Table of Contents

Advertisement

Quick Links

Argus HSG-E01

Kaba Gallenschütz GmbH

Nikolaus-Otto-Straße 1

D-77815 Bühl (Baden)

Technical documentation

Argus HSG

Tel +49 (0) 7223 / 286-0

Fax +49 (0) 7223 / 286-111

www.kaba-gallenschuetz.de

e-mail: info@kgb.kaba.com

Argus HSG-L01

As at: 28.07.2008

Document number: 30656E--

We reserve the right to make

technical modi cations.

Advertisement

Table of Contents

Summary of Contents for Kaba Argus HSG-E02

- Page 1 Technical documentation Argus HSG Argus HSG-E01 Argus HSG-L01 Kaba Gallenschütz GmbH Tel +49 (0) 7223 / 286-0 As at: 28.07.2008 Nikolaus-Otto-Straße 1 Fax +49 (0) 7223 / 286-111 Document number: 30656E-- D-77815 Bühl (Baden) www.kaba-gallenschuetz.de We reserve the right to make e-mail: info@kgb.kaba.com...

-

Page 2: Table Of Contents

Technical documentation Argus HSG Table of contents General ..............................7 Product description ..........................9 Important information on the product ..................9 1.1.1 Overview ..........................9 1.1.2 Purpose ............................ 9 1.1.3 Important information ......................10 1.1.4 Labelling of the product ......................11 1.1.5 Manufacturer’s declaration ..................... - Page 3 Technical documentation Argus HSG 2.6.1.3 Carrying out the expert inspection..................26 2.6.1.4 Documenting the expert inspection in the inspection book ............ 26 2.6.2 Detection of faults........................26 Construction and functions ....................... 27 Location and function of the most important components ............. 27 3.1.1 Protective sensors ........................

- Page 4 Technical documentation Argus HSG Cleaning ............................... 43 Safety instructions ........................43 Cleaning intervals ........................43 Cleaning agents ........................43 Maintenance and fault repair by the operator .................. 45 Carrying out maintenance ...................... 45 Maintenance tasks ......................... 45 6.2.1 Inspection of unit’s condition ....................45 6.2.2 Inspection of the sensors .......................

- Page 5 Technical documentation Argus HSG Commissioning ........................... 61 10.1 Commissioning sequence ....................61 10.2 Function test of the unit with protocol ..................61 10.3 Cleaning ..........................61 Maintenance............................63 11.1 General ..........................63 11.1.1 Maintenance intervals ......................63 11.1.2 Tools and auxiliaries ....................... 63 11.2 Maintenance tasks .........................

- Page 6 Technical documentation Argus HSG...

-

Page 7: General

SYMBOLS Notes or useful tips ABBREVIATIONS Important information. Companies and associations You must follow this information. KGB Kaba Gallenschütz GmbH, Bühl DANGER KGS Kaba Gilgen AG, Schwarzenburg Incorrect actions could lead to injuries or International Electrotechnical Commission material damage. International Classi cation for Standards Result of an action, e.g. - Page 8 KGB shall not be liable for damages resulting from incorrect action. Retain the documentation Please store the documentation in a safe place. It contains important information for the operator or the specialist personnel. Note on copyright © Kaba Gallenschütz GmbH 30656E--...

-

Page 9: Product Description

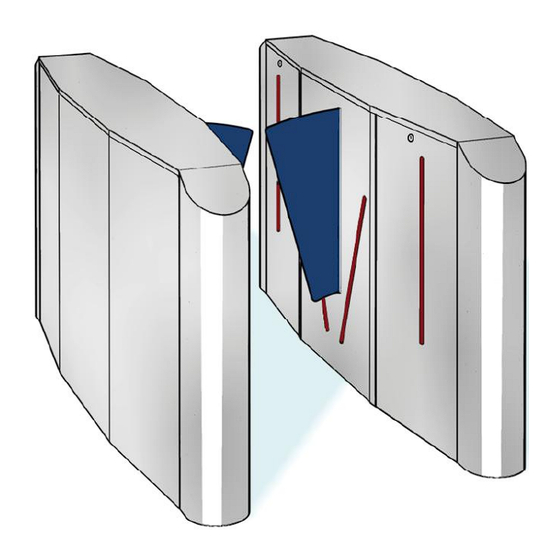

Technical documentation Argus HSG Product description This section provides basic information on the product and its proper use. Important information on the product Fig. 1.1.1-1 1.1.1 Overview Guide elements Door element Card reader (optional) Keypad (optional) OPL control unit (optional) Light (red/green) (optional) Fig. -

