Table of Contents

Advertisement

Quick Links

EN

2

Manual No. SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN

WAMGROUP S.p.A.

Via Cavour, 338

41030 Ponte Motta

Cavezzo (MO) - ITALY

SEPCOM

SIP BED Easy

CONTROL PANELS FOR

SEPCOM BEDDING

SCREW PRESS SEPARATORS

ASSEMBLY AND

MAIN INSTRUCTIONS

FOR USE AND

MAINTENANCE

Issue: A3

Latest update: July 2022

ORIGINAL INSTRUCTIONS IN ENGLISH

+ 39 / 0535 / 618111

fax

+ 39 / 0535 / 618226

e-mail

info@wamgroup.com

internet

www.wamgroup.com

®

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for WAMGROUP SEPCOM SIP BED Easy

- Page 1 MAIN INSTRUCTIONS FOR USE AND MAINTENANCE Manual No. SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Latest update: July 2022 ORIGINAL INSTRUCTIONS IN ENGLISH WAMGROUP S.p.A. + 39 / 0535 / 618111 Via Cavour, 338 + 39 / 0535 / 618226 41030 Ponte Motta e-mail info@wamgroup.com...

- Page 2 All the products described in this catalogue are manufactured according to WAMGROUP S.p.A. Quality System procedures. The Company’s Quality System, certified in July 1994 according to International Standards UNI EN ISO 9002 and extended to the latest release of UNI EN ISO 9001, ensures that the entire production process, starting from the processing of the order to the technical service after delivery, is carried out in a controlled manner that guarantees the quality standard of the product.

-

Page 3: Table Of Contents

QE SEPCOM SIP BED EASY 07.22 INDEX SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 TABLE OF CONTENTS 1.0 INTRODUCTION ............................1 1.1 Disclaimers ............................1 1.2 Symbols: meaning and use .......................1 1.3 General features ..........................2 1.4 Operating principle ..........................3 1.5 Lifting and shipment ..........................3 1.6 Storage and dismantling ........................4 2.0 APPLICATIONS ............................6... -

Page 4: Introduction

SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 1.1 Disclaimers WAMGROUP S.p.A. cannot be held responsible in case of: - Negligent handling of the low the voltage panels and non-compliance to the safety standards and wrong processing. - Lack of maintenance, non-compliance to the herein indicated Directives or improper repairs carried out with improper tools by. -

Page 5: General Features

QE SEPCOM SIP BED EASY 07.22 1.0 INTRODUCTION SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 1.3 General features The electric panel is intended for use by properly trained personnel: the installation must be designed and car- ried out only by qualified technicians. Caution Inaccurate installation or use can cause serious damage to the electric panel, to the user and to the persons involved. -

Page 6: Operating Principle

QE SEPCOM SIP BED EASY 07.22 1.0 INTRODUCTION SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 1.4 Operating principle The SEPCOM SIP BED Easy control panel manages the operating logics of the system consisting of a screw ® press separator and a pneumatic presser, in coordination with other users part of a conventional separation system, such as feeding pump, agitator and level sensors. -

Page 7: Storage And Dismantling

QE SEPCOM SIP BED EASY 07.22 1.0 INTRODUCTION SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 1.6 Storage and dismantling On storing, do not stack other items on top of the device, to avoid damaging it as well as the risk of accidental falls. Ensure the integrity of mechanical and electrical engineering parts of the electric panel during shipping. - Page 8 QE SEPCOM SIP BED EASY 07.22 1.0 INTRODUCTION SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Danger - Warning It is forbidden carrying out commissioning, maintenance operations, repairs or modifications unless entrusted to specialized personnel, under precise instructions. It is recommended to check the electric panel for integrity after unpacking; do not use it in case of any doubts.

