Table of Contents

Advertisement

Quick Links

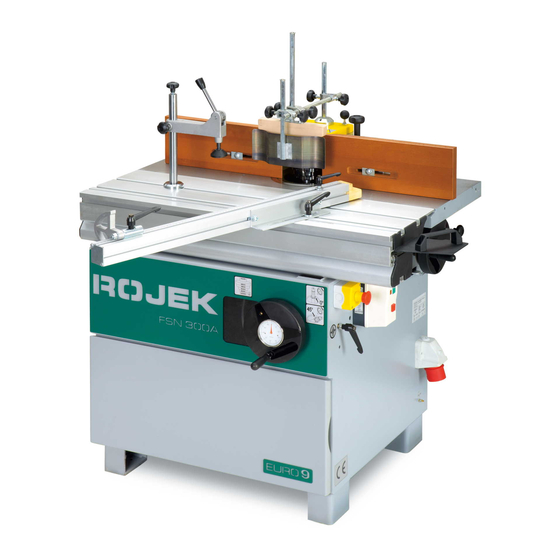

SINGLE-SPINDLE MILLING MACHINE

WITH A TILTING SPINDLE AND SLIDING TABLE

FSN 300A

translation of an original

Service instructions handbook

updated 3 / 2017

WOODWORKING MACHINES Masarykova 16, 517 50 astolovice

ROJEK

the Czech Republic - Europe export@rojek.cz www.rojek.cz

+420 494 339137, to - 41 fax -323 341, -322 701

Advertisement

Chapters

Table of Contents

Summary of Contents for ROJEK FSN 300A

- Page 1 WITH A TILTING SPINDLE AND SLIDING TABLE FSN 300A translation of an original Service instructions handbook updated 3 / 2017 WOODWORKING MACHINES Masarykova 16, 517 50 astolovice ROJEK the Czech Republic - Europe export@rojek.cz www.rojek.cz +420 494 339137, to - 41 fax -323 341, -322 701...

-

Page 3: Table Of Contents

8.1.2 Connecting the machine - above 3 kW 8.2 Safety of operation 8.3 Direction of rotation 8.4 Change in the direction of rotation 8.5 Protection of electrical devices 8.6 Controlling the machine 8.6.1 Operating switch and emergency stop controller 8.6.2 Spindle brake releasing. ROJEK a.s. FSN 300A... - Page 4 13 Special accessories 14 Spare parts 15 Guarantee 16 Dealing with packing and machine service life expiry 16.1 Dealing with packing 16.2 Dealing with machine. Enclosures : A) Electrical wiring chart B) List of electrical components ROJEK a.s. FSN 300A...

-

Page 5: Foreword

Note The text and picture part of the instructions is an intellectual property of the ROJEK Co. and will remain in the company´s ownership. No part of the instructions may be copied or reproduced without a prior consent nor any third persons are allowed to become acquainted with these instructions or with any part thereof. -

Page 6: Use Of The Machine

(BE2N2). 2 Machine marking The type of machine can be identified according to the manufacturing plate fixed to the machine stand. FSN 300 A vertical spindle milling machine with a tilting spindle and sliding table CV ROJEK a.s. FSN 300A... - Page 7 8 spindle tilt 9 range of optimal spindle rotation speed 10 switch of spindle electric brake release 11 a) rotating direction 12 setting of spindle rotation speed 11 b) OFF; still stand 11 c) electric brake released ROJEK a.s. FSN 300A...

-

Page 8: Technical Specifications

1600 x 310 travel length 1900. * el. motor with power output equal to 3.7 kW only for voltage 3 x 400 V / 50 (60) Hz ** 3kW; CV table extension; fixture; angular ruler; hose ROJEK a.s. FSN 300A... -

Page 9: Machine Dimensions

3.1 Machine dimensions ROJEK a.s. FSN 300A... -

Page 10: Possible Variants Of The Machine

Otherwise the electric motor thermal protection will be engaged and the machine will stop. While any material with a low thickness is being machined, a worse quality of machining must be taken into account due to the part springing. ROJEK a.s. FSN 300A... -

Page 11: Specifications Concerning The Noise Of The Device

3.4 Specifications concerning noise of the device ( EN 848-1:1999; ISO 7960:1995) FSN 300A without tool = 70.4 dB(A) Level of noise L with tool = 83.0 dB(A) Level of acoustic output A without tool = 78.6 dB(A) EN ISO 3746:1995... -

Page 12: Safety Instructions

- Before doing any maintenance work inside the machine switch off and lock the main switch or dis- connect the machine by pulling the plug out. - If the machine is used by more workers, do not proceed to other work without informing the other worker about what procedure you want to use. ROJEK a.s. FSN 300A... -

