Advertisement

Quick Links

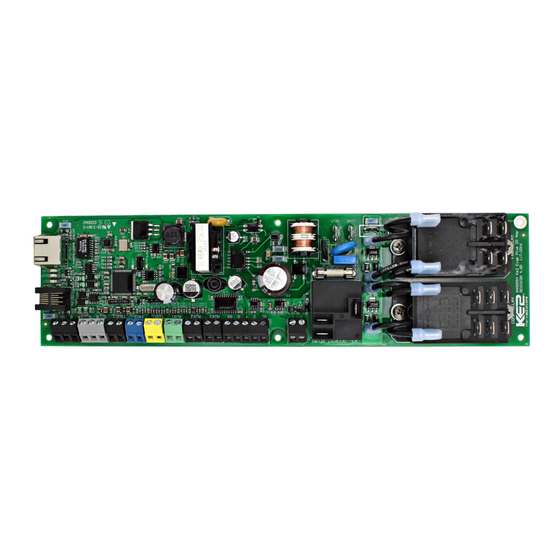

KE2 EvapOEM

Alarm Troubleshooting Guide

thermsolutions

Introduction:

The KE2 Evap OEM has advanced communications and alarming features, never

before seen in the refrigeration industry. These alarms provide early indications of

a poorly performing refrigeration system.

Text messages and/or email alerts provide notification of system issues

immediately, whether on-site or remote, as long as there is an internet connection.

Advanced alarming, diagnostic and troubleshooting are key features of the

KE2 Evap OEM controller, and help prevent catastrophic failures. This protects

contractor, owner, product, and refrigeration equipment.

When using KE2 SmartAccess, the controllers can be viewed, setpoints changed, and defrosts initiated remotely; saving time and frustration. In addition,

your home office or KE2 Therm technical support can even login with you to diagnose the system in real time.

Alarm Notifications:

Users are notified of alarms in multiple ways, described below.

From the face of the Basic Display:

The alarm is shown as a three digit code on the Basic Display, and the yel-

low or red LED light on the right side of the display will illuminate. If there

is more than one alarm present at the same time, press

the alarms.

Alarm Severity:

Red LED: Critical Alarm

expansion valve (EEV) to prevent compressor damage. This will

likely prevent refrigeration from continuing, but the con-

troller is attempting to prevent a catastrophic system fail-

ure, such as damage to the compressor. Critical alarms

must be addressed immediately.

Yellow LED: Cautionary Alarm

tinue to function to the best extent possible given the

system conditions, but the alarm should be addressed

as soon as possible.

On the controller's webpage:

Alarms can also be viewed in the top right-hand side of

the controller's webpage as a pulsing yellow or red bell

when connected to the controller via a smart device (smartphone, tablet,

PC etc.), or remotely via KE2 SmartAccess. When not in alarm, no bell is dis-

played.

These videos are relevant when troubleshooting

or for basic setup of your controller.

21214V3.0

to cycle through

- The controller will close the electric

- The controller will con-

Troubleshooting:

Video 034 – Iced Evaporator Coil on a Walk-in Freezer

Video 044 – Iced Evaporator Coil on a Walk-in Cooler

Video 107 – Troubleshooting a Temperature Sensor

Video 106 – Troubleshooting a Pressure Transducer

If the controller is connected to the internet, the KE2 Evap OEM can also send

text messages and/or emails to immediately notify all necessary personnel

of the alarm condition.

Alarm thresholds such as high temp and door alarm can be adjusted, and

Basic setup:

Video 068 – How to Determine Proper Coil Sensor Location

Video 069 – How to Properly Install a Coil Sensor

© Copyright 2023 KE2 Therm Solutions, Inc., Washington, Missouri 63090

Q.1.61 January 2023

should be set so as not to trigger

during normal loading and use.

Almost all alarms will automati-

cally clear once the alarm con-

dition no longer exists. To clear

an alarm manually, press and

hold

until tS (temperature

Setpoint) appears, press

sev-

eral times to CLA (CLear Alarm),

press and hold

until the

red LED blinks, then release.

Power cycling the controller to

clear alarms is not recommend-

ed, but will also reset the alarm

conditions.

Clearing alarms before calling

technical support will make

diagnosis more difficult or im-

possible; please call technical

support before clearing alarms

if assistance is required.

Note: If the alarm is a sensor

alarm and the sensor is still dis-

connected or shorted, the alarm

will immediately reappear.

Advertisement

Summary of Contents for KE2 EvapOEM

- Page 1 When using KE2 SmartAccess, the controllers can be viewed, setpoints changed, and defrosts initiated remotely; saving time and frustration. In addition, your home office or KE2 Therm technical support can even login with you to diagnose the system in real time.

- Page 2 Lead Lag Comms Communication lost between lead/lag controllers. Page 12 ERROR COMP SEQ COMM CompSeq. Comms Alarm Communication lost to KE2 Compressor Sequencer OEM. Page 12 Communication ERROR Email alert was not confirmed by email server provided after EMAIL FAILURE...

- Page 3 Dis Aux2 Sensor Discharge temp sen sor input is shorted or open. Page 18 AUX3 SENSOR Dis Aux3 Sensor Discharge temp sen sor input is shorted or open. Page 18 21214V3.0 © Copyright 2023 KE2 Therm Solutions, Inc., Washington, Missouri 63090...

