Summary of Contents for Dover OPW Fluid Transfer civacon 8800E

- Page 1 Operation Manual OPW Fluid Transfer Group Europe B.V. Rack Monitor 8800E/8801E Version Date 16 June 2011...

- Page 2 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 << This page is left blank intentionally >> Page 2 of 35 H71343...

- Page 3 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Disclaimer In this document an operation manual is presented of the OPW Rack Monitor 8800E/8801E. It is important that the end user (in many cases the operator) of the OPW Rack Monitor 8800E/8801E has an adult age, is skilled, reads and understands this manual, otherwise it is not recommended to use the OPW Rack Monitor 8800E/8801E.

-

Page 4: Warranty

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Warranty All parts and products are thoroughly inspected and tested from the time raw material is received at our plant, until the product is completed. We guarantee that all products are free from defects in materials and workmanship for a period of one year from the date of shipment. -

Page 5: Ec Declaration Of Conformity

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 EC Declaration of Conformity In accordance with ISO/IEC 17050:2004 DOC07001 OPW Fluid Transfer Group Europe BV Roggestraat 38 2153 GC Nieuw Vennep The Netherlands T: +31 (0)252 660 300 declare that: Product description : Rack Monitor 8800E/8801E Item number... -

Page 6: Table Of Contents

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Table of Contents Disclaimer Warranty Approvals Technical assistance in the U.S.A. EC Declaration of Conformity Specifications Electrical Specifications Inputs. Outputs. External environment reminder (see installation manual for details) Product Description. Front layout. - Page 7 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Data communications. Table 4 Table 5 Table 6 Table 7 Products. Supplied accessories. Optional system accessories. Maintenance. Check Points. Troubleshooting. Annex A – Additional Electrical Drawings Annex B – Recommended Spare Parts Annex C –...

-

Page 8: Specifications

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Specifications The Rack Monitor 8800E/8801E is a loading rack monitoring system, detects and communicates an overfill condition to the loading rack control automation equipment by means of a normally open relay contact. In addition this non-permissive condition as well as diagnostic information is displayed. -

Page 9: Inputs

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Inputs. Sensor Terminal CN2 Pin 1~ 8 : all EN13922 compliant sensors. : all industry standard format overfill detection sensors . Two-Wire sensor (maximum eight) . Two-Wire Thermistor sensors (maximum eight) . -

Page 10: External Environment Reminder (See Installation Manual For Details)

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Communications. RS485/422 : galvanic isolated data communication port (non IS) : Half duplex (RS485) : Full duplex (RS422) : multi-drop : standard 9600Bps ,8 Bits 1Stopb No parity : selectable 120 terminator. : rotary switch selectable Monitor address 00~99 See label inside box for addition dipswitch setting. -

Page 11: Product Description

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Product Description. This manual describes the operation, and troubleshooting of the Civacon 8800E/8801E Loading Rack Monitoring System. Read separate installation manual for wiring the rack monitor It is intended to help operators, maintenance persons, and equipment specifiers understand the operation and standard features of the 8800E/8801E Rack monitor It is recommended reading this manual before installation of the equipment. -

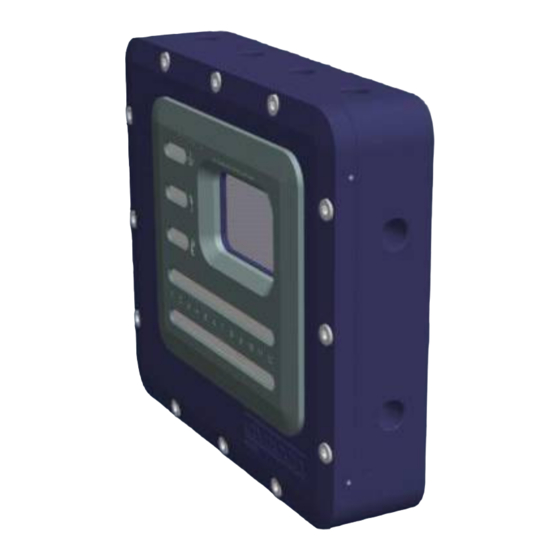

Page 12: Front Layout

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Front layout. Figure 1 Besides the large multi languages Liquid Crystal Display five Indicator bars are used to interface with the user. – The upper bar is indicating the status of the ground verification. –... -

Page 13: Led (Electronic Light Indicator) Display Info At Power Up

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 LED (electronic light indicator) Display info at power up. LED Test sequence. During power up the Red Error indicator in the middle small bar will start flashing every ½ second to indicate no communication is present. -

Page 14: Led Display Info

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 LED Display info. Two-Wire sensors Getting permissive, (connect Plug) Red compartment indicators are continuous on. White earth indicators inversely flashing (if ok). Green indicators flashing : getting permissive (e.g. heating). Green indicators continuous on : compartment dry If all (8) green indicators are continuous on (DRY) the red indicators will be switched off and truck is permissive to load. -

Page 15: Sensors Types

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Sensors Types. Two-Wire Thermistor Sensors. (NTC) Two-Wire sensors. Five-Wire sensors. Sensors and Grounding. Before continuing describing the functionality of the rack monitor a short explanation of the sensors and ground verification. -

Page 16: System Operation

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 System operation. The purpose of the Civacon 8800E Rack Monitor liquid level sensing system is to detect a liquid point level signal from a sensor mounted in compartments of a tank truck, or storage tanks. The system provides an automatic signal to the rack automation equipment to shut-off the flow of liquid and warn of an impending overflow condition of a tank truck or storage tank It can detect up to 8 Two-Wire Sensors or 12 Five-Wire Sensors As soon as the power is supplied, the monitor will perform a extensive self test of its internal functions (see power... -

Page 17: Normal Operation

Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Normal operation. The main task of the 8800E Rack Monitor is to provide a signal to the rack automation equipment to shut-off the flow of liquid as soon as a sensors in a compartment tank detect a liquid point level When the rack monitor is not used for 15 minutes it goes into sleep mode. - Page 18 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Liquid Crystal Display info during normal operation. After the power up sequence the 8800E will enter the normal operation mode. The following messages will sequential appear on the LC-Display. S Y S T E M R E A D Y P L E A S E C O N N E C T...

