Summary of Contents for Emhart Teknologies TUCKER ERF

- Page 1 Assembly Instructions Feeding Units ERF/ERD/EPS Please read the assembly instructions before any operation!

- Page 2 © Emhart Teknologies TUCKER GmbH Max-Eyth-Straße 1 D-35394 Gießen Tel.: +49 (0) 641 405 0 Fax.: +49 (0) 641 405-383 E-Mail: Info@tucker.de Internet: www.tucker.de Translation of the original assembly instructions MTA ERF ERD EPS 01...

-

Page 3: Table Of Contents

Feeding Units ERF/ERD/EPS Table of Contents Table of Contents General Information......................5 Information Regarding the Assembly Instructions..........5 Limitation of Liability....................5 Symbol Legend ..................... 6 Copyright Protection....................7 Replacement Parts....................7 Guarantee Instructions..................8 After Sales Service....................8 Remark to the Declaration of Incorporation ............8 Safety .......................... - Page 4 Feeding Units ERF/ERD/EPS Table of Contents Manual Feeding Device..................33 Connection and Installation ..................34 Connection Compressed air ................34 Connecting Feeder without Divider ..............35 5.2.1 Connecting Feeder to the Control Unit ............ 35 5.2.2 Connecting Feeder to Rivet Spindle............36 Connecting Feeder with Rivet Divider ..............

-

Page 5: General Information

Feeding Units ERF/ERD/EPS General Information General Information Information Regarding the Assembly Instructions These assembly instructions contain important information regarding the handling of this device. The compliance with all security advisories and operation instructions is a precondition for a safe operation. Furthermore the local accident prevention regulations and the general safety regulations effective for the application area of the device have to be observed. -

Page 6: Symbol Legend

Feeding Units ERF/ERD/EPS General Information Symbol Legend Warning notices The warning notices in this operation manual are indicated by symbols. The notes commence with a signal word which expresses the extent of the danger. Observe the notes and act with caution to avoid accidents and damage to persons and property. -

Page 7: Copyright Protection

Feeding Units ERF/ERD/EPS General Information Special security advisories In order to draw attention to special dangers, the following symbols are used in connection with security advisories: DANGER! Danger to life by electric current! … indicates perilous situations by electric current. Disregarding of the security advisories can lead to severe injuries or death. -

Page 8: Guarantee Instructions

Feeding Units ERF/ERD/EPS General Information Guarantee Instructions For material and manufacturing faults, the guarantee period for this feeding unit amounts to 1 year from delivery date on. Excluded from this is damage that is caused by accident or by incorrect handling. The guarantee covers free-of-charge replacement of the faulty component. -

Page 9: Safety

Feeding Units ERF/ERD/EPS Safety Safety This paragraph gives a review about all important safety aspects for an optimal protect of the personnel as well as for the safe and failure-free operation. Disregard of the operating instructions and security advices mentioned in this manual could lead to serious dangers. -

Page 10: Personnel Requisition

Feeding Units ERF/ERD/EPS Safety Personnel Requisition 2.2.1 Qualification WARNING! Risk of injury on insufficient qualification! Improper handling can lead to serious damage to persons and property. Therefore: All activities are to be carried out by skilled personnel only! The following qualifications for different areas of operations are named in the assembly instructions: ... -

Page 11: Trespassers

Feeding Units ERF/ERD/EPS Safety 2.2.2 Trespassers WARNING! Danger for trespassers! Trespassers who do not fulfil the requirements mentioned in this document do not know about the dangers of this working area. Therefore: Keep trespassers away from the working area. When in doubt, approach persons and banish them from the working area. -

Page 12: Intended Use

Feeding Units ERF/ERD/EPS Safety Intended Use 2.3.1 Self-Piercing Rivet Feeder The Self-piercing rivet feeder is designed exclusively for the intended use mentioned in this manual. The feeder ERF is intended to mount self-piercing rivets in industrial and commercial areas and only for application in premises. The feeder ERF has been designed for automatic operation in robots, semiautomatic operation and manual operation. -

