Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Miller EnPak A28 GBW

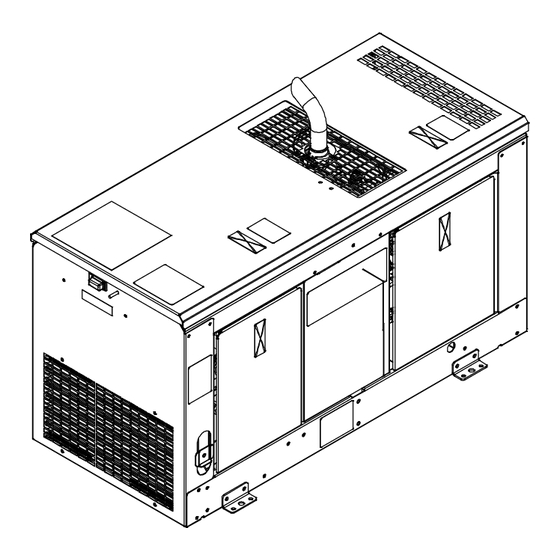

- Page 1 OM-274679C 2017−07 Processes Battery Charging Stick (SMAW) Welding Description Engine Driven Air Compressor, Generator, Battery Charger, And Welder EnPak A28 GBW File: Engine Drive For product information, Owner’s Manual translations, and more, visit www.MillerWelds.com/EnPak...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING ....... . . 1-1. - Page 4 TABLE OF CONTENTS SECTION 7 − COMPRESSOR SYSTEM ............7-1.

-

Page 5: Section 1 − Safety Precautions − Read Before Using

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING rom_2015−09 Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. not avoided, will result in death or serious injury. - Page 6 D Be alert that welding sparks and hot materials from welding can FLYING METAL or DIRT can injure easily go through small cracks and openings to adjacent areas. eyes. D Watch for fire, and keep a fire extinguisher nearby. D Welding, chipping, wire brushing, and grinding D Be aware that welding on a ceiling, floor, bulkhead, or partition can cause sparks and flying metal.

-

Page 7: Engine Hazards

1-3. Engine Hazards EXHAUST SPARKS can cause fire. BATTERY EXPLOSION can injure. D Do not let engine exhaust sparks cause fire. D Always wear a face shield, rubber gloves, and D Use approved engine exhaust spark arrestor in protective clothing when working on a battery. required areas —... -

Page 8: Additional Symbols For Installation, Operation, And Maintenance

HOT METAL from air arc cutting and MOVING PARTS can injure. gouging can cause fire or explosion. D Keep away from moving parts such as fans, D Do not cut or gouge near flammables. belts and rotors. D Watch for fire; keep extinguisher nearby. D Keep all doors, panels, covers, and guards closed and securely in place. - Page 9 BATTERY CHARGING OUTPUT and BATTERY STATIC (ESD) can damage PC boards. EXPLOSION can injure. D Put on grounded wrist strap BEFORE handling Battery charging not present on all models. boards or parts. D Use proper static-proof bags and boxes to D Always wear a face shield, rubber gloves, and store, move, or ship PC boards.

-

Page 10: California Proposition 65 Warnings

1-6. California Proposition 65 Warnings For Gasoline Engines: Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of California to Engine exhaust contains chemicals known to the State of cause birth defects and, in some cases, cancer. (California California to cause cancer, birth defects, or other reproduc- Health &... -

Page 11: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 CONSIGNES DE SÉCURITÉ − LIRE AVANT − UTILISATION fre_rom_2015−09 Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 12 D Utiliser une protection différentielle lors de l’utilisation d’un équi- LES ACCUMULATIONS DE GAZ pement auxiliaire. Ne pas tester ni réarmer les prises femelles risquent de provoquer des blessures avec différentiel au régime de ralenti/en basse tension: cela ou même la mort. endommagerait le disjoncteur différentiel, qui ne remplirait plus son rôle de protection contre une électrocution causée par un D Fermer l’alimentation du gaz comprimé...