- Page 19 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 An other example can be (e.g. 12 compartment truck with ground loop and Five-Wire Dry sensors) S Y S T R E A E N 1 3 9 2 S O C K E T D E T E C T E D G R O U N D V E R I...

- Page 20 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Sensor detection. The 8800E and 8801E rack monitor is an auto switching rack monitor and will detect automatically the 3 types commonly used overfill sensors. Before the rack monitor switch to permissive the following steps will be performed. 1.

- Page 21 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Note: When the Rack Monitor is connected to already wet sensor(s) it cannot determine the parameters of that sensor. All measured data will be compared with the stored settings and dipswitch settings. If the dipswitch is set to EN13922 the Rack Monitor will continue with step 5 If the dipswitch is set to ROW the Rack Monitor will continue with step 6 If the measure data not complies to the EN 13922 or ROW the rack monitor will continue with step 7...

- Page 22 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Bypass operation. Although the 8800E/8801E can also be bypassed in a faulty or wet sensor condition, it is not recommended. For safety reasons it is NOT possible to bypass the 8800E/8801E when no proper ground is detected with the standard bypass key.

- Page 23 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 8800E Interior. Data communication switch Language Select 110-230Vac 1Amp all relay PERM GND-OK AUX1 AUX2 RS485/422 TCP/IP contacts 5Amp Max RJ45 MAINS RELAY PERM AUX2 RS-com GND-OK AUX1 120 Ohm ON Half Duplex 120 Ohm OFF Full Duplex...

- Page 24 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Firmware upgrade. The 8800E/8801E Rack monitor is build for the future therefore new updates to expand the functionality of this rack monitor can be expected. To upgrade your 8800E/8801E rack monitor switch off all power to the rack monitor. Open the door (see installation manual for details) and if there is a memory card already placed at the lower right corner replace it with the new card.

- Page 25 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Communication settings. Before data communication can be used four switches must be set (two sets). The two left switches are for terminating the communication lines with 120 On (up) = terminated with 120 Off (down) = NOT terminated Both outgoing YZ as well as incoming AB channels are connected together when the two right switches are in the On (up ) position.

- Page 26 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Set above switches in a unique address to avoid collisions Data communications. The 8800E/8801E Rack Monitor can be set to emulate the 8500E data communication In this way the 8800E/8801E is downwards compatible with the 8500E Rack Monitor. To select this 8500E data communication set the grey (8) in the on position.

- Page 27 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Command Code OS – Overfill Status Request Command: T X AA OS T X LRC. Reply Message: T X AA OS_C1C2C3C4C5 T X LRC Where C1-C5 are defined in Tables 4~7. Character ‘C1’...

- Page 28 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Character ‘C3 & C4’ Definition Table 6 Character Hex Value Sensor 4 Sensor 3 Sensor 2 Sensor 1 Value Sensor 8 Sensor 7 Sensor 6 Sensor 5 < > X indicates a wet sensor. Character ‘C5’...

- Page 29 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Products. All Civacon Loading Rack Monitors are suitable for hazardous locations with intrinsically safe (IS) outputs, and is housed in a Explosion Proof Enclosure ( see installation manual for details) Supplied accessories.

- Page 30 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Maintenance. When servicing the Rack Monitor 8800E/8801E the following needs attention: Before maintenance the full installation must be shut down/off before proceeding, • Maintenance must be performed by authorized personnel only, •...

- Page 31 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Troubleshooting. The following troubleshooting guide will give you first aid hands-on in solving most of the problems you can encounter. there are two types of problems. 1. operational issues. 2. hardware problems. Most commonly are the operational issues.

- Page 32 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Condition Possible Cause Solution - The Rack Monitor 8800E/8801E - The mains isn’t connected. - Connect the mains. doesn’t turn ON - Check if the main wiring is connected according to the installation instruction.

- Page 33 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Annex A – Additional Electrical Drawings Annex B - Recommended Spare Parts With the purchase of the Rack Monitor the OPW Fluid Transfer Group Europe BV recommends some spare parts to be purchased.

- Page 34 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Annex C – Certificates NEN-EN-ISO 9001:2000 Certificate. • Quality certificate. • ATEX certificate. • Page 34 of 35 H71343...

- Page 35 Rack Monitor 8800E/8801E Document: Operation Manual Date: 16-Jun-2011 Version: A.6 Quality Certificate Functional Inspection OPW Fluid Transfer Group Europe BV Roggestraat 38 2153 GC Nieuw Vennep The Netherlands T: +31 (0)252 660 300 declare that: Product description : Rack Monitor 8800E/8801E Item number : 8800E/8801E Serial no./ Lot no.

Need help?

Do you have a question about the OPW Fluid Transfer civacon 8800E and is the answer not in the manual?

Questions and answers

8800E no power when cables connected to the truck