Page 13: Self-Piercing Rivet Divider Erd

Feeding Units ERF/ERD/EPS Safety 2.3.2 Self-Piercing Rivet Divider ERD The self-piercing rivet divider is designed exclusively for the intended use men- tioned in this manual. The divider ERD is intended to mount self-piercing rivets in industrial and commercial areas and only for application in premises. The divider ERD can only operate in conjunction with two self piercing rivet feeders. -

Page 14: Pre-Separation Eps

Feeding Units ERF/ERD/EPS Safety 2.3.3 Pre-Separation EPS The pre-separation EPS is designed exclusively for the intended use mentioned in this manual. The pre-separation EPS is intended to mount self-piercing rivets in industrial and commercial areas and only for application in premises. The pre-separation EPS can only operate in conjunction with a self piercing rivet feeder. -

Page 15: Personal Protective Equipment

Feeding Units ERF/ERD/EPS Safety Personal Protective Equipment At work wearing personal protective equipment is essential to minimize the risks for the health. During working time always wear the required protective equipment for the respective work. Observe the signs regarding the personal protective equipment which exist in the working area. -

Page 16: Special Risks

Feeding Units ERF/ERD/EPS Safety Special Risks The residual risks which arise from the hazard analysis are described in the following chapter. Please consider the below mentioned security advices and warnings in the following chapters of this manual to reduce health hazards and to avoid dangerous situations. - Page 17 Feeding Units ERF/ERD/EPS Safety Moved components WARNING! Risk of injury by moved components! Rotating and/or linearly moved components could cause severe injuries. Therefore: Do not grasp in or handle on moved components while operation. No not open the coverings while operation. Consider the follow-up time.

-

Page 18: Safety Installations

Feeding Units ERF/ERD/EPS Safety Safety Installations The Self-Piercing rivet feeding units are intended for the application within an installation. The self-piercing rivet feeding units are to be integrated into the safety concept of the self-piercing rivet installation. Installation of the Appliance ... -

Page 19: Technical Data

Feeding Units ERF/ERD/EPS Technical Data Technical Data General Specifications Feeder ERF Specification Value Unit Weight without rivets approx. 35 Length approx. 600 Width approx. 270 Height approx. 480 System of protection: IP 54 ac- Protected against dust penetra- cording to Splash- tion IEC 529... -

Page 20: General Specification Pre-Separation Esp

Feeding Units ERF/ERD/EPS Technical Data Divider ERD Specification Value Unit Relative humidity of air, not 5 to 95 condensing Working position Indefinite Noise emission Sound pressure level < 75 dB (A) Type of rivets: D3,3 Length 4 - 5 D5,3 Length D5,3 Length... -

Page 21: Equipment Fuses

Feeding Units ERF/ERD/EPS Technical Data Equipment Fuses DANGER! Opening the control cabinet as well as the replacement of the fuses inside the equipment is to be carried out by qualified personnel only! Fuse elements Control insertion Fuse Nominal Nominal Tripping voltage (V) current (A) characteristic... - Page 22 Feeding Units ERF/ERD/EPS Technical Data PCB Customer Fuse Nominal Nominal Tripping Interface voltage (V) current (A) characteristic 5x20 mm A1 - F1 semi time lag PCB Motor- Fuse Nominal Nominal Tripping Interface voltage (V) current (A) characteristic 5x20 mm A3 - F1 0,315 semi time lag 5x20 mm...

