Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Anton Paar Pico 3000 RC

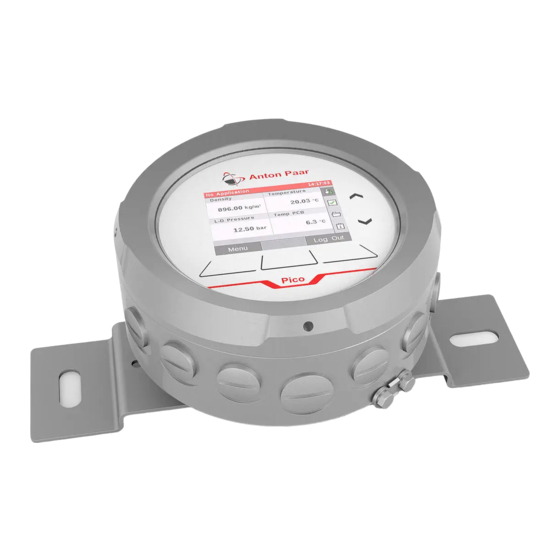

- Page 1 Measure what is measurable and make measurable that which is not. Galileo Galilei (1564-1642) Reference Guide Pico 3000 (RC)(Ex d) Process Instrumentation Controller Pico 3000 Firmware: 1.004.013 or higher Pico 3000 Software: 1.4. or higher (Original Instruction)

- Page 3 Changes, copyright, trademarks etc. This document and its contents may be changed or amended by Anton Paar at any time without prior notice. All rights reserved (including translation). This document, or any part of it, may not be reproduced, changed, copied, or distributed by means of electronic systems in any form (print, photocopy, microfilm or any other process) without prior written permission by Anton Paar GmbH.

-

Page 4: Table Of Contents

5.1.6 Cables and Preparation ......................18 5.2 Wiring.............................. 18 5.2.1 Shielding ..........................19 5.3 Wiring the Sensor and Pico 3000 RC ..................... 19 5.4 Pico 3000 AO / Pico 3000 Analog (AO Eco)................... 20 5.4.1 Wiring the Analog Output - AO ....................21 5.4.2 Wiring the Analog Input - AI.................... - Page 5 6.3.2 Filter Size / MinMax Removal ....................42 6.3.3 In-/Outputs ..........................42 6.3.4 Applications ..........................43 6.3.4.1 2-Propanol ........................44 6.3.4.2 Anton Paar Function ....................... 44 6.3.4.3 Beer Fermentation Ri...................... 44 6.3.4.4 Beverages Diet ....................... 45 6.3.4.5 Boric Acid........................45 6.3.4.6 CIP..........................

- Page 6 Contents 6.3.4.18 Live Raw Data ......................49 6.3.4.19 L-Rix Beverages ......................49 6.3.4.20 Original Extract Content....................49 6.3.4.21 Out of Operation (active) ....................50 6.3.4.22 Potassium Hydroxide....................50 6.3.4.23 Sodium Chloride ......................50 6.3.4.24 Sodium Hydroxide ......................50 6.3.4.25 Sugar - D ........................51 6.3.4.26 Sugar - S ........................

- Page 7 Appendix A: Menu Structure of the Pico 3000 ..................90 Appendix B: Technical Specifications....................95 Appendix B.1: General Technical Specifications .................. 95 Appendix B.2: Dimensions and Weight of the Pico 3000 RC ............... 97 Appendix B.3: I/O Overview........................99 Appendix B.4: Analog and Digital Output Specifications ..............99 Appendix B.5: Analog and Digital Input Specifications ...............

- Page 8 Contents...

