Summary of Contents for Triple Green PRODUCTS Compac Boiler Series

- Page 1 Compac Boiler Series TGC300 Installation and Operating Instructions Manual TGC300 Indoor Chip Burning Hydronic Heater Manual Part # TGC300 Effective: October 14, 2020...

-

Page 3: Table Of Contents

Compac Boiler Series TGC300 Table of Contents Section Page Table of Contents 1. Preface 2. Introduction 3. Safety 3.1 General Safety 3.2 Operation and Maintenance Safety 3.3 Safety Alert Symbol 3.4 Safety Signs - Signal words 3.5 Safety Signs - Locations and Decals 4. -

Page 4: Preface

9.1 Warranty Statement 9.2 Warranty Exclusions and Limitations Preface Thank you for purchasing a Triple Green Products TGC300 Indoor Chip Burning Hydronic Heater. This heater has been tested and approved by the Canadian Standard Association and Underwriter Laboratories . This manual has been prepared for the owner and operators of TGC300 Indoor Chip Burning Hydronic Heater. -

Page 5: Introduction

Congratulations on your purchase of the Triple Green Products TGC300 Indoor Chip Burning Hydronic Heater. Your heater was manufactured in Canada, by Triple Green Products. Refer to the Installation and Operating Instructions Manual for all aspects regarding the safe and efficient use of your Indoor Hydronic Heater. -

Page 6: Safety

Do not use this heater for purposes other than its intended use. Intended uses are discussed in this manual. If you are unsure please contact Triple Green Products (page 5). Do not operate this heater while tired or under the influence of drugs or alcohol. -

Page 7: Operation And Maintenance Safety

Compac Boiler Series TGC300 3.2 Operation and Maintenance Safety Do not operate the heater if the temperature control system are not functioning. If water level is low, only add water to the heater when conditions are safe to do so and the heater water temperature is below 200 degrees F. - Page 8 Compac Boiler Series TGC300 enclosure. This heater produces smoke and carbon monoxide emissions. 19. Install carbon monoxide monitors for areas that are expected to generate CO, e.g., heater fueling areas, fuel bulk storage areas, sheds containing hydronic heaters. 20. ‘‘This wood chip heater has a manufacturer-set minimum low burn rate that must not be altered.

-

Page 9: Safety Alert Symbol

Compac Boiler Series TGC300 3.3 Safety Alert Symbol This Safety Alert symbol means: Attention! Become alert! Your Safety is Involved! 3.4 Safety Signs - Signal Words Familiarize yourself with the following safety notices used in this manual: DANGER: (White letters on Red background) Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury. - Page 10 Compac Boiler Series TGC300 3.5 Safety Signs - Locations and Decals Caution Always open the burn head door or upper inspection door slowly. Opening either door quickly can cause a rush of air into the burn head area resulting in flames exiting the burn head through the door.

-

Page 11: Safety Signs - Locations And Decals

Compac Boiler Series TGC300 3.5 Safety Signs - Locations and Decals, - continued Certification Label This Certification Label contains important safety and installation information. Model and Serial Number Always provide the model and serial number of your heater when ordering parts or requesting information and services. -

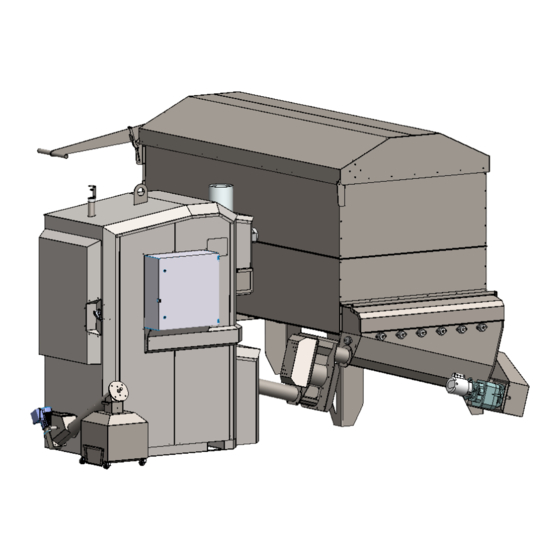

Page 12: Components Summary

Compac Boiler Series TGC300 4. Components Summary This section is to help familiarize new owners and operators to the components of the TGC300 Indoor hydronic heater. Key features and general purpose of the components are discussed. 4.1 Exterior Components The heater exterior is constructed of durable Stainless Steel sheet metal panels. Under the sheet metal is a layer of insulation keeping the exterior cool and heat loss to a minimum. -

Page 13: Front, Inside Components

Compac Boiler Series TGC300 4.2 Front, Inside Components Horizontal heat exchanger Maintenance access Fire door and latch handle. Ash Bin Ash removal auger Cover Door... -

