Summary of Contents for Post FREWITT 20 152 Series

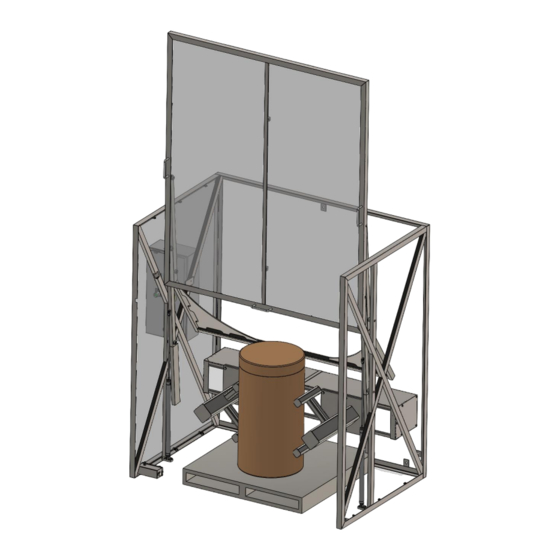

- Page 1 OPERATOR MANUAL FREWITT DRUM CONDITIONER SERIAL NUMBERS 20.152 POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355...

-

Page 2: Table Of Contents

CCOMPRESSED AIR HAZARDS ..................17 PRODUCT HAZARDS .....................17 RESIDUAL RISKS ......................17 OTHER RISKS ........................17 INTEGRATION .........................18 WARRANTY LIMIT......................18 LIMITATION OF RESPONSIBILITY OF THE PRODUCT MANUFACTURER ..18 EMERGENCIES ........................18 WARRANTY ........................18 POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355... -

Page 3: Introduction

INTRODUCTION This manual provides operating, maintenance and service information regarding the Post Material Handling Drum Conditioner. Keep this manual available to management, operator and maintenance personnel who are responsible for the equipment’s operation and maintenance. It is essential to read, understand and follow the recommendations of this manual before operating or servicing this equipment. -

Page 4: General Specifications

2. Pull the Emergency Stop button out if they have been depressed. 3. Close the safety gate. 4. Press the RESET button. The reset button light will be steady on. POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com... -

Page 5: Loading The Drum Conditioner With A Drum

Raise the safety gate with the handles provided. There are three handles available for raising and lowering the safety guard. 2. Using a pallet jack, remove the pallet and drum from the drum conditioner. POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com... -

Page 6: Emergency Stop

The status of the drum conditioner is displayed with the reset button indicator light. Steady on light SYSTEM READY All conditions/interlocks are set to start the machine. Slow blinking RESET REQUIRED POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355... -

Page 7: Installation Instructions

Reference the section CHANGING THE NUMBER OF DRUM CONDITIONING COMPRESSION CYCLES. INSTALLATION INSTRUCTIONS Mount the drum conditioner on a sturdy vertical mounting surface per the hole pattern show below. POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355... - Page 8 2. Mount the control enclosure using the provided mounting holes. POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355...

- Page 9 3. Locate the safety guard over the drum conditioner. Fasten to the wall and floor using the mounting tabs provided. Mounting hardware by others. POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355...

-

Page 10: Slot Cover And Shroud Removal

Remove the side panel removal screws to free the side panel. Pull the conditioner shroud off to gain access to the internal components of the machine. POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com... -

Page 11: Approval Drawing

APPROVAL DRAWING POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355... -

Page 12: Electrical Diagram

ELECTRICAL DIAGRAM POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355... - Page 13 POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355...

-

Page 14: Pneumatic Diagram

PNEUMATIC DIAGRAM POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355... -

Page 15: Cleaning Procedures

The following symbols are employed to provide practical guidelines regarding safety and operation of the installation. They advise the user against possible accidents to both person and equipment and provide practical guidelines for the use of the installation. POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com... -

Page 16: Operators And Maintenance Staff

The safety nuts may only be unscrewed during cleaning or maintenance work. Only properly trained cleaning and maintenance staff may have access to the special tools required for the safety nuts POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com... -

Page 17: Electrostatic Charging Hazards

In all such cases the manufacturer should always be informed. OTHER RISKS The installation under operation can have a high noise level. When operating the installation, wear ears protection. POST MATERIAL HANDLING 21 Stone Castle Road, Rock Tavern, NY 12575 www.posthoist.com 845-200-3355... -

Page 18: Integration

INTEGRATION If the installation of Post has to be integrated in a final installation, the user should ensure that the proper safety systems are operational in order to avoid the introduction of members at the fragmentation zone near the installation’s inlet-outlet.

Need help?

Do you have a question about the FREWITT 20 152 Series and is the answer not in the manual?

Questions and answers