-

Page 9: Applications

QE SEPCOM SIP BED EASY 07.22 2.0 APPLICATIONS SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 2.1 Safety distances Danger - Warning The control panel shall be placed at a safe distance from sources of heat, fuel depots, from flammable materials, chemicals. In order to limit potentially dangerous situations, isolate the area surrounding the control panel and preclude the possibility that unauthorized persons approaches the area. -

Page 10: Protection Degree

QE SEPCOM SIP BED EASY 07.22 2.0 APPLICATIONS SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Caution Evaluate if further emergency buttons are required near the utilities. It is recommended to include at least one emergency stop button with safety key to be used during equipment maintenance. -

Page 11: Safety Switches

QE SEPCOM SIP BED EASY 07.22 2.0 APPLICATIONS SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 2.4 Safety switches Caution When required by the nature of the equipment connected to the control panel, it is necessary to pro- vide specific safety switches. On opening a safety device, all dangerous movements of the equipment need to be stopped and the equip- ment must be prevented from accidentally getting restarted. -

Page 12: Mandatory Electrical Connections

QE SEPCOM SIP BED EASY 07.22 2.0 APPLICATIONS SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 2.6 Mandatory electrical connections The SEPCOM SIP BED Easy control panel can be installed in two configurations: ® MASTER = the SIP BED Easy control panel manages the plant users via the customer’s main control panel. -

Page 13: Pneumatic Connection

QE SEPCOM SIP BED EASY 07.22 2.0 APPLICATIONS SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 2.7 Pneumatic connection Item Description PID controller Air filter Air outlet towards the pneumatic presser Air inlet from the compressor Air outlet from the PID controller Condensation drain filter... -

Page 14: Commissioning

QE SEPCOM SIP BED EASY 07.22 3.0 COMMISSIONING SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Danger - Warning It is forbidden carrying out commissioning, maintenance operations, repairs or modifications unless entrusted to specialized personnel, under precise instructions. All operations must be performed in accordance with the safety regulations. -

Page 15: Setting The Operating Panel & Use

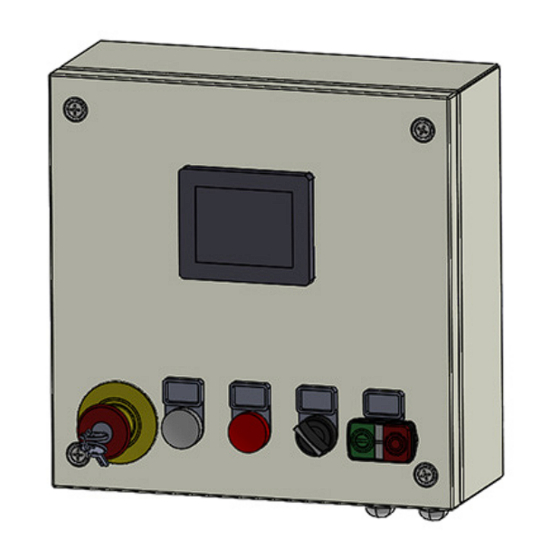

QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 4.1 How to use and set the operator panel Description PLC touchscreen panel Emergency button Power on white indicator light General alarm red warning light... - Page 16 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 4.1.2 DESCRIPTION OF THE MAIN CONTROLS Using the operator panel, the operator can select, fill in and set the various data necessary for a correct opera- tion.

- Page 17 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Control Change page (main menu) Absorption detected [Amps] Pneumatic system pressure [bar] Separator ON/OFF status Active alarms Date Time Agitator ON/OFF status Pump ON/OFF status Tap the buttons on the users side to start the corresponding electric motor: Tap the separator image to start the separator;...

- Page 18 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 4.1.2.2 Automatic cycle Use this button (no password required) to enter the automatic operation mode: Control Change page (client settings) Cycle status Change page (main menu)

- Page 19 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 When the components are managed in automatic mode, the use can check the maintenance status and select the language Only trained personnel authorized by WAM can access the maintenance and settings menu.

- Page 20 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 4.1.3 SETTINGS The settings are essential for the correct operation of the machine; they are divided into: • Operator settings, meant to modify the separator absorption;...

- Page 21 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 3) Tap in “Password” field. 4) Tap the “123” key to access the numeric keypad. Type the password provided by the installer. Tap Enter to confirm.

- Page 22 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 4.1.3.2 Operator settings On this page you can change the software language, display the version of the software installed, set the op- erating absorption of the pneumatic system, set the timer, display the operation hours on the timer expressed up to the minutes lapsed.

- Page 23 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Description Default value Previous page Grease nipple operation days / days left before maintenance is required 60 days Separator screen operation hours / hours left before maintenance is required...

- Page 24 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Screen 1 Default Description value Change page (main menu) Next page Counter-cone pressure upon separator start-up 1.0 bar Delay time between feeding pump start and separator start 5.0 sec...