- Page 4 If controller is still powered and system is running troubleshoot the Basic Display: Fuse • Make sure the plugs are fully inserted into the jacks at both the KE2 Evap OEM and the Basic Display. • Check the connection between the KE2 Evap OEM board and the Basic Display for any 0 to 10VDC Output burned, chaffed, cut or otherwise damaged sections.

- Page 5 SELECTED. care not to swap colors when repairing. rFG - Refrigerant • Confirm that a KE2 Therm pressure transducer and cable are being used. KE2 Therm’s Red LED is •Suction pressure will pressure transducer cable will have red, black, and green leads.

- Page 6 • If the new sensor is read properly by the controller, the sensor being diagnosed will Alarm need to be replaced. • If the sensor was disconnected for diagnostic purposes, return the sensor to the appropriate location on the controller once diagnostics are complete. 21214V3.0 © Copyright 2023 KE2 Therm Solutions, Inc., Washington, Missouri 63090...

- Page 7 See Q.1.45-A Multi Evap Applications for more information on bonding. Air Defrost - The KE2 Evap OEM keeps the room temperature much tighter than is typically seen in the industry. The KE2 Evap OEM’s default air temperature differential is 1.0°F, while the system is still protected from short cycling by minimum off and...

- Page 8 If suction pressure does not respond to manually oper- 21214V3.0 © Copyright 2023 KE2 Therm Solutions, Inc., Washington, Missouri 63090 ating the valve, proceed to next step.

- Page 9 HSH / LSH Corrective Action - Continued Low Superheat Alarm Only Check wiring to the EEV terminal on the KE2 Evap OEM board. Refer below for prop- er wiring of the KE2-RSV EEV and other common EEV wiring. The Low Superheat Alarm is most commonly caused by the compressor failing to start/ compressor not running.

- Page 10 • Check for outside air infiltration. Example: Infiltration from freezer into cooler. condition is 4°F below the Room Temp setpoint for 10 minutes, but can be adjusted as necessary. 21214V3.0 © Copyright 2023 KE2 Therm Solutions, Inc., Washington, Missouri 63090...

- Page 11 • Verify that the door switch is in proper working order. Door switches provided A2A - Aux Input 2 State by KE2 Therm are normally closed switches. To test them, move the two pieces of the AU3 - Aux Input 3 Mode...

- Page 12 • Verify communication to each individual controller using whatever method is usually to operate system used to communicate to the controllers in question (via IP address, KE2 SmartAccess while this alarm is etc.). If one or more are unreachable, investigate those controllers and their network present.

- Page 13 AU3 - Aux Input 3 Status propriate position (AUX 1, AUX 2 or AUX 3). state. Setpoints • Review the KE2 Evap OEM settings to make sure they match the type of device EXTERNAL If AU2 (AUX IN 2 AU1 - Aux 1 Input Mode connected to the controller.

- Page 14 • Check to see if door mullion heater circuit has power. The door heater relay is on the KE2 Combo Display board and labeled SSR-A and SSR-B. Measure each terminal to ground, it should read correct voltage from each terminal to ground for the applica- tion.

- Page 15 • Confirm suction temperature is reading correctly. Follow Suction Temp Alarm cor- rective actions. • Confirm pressure transducer is reading correctly. Follow Pressure Sensor Alarm cor- rective actions. 21214V3.0 © Copyright 2023 KE2 Therm Solutions, Inc., Washington, Missouri 63090...

-

Page 16: Troubleshooting Tables

• Check that the humidity sensor cable wires are inserted into the proper terminals on present. the KE2 Humidity Control, and that the screw down terminals are screwed down. The bare stranded wire of the cable should be inserted so that the wire is directly touch- Humidity sensor is ing the gate of the connector. - Page 17 HU - Humidity Mode HU - Humidity Mode • Check to make sure the KE2 Humidity Control is powered up and both the KE2 Hu- • Check to make sure the KE2 Humidity Control is powered up and both the KE2 Hu-...

- Page 18 Repair any damaged sections. Input can be set to • Check that the sensor is inserted into the proper position on the KE2 Evap OEM Discharge Temp). board. The sensor is not polarized; black and white wires can be inserted in either...

Need help?

Do you have a question about the EvapOEM and is the answer not in the manual?

Questions and answers

My unit is freezing up

Common causes of a KE2 EvapOEM unit freezing up include:

1. Improper coil sensor location – if the sensor is too close to a heater or pulled out, it may cause defrost to terminate too early or too late.

2. Incomplete defrost cycles – if the coil is not fully cleared of frost, it can lead to repeated defrosts and eventually freezing issues.

3. Excessive number of defrosts – caused by incorrect sensor placement or malfunction, triggering the Excess Defrost Alarm.

4. Heater circuit issues – damage in the circuit can prevent proper defrost operation.

5. Controller not terminating defrost in proper time – should be less than 30–35 minutes for air defrost and 18–22 minutes for electric defrost.

These issues prevent proper frost removal, leading to coil icing and system freeze-up.

This answer is automatically generated