Page 10: Important Information

Technical documentation Argus HSG 1.1.3 Important information Annual expert inspection For systems that are subject to BGR 232 and DIN 18650, an annual expert inspection must DANGER be carried out. However, this only relates to Risk of injury with insuf cient protective the safety of use for passers-by and is docu- equipment mented in an inspection book. -

Page 11: Labelling Of The Product

Technical documentation Argus HSG 1.1.4 Labelling of the product Various labels are af xed to the unit as a whole and to certain components, e.g. the drive or control unit. These must not be re- moved or damaged. Name plate Serial number (= plant number ): The entire order is saved under this number in KGB’s records. - Page 12 Technical documentation Argus HSG Fig. 1.1.5-1 30656E--...

- Page 13 Technical documentation Argus HSG Fig. 1.1.5-2 30656E--...

- Page 14 Technical documentation Argus HSG Fig. 1.1.5-3 30656E--...

-

Page 15: Performance Characteristics

Technical documentation Argus HSG 1.2 Technical data Mechanical properties • M05 drive motor 1.2.1 Performance characteristics Electrical properties • Types of unit Primary 100 - 230 V AC, 150 VA • • Argus HSG-E01 Secondary 24 V VDC, 5 A •... -

Page 16: Classification In Accordance With Din 18650

Technical documentation Argus HSG 1.2.2 Classification in accordance with 1.2.2 Climate class of the unit in DIN 18650 accordance with IEC 721-3-3 Fixed use; weatherproof/for indoor use 0 1, 2 1, 2, 4 • Material : Stainless steel 1.4301, AISI 304 •... -

Page 17: Equipment

Technical documentation Argus HSG Equipment 1.3.1 Design versions Argus HSG-E01 Argus HSG-L01 all unit versions • no slide mounting • various bottom sides optional Argus HSG-E01 • Fig. 1.3.1-1 Standard upper edge 1200 mm • Option of increasing upper edge to 1800 mm •... - Page 18 Technical documentation Argus HSG 30656E--...

-

Page 19: Safety Instructions

Technical documentation Argus HSG Safety instructions Safety instructions refer to hazards and residual risks that exist even when using the product as intended. Warnings are given of obvious misuse. This section contains general safety instruc- Fig. 2.1.1-1 tions that must generally be followed. Speci c safety instructions for particular situ- ations are given in the respective sections directly before the step described. -

Page 20: Safety Concept

Technical documentation Argus HSG 2.1.3 Safety concept Only operate the product in perfect condition: You are obliged to use the unit, the drive and The product represents the latest technology and the locking mechanism in accordance with complies with accepted safety standards. In spite of these operating instructions. -

Page 21: General Safety Measures

Technical documentation Argus HSG 2.1.3.1 General safety measures Systems for identifying individuals are designed in accordance with the following criteria: • maximum throughput of persons • highest possible level of personal protection • identi cation of persons • high level of monitoring These criteria cannot always be reconciled with one another. -

Page 22: Safety Categories

Technical documentation Argus HSG 2.1.3.2 Safety categories Protective sensors S2 and S3 Safety sensors S1 and S4 The protective and safety features comply with the identi cation and detection level required for safety category 2. Fig. 2.1.3.1-1 Safety category 2 Suitable for public areas. -

Page 23: Correct Use

Technical documentation Argus HSG 2.2.4 Particular user groups/change in use DANGER Risk of accident as a result of an incorrect risk assessment or failure to carry out a DANGER risk assessment Risk of injury for particular user groups To avoid accidents, please note: Carry out a risk assessment before ordering Depending on the type of use, e.g. -

Page 24: Technical Dangers

Technical documentation Argus HSG Technical dangers 2.4.1 Safety instructions for automatic door systems Technical dangers are principally of relevance for specialist personnel. They arise during De nition: Expert maintenance and servicing. Someone is an expert if he/she has acquired the required knowledge concerning the safe operation: DANGER Risk of injury from electric current... -

Page 25: Carrying Out The Initial Inspection

Technical documentation Argus HSG • The outcome and all further inspections are documented in the inspection book. see Section 2.5.1.4 Documentation of the expert inspection in the inspection book Expert inspections may only be performed by persons with knowledge of and the ability to apply the national and international regula- tions on personal safety KGB offers appropri- ate training sessions for expert inspections. -

Page 26: Carrying Out The Expert Inspection

The operator makes one copy of the signed • inspection list. The inspection list must be stored The inspector requests that the Kaba partner for at least one year, in accordance with DIN responsible draws up an offer for the work. -

