rate will be determined by the RPM range from the balance speeds entered in paragraphs 9.1.1.14 and 9.1.1.15 and the ramp time entered in paragraph 9.1.3.4. If your rate is too fast, the ribbon will turn red and the message “Too Fast”...

- Page 187 User Manual Gen II and Deg (phase angle) collected on all runs up to this point. Pressing the [] or [] keys will allow you to navigate through the readings from all runs of the current job. Press the [OK] key to acknowledge the message and continue to the shut down the engine(s) screen.

- Page 188 User Manual Gen II This screenshot displays a plot using a basic This screenshot displays a plot using a configuration of a single sensor and a single configuration with multiple sensors and multiple speed band in an Acceleration run. The function speed bands in both an Acceleration and keys available are;...

- Page 189 User Manual Gen II 9.2.5.7. After displaying a brief “Optimizing Solution” status indicator, the “Run 1 Existing Weights?” screen will be displayed. This screen will only appear after Run #1. Select “F1 Yes” if the first run was conducted with the previous trim balance weight installed.

- Page 190 User Manual Gen II the class weight for that location and repeat until all existing weights are entered into the analyzer and then press [OK] to continue. 9.2.5.9. Pressing the “F6 Graph” key on the previous screen will present the “Run 1 Existing Weights”...

- Page 191 User Manual Gen II installation of class weights. Identified in the Name: Plane # line as HF120 TRM WT (this will be the name of the default class weight set as specified in paragraph 9.1.5.14 above). The left column, with a heading of “Posn”, shows the suggested position (or preferred term selected in paragraph 9.1.5.2 above) for each class weight.

- Page 192 User Manual Gen II 9.2.5.11. The function keys operate as described below: [F1] “Inst=None” key – This will return all “Installed” values to the null or “0” weight. Once pressed, the [F1] menu will change to “Inst=Sugg”. This will return all “Installed” values to the values listed under the center “Suggest”...

- Page 193 User Manual Gen II [F4] “Sel Pla/Wt” – Appears if optional balance planes or multiple class weight sets are configured in the setup. Displays the “Select Plane / Class Wt Set” screen and allows you to select another balance plane and/or weight set. ...

- Page 194 User Manual Gen II 9.2.6. – Start Aircraft for Acceleration (Run 2) 9.2.6.1. The screen will again display the Start Aircraft banner screen and indicate a new Run number. From this point, repeat paragraphs 9.2.5 to 9.2.5.1111 until the vibration amplitude is reduced to an acceptable level or below the target amplitude entered in the setup.

- Page 195 User Manual Gen II 9.2.6.3. If certain criteria were not met indicating a good job, you will see the message below telling you the ICF was not updated. However, you have the option to update or discard the ICF. If the balance job was satisfactory with few runs, it may be acceptable to update the ICF.

- Page 196 User Manual Gen II 9.4. – Manage Jobs The features in this section are common among all jobs. Because of this, they are contained in Chapter 3, “Using the Gen II Analyzer”. 9.5. – Manage Setups The features in this section are common among all jobs. Because of this, they are contained in Chapter 3, “Using the Gen II Analyzer”.

- Page 197 Lucas 2/17/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter only applies to East the Viper II and the generalization has minimal impact. This chapter was updated with corrections to minor typographical errors.

- Page 198 (Viper II only) (Revision 2.10, Apr 2020) “Fan/Turbine Balance” is a function that is only available in the Viper II analyzer. It is accessed from the analyzer’s Main Menu banner screen as shown in the illustration below. Selecting this function from the main menu brings up the “Jobs and Setups” banner screen menu (also shown below).

- Page 199 User Manual Gen II “Incomplete Job” If another job was in progress but was not completed, the “Incomplete Job” banner screen will be displayed to inform you of this. The displayed message will give you the details of the last incomplete job and provide the opportunity to resume it. Pressing the [F1] “Yes”...

- Page 200 User Manual Gen II “Fan/Turbine Balance Setup” Screen. If you are starting a new job with no setups previously defined in the analyzer’s memory, the screen will automatically display the “Fan/Turbine Balance Setup” banner screen shown below. 10.1.1. – Fan/Turbine Balance Setup Screen The “Fan/Turbine Balance Setup”...

- Page 201 User Manual Gen II To complete the “Fan/Turbine Balance Setup” banner screen (shown below), do the following: 10.1.1.1. In the “Name” field, enter a name for this setup using the keypad. The name you choose will aid you in differentiating this setup from other stored setups should you choose to use or review it at a later time.

- Page 202 User Manual Gen II when attempts to balance on the primary balance plane do not yield the desired results. 10.1.1.6. Using the [] key, move to the “Balance Wt Type:” field. The balance weight type is a description of the balance weights for this application. Use the [] key to select from Actual, Class, or Both.

- Page 203 User Manual Gen II 10.1.1.10. Move to the “Num Sens/Eng:” field using the [] key. Select the number of sensors you will use on each engine by using the [] key to scroll between the selections. This selection will define total number of sensors being used on each engine for the balance job.

