Advertisement

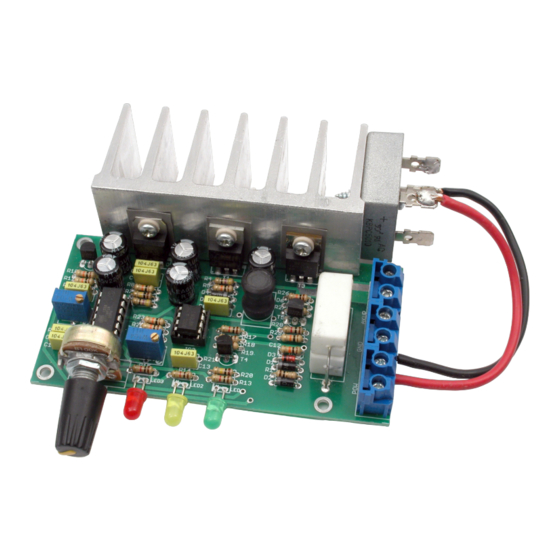

Automatic Charger

For Lead Batteries

kits

The device monitors the charging process and

determines its optimal performance. The whole cycle is

divided into 4 stages automatically switched

depending on the battery charge level. When the

battery reaches its correct voltage, charging is

automatically terminated. Battery condition and

charging stage are indicated by 3 LEDs. The charger

features adjustable charging current, so it prevents

damage to the battery (too much current) and saves

time (too little current).

Circuit description

Traditional rectifier has two main disadvantages. First:

it has no protection against overcharging and even if

you watch over it while it is charging, you will not be

able to see from the ammeter alone that it is time to

stop charging. Whilst, charging until gassing of the

electrolyte is a conscious overcharging. Second

disadvantage: no charging current regulation. The

charging current should not exceed the permissible

value for the battery in question, which depends on

its capacity. Charging with excessive current can

irreversibly damage the plates (cells) of which the

battery is composed. Exceeding the permitted

voltage or current you adversely affect the

performance and service life of the battery. The

presented device allows to avoid both of these

disadvantages. This module can be a standalone unit,

such as the model shown on the photographs, but

Characteristics

• charging of 12 V lead-acid batteries with a capacity of

10...100 Ah

• charging current regulation in the range of approx.

1...10 A

• battery overcharging protection

• multi-stage charging process

• power supply: 17 V transformer or factory rectifier

• PCB size: 103×54 mm

can also be an attachment to a simple, classic

rectifier. In both cases you receive an automatic

charger. Its diagram is shown in Figure 1 and it can

be divided into several blocks.

1. Current measurement block - built using lM358

chip (IC3A, IC3B). Positive output from the rectifier is

fed to the POW terminal and goes to a measuring

shunt R16 composed of two low-resistance power

resistors. Operational amplifier IC3B including

transistor T4 and adjacent components form a

current-to-voltage converter. At its output there is a

filter built of elements R20, C13 and amplifier IC3A.

Output signal is calibrated using precision

potentiometer R24 and goes to the microcontroller -

the signal marked CV.

2. Power stage - built with transistors T3 and T5. T3 is

used to control the voltage/current waveform

PDF

DOWNLOAD

ASSEMBLY DIFFICULTY

1

Advertisement

Table of Contents

Summary of Contents for AVT 3120

- Page 1 Automatic Charger For Lead Batteries kits DOWNLOAD ASSEMBLY DIFFICULTY The device monitors the charging process and Characteristics determines its optimal performance. The whole cycle is • charging of 12 V lead-acid batteries with a capacity of divided into 4 stages automatically switched 10...100 Ah depending on the battery charge level.

- Page 2 supplied to the battery. Transistor T5 with adjacent and adjacent components. Its task is to detect the components allow the MOSFET to be controlled halves of the sine wave applied on the battery DC directly from the microcontroller lead. voltage - this process will be discussed in more detail 3.

- Page 3 element. Waveforms in the circuit are shown in Figure can be obtained, the descending ramp marks the 2. Waveform A is the rectifier output, B is the beginning of the phase control period. The D superimposed output of the rectifier and the battery's waveform is the power stage control signal (MDR in DC voltage (VIN in the diagram).

- Page 4 can force a very high current due to the significant Stage IV - charging completed. When the green LED voltage difference. In this case, the circuit presented is on it indicates the end of the charging process, the reduces the charging current to 1/3 of the set range battery is fully charged and ready for use.

- Page 5 Photo 1 Once you cleaned the board visually inspected your voltage of approx. 29...30 V on pins 4 and 8 of the assembly, you can start your device up. You will need IC3 chip socket. If the voltages are correct then you a regulated power supply, a multimeter and a can move on to the next step.

- Page 6 Photo 2 Important note - the voltage should be increased current has a heavily distorted waveform and the slowly because the voltage measurement is cycled, ammeter may not indicate correctly, the current not continuous, and the voltage thresholds for measurement block also introduces slight distortions. switching stages have large hysteresis in the direction It is best to set the correct current in the middle of the falling voltage - switching from stage I to stage...

- Page 7 Photo 3 Photo 4...

- Page 8 AVT SPV reserves the right to make changes without prior notice.Installation and connection of the appliance not in accordance with the instructions, unauthorised modification of components and any structural alterations may cause damage to the appliance and endanger persons using it. In such a case, the manufacturer and its authorised representatives shall not be liable for any damage arising directly or indirectly from the use or malfunction of the product.

Need help?

Do you have a question about the 3120 and is the answer not in the manual?

Questions and answers