Table of Contents

Advertisement

Quick Links

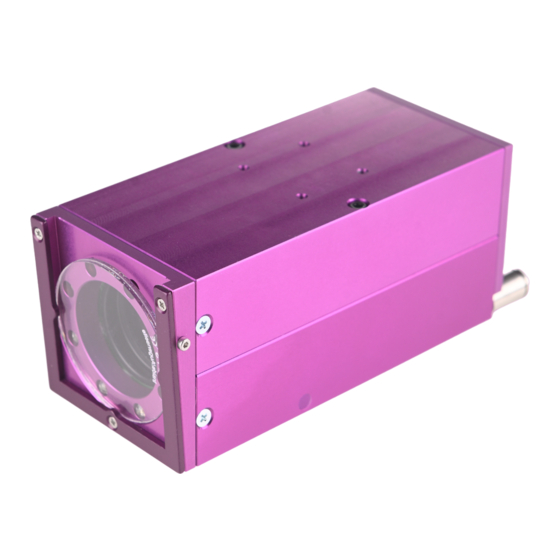

Welding camera system WVS-16

By semiautomatic or automatic welding equipment the service and control of the welding torch

mostly occurs from a control station. To set the position of the welding torch and the

parameters for the welding process optimally, however, a visual inspection from the control

station is required.

The welding camera WVS-16 provides a sharp colour picture and allows therefore an optimal

observation of welding torch, filler wire and work piece as well as welding arc and melting

area. Zoom, sharpness and brightness can be fast and simply adjusted via a small operating

panel - before, during and after the welding process. This can help you e.g., to shorten the

setup time substantially or faster recogniton of possible welding mistakes.

Two storage buttons can be overwritten with new settings by the user at any time.

The camera is in a protective case (60x60x130mm) and thereby can be inserted also in

cramped arrangements with heat and dust load. A protective glass on the front side protects

the optics of the camera and can be changed easily.

The drag chain suitable camera cable can be ordered up to 50 m length. With it, e.g., the

camera can be controlled by a remote control station or a complex cable transfer in the

machine can be carried out.

Version 4.1.1

WVS-16

1/14

Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv

Advertisement

Table of Contents

Summary of Contents for VARIOVISION WVS-16

- Page 1 The welding camera WVS-16 provides a sharp colour picture and allows therefore an optimal observation of welding torch, filler wire and work piece as well as welding arc and melting area.

-

Page 2: Table Of Contents

Rear side remote panel – Panel version: ..................Camera cable: ..........................Dimension Panel mount version....................8 Installation: ............................ Automatic Ext. Control: ......................... Operation: ........................... How to set camera parameter and brightness:................Changing of close up lenses......................13 Specification:..........................14 WVS-16 2/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 3: Safety Instructions

The installation of the system may be carried out only by certified staff and must correspond to the local regulations. WVS-16 3/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 4: The Welding Vision System Consists Of

AHD to HDMI HDMI converter Kat.Nr.: cable 401609 When usi ng an AHD monitor , e.g. our No. 401367 , the AHD/HDMI converter and the HDMI cable are not re qui red WVS-16 4/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 5: Connectors At Front- And Backside

M8 grub screw and 1/4 " tripod thread. This assembly adaptor can be mounted, when required, on lower or upper side of the camera. ATTENTION: The used screws must not longer then 2 mm fit into housing. WVS-16 5/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 6: Operation Panel Connectors

1 to file 2 which saves normally camera parameters during welding, i.e. zoom, sharpness and brightness. After switch ON the camera first uses an internal memory. To select saved adjustments of memory 1 or 2 press button to select. WVS-16 6/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 7: Rear Side Remote Panel - Panel Version

Contact is closed = Memory 2 → welding, Potentiometers active After switch ON the camera first uses an internal memory. To select saved adjustments of memory 1 or 2 press button to select. Camera cable: WVS-16 7/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 8: Dimension Panel Mount Version

Dimension Panel mount version: WVS-16 8/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 9: Installation

The system can therefore from the camera up to the operating panel connect to ground/earthing by the yellow/green earthing connection.. Automatic Ext. Control From Welding machine Please note: DIM-Function is only active if the contact on ext. control is closed WVS-16 9/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 10: Operation

2 different camera settings can be stored headlined. and recalled. Function button 3 see Table "Function of buttons" Drawing: 2 zone filter only at WVS-16 with 2 filter system included WVS-16 10/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... - Page 11 A is displayed on Monitor when automatic White Balance is active M is displayed on Monitor when manual White Balance is active R and B show values for each ( 0….20) WVS-16 11/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv...

-

Page 12: How To Set Camera Parameter And Brightness

After finishing the welding (i.e. If the contact on ext. Control is open) an automatic change back to file 1 happens. Potentiometer DIM is now without function. Please note: DIM-Function is only active if the contact on ext. control is closed WVS-16 12/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 13: Changing Of Close Up Lenses

For reassembling please check the polarity of the connector Now you can adjust the distance by using the various close up lenses. Please chose the close up lenses according the table above The reassembly occurs in reverse order. WVS-16 13/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv... -

Page 14: Specification

Protective Glas 402461 100 – 240 VAC to 12VDC Power Supply 402501 Tel. +49 89 23967195 Variovision Thomas Stelzl Fax +49 89 23967196 Pöttinger Straße 23 www.variovision.tv DE-82041 Oberhaching info@variovision.tv www.weldingcamera.com WVS-16 14/14 Variovision, Pöttinger Straße 23, DE-82041 Oberhaching, www.variovision.tv, info@variovision.tv...

Need help?

Do you have a question about the WVS-16 and is the answer not in the manual?

Questions and answers