-

Page 13: Dangers Existant En Relation Avec Le Moteur

D Porter un équipement de protection pour le corps fait d’un matériau Si des BOUTEILLES sont endomma- résistant et ignifuge (cuir, coton robuste, laine). La protection du gées, elles pourront exploser. corps comporte des vêtements sans huile comme par ex. des gants de cuir, une chemise solide, des pantalons sans revers, des chaussures hautes et une casquette. -

Page 14: Dangers Liés À L'air Comprimé

D Pour empêcher tout démarrage accidentel pendant les travaux D Toujours vérifier le niveau de liquide de refroidissement dans le d’entretien, débrancher le câble négatif (−) de batterie de la borne. vase d’expansion (si présent), et non dans le radiateur (sauf si pré- cisé... -

Page 15: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

D Pour rechercher des fuites, utiliser de l’eau savonneuse ou D Ne pas approcher les mains, cheveux, vêtements lâches et outils un détecteur à ultrasons, jamais les mains nues. En cas des organes mobiles. de détection de fuite, ne pas utiliser l’équipement. D Avant d’intervenir sur le circuit d’air comprimé, couper l’alimentation électrique, verrouiller et étiqueter l’appareil, D Remettre les portes, panneaux, recouvrements ou dispositifs... - Page 16 D Réduire le courant ou le facteur de marche avant de poursuivre le LA SORTIE DE RECHARGE et L’EXP- soudage. LOSION DE LA BATTERIE peuvent D Ne pas obstruer les passages d’air du poste. provoquer des blessures. LES CHARGES ÉLECTROSTATI- La recharge de batterie n’existe pas sur tous les QUES peuvent endommager les modèles.

-

Page 17: Proposition Californienne 65 Avertissements

2-6. Proposition californienne 65 Avertissements Pour les moteurs à essence : Les équipements de soudage et de coupage produisent des fumées et des gaz qui contiennent des produits chimiques Les gaz d’échappement des moteurs contiennent des pro- dont l’État de Californie reconnaît qu’ils provoquent des mal- duits chimiques dont l’État de Californie reconnaît qu’ils formations congénitales et, dans certains cas, des cancers. - Page 18 OM-274679 Page 14...

-

Page 19: Section 3 − Definitions

A complete Parts List is available at www.MillerWelds.com SECTION 3 − DEFINITIONS 3-1. Additional Safety Symbol Definitions Warning! Watch Out! There are possible hazards as shown by the symbols. Safe1 2012−05 Never use generator inside a home or garage, even if doors and win- dows are open. -

Page 20: Section 4 − Specifications

A complete Parts List is available at www.MillerWelds.com SECTION 4 − SPECIFICATIONS 4-1. Serial Number And Rating Label Location The serial number and rating information for this product is located on the front and side panels. Use rating label to determine rated output. For future reference, write serial number in space provided on back cover of this manual. -

Page 21: Sound Level Table − 7 Meter (23 Ft) (Reference Sae J2101)

A complete Parts List is available at www.MillerWelds.com 4-7. Sound Level Table − 7 Meter (23 Ft) (Reference SAE J2101) Idle 66 dB High Speed, No Load 73 dB High Speed, Loaded 75 dB 4-8. Dimensions, Weights, and Operating Angles Dimensions 24.25 in. -

Page 22: Duty Cycle And Overheating

A complete Parts List is available at www.MillerWelds.com 4-9. Duty Cycle And Overheating Duty cycle is the percentage of 10 minutes that unit can weld at rated load without overheating. This unit is rated for welding at 150 amperes continuously. NOTICE −... -

Page 23: Volt-Ampere Curves

A complete Parts List is available at www.MillerWelds.com 4-11. Volt-Ampere Curves The volt-ampere curves show the minimum and maximum voltage and amperage output capabilities of the unit. Curves of other settings fall between the curves shown. Weld CC/DC HI MAX LOW MAX LOW MIN HI MIN... -

