Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for NAPCO NAP9600

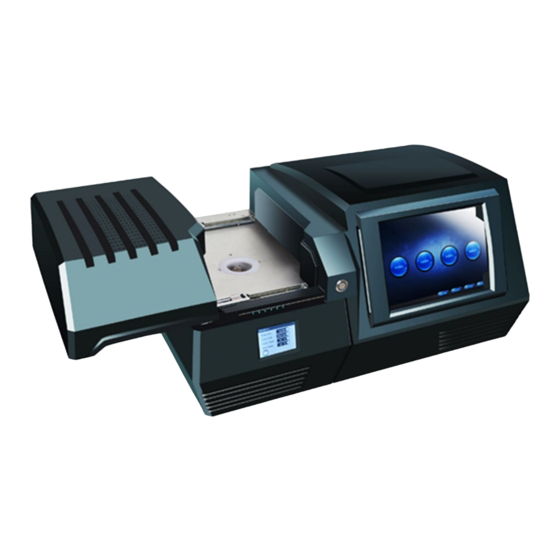

- Page 1 NAP9600 X-Ray Fluorescence Spectrometer User Manual...

- Page 2 NAPCO9600 / Basic Knowledge & Operation NAPCO9600/Basic Knowledge A-1 / Introduction Working Principle...

-

Page 3: Working Principle

NAPCO9600 / Basic Knowledge & Operation Working Principle... - Page 4 NAPCO9600 / Basic Knowledge & Operation NAPCO / Operation B-1/ Accessories List B/2 Power Cables &USB Port B/2 Turn on Instrument B/3 Turn on Computer B-4 / Software Operation System PC Hardware Software Installation Software Introduction a) Interface b) Function...

-

Page 5: Accessories List

NAPCO9600 / Basic Knowledge & Operation Accessories List Item Remarks Power Supply cable For turning on instrument and computer Silver sample For initialization Test Film Placing sample on it User Manual For operator reference Bracket For holding the sample... - Page 6 NAPCO9600 / Basic Knowledge & Operation Power Cables & USB Port Power Cables: One power cable connects to instrument. USB Port: You can connect mouse or printer. Turn on Instrument Press the POWER button to turn on the instrument. Turn on Computer Press the button to turn on the computer.

-

Page 7: Software Installation

NAPCO9600 / Basic Knowledge & Operation Software XRF6.0 is a professional precious metal testing software Operating system Operation system: Win 7 PC hardware Advice configures: CPU: 1.60GHz Memory(RAM): 2.00GB Hard disk: 60 GB System type: 32-bit Operating System Pen and Touch: Touch Input Available Software installation 1. -

Page 8: Software Introduction

NAPCO9600 / Basic Knowledge & Operation Software Introduction Instrument Operating Manual 1.Turn on instrument and computer 2.Run Software Double click below icon" NAPCO9600” to run software 3.System automatic preheating After the system self-test finished, the instrument will be preheated for 5 minutes. If the user opens the testing chamber cover, the preheating will be automatically ended. - Page 9 NAPCO9600 / Basic Knowledge & Operation Test status information: Test mode: Single test, Repeat test, Multi-point test, Peak adjustment. Curve Name: The name of template which is automatically selected for testing and calculating. Spectrum name: The name of spectrum which is testing or opening. ...

- Page 10 NAPCO9600 / Basic Knowledge & Operation B. Channel information of current cursor The information display when the mouse cursor in the cross position of the spectral area, X axis represents the channel position (0~2048), Y axis represents the count rate of current channel position;...

- Page 11 NAPCO9600 / Basic Knowledge & Operation 5.Initialization (Peak Adjust) The purpose of peak adjustment is to correct instrument hardware parameter to ensure the test accuracy and stability. If the result has big deviation, system will remind customers to carry out this operation, because this operation must be implemented with silver sample, so it must be manually operated.

- Page 12 NAPCO9600 / Basic Knowledge & Operation 6. Testing a) Click Test button ,pop up below screen: b) Select “Single” test, input sample name (If don’t type, system use default name “TempSample” automatically) Use high-efficient convenient digital small keyboard to input the name, and then click OK. If same name exists, system will ask you “want to cover”? Click “Yes”...

- Page 13 NAPCO9600 / Basic Knowledge & Operation e) Click the print button at the right lower corner, then choose different external or internal printer. Test Report:...

- Page 14 NAPCO9600 / Basic Knowledge & Operation 6.2. Repeat Test a) Click Test button , select “Repeat” test, input name and test frequency, click “OK” : Notice: if input test frequency as 5, the total testing duration is 5 times more than single test duration.

- Page 15 NAPCO9600 / Basic Knowledge & Operation Test Report :...

- Page 16 NAPCO9600 / Basic Knowledge & Operation 6.3. Multi-point test a) Click Test button , select “Multi” test, input name and test frequency, click “OK”. b) After testing one point, system will remind user to continue the test with another point as below: c) After completing all five points, system will automatically switch to the results page as below d) Click”...

- Page 17 NAPCO9600 / Basic Knowledge & Operation Test Report:...

- Page 18 NAPCO9600 / Basic Knowledge & Operation Q&A Q: Software keep reminding” Newyork connection error “and “DSP connection error”, how to do? A: please contact engineer as soon as possible. Q: what time to do peak adjustment A: After testing pure silver sample, the peak channel more than +/- 3 comparing with standard 1100 channel.

-

Page 19: Basic Maintenance

NAPCO9600 / Basic Knowledge & Operation Maintenance Basic Maintenance: There should be someone specially be in charge of operation and maintenance, it can’t be operated or moved without permission; There should be none disturb during testing, for example: generator, motor, electric welding; It’s suggested to work with UPS(power stabilizer) ;...

Need help?

Do you have a question about the NAP9600 and is the answer not in the manual?

Questions and answers