Table of Contents

Advertisement

Quick Links

SERVICE MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

888-994-7636, fax 888-864-7636

unifiedbrands.net

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

WARNING Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

NOTIFY CARRIER OF DAMAGE AT ONCE It is the responsibility of the

consignee to inspect the container upon receipt of same and to determine

the possibility of any damage, including concealed damage. Unified

Brands suggests that if you are suspicious of damage to make a notation

on the delivery receipt. It will be the responsibility of the consignee to file

a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

INTRODUCTION AND CONVENTIONS

PRODUCT INTRODUCTION

Thank you for purchasing a Power Soak ware washing machine. Your new Power Soak

pot, pan and utensil washing machine will provide years of dependable, efficient and

trouble-free service. As a Power Soak owner, you will benefit in numerous ways:

Your ware washing operation will be more efficient.

Pots, pans and utensils will be cleaner.

The overall level of sanitation in your scullery area will improve.

Ware washing hours will decrease as employee morale increases.

Chemical and water usage will decrease.

Every machine is manufactured to last, with only high-quality, heavy-duty, 14 gauge

stainless steel used in its construction. All electrical components used in a Power

Soak machine are of the highest quality. The faucets and drains are designed for

quick filling and emptying of the machine's tanks. At Unified Brands, we take pride

in manufacturing the Power Soak line and are committed to standing behind our

customers and products 100%. Should you ever need assistance, please contact us

directly at the factory by dialing 888-994-7636 or fax: 601-371-9732.

EXPLANATION OF WARNING MESSAGES

Read, understand and follow all DANGER, WARNING, and CAUTION messages located

in this guide and on the equipment.

Personal Injury and Property Damage Hazard Will result in serious injury

or death. Will cause extensive equipment damage.

Property Damage Hazard Will result in property or equipment damage.

Information contained in this document is known to be current and accurate at the time of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and specifications. © 2023 Unified Brands. All Rights Reserved.

This manual provides information for:

PS-100

Chemical Hazard Will result in serious injury or death. Instructions, labels and

Material Safety Data Sheets (MSDSs) should be supplied with all detergents

and sanitizing chemicals. The manufacturers, importers and distributors of

the cleaning chemicals are responsible for providing this information. Power

Soak is not a chemical manufacturer, importer or distributor. Power Soak

can assist the chemical representative but will not make specific brand

recommendations.

Personal Injury Hazard Hazard from sharp objects, scalding, falling and/or

drowning. Will result in serious injury or death.

Personal Injury Hazard HOT WATER! Wash sink water can exceed 120°F

(49°C). Wear personal protective equipment to avoid scalding or burns.

Personal Injury Hazard To avoid damaging your Power Soak or risking personal

injury, avoid washing small objects (such as spoons, forks, towels, scrub pads,

or brushes...etc.)unless they are placed in the utensil basket or the designated

utensil area of the AWI.

Children must not be allowed to play in the sinks, on countertops or with the controls

of the Power Soak equipment. Cleaning or use of this machine must not be done by

children without super vision. This machine can be used by children aged 8 years or

above and by persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they are given supervision and instruction concerning use

of the appliance in a safe way and understand the hazards involved. There is a potential

of drowning for any person whose head becomes submerged in the fluid contained in

the sinks along with other hazards identified in this manual.

REQUIREMENTS FOR DETERGENTS AND SANITIZERS

THE POWER SOAK PS-100 REQUIRES A LOW-FOAMING DETERGENT THAT

IS SAFE FOR HUMAN HANDS. THE DETERGENT SHOULD HAVE GOOD

GREASE CUTTING ABILITIES BUT NOT HAVE AN EXCESSIVELY HIGH OR

LOW PH LEVEL. A METAL/ALUMINUM-SAFE FORMULA IS RECOMMENDED.

CONSULT A CHEMICAL PROVIDER FOR A SUITABLE DEEP CLEANING

CHEMICAL.

Detergents

The PS-100 can use two types of detergents, one type for normal cleaning and one type

for "Deep Cleaning" for more effective deep cleaning. The materials to be cleaned and

the type of debris to be removed will be a factor in selecting the proper detergent. Provide

this information to a chemical supplier when selecting the type of detergent. Use of the

PART NUMBER 50826, REV. A (01/23)

Advertisement

Table of Contents

Summary of Contents for Power Soak PS-100

- Page 1 Detergents or death. Will cause extensive equipment damage. The PS-100 can use two types of detergents, one type for normal cleaning and one type Property Damage Hazard Will result in property or equipment damage. for “Deep Cleaning” for more effective deep cleaning. The materials to be cleaned and the type of debris to be removed will be a factor in selecting the proper detergent.

-

Page 2: Operation

Sanitizers • Wash tank (115ºF / 48ºC) The method of sanitizing used in the Power Soak PS-100 is a “chemical sanitizing” • Rinse tank (75ºF / 24ºC) method. There are a number of products on the market that work well in this •... -

Page 3: Troubleshooting

WHEN PERFORMING TROUBLESHOOTING PROCEDURES, THE AUTHORIZED pump housing. the wall mounted electrical enclosure SERVICE AGENCY WILL NEED TO OPEN THE POWER SOAK MACHINE’S MAIN ELECTRICAL ENCLOSURE COVER. 2. Remove the motor assembly (see DISASSEMBLY/ASSEMBLY section). Be sure that the heater cover in the back wall of the THE COVER TO THE ENCLOSURE MUST BE PROPERLY CLOSED BEFORE RECONNECTING THE POWER TO THE MACHINE. - Page 4 (Foam of low foaming soap that is added to the water. causes excess heat by reducing the efficiency of the pump and it insulates the top of the tank which holds in heat). SM-PS-100...