Page 24: Fuel Consumption Curves

A complete Parts List is available at www.MillerWelds.com 4-12. Fuel Consumption Curves Air Compressor at 175 psi 2.00 1.75 1.50 1.25 1.00 0.75 0.50 0.25 0.00 SCFM Auxiliary Power 2.00 1.75 1.50 1.25 1.00 0.75 0.50 IDLE 2400 RPM 0.25 0.00 POWER KVA AT 100% DUTY CYCLE Welding... -

Page 25: Section 5 − Installation

A complete Parts List is available at www.MillerWelds.com SECTION 5 − INSTALLATION 5-1. Installing Unit Movement / Airflow Clearance 24 in. (610 mm) 2 in. (51 mm) 2 in. (51 mm) 18 in. 18 in. (460 mm) (460 mm) Location / Mounting Possible Mounting Position... -

Page 26: Installing Remote Panel

A complete Parts List is available at www.MillerWelds.com 5-2. Installing Remote Panel Mounting Hole (6) Select mounting location and mark hole placement. Ensure cables will reach from base unit to remote. Drill holes and attach remote to truck. Hardware is customer supplied. Warning Label Install provided warning label in an easily visible location. -

Page 27: Connecting Remote Panel

A complete Parts List is available at www.MillerWelds.com 5-3. Connecting Remote Panel Tools Needed: 3/8 in., 11/16 in. Brown lead (8) Black lead (8) Ref. 275810-C Pull latch out and depress tab to remove Power Cable Only qualified individuals should plug. -

Page 28: Grounding Generator And Remote Panel To Truck Or Trailer Frame

A complete Parts List is available at www.MillerWelds.com 5-4. Grounding Generator And Remote Panel To Truck Or Trailer Frame GND/PE rot_grnd3 2017−01 − 800 652-D nect a ground wire from the genera- Equipment Grounding Terminal (On Always ground generator frame to tor equipment grounding terminal to Front Panel) vehicle frame to prevent electric... -

Page 29: Engine Prestart Checks

A complete Parts List is available at www.MillerWelds.com 5-6. Engine Prestart Checks Check all fluids daily. Engine must be cold and on a level surface. Unit is shipped with 10W30 engine oil. Follow run-in procedure in en- gine manual. This unit has a low oil pressure shutdown switch. -

Page 30: Compressor Prestart Checks

NOTICE − Do not mix oil types. Do not Inspect compressor air cleaner element The unit is shipped with oil in the com- overfill. Use only Miller oil 276620. and replace if dirty (see Section 11-3). pressor reservoir. Oil level sight glass Check all fluids daily. -

Page 31: Connecting The Battery

A complete Parts List is available at www.MillerWelds.com 5-8. Connecting The Battery Connect negative (−) battery cable last. To connect battery, open top ser- vice door. Open top cover. Connect battery, negative cable last. − Do not allow the battery cables to touch opposing termin- als. -

Page 32: Connecting External Fuel Supply

NOTICE − Do not fill tank more than halfway. Overfilling will cause an- tifreeze mixture to interfere with fuel tank vent. Miller electric fuel pump kit 301450 is recommended for use with an ex- ternal fuel tank. The pump provides a 50 in. vertical lift between the Empty level of the fuel tank and the pump inlet. -

Page 33: Section 6 − Controls

A complete Parts List is available at www.MillerWelds.com SECTION 6 − CONTROLS 6-1. Control Panel Ref. 274580-C Air Compressor Switch Positive Weld Output Terminal 11 Engine Hour Meter/Fuel Gauge/Idle Control See Section 7-1. Negative Weld Output Terminal Low fuel is indicated by an orange flashing Generator−Weld/Battery Charge light on the right side of the display. -