- Page 204 User Manual Gen II applicable Maintenance Manual if you are not familiar with the modifier used for this application. 10.1.1.17. When all fields are completed as required, press [OK] to proceed. 10.1.2. – Fan/Turbine Balance Speeds Screen 10.1.2.1. If you selected a number of balance speeds in paragraph 10.1.1.11 above, the “Fan/Turbine Balance Speeds”...

- Page 205 User Manual Gen II 10.1.2.4. Use the [] key to move to the toggle field at the bottom of the screen. This field gives you the option to use the Actual Speeds acquired during the first run as the target speeds for all subsequent runs OR use the speeds defined on this screen as the target for ALL runs.

- Page 206 User Manual Gen II 10.1.3.3. Use the [] key to move to the “SplitErr:” field. Use the numeric keypad to enter a number that will be used to determine the maximum amount of error between the suggested solution and the available class weight placement combination.

- Page 207 User Manual Gen II input. If you have specified more than one class weight set for this setup in paragraph 10.1.1.7 above, another Define Class weight screen will be displayed, such as the two screens below, when you press [OK] to store the current screen and continue.

- Page 208 User Manual Gen II 10.1.4.2. Use the [] key to move to the “Posn Type:” field. This field will define the terminology used to refer to the weight locations throughout the balance job. The choices in this field are <Position>, <Hole> or <Blade>. After you exit this field the remaining references will change to the selected term.

- Page 209 User Manual Gen II 10.1.4.8. Use the [] key to move to the “in/mm” toggle field. This field is used to define the Radius measurement and will only appear if an optional balance plane is identified in paragraph 10.1.1.5 above. Use the [] key to select “in” (inches) or “mm”...

- Page 210 User Manual Gen II 10.1.4.13. Use the [] key to move to the “MaxWt/Plane" (maximum weight for this balance plane) field. Enter a numeric value to define the maximum total number of grams or ounces (as defined in paragraph 10.1.1.9 above) allowed for installation on this balance plane.

- Page 211 User Manual Gen II 10.1.4.17. If you selected “Uneven” in step 10.1.4.9 above, the “Angle of #1 Posn:” field will not be displayed, but when you press [OK] the multiple angle/position number fields are displayed as shown in the example above. Each position angle must be defined individually.

- Page 212 User Manual Gen II 10.1.5. – Label Detail Wt Holes Screen 10.1.5.1. If you selected to label the detail weights in the Setup in paragraph 10.1.1.8 above the next screen to appear will be the Label Detail Wt Holes screen. Use the [] key to move from hole number to hole number.

- Page 213 User Manual Gen II 10.1.6.2. Use the [] to select the “Tach Chan” (tachometer channel) you will use for this job. Be sure the channel you select here is the channel you actually connect the tachometer-input signal to when setting up the equipment. Press the [] key to move to the next field.

- Page 214 User Manual Gen II 10.1.6.10. Use the [] key to select the “Ch” (Channel A, B, C, or D) where you will connect the sensor input from the vibration sensor in this same row. Use the [] key to move to the next field. 10.1.6.11.

-

Page 215: Job Identification Screen

User Manual Gen II 10.1.7.2. The “All Planes Use the Same ICF:” field is only available if multiple balance planes were defined in paragraph 10.1.1.4 or 10.1.1.5 above. Use the [] to toggle the YES / NO answer field to indicate if all balance planes should use the same influence coefficient. -

Page 216: Engine Information Screen

User Manual Gen II 10.1.9. – Engine Information Screen 10.1.9.1. The Engine Information screen will be displayed where you may enter the optional information of Position, Engine S/N, Type, TSO, TSN, and Cyc. Complete each field as necessary using the analyzer keypad. If Serial Numbers or Engine Types have previously been entered in this analyzer, you may optionally press the [F3] “Eng S/N”... - Page 217 User Manual Gen II 10.1.10. – Fan/Turbine Balance Equipment Setup 10.1.10.1. The “Fan/Turbine Balance Equipment Setup” banner screen, shown below, will be displayed. Install the speed sensor, vibration sensor, and cables as indicated. Near the center of the screen, the information message “Tach power is off” will be displayed.

- Page 218 User Manual Gen II procedures and allow the engine to warm up to normal operating temperatures. When warm up is complete, allow the engine to stabilize at speed, make any minor adjustments as necessary, and then press [OK] to continue. Use the [F3] “+/- Pol.”...

- Page 219 User Manual Gen II 10.1.11.3. A data acquisition screen similar to the one shown below will be displayed. If you are unfamiliar with reading this screen, see Chapter 24 of this manual, “Reading Spectrum and Scales”. Allow the analyzer to average the acquired data until the indications are stable.

- Page 220 User Manual Gen II stabilize the reading. This option may be necessary when some of the Tooth settings (Mod Tth or Adj Tth) are selected on some engines. NOTE While collecting data, if the amplitude is high, the Error number will decrease toward 0.00 very rapidly.