Page 13: Clothes And Personal Safety

- Do not remove or interfere otherwise in safety devices such as covers, end switches, and do not block them mutually. - While handling parts above your possibilities, ask for assistance. - It is recommended not to work on the machine during a storm. ROJEK a.s. FSN 300A... -

Page 14: Safety Regulations For Maintenance

- Ensure sufficient lighting in the working area which will not create shadows or cause the strobo- scopic effect. For safe and quality work the hygienic standards specify the minimum intensity 500 - Never put any tools or any other objects on working tables or covers. ROJEK a.s. FSN 300A... -

Page 15: Transport And Storage

The mass of a FSN 300 A is 260 kg. A machine can be havier, the mass depends on a machine making as per ordered specification. ROJEK a.s. FSN 300A... -

Page 16: Positioning The Machine

(included in the delivery) and level the machine horizontally with tolerance of 1mm/1000 mm and screw in to the floor (anchor). The attached drawing shows the location of the anchoring holes on the machine. ROJEK a.s. FSN 300A... -

Page 17: Connecting Exhaustion System

Ø 40 mm hose (C - lower exhaustion), and with Ø 100 mm hose, as well. Wood waste should be liquidated in an environment-friendly manner so that the environment does not become deteriorated. ROJEK a.s. FSN 300A... -

Page 18: Connecting To The Mains

A, if it is required. Cross-sections of the phase conductors and of the protective wire must be in compliance with the standards prescribed. Check that the connection is correct and screw the terminal board cover back. ROJEK a.s. FSN 300A... -

Page 19: Safety Of Operation

! Protection against dangerous contact with unlive wires is made by automatic disconnection from the power supply source in compliance with art. 6.3.1 of EN 60 204-1 and IEC 60 346-4-41. ROJEK a.s. FSN 300A... -

Page 20: Controlling The Machine

(B) on the operation switch (A), the spindle brake will be released. position 0 - OFF If the switch is turned over through position 0, the machine must always be turned on by pushing the green button (B) on the operation switch (A). ROJEK a.s. FSN 300A... -

Page 21: Operating And Adjusting The Machine

(A) in hand wheel (B), take indica- tor out ( e.g. by sticky tape), align the needle with 0° by turning the indicator. Put indicator into hand wheel and tighten fixing screw again. Adjust the machine only in machine still stand ! ROJEK a.s. FSN 300A... -

Page 22: Setting The Guide Rulers

(A) can be shifted in a groove of fixed table. Cross-ruler (A) position can be also changed by replacing the ruler onto another frame (B) side. When changing the ruler position, the frame measure scale must be controled, eventually adjusted. ROJEK a.s. FSN 300A... -

Page 23: Change Of Revolutions

Shift the belt to the new position according to label (E)and tighten it with the handle back up to the self-locking position. Close and secure the cover of gears. Revolutions allowed for the used tool di- ameter are shown in the diagram (D) placed on hinged cover of the milling machine gear. ROJEK a.s. FSN 300A... -

Page 24: Longitudinal Milling

Fasten the workpiece by clamping to the sliding table (B). Use tool cover (A) designed for this operation. While making joints for short pieces, use aid (C). ROJEK a.s. FSN 300A... -

Page 25: Milling Of Workpieces With Small Cross-Section

The cover is designed for milling of formed, rounded and circular profiles of workpieces with use of the form plate led along the guide ring. The standard design contains the only ring suitable for the tool in the scope of 120 to 150 mm. ROJEK a.s. FSN 300A... -

Page 26: Mounting Of The Device

It is recommended that guide ring (1) should be below the tool, if possible. ROJEK a.s. FSN 300A... -

Page 27: Working Places

9.10 Working place The picture shows location of the working place at the machine FSN 300A. 9.11 Protective aids For work on the machine, a short strengthened apron and eye protection is prescribed. It is advisable to use appropriate ear protection and recommended working shoes. Working overall coats are not allowed to use. - Page 28 ROJEK a.s. FSN 300A...

-

Page 29: Forbidden Handling

Tools must be produced according to the norm EN 847-1: 2014. The milling head FH 40, made by the ROJEK Co., is a suitable tool to be used with the machine. 10.2 Replacement of milling tools Use only milling tools that are designed for manual feeding and may be clamped safely. -

Page 30: Maintenance

Avoid contamination of belts with oil or grease. If this occurs, clean the belt with paper only or dry it. Removing the dust is best to be done with a vacuum cleaner. Perform this activity regularly, at least once a week. ROJEK a.s. FSN 300A... - Page 31 Lubricate with an oil tools or if the ma- chine is out of op- eration Plastic grease or oil LV-2-3 LV-2-3 OL-B5 OL-B5 OL-B5 Equivalent ISO-L-XCBEA 3 ISO – LAN 68 Chart to the greasing table ROJEK a.s. FSN 300A...