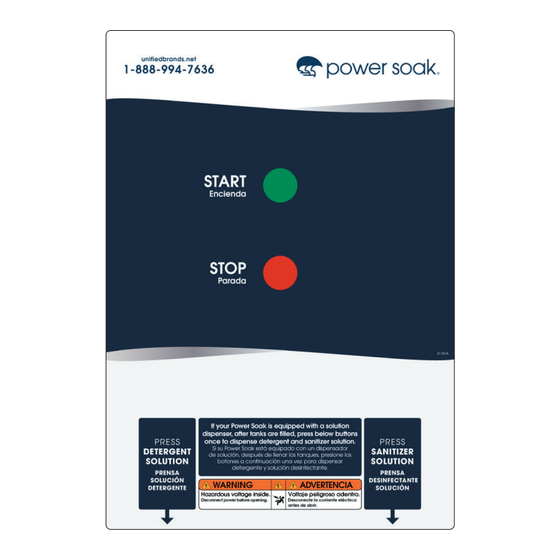

- Page 5 HEATER ELEMENT PUSH ON / PUSH OFF START AND STOP BUTTONS The heater in a Power Soak sink is rated at 7000 watts. It includes 3 individual TURN POWER OFF AT BREAKER PANEL. 2333 watt heater elements. The start and stop buttons are connected to the 24V circuits that switches all To check operations of the heat element, first turn the power off at the breaker.

-

Page 6: Parts List

30”-36” 27591 The part numbers for the Volute (1), Impeller (6) and Motor (16) are different for the 28.75" different configurations of machines. Contact the Power Soak Service Department 30”-36” 31.75" 27593 (888-994-7636) and provide the serial number of the machine for help with the part numbers. - Page 7 CONTROL BOX PS-100 208/60/1, W/HEAT 27934 HEATER GASKET 45570 CONTROL BOX PS-100 230/60/1, W/HEAT 27900 HEATER COVER 50546 CONTROL PANEL PS-100 208/60/3, NO HEAT PS_14424 ¼”-20 NYLOCK NUTS 50547 CONTROL PANEL PS-100 230/60/3, NO HEAT 42645 ACORN NUT #10-24, LOCKING, S/S 50548...

- Page 8 WASH SINK CONTROL (HEATED 208/60/3 CONTROL (45564) PICTURED) WASH DISPENSOR SWITCH SAFETY CONTACTOR (K1) SANITIZE DISPENSOR SWITCH MOTOR CONTACTOR (K2) HEATER CONTACTOR (K3) 2.300 8.055 SM-PS-100...

- Page 9 208-240 50541 CONTACTOR 50FLA, 24V COIL 31932 START SWITCH GREEN MX/PS-100 41655 CONTACTOR, MOTOR, 24VAC COIL 31933 STOP SWITCH RED / MX /PS-100 HARNESS, CONTROL OUT, HEAT/CHEMICAL 31199 29231 SOAP DISP METAL SWITCH DISP 29230 BUTTON GUARD CHEMICAL DISPENSER 29776...

- Page 10 VELCRO DOT, 1.375 DIA, LOOP SIDE 34380 VELCRO DOT, 1.375 DIA, HOOK SIDE 27938 KAY BOX LOCKING TAB 27858 GASKET 44287 HARNESS, INTERNAL, CHEM DISPENSER, DUAL *Not Shown MISCELLANEOUS Part Number Description 28065 WIRING HARNESS EXTENSION – 3FT 28066 WIRING HARNESS EXTENSION – 6FT SM-PS-100...

-

Page 11: Disassembly/Assembly Procedures

7. Mark the motor (14), adaptor plate (13), and volute (1) for reassembly temporarily until the impeller is secured. orientation. 6. Install the key on the motor shaft and place the impeller on the motor shaft engaging the key. 7. Put the gasket on the washer head cap screw. SM-PS-100... - Page 12 3. Slide the pad assembly back into the mounting bracket and bolt the bracket to 3. Push the wires through the center opening and align the studs with the the side of the wash tank. mounting holes on the bottom surface of the tank. 4. Turn on power at the breaker panel SM-PS-100...

-

Page 13: Replacement Parts

The wiring harness has connections to supply power and operating signals to the chemical dispenser pumps. Malfunctions in the chemical dispenser can lower the operating voltage of the PS-100 to levels that are unacceptable and will cause problems with the operation of the PS-100 control system. See the chemical dispenser literature for more information on the operation and service of the dispenser. -

Page 14: Wiring Diagrams

WIRING DIAGRAMS WASH TANK HEAT 208/240V 3 PHASE WASH TANK HEAT 480V 3 PHASE SM-PS-100... - Page 15 WASH TANK HEAT 208/240V SINGLE PHASE NO WASH TANK HEAT 208/240V SINGLE PHASE SM-PS-100...

- Page 16 NO WASH TANK HEAT 208/240V 3 PHASE SM-PS-100...

Need help?

Do you have a question about the PS-100 and is the answer not in the manual?

Questions and answers