Summary of Contents for Jevatec JEVAmet

- Page 1 ® JEVAmet IOM Active hot chathode ionisation gauge Instruction Manual BA_IOM_02.2018_EN...

-

Page 3: Table Of Contents

Contents Contents List of Figures List of Tables Legal Instructions Validity Scope of Delivery Conventional Application Responsibility and Warrenty Transport Damages Safety General Information Signs and Symbols Basic Safety Regulations Technical Product Description Function Measuring Principle Technical Data Vacuum Measurement Sensor Emission Degassing... - Page 4 Installation Mechanische Installation Electrical Installation 5.2.1 Rear of the Instrument 5.2.2 Input / Output Operation Operating Modes and Error Conditions (LED “Mode”) Readiness for Operation Measuring Mode (Emission) Analog Output Emission Current Degas Mode Selection oft he Filaments Dependence on the Gas Type Maintenance and Service Maintenance 7.1.1...

-

Page 5: List Of Figures

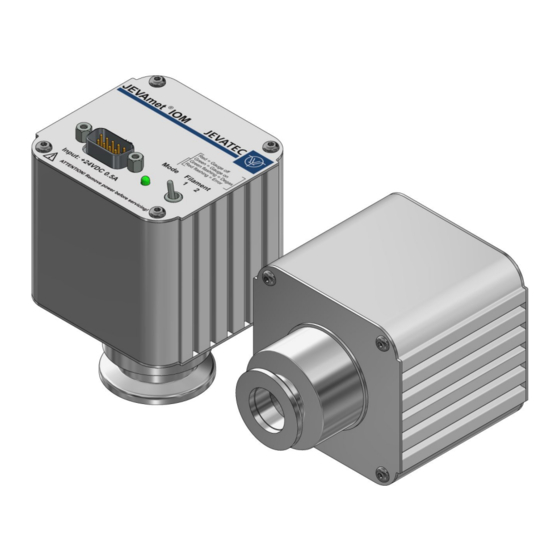

® IOM (in mm) Figure 3 – Rear of the Instrument Figure 4 – Connector for Input / Output (D-SUB, 9 pin, male) Figure 5 – Schematic design of the JEVAmet ® List of Tables Table 1 – Part numbers Table 2 –... -

Page 6: Legal Instructions

We assume the warranty for the faultless function of the device for one year. All in material and manufacturing defects will be cleared free of charge within this period. The JEVATEC GmbH will not assume any responsibility or warranty in case the operator or third persons •... -

Page 7: Transport Damages

Transport Damages • Check the packaging for visible damages • Send an advice of damage to the carrier and to the insurer in case of damage • Retain the packaging material, because the reconsignment in the original packaging of the manufacturer is prerequisite for warranty claims •... -

Page 8: Safety

IOM is delivered ready for operation. Even so, we recommend that you carefully read these Operating Instructions so as to ensure optimum operating conditions right from the start. This manual contains important information for understanding, installing, ® commissioning, operating and troubleshooting the JEVAmet IOM. Signs and Symbols DANGER or WARNING: Information on the prevention of injury. -

Page 9: Technical Product Description

At lower pressures the measurement ® range is primarily limited by the geometry of the sensor. For the JEVAmet IOM sensor the low-pressure limit is in the range of < 5∙10... -

Page 10: Technical Data

Technical Data Vacuum Measurement – 5∙10 Measuring Range: 5∙10 mbar Measuring Principle: Hot Cathode Ionization (Bayard-Alpert) Sensitivity for N ca. 16 mbar Accuracy: typically ± 20% of reading Reproducibility: ± 5% of reading Sensor Mounting Position: Arbitrary Filaments (Cathodes): Ir coated with Y Number of Filaments: Filament Operation Modes: Manual Switching via Toggle Switch... -

Page 11: Analog Output Signal

Analog Output Signal 0 – 10.5 V DC Output Voltage: Error Signal: > 9 V: Emission Off Measuring Range: 0 V = 1∙10 mbar; 8.7 V = 5∙10 mbar Relation Between Voltage logarithmic, 1 V / Decade (U-10) and Pressure: p = 10 [mbar] U = 1∙lg(p/10... -