Page 27: Construction And Functions

Technical documentation Argus HSG Construction and functions Location and function of the most important components Guide elements Door element Card reader (optional) Keypad (optional) OPL control unit (optional) Light (red/green) (optional) Safety features Finger protection curtain on door rim at upper edge of housing S2 protective sensor to monitor exterior of door leaf... -

Page 28: Opl Control Unit

Technical documentation Argus HSG 3.1.2 OPL control unit Key for permanent release, incoming* Block key Key for permanent release, outgoing* Key for single release, incoming Release key Key for single release, outgoing * Depending on the unit settings, this key may also trigger permanent opening. -

Page 29: Card Reader (Optional)

Technical documentation Argus HSG Operating modes Home position all off • In day mode, the light is off where there is no The operating modes can be divided into basic func- release. tions and may be triggered by various systems such •... -

Page 30: Operation/Functions

Technical documentation Argus HSG Operation/functions authorised person in this location authorised person has left this location Fig. 3.6-1 unauthorised person in this location unauthorised person has left this location The symbols shown in Fig. 3.6-1 and Fig. 3.6-2 are used in Fig. 3.6.1-1 to Fig. 3.6.3.2-3 Fig. -

Page 31: Permanent Release/Outgoing

Technical documentation Argus HSG 3.6.1.3 Permanent release/outgoing The following section explains the procedure for selecting the permanent release func- tion, incoming. When the permanent release function, outgoing, is selected, the process is carried out in the opposite direction. Prerequisites: • Light is in home position. -

Page 32: Permanently Open Incoming/Outgoing

Technical documentation Argus HSG 3.6.1.5 Permanently open incoming/outgoing The following section explains the procedure for selecting the permanently open function, incoming. When the function permanently open, outgoing, is selected, the door opens outwards. Prerequisites: • Door element closed • Lights off (standard) Select permanently open, incoming. -

Page 33: Day And Night Mode

Technical documentation Argus HSG 3.6.2 Day and night mode 3.6.2.1 Night mode (standard) The door element is closed as standard. Select night mode function. Door element remains closed. Select individual release, outgoing. Lights: inner green, outer red. Sensor is activated (run mode via sensor). -

Page 34: Monitoring Movement Of Door Leaves

Technical documentation Argus HSG Unauthorised attempt at passage The door element is closed as standard. Select day mode function. Door element opens and remains open. Unauthorised person activates sensor. Door element closes if sensors S2 + S3 are not allocated. Lights: outer red, inner red. -

Page 35: Monitoring During Opening Of The Door Element

Technical documentation Argus HSG 3.6.3.1 Monitoring during opening of the door element Door element opens Door element opens. Protective sensor S2 or S3 is activated. Door element opens fully. Activation of protective sensor S2 or S3 has no in uence on the opening of the door element. -

Page 36: Monitoring During Closing Of The Door Element

Technical documentation Argus HSG 3.6.3.2 Monitoring during closing of the door element Door element closes; range 0 % - 10 % Door element closes. Protective sensor S2 or S3 is activated. Door element opens again. Door element closes; range 10 % - 90 % Door element closes. -

Page 37: Matrix Of Functions

Technical documentation Argus HSG 3.6.4 Matrix of functions Explanation of the matrix of functions using an example: Function Sensors Using examples, the following matrix explains how the unit behaves in various situations. > Meaning of the symbols: • Permanent release, incoming, is selected. •... - Page 38 Technical documentation Argus HSG Night mode (Standard, door closed in home position) Function Sensors Signal Door Comment Out- Inside Alarm side > < ---- Alarm upon entering the unit -- -- > Green Sensor-controlled opening < -- -- > -- -- <...

- Page 39 Technical documentation Argus HSG Day mode (door open in home position) Function Sensors Signal Door Comment Out- Inside Alarm side > < ---- Alarm upon entering the unit > Green -- -- Door remains open. < ---- Door closes. > ---- Door closes.

-

Page 40: Exchange Of Signals With Other Assembly Sections

Technical documentation Argus HSG Exchange of signals with other Parameter settings at the sensor assembly sections gate • The properties of the unit are determined by the Standard relay contacts and transistor outputs (24 unit software and what are known as parameters. VDC) are available for feedback signals, e.g. -

Page 41: Safety Features

Technical documentation Argus HSG Safety features Any modi cations with a negative impact on safety, however slight, are unacceptable. Unauthorised modi cations made to the unit shall exclude any liability of the manufacturer. Protective/safety sensors Fig. 4.1-1 50 mm Protective sensors S2 and S3 Safety sensors S1 and S4 The sensors are set and tested in the factory. - Page 42 Technical documentation Argus HSG Place secured Upper edge of the housing at the door rim Type of danger Squashing of ngers Operating principle • Door leaf in closed position: Finger protection curtain covers the upper edge of the housing at the door rim and prevents people reaching into this area.