Page 14: Interior Components Heater

Compac Boiler Series TGC300 4.3 Interior Components, Heater The exhaust fan and motor are removable for serviceability. The exhaust fan induces flow of combustion air into the heater and creates a positive exhaust flow. The heater control system regulates the fan speed to control the exhaust flow rate. -

Page 15: Interior Components Chip Bin

Compac Boiler Series TGC300 4.4 Chip Bin Components Lid Hinge Lid Lock Lid Arm Floor Auger Drive Floor Auger Main Auger Drive Main Auger... -

Page 16: Back Fire Chamber

Compac Boiler Series TGC300 4.5 Back Fire Chamber 1. Have the lid locked at all time to ensure safety of everyone. 2. If there is a Jam in the back fire chamber, open the lid or the access cover to clean. -

Page 17: Installation

Compac Boiler Series TGC300 5. Installation 5.1 Handling Crushing Hazard to prevent serious injury or death. Use extreme caution while handling heater with forklift, hoist, crane or overhead lifting device. Do not, for any reason, place your body or body parts under the heater while suspended. Use extreme caution when heater is suspended above the floor for any reason. -

Page 18: Indoor Installation Notes, Clearances And Chimney

Compac Boiler Series TGC300 5.2 Indoor Installation Notes, Clearances and Chimney Note: Installation is to be performed by a qualified installer and will comply with all requirements of the AJH (Authority having jurisdiction). All installations must be done following applicable building, plumbing, electrical and fire codes. -

Page 19: Electrical Connections

Compac Boiler Series TGC300 5.3 Electrical Connections Note: Installation is to be performed by a qualified installer and will comply with all requirements of the AJH (Authority having jurisdiction). All installations must be done following applicable building, plumbing, electrical and fire codes. -

Page 20: Plumbing Connections

Compac Boiler Series TGC300 5.4 Plumbing Connections Note: Installation is to be performed by a qualified installer and will comply with all requirements of the AJH (Authority having jurisdiction). All installations must be done following applicable building, plumbing, electrical and fire codes. - Page 21 Compac Boiler Series TGC300 Note: The following four points of discussion and schematics are provided as a guideline only. EXISTING FORCED AIR SYSTEM Install a water to air heat exchanger into your existing forced air system. Separate thermostatic controls for the existing and newly install system are recommended. Your existing heater remains as a back-up.

- Page 22 Compac Boiler Series TGC300 CONNECTION TO A NEW BASEBOARD SYSTEM Install a new baseboard and Triple Green Products heater. DOMESTIC WATER HEATER AND HEATING SYSTEM In addition to comfort heating, the heater system may be connected to heat domestic hot water using a side arm heater.

-

Page 23: Water Fill And Corrosion Protection

Compac Boiler Series TGC300 5.5 Water Fill and Corrosion Protection Please consult your dealer to obtain the specifications for products referred to in the following points on water fill and corrosion protection. • Use only good quality water. Do not use water with iron, minerals, or hard water. Do not use reverse osmosis water. - Page 24 Compac Boiler Series TGC300 Operation Important: Prior to operation, review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. 6.1 Controls and Settings ‘‘This wood chip heater needs periodic inspection and repair for proper operation. It is against federal regulations to operate this wood heater in a manner inconsistent with operating instructions in this manual.’’...

-

Page 25: Additional Installation Requirements For Canadian Installations

Compac Boiler Series TGC300 5.7 Additional Installation Requirements for Canadian Installations • If fans are installed in the fuel storage area they should not create negative pressures in the room where the solid fuel-burning appliance is located. • "DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE". - Page 26 Compac Boiler Series TGC300 Important: Prior to operation review Safety section 3. Understand all safety messages in this manual and Warning Decals on the heater. differential produces the maximum exhaust fan modulation. To change the Blower Differential, press SET until the Indicator Digit displays “b”...

-

Page 27: Recommended Wood Fuels

Warning Decals on the heater. 6.2 Recommended Wood Chip Fuels Triple Green Products heaters are designed to burn wood chip fuel only. Liquid fuels are prohibited. Adding liquid fuel or oils to this heater is dangerous and can lead to serious injury and/or damage the heater. - Page 28 Compac Boiler Series TGC300 Important: Prior to operation, review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. • The type of wood chip fuel is a mater of personal choice and may be based on cost and availability.