-

Page 23: Fastening Ttorques For Metric Screws

Feeding Units ERF/ERD/EPS Technical Data Fastening Torques for Metric Screws Values according VDI 2230 under utilization of the minimum yield stress of 75% Metric screws Fastening torques Thread size Property class Property class 10.9 1,1 Nm 1,65 Nm 2,5 Nm 3,65 Nm 4,9 Nm 7,25 Nm... -

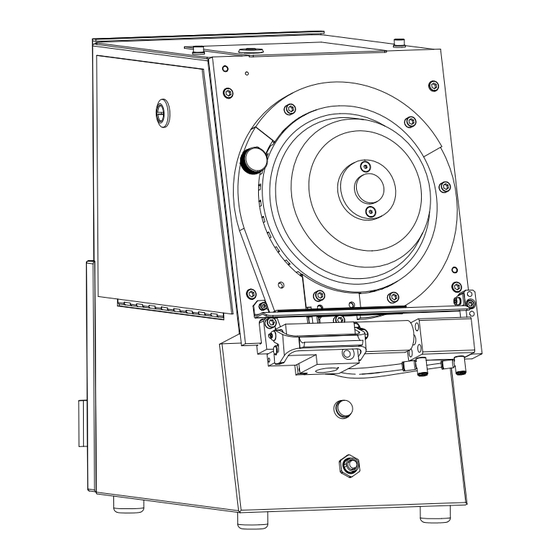

Page 24: System Components

Feeding Units ERF/ERD/EPS System Components System Components In this chapter you will receive an overview concerning the system components feeder ERF, divider ERD and pre-separation EPS. Here you will find information on the connections and the control elements. Familiarise yourself with the system components before installation. - Page 25 Feeding Units ERF/ERD/EPS System Components Connection X4: The feeder is connected to the program selection box “Interface foot switch” by means of the control cable (manual application). Connection X5: The Master feeder ERF is connected to the linear slide control LSC or to the pre-separation EPS by means of the control cable. Maintenance unit with air connection: Connecting of the compressed air to the rivet feeder and setting the operating pressure.

- Page 26 Feeding Units ERF/ERD/EPS System Components 11. Proximity switch: Connecting for the feed tube proximity switch. 12. Level control signal lamp: The lamp lights up when the separation drum is sufficiently full. Normal flashing of the lamp (35/min): The rivets in the drum fall below the level.

-

Page 27: Rivet Divider Erd

Feeding Units ERF/ERD/EPS System Components Rivet Divider ERD Terminal box Slider Electrical connection X1: Plug socket for the electrical connecting cable to the master feeder. Electrical connection X2: Plug socket for proximity switch of rivet checking behind the divider. - Page 28 Feeding Units ERF/ERD/EPS System Components Electrical connection X3: Here the sensor for the piston rod–sided end position of the cylinder is connected. If the LED on the cylinder lights up the end position is reached. The divider is in position “Master“. Electrical connection X4: Here the sensor for the piston–sided end position of the cylinder is connected.

-

Page 29: Control Pre-Separation

Feeding Units ERF/ERD/EPS System Components Control Pre-Separation Electrical connection X1: The control pre-separation is connected to the master feeder or to the LSC by means of the electrical control cable. Electrical and pneumatically connection X2: The control pre-separation is connected to the pre-separation by means of the electrical and pneumatic supply lines. -

Page 30: Pre-Separation Eps

Feeding Units ERF/ERD/EPS System Components Pre-Separation EPS Pneumatic connection: “Stopper closed“ Connection for the green compressed-air hose. Pneumatic connection: “Stopper open“ Connection for the blue compressed-air hose. Pneumatic connection: “Slider position chamber 2“ Connection for the black compressed-air hose. Pneumatic connection: “Slider position chamber 1“ Connection for the red compressed-air hose. -

Page 31: Feeding Tube

Feeding Units ERF/ERD/EPS System Components Feeding Tube Tube connection: Connecting feeding tube to the ERF feeder. Feeding tube standard (0°) connection: The tube is supplied with a straight attachment for standard application. Feeding tube 90° connection: Certain applications require a 90° elbow tube connection, which can also be supplied. -

Page 32: Receiver

Feeding Units ERF/ERD/EPS System Components Receiver Quick-action lock SRT tool: The quick-action lock connects the receiver and the ERT tool. Quick-action lock feeding tube: The quick-action lock connects the receiver and the rivet feeder ERF. Quick-release mechanism: With the help of the quick-release mechanism you can remove a rivet from the receiver without having to dismantle the receiver from the rivet spindle. -

