Advertisement

Table of Contents

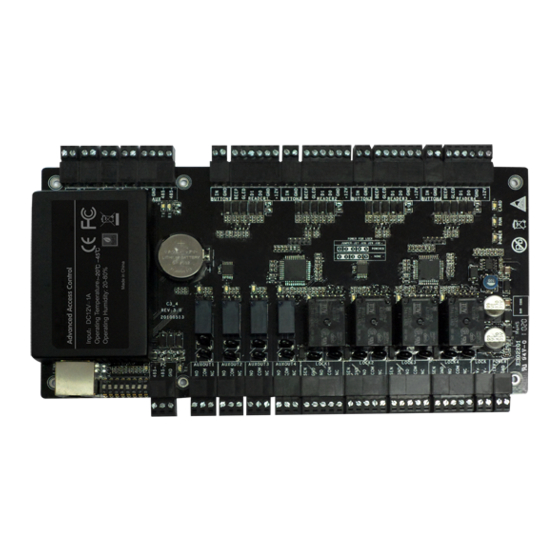

- 1 LED Indicators, Wires, Auxiliary Input and Output

- 2 Components

- 3 Equipment Communication

- 4 RS485 Address Setting, Restore Factory Setting, Terminal Resistance Setting

- 5 TCP/IP Communication

- 6 RS485 Communication

- 7 Connection of Lock

- 8 “Wet Mode” Wiring Diagram of Lock Connecting with External Power Supply

- Download this manual

C3-400 Installation Guide

1.

Cautions

Please note the following cautions. Mis-operation may lead to personal injury or equipment failure:

1) Do not energize the system before installation is complete; never carry out installation activities when the system is energized.

2) All peripheral devices must be grounded.

3) It is preferred that all wires run through PVC or galvanized conduit.

4) It is strongly recommended that the length of the exposed part of any connection cable not be longer than 4 mm. Professional

clamping tools may be used to avoid unintentional contact of exposed wires to avoid short-circuit or communication failure.

5) It is recommended that card readers and buttons be installed at a height of 1.4m-1.5m above ground.

6) It is recommended to use the accompanying power supply for the control panel, and external power supply for each lock.

Description of normal working state:

Connect the system to the power supply. If the system works properly, the POWER indicator (red) is lit constantly and the RUN

indicator(green) flashes.

2.

Components

Key hole

Heat

dissipation

hole

Thread hole

Appearance of case

3.

Get through the thread hole

Thread hole

Get through the thread hole

Vision: 1.0.1

Date: Oct.

2010

Backup battery Power supply Control panel

2

1

Fixed case

4.

LED Indicators, Wires, Auxiliary Input and Output

Notes:

1) Meaning of LED indicators:

LINK indicator (green): always (green) indicates TCP/IP

communication is proper;

ACT indicator (yellow): flashing indicates data is transmitting

through TCP/IP communication.

TX indicator (yellow): flashing indicates it is sending data through

RX indicator (green): flashing indicates it is receiving data through

RS485 communication.

Auxiliary output indicator (green): always (green) indicates it is in use.

Lock indicator (green): always (green) indicates lock is open.

POWER indicator (red): always (red) indicates control panel power is on.

RUN indicator (green): flashing indicates the system works normally.

CARD indicator (yellow): flashing indicates card is punched on reader.

LINK

SD Card

Ethernet interface

ACT

Dip switch

Advanced Access Control

485+

PC RS485 interface

485-

GND

TX

RX

NO

D

COM

t1

Auxiliary outpu

NC

{

D

NO

COM

Auxiliary output2

NC

{

NO

D

COM

Auxiliary output3

NC

{

NO

D

COM

Auxiliary output4

NC

{

SEN

GND

C

NO

Door1

COM

NC

{

SEN

GND

C

Door2

NO

COM

NC

{

SEN

C

GND

Door3

NO

COM

NC

{

SEN

GND

C

NO

Door4

COM

NC

V+

A

Power to lock

V-

+12V

A

Power to control panel

GND

2) Recommended use of wires:

A Use 2-conductor power cord

B Use 6-conductor wire between Wiegand reader and control panel

(RVVP 6x0.5mm) (choose the appropriate cord for the interface

you connect, such as 6, 8, 10 cord)

C Use 4-conductor lock power cord (RVV 4x0.75mm)

D Use 2-conductor switch power cord (RVV 2*0.5mm)

3) The auxiliary input may be connected to infrared body detectors,

alarms, switches, etc.

4) The auxiliary output may be connected to door bells, alarms, etc.

D

IN

GND

Auxiliary input1

D

IN

Auxiliary input2

GND

D

IN

GND

Auxiliary input3

IN

D

GND

Auxiliary input4

+12V

Extended

GND

RS485 output

485-

TX

485+

RX

D

IN

#1 Door Button

GND

BEEP

GLED

B

WD1

#1 Door

WD0

W

iegand reader

GND

+12V

IN

D

#2 Door Button

GND

BEEP

GLED

B

WD1

WD0

#2 Door

Wiegand reader

GND

+12V

D

IN

#3 Door Button

GND

BEEP

GLED

B

WD1

#3 Door

WD0

Wiegand reader

GND

+12V

D

IN

#4 Door Button

GND

BEEP

GLED

B

WD1

#4 Door

WD0

Wiegand reader

GND

+12V

POWER

RUN CARD

Advertisement

Table of Contents

Summary of Contents for Zksoftware C3-400

- Page 1 LED Indicators, Wires, Auxiliary Input and Output Notes: C3-400 Installation Guide 1) Meaning of LED indicators: Vision: 1.0.1 2) Recommended use of wires: Date: Oct. LINK indicator (green): always (green) indicates TCP/IP communication is proper; A Use 2-conductor power cord...

- Page 2 Equipment Communication RS485 Address setting, Restore factory setting, Terminal resistance setting Set RS485 address through DIP switch: The background PC software is able to communicate with the system according to two protocols (RS485 and TCP/IP) for data exchange and 1) Places 1-6 on the DIP switch are for setting the number of control panels when communicating through RS485. It is adapted for binary remote management.

- Page 3 “Wet mode” wiring diagram of lock connecting with external power supply. 1 2 3 4 5 6 7 8...

Need help?

Do you have a question about the C3-400 and is the answer not in the manual?

Questions and answers