- Page 221 User Manual Gen II 10.1.13. – Shut Down Engines 10.1.13.1. The screen will display the message “Shut Down engine per flight manual instructions”. Press the [F5] “Continue” key to acknowledge the message and shut down the engine(s). 10.1.14. – Fan/Turb Suggested/Installed Wts 10.1.14.1.

- Page 222 User Manual Gen II “Remove Old Wts, Inst. New Wts” is shown. All previously installed weights must be removed EACH TIME a new solution is installed. This means that weights installed on the previous run of a balance job must be removed completely before a new solution is installed.

- Page 223 User Manual Gen II 10.1.14.2. The function keys operate as described below: [F1] “Inst=None” key – This will return all “Installed” values to the null or “0” weight. Once pressed, the [F1] menu will change to “Inst=Sugg”. This will return all “Installed” values to the values listed under the center “Suggest”...

- Page 224 User Manual Gen II [F4] “Sel Pla/Wt” – Appears if optional balance planes or multiple class weight sets are configured in the setup. The “Select Plane / Class Wt Set” screen and allows you to select an optional balance plane and/or weight set. ...

- Page 225 User Manual Gen II 10.1.15. – Start Aircraft 10.1.15.1. The screen will again display the Start Aircraft banner screen and indicate a new Run number. From this point, repeat steps 10.1.11 to 10.1.14 above until the vibration amplitude is reduced to an acceptable level or below the target amplitude entered in the setup.

-

Page 226: Resume Job

User Manual Gen II 10.1.15.3. If certain criteria were not met indicating a good job, you will see the message below telling you why the ICF could not be updated. 10.2. – Resume Job The features in this section are common among all jobs. Because of this, they are contained in Chapter 3, “Using the Gen II Analyzer”. -

Page 227: Manage Setups

Lucas 1/14/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter only applies to East the Viper II and the generalization has minimal impact. This chapter was updated with corrections to minor typographical errors. -

Page 228: Start Job

(Revision 3.00, Apr 2020) The Fan Blade Mapper is an accessory program that is only available in the Viper II analyzer. It allows you to remove as little as a single blade from a fan disk then enter the weight moment information for the new blade and all other blades currently installed on the disk. - Page 229 User Manual Gen II 11.1.2. – Select Setup List 11.1.2.1. If no setups were previously entered, the analyzer will open a new setup screen as shown in paragraph 11.1.2.2 below. If a setup has previously been entered for the engine model you are currently working, you may select it from the “Select, Setup List”...

- Page 230 User Manual Gen II 11.1.2.3. In the Name: field, use the analyzer keypad to enter a name for this setup. The engine model is usually a good choice for this name. 11.1.2.4. In the Number of Blades: field, use the analyzer keypad to enter the total number of blades on the disk.

-

Page 231: Job Identification Screen

User Manual Gen II paragraph 11.1.5.1 below. Selecting “No” will not present the Serial Number fields. 11.1.2.9. The Define Max Weight Difference for Opposite Blades: field will become visible when an even value is entered in the Number of Blades: field (paragraph 11.1.2.4 above). - Page 232 User Manual Gen II 11.1.4. – Engine Identification 11.1.4.1. The “Engine Information” screen, shown below will be displayed. Use the [] key to select the Position for the engine (1, 2, 3, or 4). Enter the optional Engine Serial Number (S/N), Type, Time Since Overhaul (TSO) and Time Since New (TSN) as required.

- Page 233 User Manual Gen II 11.1.6. – Optimizing Solution 11.1.6.1. A momentary screen reading “Optimizing Mapping” will be displayed along with a progression bar. The “Fan Blade Mapper Result” screen, shown below, will be displayed showing the optimal blade placement for each blade in the set to achieve the best weight distribution and balance.

-

Page 234: Manage Jobs

User Manual Gen II 11.1.6.2. Once the blade placement is complete, a vibration survey should be completed to ensure the balance is acceptable. If the balance is not acceptable, perform a Transient Balance in accordance with Chapter 9 or a Fan/Turbine Balance in accordance with Chapter 10. -

Page 235: Manage Setups

1.02: Updated to reflect “Define Max Weight Difference Between Opposing Blades” feature East 1/14/2016 2.00: Major rewrite generalizing the manual to cover both the Viper II and Cobra II. This chapter only applies to East the Viper II and the generalization has minimal impact. -

Page 236: Honeywell Performance (Viper Ii Only) (Rev 2.20, Apr 2020)

N1 DEEC computer without the need of the JEDA module. The Honeywell Performance function is available as part of the Viper II Main Menu and is used with or without the model 1752B JEDA dependent on the engine computer model. If you are not sure what performance equipment and accessories you currently have or need, contact ACES Systems at (865) 671-2003 or via email at Support@acessystems.com. - Page 237 S Y S T E M S VIPER II Analyzer Boot V ers ion App Versi on GH I J KL M NO PQ R • Viper II Analyzer & EMS N1 DEEC Direct Connect Equipment Setup 12-2 – Honeywell Performance Chapter 12 Revision 2.20,...