Page 34: Engine Controls

A complete Parts List is available at www.MillerWelds.com 6-2. Engine Controls Ref. 804 857-C / 275810 Engine Control Switch Compressor 3600 RPM To Start: Turn Engine Control switch to Start position. Release switch when engine Use switch to start engine, select speed, Generator Power 3600 RPM starts. -

Page 35: Section 7 − Compressor System

A complete Parts List is available at www.MillerWelds.com SECTION 7 − COMPRESSOR SYSTEM 7-1. Air Compressor Switch Ref. 274580 disables compressor. Power to compressor Compressor Function Switch Weld output and generator power are is disabled until air compressor switch is reduced when the air compressor is on. -

Page 36: Air Compressor Controls And Adjusting System Pressure

A complete Parts List is available at www.MillerWelds.com 7-2. Air Compressor Controls And Adjusting System Pressure 275810 / 277873 occur. Frequent over pressure cycling can engine is stopped. The blow down valve After the air compressor shuts off, cause clutch and belt damage. slowly discharges the pressure in the com- the blow down cycle begins and pressor. -

Page 37: Section 8 − Battery Charging

A complete Parts List is available at www.MillerWelds.com SECTION 8 − BATTERY CHARGING 8-1. Battery Charging Guidelines Stop engine. Keep battery charging cables away Disconnect cables from weld termi- from vehicle hood, door, and mov- nals before charging a battery. ing parts. -

Page 38: Connecting Installed Battery To Battery Charge Receptacle

A complete Parts List is available at www.MillerWelds.com 8-3. Connecting Installed Battery To Battery Charge Receptacle Battery located in vehicle (Negative post grounded to chassis) See information below regarding vehicles with battery Positive (+) grounded to chassis. − Connect black (Negative) char- ging cable to chassis or engine block (and away from battery). -

Page 39: Setting Battery Charge Controls

A complete Parts List is available at www.MillerWelds.com 8-4. Setting Battery Charge Controls Have only qualified persons charge batteries. Never place 12V battery on 24V only setting. Generator−Weld /Battery Charge Switch Place switch in position matching voltage of battery being charged. Battery charge output is independent of weld settings. -

Page 40: Battery Charge Led Indicators

A complete Parts List is available at www.MillerWelds.com 8-6. Battery Charge LED Indicators Ref. 274580 Battery charge LED indicators function only Reverse Polarity LED7 (Yellow) Never remove battery cable clamps when the Generator−Weld/Battery Charge during a charge or jump start/crank When lit and not flashing, LED7 indicates a switch is in the 12V or 24V position. -

Page 41: Section 9 − Operating Auxiliary Equipment

A complete Parts List is available at www.MillerWelds.com SECTION 9 − OPERATING AUXILIARY EQUIPMENT 9-1. Generator Power Receptacles And Supplementary Protectors Ref. 274580 RC1 supplies 60 Hz single-phase power at Supplementary Protector CB1 (Not Use GFCI protection when operat- weld/power speed. Maximum output is 5.5 Shown) ing auxiliary equipment. -

Page 42: Wiring Instructions For Optional 240 Volt, Single-Phase Plug (Nema 14-50P)

A complete Parts List is available at www.MillerWelds.com 9-2. Wiring Instructions For Optional 240 Volt, Single-Phase Plug (NEMA 14-50P) The plug can be wired for a 240 V, 2-wire load or a 120/240V, 3-wire load. See circuit diagram. Plug Wired for 120/240 V, 3-Wire Load When wired for 120 V loads, each duplex receptacle shares a load... -

Page 43: Section 10 − Welding Operation

**Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. ( ) = mm for metric use ***For distances longer than those shown in this guide, call a factory applications rep. at 920-735-4505 (Miller) or 1-800-332-3281 (Hobart). Ref. S-0007-L 2015−02 10-2. Weld Output Terminals Turn off power before connecting to weld output terminals. -

