Advertisement

Quick Links

Advertisement

Summary of Contents for SSK SDIS - 1050

- Page 1 USER MANUAL Universal position sensor and hot metal detector SDIS – 1050...

-

Page 2: Principle Of Operation

1. Introduction SDIS is universal configurable sensor for the detection of hot metal and its position. For its versatility can sensor operate as a hot metal detector (responds to the presence of hot material), or as a loop scanner (determines the position of the material in the field of view). Main advantages of SDIS are high speed scanning, comfortable and easy setting and displaying parameters using the push buttons and display on the unit or remote (RS232, RS485), wide set of options, two independent sets of detection parameters and switching between them (also... -

Page 3: General Description

HMD - hot metal detector - a device only detects the exceeding signal amplitude of photocells over the set threshold. It does not matter if the field of view of the sensor is an edge of the material. It is necessary to limit field of view (depending on site conditions) by the appropriate mechanical shutters or cover. - Page 4 4. The mounting and wiring 4.1. Location The distance between the SDIS and the measured product is not critical and depends on the scanning angle so as to cover the entire measurement field. Measured product may not fill the entire sensor field of view. Just intersects only a portion of 1 cm ² at a distance of 4 m sensor The optimal distance between the sensor and the various types of materials are as follows: Material Distance between product and sensor...

- Page 5 4.3. Electrical connection SDIS sensor is equipped with a 14-pin connector Amphenol PT. Specification of Lapp Cable Ölflex Servo FD770 CP: Multiple core cable: 6 × 2x0, 25 mm ² and 2 x 0.5 mm ² shielded Rugged design for industrial applications ...

-

Page 6: Technical Specification

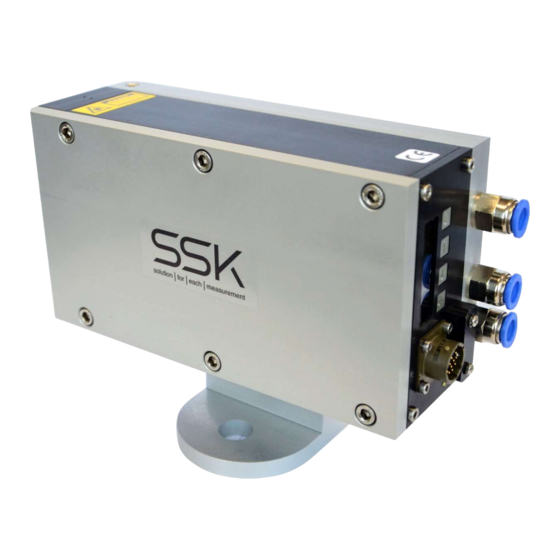

5. Technical specification 5.1. Mechanical Weight: 4 kg Adjustable stand with mounting hole dia. 18 mm Dimensions: see drawing 5.2. Optical Spectral sensitivity: PbS photocell, range 1-3 micron with a maximum response at 2.2 micron Temperature range of materials: depends on the material to be scanned: For iron and steel from 250 °... - Page 7 5.4. Environment Operating temperature: -10 ° C to +60 ° C. At an ambient temperature above 40 ° C it is recommended to cool sensor with industrial water at a temperature up to 25 ° C, pressure of 1-2 bar, flow rate of 1-2 l / min ...

-

Page 9: Indication Leds

6. Control Indication LEDs green - it is blinking at one-second interval when the devise is turned on and the program is running yellow - indicates the presence of hot material - lights in case of malfunction (and during startup): - motor failure (motor is not running at correct speed –... - Page 10 The buttons have their numerical meanings: [↑] = 1 [←] = 2 [→] = 3 [↲] = 4, then confirm PIN by [↲]. There are two levels of user privileges to change the settings: Basic - for change the most important parameters- PIN: 3412 Advanced - for adaptation of the sensor on actual measuring site - PIN: 2314 - includes all items of the main menu (PIN: 3412)

- Page 11 Sensor -> ValSet1 -> Gain 25% gain detection setting (value set 1) Thre 25% switching threshold HysT 10% hysteresis of switching threshold ValSet2 -> Gain 75% gain (value set 2) Thre 50% switching threshold HysT 10% hysteresis of switching threshold Set=Rel Rel –...

- Page 12 Comm -> RS232 -> Term ? (=Noname, VT100, SoftCon) communication type of connection-PC or type of terminal settings Sp=19200 speed Par=None parity Stop= 1 stop-bit RS485 -> Addr= 0 address Prot=Asc protocol Ascii, RTU Sp=19200 speed Par=None parity Stop= 1 stop-bit SysInfo ->...

- Page 13 Window – measuring window configuration For position measurement there is possibility to adjust measuring window - e.g. narrow max. field of view range or adjust start and end limits for analog output signals 4 - 20 mA (menu items Beg and End), and adjust hysteresis to eliminate signal bouncing at the edges of measuring window (menu items HysB and HysE).

- Page 14 7. Connector Amphenol connector – cable wiring color of wire function Power: 24VDC/0,5A , protected by fuse T 0,8A blue Analog outputs: yellow Analog1 signal 4-20mA (intensity or position–depends on setting) green Analog2 signal 4-20mA (intensity or position–depends on setting) Digital outputs (push-pull): gray presence of material (detect = 24VDC/max.

Need help?

Do you have a question about the SDIS - 1050 and is the answer not in the manual?

Questions and answers