-

Page 9: Safety Instructions

• Do not operate the instrument beyond its electri- 1.1 General Safety Instructions cal, thermal and mechanical specifications. • Do not step on the Pico 3000 RC. Liability Maintenance and service • This document does not claim to address all safety issues associated with the use of the •... -

Page 10: Special Safety Instructions

Ex-sign. Only open the electronics housing in a de-energized By attaching the Ex-sign, Anton Paar GmbH con- state (once a delay of 10 minutes has elapsed after firms that the instruments meet the requirements of... -

Page 11: Conventions For Safety Messages

Description of risk. Warning indicates a hazardous situation which, if not avoided, could result in death or serious injury. Fig. 2: Position of the warning sign on Pico 3000 RC Ex d WARNING CAUTION Follow all warnings and cautions listed in this Description of risk. -

Page 12: Special Conditions Of Use

The Pico 3000 electronics board is either installed in • Standardized user interface for all sensors the electronics housing of the sensor or in the Pico 3000 RC housing for remote control. Different • Higher plant availability and lower down times interfaces are available for communication (Analog, by data and diagnosis information Hart, PROFIBUS, ..) -

Page 13: Checking The Supplied Parts

Pcs. Article Description Mat. No. Transmitter for calculation and communication Installed either in the electronics housing of the sensor or in the Pico 3000 RC housing Pico 3000 Version Analog/Digital 192258 (available from September 2018) Pico 3000 Version Analog (former name: AO Eco) -

Page 14: Optional Parts Supplied

Version Wall Mounting with HMI PICO 3000 RC Ex d Remote Control Housing 179380 Version Wall Mounting with HMI Pico 3000 RC NPT Ex d Remote Control Housing 191812 Version Wall Mounting with HMI Cabinet mounting: PICO 3000 RC Remote Control Housing... -

Page 15: Installing The Pico 3000

1. The Pico 3000 with or without HMI is already installed in the electronics housing of the sensor The Pico 3000 is installed in the Pico 3000 RC or in the Pico 3000 RC housing. housing which is separated from the sensor and an own unit. -

Page 16: Electronics Housing With Pico 3000 Hmi Ex D

• Analog/Digital (Chapter 5.5 ) 5.1.2 Grounding • HART (Chapter 5.6 ) The Pico 3000 RC must be solidly grounded. If the • Frequency (Chapter 5.7 ) holder is grounded, no additional grounding is nec- • PROFIBUS DP (Chapter 5.8 ) essary. -

Page 17: Power Supply

5.1.5 Cable Glands and Sealing Plugs for Pico 3000. It may be supplied together with the sen- Ex d Housing sor using the Anton Paar power supply. Make sure that the used power adapter is capable In addition to the requirements given in Chapter 1.5 of providing enough current to both, the Pico 3000 "Special Conditions of Use"... -

Page 18: Cables And Preparation

1 Interface connection (Chapter 5.4 to Chapter 5.7 ) end ferrule 2 Power supply and CAN connection (CAN only for Pico 3000 RC) Diameter of cables 4.5 to 10 mm to ensure 3 Optional connection to a pump or external pressure... -

Page 19: Shielding

Fig. 14: Sensor and Pico 3000 RC housing Specifications for the CANopen connection • The maximum cable length of the CAN bus - from the Pico 3000 RC to the sensor - is 250 m. Fig. 13: Cable clamp • Each sensor is delivered with a terminating resistor. -

Page 20: Pico 3000 Ao / Pico 3000 Analog (Ao Eco)

Sensor 1 There is NO fuse for the power line on the circuit board! Fig. 15: Block diagram of connecting the Pico 3000 RC 5.4 Pico 3000 AO / Pico 3000 Analog (AO Eco) The Pico 3000 AO has two active analog outputs, one analog input, two digital inputs and a relay con- nection.The Pico 3000 Analog (AO Eco) has only... -

Page 21: Wiring The Analog Output - Ao

5 Electrical Installation TIP: As of September 2018 Pico 3000 AO is re- Analog input placed by Pico 3000 Analog/Digital offering addi- Passive transmitter tional interfaces and "Pico 3000 AO Eco" is 4 - 20 mA galvanically renamed by "Pico 3000 Analog". isolated AI Aux (+15V) The L-Rix 5000 Transmitter always comes with a... -

Page 22: Pico 3000 Analog/Digital

5 Electrical Installation Relay Relay 13 24 V Relay 14 Fig. 21: Block diagram of the relay output 5.5 Pico 3000 Analog/Digital This version of the Pico 3000 provides analog in- puts/outputs, one relay output and compared to the Pico 3000 AO additional digital inputs primarily for selecting up to 32 different products. -