Page 44: Weld Controls

If arc goes out electrode was lifted to high. If electrode sticks to workpiece, use a quick twist to free it. For better arc starts, turn the Engine Control switch to Run. Miller recommends Hobart filler metals. OM-274679 Page 40... -

Page 45: Section 11 − Maintenance And Troubleshooting

A complete Parts List is available at www.MillerWelds.com SECTION 11 − MAINTENANCE AND TROUBLESHOOTING 11-1. Maintenance Label 275158-B OM-274679 Page 41... -

Page 46: Routine Maintenance

A complete Parts List is available at www.MillerWelds.com 11-2. Routine Maintenance Stop engine before maintaining. See Maintenance Label for important start-up, service, and Recycle storage information. Service more often if used in severe engine conditions. fluids. Engine speed is regulated by an electronic governor. Engine speed adjustments may only be performed by a Factory Authorized Service Agent. Follow the storage procedure in the engine owner’s manual if the unit will not be used for an extended period. -

Page 47: Changing Compressor Oil, Oil Filter, Air Cleaner, And Air/Oil Separator

A complete Parts List is available at www.MillerWelds.com 11-3. Changing Compressor Oil, Oil Filter, Air Cleaner, And Air/Oil Separator Stop engine. Do not open oil fill cap until unit has been off for 10 minutes the air compressor gauge reads zero. Do not open while running. -

Page 48: Servicing Engine Air Cleaner

A complete Parts List is available at www.MillerWelds.com 11-4. Servicing Engine Air Cleaner Stop engine. NOTICE − Do not run engine with- out air cleaner or with dirty element. Engine damage caused by using a damaged element is not covered by the warranty. -

Page 49: Changing Engine Oil, Oil Filter, And Fuel Filter

A complete Parts List is available at www.MillerWelds.com 11-5. Changing Engine Oil, Oil Filter, And Fuel Filter Stop engine and let cool. To change engine oil and oil filter: Oil Drain Valve Change engine oil and filter accord- Tools Needed: ing to engine owner’s manual. -

Page 50: Overload Protection

A complete Parts List is available at www.MillerWelds.com 11-6. Overload Protection Stop engine. When a circuit breaker, supple- mentary protector or fuse opens, it usually indicates a more serious problem exists. Contact a Factory Authorized Service Agent. Supplementary Protector CB1 CB1 is located on the front panel of the base unit and protects the auxil- iary power receptacles from over-... -

Page 51: Adjusting Engine Speed

A complete Parts List is available at www.MillerWelds.com 11-7. Adjusting Engine Speed After tuning engine, check engine speeds with a tachometer (see table). If necessary, adjust speeds as follows: 2300 − 2400 rpm Start engine and run until warm. (38.3 − 40.0 Hz) Turn Fine Control to 10. -

Page 52: Troubleshooting

A complete Parts List is available at www.MillerWelds.com 11-8. Troubleshooting A. Compressor Troubleshooting Trouble Remedy Air compressor does not operate; no air Place Air Compressor switch in an On position. If compressor is turned off, wait for air pressure to bleed pressure on gauge;... - Page 53 A complete Parts List is available at www.MillerWelds.com Trouble Remedy Oil in air from compressor (continued). Change compressor air/oil separator if close to replacement hours (see Section 11-3). Wrong or mixed oil results in foaming which can cause oil in air. If mixed oil is suspected, replace oil, oil filter, and air/oil separator.

- Page 54 A complete Parts List is available at www.MillerWelds.com C. Generator Power Troubleshooting Trouble Remedy No or low generator power output at Reset supplementary protector(s) (see Section 11-6). AC receptacles; weld output okay. Check remote connection to base unit. Make sure the switch is in Gen/Weld Position. Have Factory Authorized Service Agent check brushes and slip rings.

- Page 55 A complete Parts List is available at www.MillerWelds.com E. Engine Troubleshooting Trouble Remedy Engine will not crank. Check fuse F6, and replace if open (see Section 11-6). Check battery voltage. Check battery connections and tighten if necessary. Check plug PLG10 and PLG8 (ignition switch). Have Factory Authorized Service Agent check Engine Control switch S1.