Page 33: Manual Feeding Device

Feeding Units ERF/ERD/EPS System Components Manual Feeding Device Loading: Opening for insertion of the rivet. Loading slider: The loading slider transports the inserted rivet from the loading opening into the rivet channel of the receiver. Coupling: The coupling piece allows a fixing in correct positional arrange- ment of the feeding unit directly at the receiver. -

Page 34: Connection And Installation

Feeding Units ERF/ERD/EPS Connection and Installation Connection and Installation Start up the feeding units only if you have completely and orderly installed all system components and linked them with each other. CAUTION! Only connect the feeding units with the ERC control unit switched off. -

Page 35: Connecting Feeder Without Divider

Feeding Units ERF/ERD/EPS Connection and Installation Connecting Feeder without Divider If the self-piercing rivet installation is operated only with one type of rivet, link the control unit ERC and rivet spindle directly with the feeder. 5.2.1 Connecting Feeder to the Control Unit The connection for the electrical control cable to the ERF feeder is located on the back side, and is labelled with the designation “X1”. -

Page 36: Connecting Feeder To Rivet Spindle

Feeding Units ERF/ERD/EPS Connection and Installation 5.2.2 Connecting Feeder to Rivet Spindle A feed tube with quick-action lock connects the ERF feeder and the rivet spindle. The rivet spindle is supplied with rivets by means of the feed tube. Connecting feed tube to ERF feeder open close For connection observe the following sequence:... - Page 37 Feeding Units ERF/ERD/EPS Connection and Installation Connecting feed tube to rivet spindle Quick-action lock feeding tube connection close open For connection observe the following sequence: Press an Allen key (size 3 mm) into the connection of the receiver. Loosen the quick-action locks on the receiver by pressing (1) and a half-turn to the left (2).

-

Page 38: Connecting Feeder With Rivet Divider

Feeding Units ERF/ERD/EPS Connection and Installation Connecting Feeder with Rivet Divider By the use of a divider two rivets of a different length with the same diameter can be fed to the rivet spindle. In this case two feeders (Master and Slave) are used with one rivet spindle. -

Page 39: Connecting Slave Feeder To Master Feeder

Feeding Units ERF/ERD/EPS Connection and Installation 5.3.2 Connecting Slave Feeder to Master Feeder The connection for the electrical control cable is located on the back Slave feeder side, and is labelled with the designation “X1“.The connection for the electrical control cable is located on the back Master feeder side, and is labelled with the designation “X2“. - Page 40 Feeding Units ERF/ERD/EPS Connection and Installation For connection observe the following sequence: The control unit ERC must be switched off at the main switch. Connect one end of the electrical control cable to connection “X1” on the rivet divider ERD.

- Page 41 Feeding Units ERF/ERD/EPS Connection and Installation Press an Allen key (size 3 mm) into the connection of the coupling plate, before connecting the feeding tube to the Master feeder ERF 1. Loosen the connection on the feeder by pressing and a half-turn to the left. ...

-

Page 42: Connecting Divider With Spindle Or Tool Changer System

Feeding Units ERF/ERD/EPS Connection and Installation 5.3.4 Connecting Divider with Spindle or Tool Changer System A feeding tube connects the rivet divider with the rivet spindle or the tool changer system. The rivet spindle is supplied with rivets by means of the feeding tube. The connection for the feeding tube to the divider is located on the back slider side and is labelled with the designation “ERT”. -

Page 43: Connecting Feeder With Divider And Pre-Separation

Feeding Units ERF/ERD/EPS Connection and Installation Connecting Feeder with Divider and Pre-Separation On the use of two feeders (Master- and Slave feeder) in the application, the feeders have to be connected via a divider. The pre-separation is an optional kit, which is intended for the stocking of two rivets (of different length and of the same diameter). -