Page 23: Pico 3000 Hart

PV, device status, diagnostics, and addi- tional measured or calculated values, etc. The Anton Paar Pico 3000, revision 1 complies with Protocol Revision 7.0. Fig. 24: Wiring of digital inputs for "Product Selection Additionally to the HART interface, the Pico 3000 Mode"... -

Page 24: Wiring The Hart Output

5 Electrical Installation Analog output Analog input HART + 4 - 20 mA galvanically isolated HART- 12 mA Sensor 250 Modem HART - GND AO1 <500 Hx = HART device Fig. 30: Active multidrop network GND AO1 5.6.2.3 Mixed Active/Passive Multidrop Network A sensor with Pico 3000 HART interface, working as Fig. -

Page 25: Wiring The Analog Output - Ao

5 Electrical Installation 5.7.1 Wiring the Analog Output - AO 2. Flow computer with external power supply and current input The analog output is an active galvanically isolated External power supply 4 to 20 mA interface. DC24V The cable length is limited by the maximum load re- sistance of 500 Ω. -

Page 26: Wiring Profibus

5 Electrical Installation 5.8.2 Wiring PROFIBUS Table 1: Wiring parts PROFIBUS Symbol Description Mat.No. The non-Ex version of Pico 3000 PROFIBUS is de- livered with a standard M12 socket. Female con- 17043 nector M12 715, 5 pole B- Cod. (For PROFIBUS input) T-fitting PROFI-... -

Page 27: Pico 3000 Is Not The Last Device In The Bus

5 Electrical Installation 5.8.2.2 Pico 3000 is not the last Device in the Bus Turn off the termination as shown in Fig. 40, if Pico 3000 is not the last device in the bus. Fig. 40: Pico is not the last device in the bus 5.9 Pico 3000 Version Modbus RTU 5.9.1 Wiring Modbus Modbus Input... -

Page 28: Pico 3000 Is The Last Device In The Bus

5 Electrical Installation 5.9.1.1 Pico 3000 is the last Device in the Bus If Pico 3000 is the last device in the bus, the termination must be turned on. Fig. 42: Pico 3000 is the last device in the bus TIP: Use the terminals marked with "IN". -

Page 29: Wiring Profinet Io, Ethernet/Ip And Modbus Tcp

5 Electrical Installation 5.10 Wiring PROFINET IO, EtherNet/ • Make sure that the cable is not longer than 100 meters. IP and Modbus TCP • Connect the Pico 3000 to the host system via a LAN (Local Area Network) and not a WAN The non-Ex version of Pico 3000 Version PROF- (Wide Area Network). -

Page 30: Start-Up And Use Of Pico 3000

Read and export the logging information stored installation. Alternatively, download the Pico 3000 by Pico 3000 Sofware package from the Anton Paar website and store it on a local drive of the computer. Use the fol- • Read and export the error log stored by... -

Page 31: Starting The Pico 3000 Software

6 Start-up And Use Of Pico 3000 6.1.3 Starting the Pico 3000 Software "Run as administrator" option from a standard user account. The Pico 3000 Software can be used online, i.e. TIP: Installing the Pico 3000 Software from an ad- connected to an instrument, or offline without con- ministrator account and then switching to a standard nection to an instrument. -

Page 32: Backup

<Open> in the "Offline Configuration" area These parameters may only be changed during (see Fig. 6-1 (4)) the adjustment procedure at the Anton Paar When you use <Open>, you can load a configura- headquarter or subsidiary. Never change these tion from a Backup File (.abf) and from a Diagnos-... -

Page 33: User Management And Log In

"read only" mode. If you want to change the con- copy-protected with the instrument serial number. If figuration of the instrument, use the <Log in> button you install a configuration with "Anton Paar Func- on the menu bar. tion" on an instrument with invalid serial number, you will not be able to activate this application. -

Page 34: Main Screen

6 Start-up And Use Of Pico 3000 6.1.9 Main Screen Click <Edit> on the Welcome screen to proceed to the main screen. Fig. 51: Main Screen with tabs The main screen provides all tabs you need to work • Close and re-open the Pico 3000 Software. with the connected instrument. -