-

Page 56: Section 12 − Parts List

A complete Parts List is available at www.MillerWelds.com SECTION 12 − PARTS LIST 12-1. Recommended Spare Parts Dia. Part Mkgs. Description Quantity ....493509 Brushholder Assy, Generator . - Page 57 Notes OM-274679 Page 53...

-

Page 58: Section 13 − Diagrams

SECTION 13 − DIAGRAMS Figure 13-1. Circuit Diagram For Welder/Generator OM-274679 Page 54... - Page 59 279063-C OM-274679 Page 55...

- Page 60 279125-B Figure 13-2. Air Compressor Schematic OM-274679 Page 56...

-

Page 61: Section 14 − Generator Power Guidelines

SECTION 14 − GENERATOR POWER GUIDELINES The views in this section are intended to be representative of all engine-driven welder/generators. Your unit may differ from those shown. 14-1. Selecting Equipment Generator Power Receptacles − Neutral Bonded To Frame 3-Prong Plug From Case Grounded Equipment 2-Prong Plug From Double Insulated Equipment... - Page 62 14-3. Grounding When Supplying Building Systems Equipment Grounding Terminal Grounding Cable Use #8 AWG or larger insulated copper wire. GND/PE Ground Device Use ground device as stated in electrical codes. Ground generator to system earth ground if supplying power to a premises (home, shop, farm) wiring system.

- Page 63 14-5. Approximate Power Requirements For Industrial Motors Industrial Motors Rating Starting Watts Running Watts Split Phase 1/8 HP 1/6 HP 1225 1/4 HP 1600 1/3 HP 2100 1/2 HP 3175 Capacitor Start-Induction Run 1/3 HP 2020 1/2 HP 3075 3/4 HP 4500 1400 1 HP...

- Page 64 14-7. Approximate Power Requirements For Contractor Equipment Contractor Equipment Rating Starting Watts Running Watts Hand Drill 1/4 in. 3/8 in. 1/2 in. Circular Saw 6-1/2 in. 7-1/4 in. 8-1/4 in. 1400 1400 Table Saw 9 in. 4500 1500 10 in. 6300 1800 Band Saw...

- Page 65 14-8. Power Required To Start Motor Single-Phase Induction Motor Starting Requirements Motor Start Code KVA/HP 10.0 11.2 12.5 14.0 Motor Start Code Running Amperage Motor HP Motor Voltage To find starting amperage: Step 1: Find code and use table to find kVA/HP.

- Page 66 14-10. Typical Connections To Supply Standby Power Have only qualified persons perform these connections according to all applicable codes and safety practices. Properly install, ground, and operate this equipment ac- cording Owner’s Manual and national, state, and local codes. Customer-supplied equipment is required if generator will sup- ply standby power during Fused...

- Page 67 14-11. Selecting Extension Cord (Use Shortest Cord Possible) Cord Lengths for 120 Volt Loads Use GFCI protection when operating auxiliary equipment. If unit does not have GFCI receptacles, use GFCI-protected exten- sion cord. Do not use GFCI receptacles to power life support equipment. Maximum Allowable Cord Length In ft (m) for Conductor Size In AWG (mm Current Load (Watts)

- Page 68 Notes...

- Page 69 Notes...

- Page 70 Notes...

- Page 71 Miller must be notified in writing within thirty costs of any kind will be allowed. (30) days of such defect or failure, at which time Miller will provide instructions on the warranty claim TO THE GREATEST EXTENT PERMITTED BY procedures to be followed.

- Page 72 Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © ORIGINAL INSTRUCTIONS − PRINTED IN USA 2017 Miller Electric Mfg. Co. 2017−01...

Need help?

Do you have a question about the EnPak A28 GBW and is the answer not in the manual?

Questions and answers