-

Page 29: Starting And Maintaining A Fire

Compac Boiler Series TGC300 Important: Prior to operation, review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. 6.3 Starting and Maintaining a Fire Prior to starting or maintaining a fire: Ensure that the Master switch is “on” and the control settings are set. -

Page 30: Information On Creosote And Cleaning

Compac Boiler Series TGC300 Important: Prior to operation, review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. Reducing Visible Emissions: • Visible emissions may include smoke and/or steam. Typically, emissions are only visible on start-up and during extended periods of running on minimum output. -

Page 31: Operational Trouble Shooting

Compac Boiler Series TGC300 Important: Prior to operation, review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. 6.5 Operational Trouble Shooting Problems related to operation or performance can often be traced back to maintenance issues. -

Page 32: Additional Instructions For Canadian Requirements For Add-On Boilers

Compac Boiler Series TGC300 Important: Prior to operation, review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. 6.7 Additional Instructions for Canadian Requirements for add-on boilers • OPERATE THE BOILER PERIODICALLY TO ENSURE THAT IT WILL OPERATE SATISFACTORILY WHEN NEEDED. -

Page 33: Maintenance

Compac Boiler Series TGC300 Important: Prior to preforming any maintenance review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. Maintenance ‘‘This wood chip heater needs periodic inspection and repair for proper operation. It is against federal regulations to operate this wood chip heater in a manner inconsistent with operating instructions in this manual.’’... -

Page 34: Ash Removal And Reaction Chamber Cleaning

Compac Boiler Series TGC300 Important: Prior to preforming any maintenance review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. Ash Removal and Reaction Chamber Cleaning Ash removal is performed automatically and set on a timer inside the electrical box. -

Page 35: Nozzle Inspection

Compac Boiler Series TGC300 Important: Prior to preforming any maintenance review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. Fan Inspection There are two fans on this heater, the burn head fan and the exhaust fan. Both fans should be inspected to ensure they are working. -

Page 36: Refractory Inspection And Replacement

Compac Boiler Series TGC300 Important: Prior to preforming any maintenance review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. 7.4 Refractory Inspection and Replacement The refractories are consumable items. The life expectancy of refractories cannot be predicted by usage or specified period. -

Page 37: Burn Head Inspection And Replacement

Compac Boiler Series TGC300 Important: Prior to preforming any maintenance review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. 7.6 Burn Head Inspection and Replacement The burn head components are consumable items. The life expectancy of burn head cannot be predicted by usage or specified period. -

Page 38: Off Season (Preparing Heater For Summer Shut Down)

Compac Boiler Series TGC300 Important: Prior to preforming any maintenance review Safety, Section 3. Understand all safety messages in this manual and Warning Decals on the heater. 7.8 Off Season (Preparing Heater for Summer Shut Down) Please consult your dealer to obtain the off season service products and detailed repair procedures. -

Page 39: Electrical Schematic

Compac Boiler Series TGC300 7.9 Electrical Schematic The following schematic for the electrical control box and is provided for reference only. Please consult your dealer to obtain the service parts as required and detailed repair procedures. Use copper wiring only when connecting to supply power... - Page 40 Compac Boiler Series TGC300...

- Page 41 Compac Boiler Series TGC300...

- Page 42 Compac Boiler Series TGC300...

-

Page 43: Specifications

Compac Boiler Series TGC300 Specifications *Specifications are subject to change without notice. MODEL TGC300 Heat Output, (EPA phase II ) 300,000 BTU CAN/CSA B 366.1-M91 UL 391-2006 and 726-2006 Weight (shipping, dry), Heater and Bin 5380 lbs Estimated weight for foundation (water filled and... -

Page 44: Efficiency And Emissions

Compac Boiler Series TGC300 8.2 Efficiency and Emissions The efficiency and emission values presented here were determined through live testing. The testing agency is: Intertek of Middleton, WI The heat value given to the wood chip fuel (input) varies between sample, wood chip condition and wood chip type. -

Page 45: Warranty

Warranty 9.1 Warranty Statement Triple Green Products warrants every product it sells. If one of our heaters needs service or repair, one of our factory authorized agents in the Canada or United States can assist in making a warranty claim, finding replacement parts or finding a qualified repair technician. - Page 46 This heater is not intended to be the only source of heat; therefore, it is recommended that a back- up system be in place to prevent damages caused by lack of heat. Triple Green Products is not liable for any accidents which may occur from the operation of the heater, or damages incurred due to heating system failure.

-

Page 47: Warranty Exclusions And Limitations

Compac Boiler Series TGC300 9.3 Warranty Registration Card Purchaser’s Name: Address: Phone: Model: Serial No. Date of Purchase: Dealer: Address: Dealer’s Signature: Date: “I have read, understood and accept the conditions of this Warranty and Warranty Exclusions and Limitations.” (pages 3 and 4).

Need help?

Do you have a question about the Compac Boiler Series and is the answer not in the manual?

Questions and answers