Page 35: Operation Modes

6 Start-up And Use Of Pico 3000 Table 3: System Settings (depending on the sensor type and Pico 3000 type) Display Layout Select 1, 2, 3 or 4 measurands Operation Mode Choose "Application Mode" or "Product Selection Mode" (find more details below) Adjustment Enter offsets or gain factors Filter... -

Page 36: Live Values

6 Start-up And Use Of Pico 3000 Table 4: Application Settings (depending on the Pico 3000 type) Setting Description Pico 3000 HMI menu Parameters Enter values for the application specific Application Config > Appli- parameters. cation Selection > Parame- ters User Function Pico 3000 provides a general user function. -

Page 37: Data Memory

Send this file to Anton Paar for further analysis. Fig. 56: Add a new product Use the button <Update Firmware> to carry out firm- It is possible to create, configure and select a prod- ware updates for sensor and transmitter. -

Page 38: Software And Firmware Updates

6 Start-up And Use Of Pico 3000 menu you get the information if the sensor is sealed Module Firmware Update or not defined by the position of the dip-switch. The Pico 3000 Software stores firmware packages <Gauge Seal> = Deactivated --> The instrument is (versions) for Pico 3000 and all Pico 3000 compati- not sealed. -

Page 39: Pico 3000 Hmi

6 Start-up And Use Of Pico 3000 6.2 Pico 3000 HMI A scrollbar appears when the contents of the menu exceed the display area. Scroll up and down with the scroll keys. 6.2.1 Overview After powering the instrument up the main screen appears (Fig. -

Page 40: Side Menu

6 Start-up And Use Of Pico 3000 1. Log In / Log out Key function Description The Pico 3000 has four different user levels: Unlock Press both <Unlock> buttons at • Read Only the same time to unlock all but- •... -

Page 41: Menu

6 Start-up And Use Of Pico 3000 6.2.4 Menu 6.2.4.1 User Management It is required to log in to read and/or change a confi- guration. There are four different user groups with different rights: Read only: no PIN Operator PIN: 3333 (default) Administrator PIN: 2222 (default) For safety reasons change the PINs during installa- tion (see Chapter 6.1.8 Menu "System Setup >... -

Page 42: Settings

6 Start-up And Use Of Pico 3000 6.3 Settings and to remove spikes. Filter size: The number of values used for the filter. MinMax Removal: The number of minimum and ma- 6.3.1 Adjustment ximum values which are removed. Pico 3000 Software (Application Mode): "Edit >... -

Page 43: Applications

• Beverage tration in °Brix; 4 mA = 5 °Brix ; 20 mA = 15 Brix) Anton Paar Function In addition, you can select a fixed value for each Beverages Diet analog output. Any even integer value between 0 ... -

Page 44: 2-Propanol

OE Stored [°Plato] cific formula. It is stored internally and cannot be parameters see Chapter 6.3.4.31 read or changed.The Anton Paar Functions have to be bought separately and can only be used in com- Input values Ri/Temperature/(Original bination with a specific Pico 3000. When ordering... -

Page 45: Beverages Diet

6 Start-up And Use Of Pico 3000 6.3.4.4 Beverages Diet 6.3.4.5 Boric Acid Table 11: Beverages Diet Table 12: Boric Acid Application Application Beverages Diet Boric Acid name name Application Application Application Application Beverages Chemical groups groups Beverages without sugar but Media Boric Acid Media... -

Page 46: Ethanol - D

6 Start-up And Use Of Pico 3000 6.3.4.7 Ethanol - D Table 15: Ethanol - S Output Concentration-M [% m/m] Table 14: Ethanol - D values Concentration-V [% v/v] Application Ethanol - D Description name Application 6.3.4.9 Extract of Wort - D Table 16: Extract of Wort - D Application Beverages, Chemical... -

Page 47: Fruit Juice

6 Start-up And Use Of Pico 3000 6.3.4.12 Group A - Crude Oil Table 17: Extract of Wort - S 0-32 °Plato Table 19: Group A - Crude Oil 60-106°C for lauter tun Application Group A - Crude Oil name Measuring 0-32 °Plato range... -