-

Page 43: Cleaning

Technical documentation Argus HSG Cleaning Material Cleaning agents Stainless steel Inox Top, Kaba item No. 19110045 Safety instructions Anodised aluminium Inox Top, Kaba item No. 19110045 plastic-coated surfaces or Final Touch, Kaba item plastic surfaces No. 19110043 DANGER Electric shock if electrical parts come into... - Page 44 Technical documentation Argus HSG 30656E--...

-

Page 45: Maintenance And Fault Repair By The Operator

Technical documentation Argus HSG Maintenance and fault repair by the operator Carrying out maintenance The Argus HSG may only be maintained by specialist personnel. see Section 2.4 Quali cation of specialist personnel Maintenance tasks The maintenance tables below show which maintenance tasks must be carried out, and at what intervals. -

Page 46: Inspection Of The Blocking Function

Technical documentation Argus HSG 6.2.3 Inspection of the blocking function Activity Comment Door closed in home position. Carry out inspection for both directions. Select blocking mode. Lights: Inner red, outer red. Step into the unit. Alarm is triggered. Door cannot be opened. 6.2.4 Inspection of the permanent release function... -

Page 47: Inspection Of The Night Mode Function

Technical documentation Argus HSG 6.2.6 Inspection of the night mode function Activity Comment Door closed in home position Carry out inspection for both directions. Select night mode (day mode off). Generate release (using card reader or sensor). Lights: Direction of passage green, opposite direc- tion red. -

Page 48: Elimination Of Faults

Technical documentation Argus HSG Elimination of faults The following list is intended exclusively for operators and describes faults that can be detected and eliminated without specialist knowledge. DANGER Only have technical faults resolved by specialist personnel Incorrect actions can lead to physical injury, e.g. -

Page 49: Malfunction - No Release

Technical documentation Argus HSG 6.3.3 Malfunction - no release Fault Cause Remedy No release Sensor dirty Clean sensor. Sensor faulty Inform customer service department. Reader device faulty Deactivate blocking function. 6.3.4 Malfunction - door element does not block when function is selected Fault Cause Remedy... - Page 50 Technical documentation Argus HSG 30656E--...

-

Page 51: Prerequisites For Installation

Technical documentation Argus HSG Prerequisites for installation This section looks at the issues that must be dealt with before installation. Requirements relating to the installation site The environmental conditions set out in the climate classi cation must be observed. see Section 1.2.2 Climate class of the unit in accordance with IEC 721-3-3 The ground must be suitable for dowelling the unit. -

Page 52: Tools And Auxiliaries

Technical documentation Argus HSG Tools and auxiliaries The tools for installation and for maintenance and service are largely identical. Standard tools • Percussion drill • Stone drill Ø 12 mm • Spirit-level • 2 m folding rule • Screwdriver (cross-head): No. 2 •... -

Page 53: Cabling The Components Onsite

Technical documentation Argus HSG Cabling the components onsite DANGER Risk of injury from electric current Only allow electrical work to be carried out by specialist personnel. Comply with the national regulations. Observe local particularities in energy provision. For installation instructions for the mechanical components, see Section 9.1.1 Cabling with individual units. - Page 54 Technical documentation Argus HSG 30656E--...

-

Page 55: Installation Of Mechanical Components

Technical documentation Argus HSG Installation of mechanical components DANGER Risk of injury during installation Ensure that the safe separation distances are observed during installation, in order to avoid places where there is a risk of squashing. Standard units are completely assembled in the factory. -

Page 56: Installation On Finished Floors

Technical documentation Argus HSG Installation on finished floors The unit is installed on the nished oor using an- chor rods. Fig. 8.2-1 shows the dimensions of the sub-structure in cm. Fig. 8.2-1 30656E--... -

Page 57: Installation Of Electrical Components

Technical documentation Argus HSG Installation of electrical components Installation of hardware DANGER Risk of injury from electric current Only allow electrical work to be carried out by specialist personnel (see Section 2.4 Quali cation of service personnel). Comply with the national regulations. Observe local particularities in energy provision. -

Page 58: Installation Of Software

Technical documentation Argus HSG one oating contact per direction of passage (at KGB) or control of the card reader in line with the system supplier’s speci cations If the identi cation system required additional feedback signals, further cables are required. Mains supply line The mains supply line must be laid in accord- ance with the line lengths stipulated in the... -

