Summary of Contents for Brookfield TC-102D

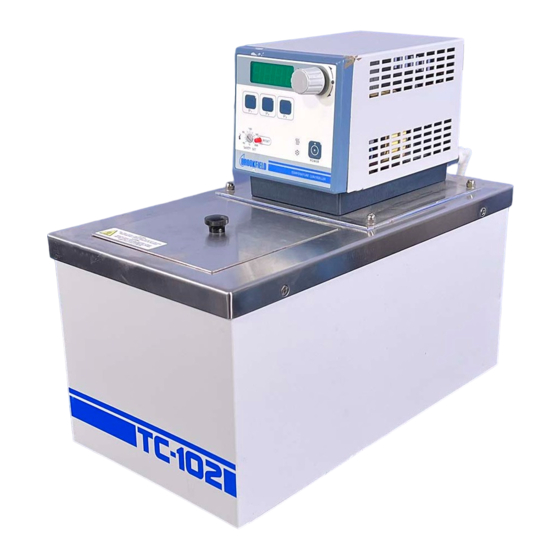

- Page 1 Operators Manual Circulating Bath with Digital Controller 110-241 Rev. D ECN 1970 7/04...

-

Page 2: Table Of Contents

Table of Contents Section 1 - General Information Unpacking Contents General Description Circulator Pump Pump Inlet and Outlet Connections Closed Loop Circulation Reservoir Purge Ambient and Cooling Coil Section 2 - Standard Controller Information Front and Rear Panels Heater/Pump Assembly Section 3 - Operation Circulator Location Filling the Reservoir... -

Page 3: Section 1 - General Information

(spindle/guard clearance), either a 4 inch rod extension (part number BLM-4E) used with type A lab stand or an 18 inch rod replacement (part number VS-38) used with type S lab stand are available from Brookfield or an authorized dealer. *Included with 50Hz Models only. -

Page 4: General Description

Refrigeration is normally required for operation at temperatures below 40°C. However, refrigeration should not be used when the fluid temperature is above 55°C. Refrigeration should not be turned on when the ambient air temperature is above 32°C. Model Specifications TC-102D TC-202D TC-502D TC-602D Temperature Range Ambient +5°... -

Page 5: Pump Inlet And Outlet Connections

Pump Inlet and Outlet Connections The pump inlet and outlet ports are female ¼ inch NPT connections that permit use of barbed tubing adapters or hard plumbing fittings. ½ inch (13mm) ID tubing may also be slid over these connections and held in place with a hose clamp. -

Page 6: Reservoir Purge

The temperature control stability of a closed loop system is better at the external apparatus than in the Circulator reservoir (provided the control point of the apparatus represents a constant load and is well insulated). For example, if you circulate fluid through a viscometer at 50°C, the temperature variation observed in the Circulator reservoir may be ±0.2°C while the temperature variation in the viscometer may be only ±0.1°C. -

Page 7: Section 2 - Standard Controller Information

Section 2 - Standard Controller Information Front and Rear Panels PURGE PORT Front View Rear View Display Pump Speed Switch Preset Temperature Buttons Identification Label Safety Set Reset Button Pump Inlet Safety Set Indicator Knob Reservoir Purge Cooling Light Pump Outlet Power ON / OFF Button AC Input Heating Light... -

Page 8: Section 3 - Operation

Section 3 – Operation Circulator Location Locate the Circulator on a level surface, free from drafts and out of direct sunlight. Do not place it where there are corrosive fumes, excessive moisture, high room temperatures, or excessive dust is present. Refrigerating/Heating Circulators must be a minimum of four inches (102mm) away from walls or vertical surfaces so air flow around the unit is not restricted. -

Page 9: Selecting Temperature Units

Once the Safety Set temperature has been set, turn power to the Controller ON by pressing the Power Switch on the front of the Controller. The pump will begin operating, the display will flash the current temperature set point (tx.xx), the °C LED will light, and the current bath temperature will appear on this display. -

Page 10: User-Defined Preset Temperatures

User-Defined Preset Temperatures With the unit on, press the desired Preset Button — P1, P2, or P3. The LED associated with the selected Preset Button will begin to flash. Rotate the Select/Set Knob to the desired temperature set point. Press the selected Preset Button a second time to enter the new set point. -

Page 11: Controller Display Messages

3.12 Controller Display Messages Display Description Action Required Normal — Indicates that the Circuit Breaker/Power Switch is ON Standby mode …. and the Controller Power Switch is OFF tx.xx Power up self-test Normal — Appears momentarily at startup oCx.x Calibration offset value Normal —... -

Page 12: Pump Motor

Pump Motor The pump bearings are permanently lubricated with high-temperature silicone grease and do not require additional lubrication. Should the bearings become noisy, replacement of the entire pump motor is recommended. This will reduce repair labor costs and retain fluid pumping reliability. Cleaning Only mild detergents and water or an approved cleaner should be used on the painted and stainless steel surfaces of the Circulator. -

Page 13: No Heating

No Heating • Verify that the unit is pumping properly. • If the heat light is not lit, check the control temperature set point and bath temperature to verify that heating is required. • Verify that the liquid in the bath covers the heater coils. •... -

Page 14: Section 6 - Reservoir Fluids

Section 6 - Reservoir Fluids Depending on your needs, a variety of fluids can be used with your Circulator. No matter what bath medium is selected, it must be chemically compatible with the reservoir and with the 300 series stainless steel in the pump and heater. It must also be suitable for the desired temperature range. Always use fluids that satisfy safety, health, and equipment compatibility requirements For optimum temperature stability, the fluid’s viscosity should be 50 centistokes or less at its lowest operating temperature. -

Page 15: Section 7 - Service And Technical Support

Application Notes At a fluid's low temperature extreme: 1. The presence of ice or slush adversely affects temperature stability. 2. A viscosity above 10 centistokes adversely affects temperature uniformity. 3. A high fluid viscosity and high pump speed adds heat to the fluid being pumped. At a fluid's temperature above ambient without refrigeration: 1. -

Page 16: Section 8 - After-Sale Support

All instruments requiring warranty service must be returned to Brookfield Engineering Laboratories, Inc. or the Brookfield dealer from whom it was purchased. Obtain return authorization number prior to returning bath for service. Transportation is at the purchaser’s expense. See Section 9 – Warranty, below. -

Page 17: Section 10 - Ec Declaration Of Conformity

73/23/EEC and EC Electromagnetic Compatibility Directive 89/336/EEC, and carries the marking accordingly. We herewith declare: Brookfield Engineering Laboratories, Inc 11 Commerce Boulevard Middleboro, MA 02346 That the following equipment complies with the essential requirements in respect to safety and health, in accordance to the EC Directives based on its design and type, as brought into circulation by us.