Page 44: Connecting Pre-Separation Eps To Control Eps

Feeding Units ERF/ERD/EPS Connection and Installation The connection for the compressed-air supply of the pre-separation is situated at the maintenance unit of the linear slide control (chapter 3.3) and will be connected with a compressed-air line of Ø 8 mm to the T-fitting. Connect the compressed-air line of the pre-separation to the air supply of the linear slide control. -

Page 45: Connecting Pre-Separation To Rivet Divider

Feeding Units ERF/ERD/EPS Connection and Installation 5.4.3 Connecting Pre-Separation to Rivet Divider The feeding tube connects the pre-separation and the rivet divider. The connection for the feeding tube at the pre-separation is situated on the side of the air blast supply (1). At the divider the feeding tube is connected to the connection with the designation ERT (chapter 5.2.4). -

Page 46: Connecting Pre-Separation To Spindle Or Tool Changer System

Feeding Units ERF/ERD/EPS Connection and Installation 5.4.4 Connecting Pre-Separation to Spindle or Tool Changer System A feeding tube connects the pre-separation with the rivet spindle or with the quick- change system. The rivet spindle is supplied with rivets by the feeding tube. The connection for the feeding tube at the pre-separation is situated at the side of the stopper (2). -

Page 47: Connecting Manual Feeding Device

Feeding Units ERF/ERD/EPS Connection and Installation Connecting Manual Feeding Device The manual feeding unit is designed for the use in test mode and allows the conveying of several rivets of different lengths into the receiver without a feeder. Manual feeding device ... -

Page 48: Operating The Rivet Feeder

Feeding Units ERF/ERD/EPS Operating the Rivet Feeder Operating the Rivet Feeder In conjunction with the ERC control unit the ERF rivet feeder guarantees the separation and feeding of the rivets in keeping with the requisite riveting process. Replenish Rivets Open the filler flap on the rivet feeder and pour the rivets into the rivet filling box. CAUTION! On filling the rivet feeder mind that no impurities or wrong rivet dimensions arrive at the replenishing box. -

Page 49: Check Correct Level

Feeding Units ERF/ERD/EPS Operating the Rivet Feeder Check Correct Level Function lamp: The "Level" lamp shows the correct level in the separation drum and the readiness for service of the feeder. The lamp lights up: The feeder is ready for service and the separation drum is sufficiently full. Normal flashing of the lamp (35/min): The rivets in the drum fall below the level. -

Page 50: Transport, Packaging And Storing

Feeding Units ERF/ERD/EPS Transport, Packaging and Storing Transport, Packaging and Storing Security Advice for the Transport Improper transport CAUTION! Damages caused by improper transportation. Improper transport could cause serious damage of property. Therefore. Transport and lifting operations are to be carried out exclusively using the crane eyes designed for this purpose. -

Page 51: Terms And Conditions For Overseas Transport

Feeding Units ERF/ERD/EPS Transport, Packaging and Storing Terms and Conditions for Overseas Transport NOTE! For onward transportation overseas use sea freight transport crate with the corresponding number of desiccant pouches for packing according to DIN 55473! The manufacturer bears no liability for damages caused by improper onward transportation. -

Page 52: Packaging

Feeding Units ERF/ERD/EPS Transport, Packaging and Storing Packaging The respective packaging pieces are packed according to the transport conditions to expect. Exclusively non-polluting materials were used for packaging. The packaging shall protect the respective components against transport damages, corrosion and other damages until assembly. Therefore do not destroy the packaging and remove just shortly before assembly. -

Page 53: Maintenance And Cleaning

Feeding Units ERF/ERD/EPS Maintenance and Cleaning Maintenance and Cleaning Safety Personnel The maintenance work described can be executed by the operator, unless it is marked differently. Some maintenance work may only be executed by specially trained experts. Maintenance work on the electric installation basically may only be executed by specialists for electronics. - Page 54 Feeding Units ERF/ERD/EPS Maintenance and Cleaning Interval Wearing work To be carried out by daily Check connection cables, pneumatic lines, plug Operator connectors and feeding tubes for mechanical damage and loose contacts weekly Emptying maintenance unit Qualified personnel Control cables: Qualified personnel Check of mechanical or electrical damage and the min.