- Page 25 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Default Description value Previous page Next page Correction time 4 sec Maximum pneumatic pressure when the system runs 4.9 bar Tolerance on the detected absorption of the separator -1.0 A...

- Page 26 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Screen 4 On the screen you can check the actual operation hours of each user and the maximum hours before mainte- nance is required.

- Page 27 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Screen 5 Description Previous page Software version installed Enabling the “agitator” user, if provided and connected to the control panel. If the icon is stricken out by a red line, no agitator is installed.

-

Page 28: Reset To Factory Settings

QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 4.2 Reset to factory settings To reset the PLC to factory settings, follow this procedure: 1. Note down the operation hours and the values set for each parameter by scrolling through the settings pages. -

Page 29: How To Change Time And Date

QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 4.4 How to change time and date It is recommended to set the local date and time upon each new installation in order to correctly display the alarm history on the menu. - Page 30 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 List of possible alarms, description and type: Alarm Description Type MINIMUM Minimum setpoint value has been reached Shut-down CURRENT PRESSURE Shut-down FAULT NO AIR...

- Page 31 QE SEPCOM SIP BED EASY 07.22 4.0 SETTING THE OPERATING PANEL & USE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 4.5.1 HOW TO RESET THE WARNING ALARMS 4.5.1.1 Maintenance performed In case of maintenance, follow the procedure bellow to reset the alarm: 1. Log in to the PLC of the control panel with ADMIN credentials (technician) 2.

-

Page 32: Maintenance

QE SEPCOM SIP BED EASY 07.22 5.0 MAINTENANCE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Each electric plant requires a proper and suitable maintenance, carried out by specialized skilled personnel only; this will ensure a constant and proper operation of the plant under due safety conditions. -

Page 33: Personnel Training

QE SEPCOM SIP BED EASY 07.22 5.0 MAINTENANCE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 Optimizing prevention is based on having a knowledge of the experimental data measured on plant compo- nents having similar features. The prevention is necessary in case components meant to ensure the safety of the operators involved. -

Page 34: Trouble-Shooting

QE SEPCOM SIP BED EASY 07.22 5.0 MAINTENANCE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 5.2 Trouble-shooting The personnel authorized to perform interventions in most failure cases or in cases not signalled otherwise, is an expert maintenance technician or an operator who is authorized by special training on electric and elec- tronic components. - Page 35 QE SEPCOM SIP BED EASY 07.22 5.0 MAINTENANCE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 SCENARIO CAUSES/CONDITION CORRECTIVE ACTIONS The plant was not running and the The system is working properly. level is below the maximum The level has exceeded the maxi- The agitator starts without delay when the maxi-...

- Page 36 QE SEPCOM SIP BED EASY 07.22 5.0 MAINTENANCE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 SCENARIO CAUSES/CONDITION CORRECTIVE ACTIONS Check the working of the level indicator The level displayed exceeds The separa- tor won't shut the minimum but the actual Ensure there is no material that distorts the functioning of...

- Page 37 QE SEPCOM SIP BED EASY 07.22 5.0 MAINTENANCE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 SCENARIO CAUSES/CONDITION CORRECTIVE ACTIONS The display is red and Open the panel and check what thermal protection is an error message ap- tripped pears. If the QM100 thermal protection has tripped, make...

- Page 38 QE SEPCOM SIP BED EASY 07.22 5.0 MAINTENANCE SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 SCENARIO CAUSES/CONDITION CORRECTIVE ACTIONS The water level in the Empty the tank according to the procedures of refer- The plant is shut down outlet tank is higher than ence...

-

Page 39: Aannexes

QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 A1 Electric layout Copyng of this document, and giving it to other and the use or comunications of the contents thereof, are forbidden without express authority. Offenders are liable to the payment of damages. All rights are reserved in... - Page 40 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 41 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 42 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 43 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 44 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 45 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 46 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3 BROWN WHITE...

- Page 47 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 48 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 49 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 50 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 51 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

- Page 52 QE SEPCOM SIP BED EASY 07.22 A ANNEXES SEP.QE_SEPCOM_SIP-BED-EASY--.M.A3.0722.EN Issue: A3...

Need help?

Do you have a question about the SEPCOM SIP BED Easy and is the answer not in the manual?

Questions and answers