Page 59: Unit Software

Technical documentation Argus HSG 9.2.2 Unit software The software is imported onto every ETS 21. The transfer takes place via an RS 232 interface, with the aid of computer. The program MSK-Termi- nal is required to download the unit software. The latest unit software can be requested via the customer service department. -

Page 60: Software Flap Control Center (Fcc) For Unit Parameterisation

Technical documentation Argus HSG 9.2.3 Software Flap Control Center (FCC) Wait until the acknowledgement <MSK534...> appears on the screen. for unit parameterisation Select Download, then select the unit software from the Windows directory (e.g. KABA_Flap\ Detailed information on the programmable FlapSoftware\FLAP_V9.8.19.mhx), and down- functions in the Flap Control Center (FCC) load the appropriate le. -

Page 61: Commissioning

Technical documentation Argus HSG Commissioning 10.3 Cleaning For information on cleaning, see Section 5 For commissioning, the unit must be in a safe Cleaning condition. To ensure this, an expert inspection is necessary. The Argus HSG may only be commissioned by specialist personnel. - Page 62 Technical documentation Argus HSG 30656E--...

-

Page 63: Maintenance

Technical documentation Argus HSG Maintenance 11.2 Maintenance tasks The maintenance tables below show which The Argus HSG may only be maintained by maintenance tasks must be carried out, and specialist personnel. at what intervals. see Section 2.4 Quali cation of specialist personnel Regular maintenance maintains operating safety and long-term reliability, thereby aiding... -

Page 64: Inspection Of Unit's Condition

Technical documentation Argus HSG 11.2.1 Inspection of unit’s condition Activity Comment Carry out visual inspection for external damage. X In the event of severe damage, notify the operator of the faults and, if appropriate, make an offer for repairs. Carry out visual inspection for internal damage. Check cabling for squashed cables or loose con- nections. -

Page 65: Check On Running Behaviour

Technical documentation Argus HSG 11.2.4 Check on running behaviour Activity Comment Disconnect power to the unit. If the door does not run smoothly, it may be neces- sary to change the drive. Move the door leaf by hand. Door leaf runs smoothly. 11.2.5 Function test of locking mechanism Activity Comment... - Page 66 Technical documentation Argus HSG 30656E--...

-

Page 67: Fault-Finding

Technical documentation Argus HSG Fault-finding 12.1.1.2 Possible sources of faults In principle, two types of fault- nding are pos- This section describes sible: • The principles for understanding the unit • Searching on the basis of symptoms, e.g.: from an electrical perspective. Can the door elements be moved freely? •... -

Page 68: Service Case - Door Elements Can Be Moved Freely

Technical documentation Argus HSG 12.2.1 Service case - door elements can be moved freely Fault Cause Remedy The door element of Motor cable is faulty Control board faulty. unit can be moved freely Inspect cable and plug Replace control board (ETS 21cc). 12.2.2 Service case - unit blocked Fault Cause... -

Page 69: Service Case: Irregular Running Behaviour

Technical documentation Argus HSG 12.2.5 Service case: irregular running behaviour Fault Cause Remedy Runs too fast/too slowly Parameters not set correctly Check parameters and re-enter them. Motor faulty Detach motor cable and push on again by hand. Check whether motor is sluggish. Shaft encoder faulty Check shaft encoder LED on ETS 21. -

Page 70: Service Tasks

Technical documentation Argus HSG 12.3 Service tasks 12.3.1 Service task - replace sensors Sensor tting Setscrew with hexagon socket Sensor panel Button cell Clip closure Sensor connection Replace sensor panel Disconnect voltage to unit. Unscrew the covering plate. Using an allen key, loosen the two setscrews on the sensor ttings. -

Page 71: Service Task - Replace Motor

Technical documentation Argus HSG 12.3.2 Service task - replace motor Spline shaft (not visible) Motor Clamping screw Opening in holding plate Holding plate Front xing screws Shock absorber Replace motor Disconnect voltage to unit. Unscrew the clamping screw until the thread is no longer visible in the opening of the holding plate. -

Page 72: Service Task - Replace Motherboard

Technical documentation Argus HSG 12.3.3 Service task - replace motherboard Fixing points Plug connections Replace motherboard Save the set unit parameters with FCC (<Save project> button). Switch off the unit. Loosen the plug connections. Loosen the board at the xing points and lift it upwards. - Page 73 Technical documentation Argus HSG 30656E--...

Need help?

Do you have a question about the Argus HSG-E02 and is the answer not in the manual?

Questions and answers