Summary of Contents for CleanLogix FBHS-MR

- Page 1 USER MANUAL MODEL: FBHS-MR Foot Bath Hand Sanitizer English (Original Instructions) Updated: 05/12/20...

- Page 2 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Table of Contents Cleaning System Requirements Maintenance Installation Troubleshooting Physical Set-Up Appendices Plumbing Connections Parts Callouts Priming Electrical Schematics Traffic Direction P&I Diagram Operation WARNING: 1. All personnel using this unit must be familiar with the information contained in this manual.

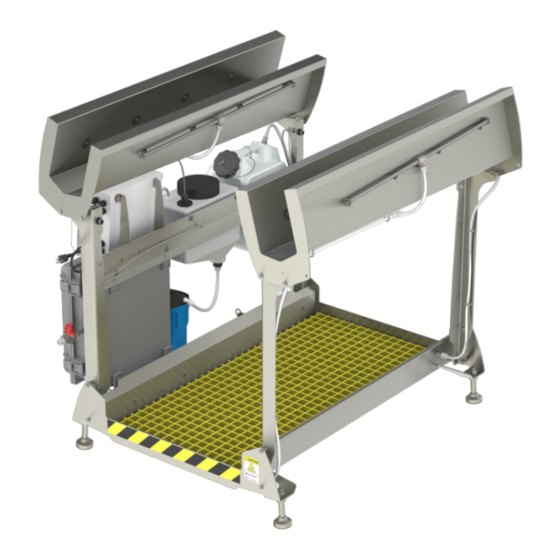

- Page 3 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Overview System Requirements Water Supply The FBHS, Foot Bath and Hand Sanitizer, applies a fine mist spray onto the hands through 16 anti-drip • Flow: 5 GPM (3.8L/m) minimum* nozzles. Concentrated sanitizer and water are pre- mixed in the onboard batch tank before it is applied •...

- Page 4 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Installation NOTE: For fixed installations, area in front of electrical panel must be clear at least 36" FBHS Manual Page 4 of 23 Updated: 05/12/20...

- Page 5 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Installation NOTE: Traffic flow direction can be reversed by swapping wires on inputs I-00 and I-001 of microcontroller (see electrical schematic for more information). NOTE: Model -MR (Manual Refreash Foot Bath) is for locations which do not have a dedicated drain.

- Page 6 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Installation Physical Set Up: 1. Set unit in desired location. 2. Aspects to consider when deciding on placement: • Clearance for general use • Location of drain • Emergency exit paths or egress •...

- Page 7 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Installation Plumbing Connections: • Full length capillary tube results in a dilution ratio of approximately 1:670 at 30-50 psi water inlet pressure. • When complete, re-connect solution lines to green hose barb of the Venturi Injector located in plumbing enclosure [Figure 7.1].

- Page 8 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Operation 1. Make sure the drain valve is closed [Figure 8.1] 2. Turn the power switch to “ON” [Figure 8.2] • If the batch tank is low or empty, it should begin to fill.

- Page 9 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Cleaning Procedures Cleaning Instructions 1. Turn the power switch to “OFF” [Figure 9.1]. 2. Open the drain valve to drain the foot bath [Figure 9.1]. 3. Use a cleaner that will not attack 304 stainless steel or any of the materials listed in the unit Fig.

- Page 10 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Preventative Maintenance Notes: The following maintenance procedures are recommended for normal use. Units which see a high amount of use should be inspected more frequently. Weekly: • Check unit for proper sensor and spray function.

- Page 11 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Preventative Maintenance Foot Bath Depth Adjustment Nozzle Disassembly and Cleaning The depth of the foot bath can be adjusted by sliding 1. Unscrew nozzle from outside of trough using the foot bath float switch assembly up or down.

- Page 12 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Troubleshooting Problem Causes Solutions Notes If the foot bath or batch Close the drain valve. tank fail to fill up within The drain valve was left a specific amount of open while the unit was...

- Page 13 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Troubleshooting Problem Causes Solutions Notes Open the drain valve to lower the water level in the foot bath such that it is below the walkway grating. Reset the unit by turning The float switch is faulty the power switch to “OFF”...

- Page 14 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Troubleshooting Problem Causes Solutions Notes Make sure the air supply is on and the red-handled shutoff Compressed air supply is valve is set to “SUP”. The air turned off pressure regulator gauge on the unit should read between 80 and 100 psi.

- Page 15 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Troubleshooting Problem Causes Solutions Notes Turn the power switch to “OFF” and turn the red- handled air shutoff valve to “EXH”. Clean or replace the Clogged nozzles nozzles as detailed in the maintenance instructions.

- Page 16 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Appendix A - Parts Callout DETAIL ON NEXT PAGE FBHS Manual Page 16 of 23 Updated: 05/12/20...

- Page 17 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Appendix A - Parts Callout FBHS Manual Page 17 of 23 Updated: 05/12/20...

- Page 18 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Appendix A - Parts Callout FBHS Manual Page 18 of 23 Updated: 05/12/20...

- Page 19 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Appendix A - Parts Callout FBHS Manual Page 19 of 23 Updated: 05/12/20...

- Page 20 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Appendix A - Parts Callout PART NUMBER DESCRIPTION PART NUMBER DESCRIPTION F1012 SCREW MACHINE 10-32 x 5/8 SS PHILLIPS P1172 WIRE DUCT 25X60 X 188mm LONG F1024 SCREW MACHINE 1/4-20 x 3/4 SS PHILLIPS P1184 CORD GRIP 1/2 NPT X .095-.260 BLK...

- Page 21 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Appendix A - Parts Callout PART NUMBER DESCRIPTION P1586 ENCLOSURE 10 X 10 X 6 POLY W/ PLASTIC LOCKABLE LATCHES P1588 MICROCONTROLLER ALLEN BRADLEY MICRO810 P1590 ENCLOSURE 16X13X8 PLASTIC P1592 VALVE, SOLENOID, 3/8" PP 24VDC DIN COIL...

- Page 22 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Appendix B - Electrical Schematic FBHS Manual Page 22 of 23 Updated: 05/12/20...

- Page 23 USER MANUAL: FBHS-MR READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT Appendix C - P & I Diagram FBHS Manual Page 23 of 23 Updated: 05/12/20...

Need help?

Do you have a question about the FBHS-MR and is the answer not in the manual?

Questions and answers