Summary of Contents for Chennai Metco BAINMOUNT Mounting Press - P

- Page 1 BAINMOUNT Mounting Press - P Manual Instruction Manual Pneumatic Mounting Press Chennai Metco...

- Page 2 Intended usage When sectioned samples or components are irregular in shape, mounting is an essential step for further processing. Based on the requirement of quality and characteristics of the mould, proper mounting material should be selected. With the appropriate mounting material, and right mounting parameters high quality mounts can be obtained with Bainmount mounting machine.

-

Page 3: Table Of Contents

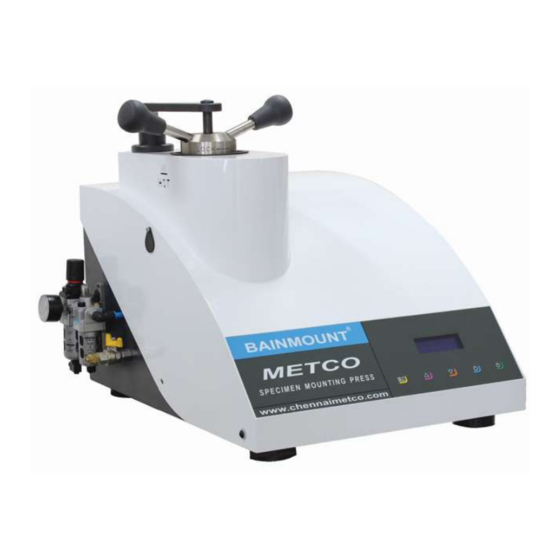

Contents 1. Safety -------------------------------------------------------------------------------------- 2. Transport ----------------------------------------------------------------------------------- 3. System Features and Principles of Operation ---------------------------------------- 4. Machine Layout ----------------------------------------------------------------------- 5. Installation ---------------------------------------------------------------------------------- 6. Operation --------------------------------------------------------------------------------- 7. Maintenance and Inspection ------------------------------------------------------------- 8. Dismantling ------------------------------------------------------------------------------- 9. Technical Specification ---------------------------------------------------------------------- 10. Electrical Circuit ---------------------------------------------------------------------- 11. - Page 4 Take a Moment to familiarize yourself with the location and names of the MP Pneumatic components. 1. Mould closure, 2.Mould Chamber, 3. Heater cover, 4. Display, 5.Parameter Selection 6. Parameter Increase/Ram Up, 7.Parameter Decrease/Ram Down, 8.Cycle Start/Stop 9.Power on/off Bainmount Pneumatic Pag4...

-

Page 5: Safety

1. SAFETY 1 Safety 1.1 Proper Use 1.1.1 Principle The Bainmount mounting press is state of the art and designed in accordance with recognized technical research and experience and safety regulation. Failure or neglect to properly install, operate and maintain the machine/system may be risk of serious or fatal injury to users or third parties or result in unnecessary damage of the system or other equipment. - Page 6 Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury. Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. Indicates a potentially hazardous that, if not avoided, might result in minor or moderate injury.

- Page 7 Before initial startup, personnel have to read and understand all instructions contained within the supplied documentation. Equipment obligation: The operating company is required to equip personnel with the necessary protective clothing as follow: Safety shoes. Safety goggles ...

- Page 8 14. Even though the plant may be equipped with automatic sprinklers or other means of the fire protection, portable fire extinguishers should be available to the machine operator. To be effective, portable extinguishers must be reliable, the proper type for each class of fire that may occur in the area, in sufficient quantity to protect against the exposure in the area, located where they are readily accessible for immediate use, and maintained in perfect operating condition.

- Page 9 1.7.2 Location of Hazard Warning Label Users are NOT allowed to change the location of hazard warning labels. Make sure to apply new labels upon replacement of the peeled off or worn out labels Safety devices 1.8.1 Insulating chamber lock nut The handle of the mounting press is equipped with a insulating material that helps to protect the operator from the heat during operation.

- Page 10 Be careful while handling waste fluid, which may corrode skin and clothing upon contact. Machine frame and all mechanical machine components are made of steel, light metal and plastics. These materials are recyclable. Take non-reusable difficult waste, lubricant and batteries, to the appropriate waste disposal point. ...

-

Page 11: Transport

2. Transport 2.1 Unpacking and Inspection Inspect equipment and shipping crate immediately upon receipt. Check the packing slip carefully and make sure all the materials have been received as indicated on the packing ticket. If any damage apparent, you should both report it to the trucking delivery person and contact the transportation company immediately. - Page 12 Insert the fork carefully so that the centre of gravity of the box lies in the middle of the forks Lift it to a safe level so that the box can be moved to the required place 2.4 Unload Distribution Box Risk of falling items.