-

Page 32: Troubleshooting

Recess on the rear part of the machined workpiece: Uneven lower guiding surface of the part being milled. Incorrectly adjusted guide rulers in relation to the tool. Incorrectly pressed or guided material during the milling operation. ROJEK a.s. FSN 300A... -

Page 33: Scope Of Delivery

Table extension rial feeding Table of the feeder May be fixed below the device. Eccentric clamp Device for short pieces tenoning Frame with supporting telescopic arm and ruler (on CV) Cover of tool for milling of bends ROJEK a.s. FSN 300A... -

Page 34: Spare Parts

15 Guarantee Work and activities not specified herein require a consent in writing granted by the ROJEK Co., Ma- sarykova 16, R, 517 50 astolovice. The warranty certificate is attached to each machine and its accessories. - Page 35 Enclosure A Electric connection diagram 2,2 (3) kW, 3x400 (230) V, 50 (60) Hz, socket, stop-pusher ROJEK a.s. FSN 300A...

- Page 36 2,2 (3) kW, 3x400 (230) V, 50 (60) Hz, socket, stop-pusher, brake release ROJEK a.s. FSN 300A...

- Page 37 3,7 kW, 3x400 (230) V, 50 (60) Hz, main switch, supply terminal board, stop-pusher ROJEK a.s. FSN 300A...

- Page 38 3,7 kW, 3x400 (230) V, 50 (60) Hz, main switch, supply terminal board, stop-pusher, brake release ROJEK a.s. FSN 300A...

- Page 39 ENCLOSURE B - LIST OF ELECTRIC PARTS LIST OF ELECTRICAL PARTS FSN 300A 1-phase 3-phase Marking function type, specifications 2.2kW supplier alternative note 2.2 kW 3.7 kW pcs. pcs. pcs. pcs. ELECTRIC MOTORS BSNB 90L/2D-11R CEG M90lb/FPC 2,2kW 1x230V 2,2kW 1x230V...

- Page 43 GRADUAL DC BRAKES MAINTENANCE ADJUSTING, INSTRUCTIONS General information This brake type is desidned for machinery where a gradual but not necessarily precise braking is required. Thank to the single friction surface, the FCP brake provides noisless controlled stopping with low a brake torque to prevent any damage to machinery and operator alike. The brake friction is applied by the action of a set of springs that push the armature plate against the internal surface of the cast iron cooling fan.

- Page 44 the air gap adjustment instructions So as to re-adjust the air gap, it is necessary to tighten up the adjustment screw up to the rated values, scheduled below. brake brake torque input power turn-on time release time air gap dimension M 63 M 71 M 80...

- Page 45 KPSN 300 A KPSN 400 A KPFN 300 A original translation of a Service instructions handbook WOODWORKING MACHINES Masarykova 16, 517 50 astolovice ROJEK Czech Republic - Europe export@rojek.cz www.rojek.cz +420 494 339137, to - 41 fax 323 341, 322 701...

- Page 47 Contents Introduction 1.0 Safety instructions 2.0 Description of exchangeable spindle 2.1 Description 2.2 Making 3.0 Assembly and dismantling of exchangeable spindle 3.1 Assembly 3.2 Dismantling 4.0 Maintenance 5.0 Delivery extent ROJEK a.s. vým nná v etena svislá...

-

Page 49: Introduction

Notice The text and picture part of this manual is a know how of the ROJEK Co. and continue to be the company´s property. No part of the manual is allowed to be copied nor to let third persons learn the manual or its parts. -

Page 50: Description Of Exchangeable Spindle

35 | 100 impossible 1“ | 5/4“ 79 | 100 impossible 5/4“ ø 8 | 12 | 12,7 possible ø 10 | 14 ø 8 | 12 | (12,7) 5/4“ possible ø 10 | 14 ROJEK a.s. vým nná v etena svislá... - Page 51 Attention ! The difference of the warm lead at the body and head of fastening screw is 0,25 mm, herewith a big thrust arises. Do not forget to blind the hole with a plastic cap (3) after every mounting of the exchangeable spindle. ROJEK a.s. vým nná v etena svislá...

-

Page 52: Dismantling

15 dist. r. 20 dist. r. 30 “T “ spanner nr. 6 plastic cap clamping chuck - nut - insert ø ø 12 (12,7) spanner size 10 span. 27 one-sided spanner 32 ROJEK a.s. vým nná v etena svislá...

Need help?

Do you have a question about the FSN 300A and is the answer not in the manual?

Questions and answers