Page 12: Environment

96.5 mm Width: 72.7 mm Depth: 66.0 mm Weight: 0.3 kg Figure 2 – Dimensions JEVAmet ® IOM (in mm) 4.11 Standards • Compliance with EMC Directive 2014/30/EU • Compliance with RoHS Directive 2011/65/EU • Compliance with WEEE Directive 2012/19/EU International/national standards as well as specifications: •... -

Page 13: Installation

It is recommended to choose a mounting location with unimpeded airflow. During bakeout ® of the vacuum chamber for achieving very low pressures the JEVAmet IOM should be mounted in a way so that the convection heat of the heated vacuum chamber does not significantly heat up the instrument. -

Page 14: Electrical Installation

Electrical Installation 5.2.1 Rear of the Instrument ® Figure 3, page 14 is showing the rear of the JEVAmet IOM. The pin assignment of the connector as well as the operating and display elements are described in the following chapters. -

Page 15: Operation

Instrument is not ready for operation. The polyswitch fuse has been activated. Disconnect the instrument from the voltage supply and reconnect. If the fuse is activated again there is a failure of the electronics. Please contact JEVATEC. Red blinking Emission error. Automatic deactivation of the emission. -

Page 16: Measuring Mode (Emission)

Measuring Mode (Emission) Start the emission as follows: • Apply LOW level on pin 1 of the input / output connector ( Figure 4, page 14). • The LED “Mode” lights up green. Stop the emission as follows: • Disconnect pin 1 of the input / output connector (... -

Page 17: Degas Mode

The pressure reading serves as an orientation about the cleaning ® procedure but is beyond the accuracy specifications of the JEVAmet IOM. By degassing of the sensor, the contaminations are removed to a large extent. -

Page 18: Maintenance And Service

Contaminated products (e.g. radioactive, toxic, caustic or microbiological hazard) can be detrimental to health and environment. Products returned to JEVATEC should preferably be free of harmful substances. Adhere to the forwarding regulations of all involved countries and forwarding companies and enclose a duly completed declaration of contamination You will find the copy template in the appendix 2 of this manual. -

Page 19: Troubleshooting

If the malfunction persists even after having switched on and off the instrument several times and/or having replaced the sensor, please contact JEVATEC. 7.2.2 Repair Defective products must be sent to JEVATEC. JEVATEC will not assume any responsibility ® or warranty in case the operator or third persons repair the JEVAmet IOM. -

Page 20: Storage And Waste Disposal

Preferably in a sealed plastic bag with desiccant. Waste Disposal Regarding waste disposal, the branch specific and local waste disposal and environment protection regulations for systems and electronics components are valid. In case of return JEVATEC will execute the professional resource separation and disposal. BA_IOM_02.2018_DE... - Page 21 The manufacturer can refuse to accept any equipment without a declaration. A separate declaration has to be completed for each single article. For diagnosis and shipping by JEVATEC costs will be incurred. Please consider also the safety information on the back of this declaration! This declaration may be completed and signed only by authorized and qualified staff.

-

Page 22: Vacuum Devices And Components

Declaration of Contamination FB6001 JEVATEC Seite Ideen in der Vakuumtechnik 2 von 2 Safety information for returning contaminated vacuum engineering (vacuum measuring instruments, vacuum pumps and vacuum components) General Information According to German laws, every employer is held responsible for the health and safety of his employees. -

Page 23: Annex 2 - Eu Declaration Of Conformity

EU Declaration of Conformity We, the JEVATEC GmbH, hereby declare that the products specified and listed below which we have placed on the market, comply with the applicable EU Council Directives. This declaration becomes invalid if modifications are made to the product without agreement with us. Compliance with the EMC Directives requires that the components are installed within a system or machine in a manner adapted to the EMC requirements. - Page 24 JEVATEC GmbH Schreckenbachweg 8 07743 Jena GERMANY Phone: +49 3641 3596-0 Fax: +49 3641 3596-39 E-mail: info@jevatec.de...

Need help?

Do you have a question about the JEVAmet and is the answer not in the manual?

Questions and answers