- Page 13 i. Place the Distribution Box into proper size of empty pallet. ii. Place the fork lift insertion position on the pallet. iii. Lift the pallet and transport to the installation site. iv. Place Distribution Box according to installation plan. 2.5 Unload the Bainmount Mounting Machines Risk of falling transport items.

- Page 14 2.6 Relocating the Mounting Machine 2.6.1 Preparing for repositioning Turn off the Main Switch of Electrical Control Panel and remove attachment of the main power supply to system. Remove the connecting pipe between Oil Tank and Distribution Box. ...

-

Page 15: System Features And Principles Of Operation

3. System Features and Principles of Operation 3.1 Introduction The Bainmount Mounting Press is exclusively designed for mounting the materials for metallographic analysis. The machine offers that, mounting techniques can be programmed through a Programmable Logic Unit (PLC) for various mounting materials. For this reason, the user can increase the quality and quantity of the mount. - Page 16 3.3.2 Temperature Control Assembly The temperature control assembly consists of the thermocouple, temperature indicator, tube heater unit etc. The temperature control assembly is used to monitor the working temperature inside the mold cylinder. 3.4 Working principle of the Bainmount Mounting presses Initially when the mounting press is switched on, workpiece is placed with the surface of interest facing downwards and the moulding powder is filled in the moulding chamber.

-

Page 17: Machine Layout

4. Machine Layout Bainmount Pneumatic Pag17... -

Page 18: Installation

5. Installation 5.1 Installation Environment Do not install the unit at the location as potentially flammable and/or explosive atmosphere Do not install the unit in a corrosive environment. A corrosive environment may lead to poor performance and deterioration of unit. Temperature : 5 to 40°C2 Humidity... - Page 19 5.4 Making pipe connection 5.4.1 Connecting between Coolant tank and Machine Do not loosen fitting to arrive at proper position or leak may occur. Over tightening may cause piper fitting to deform and damage to the joining fitting Remove all foreign matter from inside the piping The recirculation coolant system connects pipe to and from the coolant tank which must be secured properly without leakage.

-

Page 20: Operation

6. Operation Machine Start up 6.1.1 Preliminary work before start – up system The water to be used as coolant is to be filled in the tank. The Main Switch and the coolant motor is switched on which is on the rear of the machine. ... -

Page 21: Maintenance And Inspection

7. Maintenance and Inspection It is not allowed to carry out any repair or maintenance during use. Only qualified service personnel should ever be permitted to perform any service related to this machine The coolant water flow should be clean and free of liquids, dust or foreign material, which could damage various mechanisms on the machine 7.1 Preventive Maintenance... -

Page 22: Dismantling

8. Dismantling No dismantling can be done while the machine is activated/running Ensure the power supply to the machine is turned off and locked out until the wiring job is finished Ensure the grounding wire is connected To dismantle or disconnect the machine, proceed as follows: i. -

Page 23: Technical Specification

9. Technical Specification Ambient Temperature • 2 to 50º C Ambient Humidity • 10 to 80% Operating Altitude • At an altitude up to 1000 meter above means sea level Transportation and Storage Temperature • -2 to 60º C Electrical Supply Phase •... -

Page 24: Electrical Circuit

10. Electrical Circuit Bainmount Pneumatic Pag24... -

Page 25: Warranty Certificate

If for any reason this unit must be returned to our plant, please inform us in advance with shipping details, Invoice Number, Date and reason for returning. Warranty certificate Sl.No: ....Ref: D.C Cum Invoice No..........Dated ....Purchase Order No: ............For CHENNAI METCO PVT LTD Authorized Signatory. Bainmount Pneumatic Pag25... -

Page 26: Contact Us

12. Contact Regional Offices Delhi Mobile: 09282204559, e-mail: delhi@chennaimetco.com Pune Mobile: 07358211144, e-mail: pune@chennaimetco.com Jamshedpur Mobile: 09282213259, e-mail: jamshedpur@chennaimetco.com Bangalore Mobile: 09282213260, e-mail: bangalore@chennaimetco.com Coimbatore Mobile: 09840793573, e-mail: coimbatore@chennaimetco.com Head Office SP100A, Ambattur Industrial Estate, Chennai 600 058. Ph: 044-2688 0005, 044-3999 5000, Fax: 044-2688 0850 e-mail:mktg@chennaimetco.com, mktg@chennaimetco.co.in Service / Spares / Calibration We provide service of industrial microscopes, micro hardness testers and metallography machines. - Page 27 Chennai Metco provides a wide range of industrial microscopes, image analysis and material testing equipment and consumables, etc., Bainmount Pneumatic Pag27...

Need help?

Do you have a question about the BAINMOUNT Mounting Press - P and is the answer not in the manual?

Questions and answers