-

Page 55: Pre-Separation (Small Cleaning)

Feeding Units ERF/ERD/EPS Maintenance and Cleaning Pre-Separation (Small Cleaning) Monthly or all 80000 cycles Proceed as follows: Remove feeding tubes. Release the two screws from the cover of pre-separation. Swivel the cover in that way that it opens up the whole interior. ... -

Page 56: Pre-Separation (Large Cleaning)

Feeding Units ERF/ERD/EPS Maintenance and Cleaning Pre-Separation (Large Cleaning) Three months or all 250000 cycles Proceed as follows: Close the shut-off valve at the control pre-separation, wait until you hear a clear hearable noise for confirmation of the ventilation. ... -

Page 57: Stopper With Housing

Feeding Units ERF/ERD/EPS Maintenance and Cleaning Stopper with Housing Three months or all 250000 cycles Proceed as follows: Close the shut-off valve at the control pre-separation, wait until you hear a clear hearable noise for confirmation of the ventilation. ... -

Page 58: Self-Piercing Rivet Feeder (Small Cleaning)

Feeding Units ERF/ERD/EPS Maintenance and Cleaning Self-Piercing Rivet Feeder (Small Cleaning) Three months or all 250000 cycles Proceed as follows: Ensure that the compressed-air supply at the maintenance unit of the feeder is interrupted and the needle of the manometer shows “0 bar”. ... -

Page 59: Self-Piercing Rivet Feeder (Large Cleaning)

Feeding Units ERF/ERD/EPS Maintenance and Cleaning Self-Piercing Rivet Feeder (Large Cleaning) Semi annually or all 500000 cycles Proceed as follows: Ensure that the compressed-air supply at the maintenance unit of the rivet feeder is interrupted and the needle of the manometer shows “0 bar”. ... -

Page 60: Feeding Tubes

Feeding Units ERF/ERD/EPS Maintenance and Cleaning Feeding Tubes Three months or all 250000 cycles NOTE! The durability of the feeding tubes strongly depends on the feeding tube-laying. Therefore: Regard the bending radii! Proceed as follows: Release the proximity switch cable from feeder and rivet spindle. ... -

Page 61: Disposal

Feeding Units ERF/ERD/EPS Disposal Disposal Unless no recovery- or disposal arrangement was made disassembled parts have to be recycled: Scrap metals. Recycle plastic elements. Dispose sorted all the rest of the components according material properties. CAUTION! Damage caused to the environment due to wrong disposal! Electronic waste, electronic components, lubricants and other additives are subject to treatment of hazardous waste and may... - Page 62 Notizen/Notes:...

- Page 63 Translation of the Original Declaration of Incorporation Declaration of Incorporation acc. to the EC Machinery Directive 2006/42/EC, Document number: EBE ERF 01 Authorized person to compile the relevant Manufacturer: documentations: Technische Dokumentation TUCKER GmbH TUCKER GmbH Max-Eyth-Straße 1 Max-Eyth-Straße 1 35387 Gießen 35387 Gießen Deutschland...

- Page 64 Appendix to the Original Declaration of Incorporation Appendix to the Declaration of Incorporation List of applied and adhered to basic safety and health requirements for construction and assembly of machines with respect to the product mentioned on page 1. Description Essential health and safety Requirements 1.1.

- Page 65 Appendix to the Original Declaration of Incorporation Description 1.5.6. Fire 1.5.7. Explosion 1.5.8. Noise 1.5.9. Vibration 1.5.10. Radiation 1.5.11. External radiation 1.5.12. Laser radiation 1.5.13. Emissions of hazardous materials and substances 1.6. Maintenance 1.6.4. Operator intervention 1.7. Information 1.7.1.1. Information and information devices 1.7.1.2.

Need help?

Do you have a question about the TUCKER ERF and is the answer not in the manual?

Questions and answers