Page 48: Group D - Lubricating Oil

6 Start-up And Use Of Pico 3000 Table 20: Group B - Refined Products Table 22: Hydrochloric Acid - D Output °API @T [°API] Application values SG @ T parameters Density @ T [kg/m³] Input values Density/temperature Output Concentration HCI [%] Description values Description... -

Page 49: Live Raw Data

6 Start-up And Use Of Pico 3000 Table 24: ICUMSA Table 26: L-Rix Beverages Measuring 0 ... 100 °Brix Application Beverages range -20 ... 105 °C groups (ICUMSA standard Media Beverages with sugar, sugar covers 20 ... 40 °C) solutions Application Type of sugar (Sucrose, Glu- Sensor... -

Page 50: Out Of Operation (Active)

6 Start-up And Use Of Pico 3000 6.3.4.21 Out of Operation (active) 6.3.4.23 Sodium Chloride Table 28: Out of Operation Table 30: Sodium Chloride Application Application Out of Operation Sodium Chloride name name Application Application 39319 Application Application Chemical groups groups Media Application specific... -

Page 51: Sugar - D

6 Start-up And Use Of Pico 3000 6.3.4.25 Sugar - D Table 33: Sugar - S Measuring 50 - 80 °Brix(%m/m) Table 32: Sugar - D range 55 - 80 °C Application Sugar - D Application name parameters Application Input values Sound velocity/temperature Output Application... -

Page 52: Sulfuric Acid - D

6 Start-up And Use Of Pico 3000 6.3.4.28 Sulfuric Acid - D 6.3.4.30 User Function A User function can be defined by the user via the Table 35: Sulfuric Acid -D Pico 3000 Software. Application Sulfuric Acid -D Unlike the other applications, you cannot configure name the user function while it is the active application. - Page 53 6 Start-up And Use Of Pico 3000 Table 37: 2D Polynomial Table 38: 3D Polynomial KA to KU Polynomial coefficients Application User function for the output (= R) name measurand 1 (default = Application 8192 temperature [°C]) measurand 2 (default=density [kg/m³] or sound velocity [m/s]) Application ref.

-

Page 54: Application Parameters - Additional Information

6 Start-up And Use Of Pico 3000 The concentration formula for C is equal to C with the coefficients BA to BS. "User function - Table" Table 39: Table Application User function name Application 8192 Application groups Media Application specific Sensor Measuring Application specific... -

Page 55: Units

6 Start-up And Use Of Pico 3000 6.3.5.1 Units of Derived Values "Stored CO2" is also used when: • the AI of the Pico 3000 version analog/digital is See the corresponding application chapter (Chapter not configured for CO measurement 6.3.4 ) to find all available derived values and their units. -

Page 56: Brightness

6 Start-up And Use Of Pico 3000 6.3.6.3 Brightness Date and Time Format" In the Pico 3000 menu it is possible to change the Pico 3000 Software: date and time format and to edit the date and the Not implemented time. -

Page 57: Error Log

6 Start-up And Use Of Pico 3000 Pico 3000 HMI: "Menu > Service > Diagnosis > Error Log" • View the System Log • Clear the System Log 6.4 Write Protection A dip-switch inside the instrument provides a write Fig. 71: Data memory protect function. -

Page 58: Fieldbus Communication

The device variable which is mapped to the primary variable is automatically the value for the analog current of the HART Analog Output. The Anton Paar Pico 3000 model HART revision 1 complies with HART Protocol Revision 7.0. Fig. 72: Device variables... -

Page 59: Dynamic Variables

7 Fieldbus Communication 7.1.3 Status Information Upper limit for the density 4000 kg/m³ Lower limit for the density 0 kg/m³ 7.1.3.1 Device Status Min. span between the upper and 10 kg/m³ Bit 4 ("More Status Available") is set whenever any lower the limit of the density failure is detected. -

Page 60: Common-Practice Commands

7 Fieldbus Communication 7.1.4.2 Common-Practice Commands Table 41: Supported Commands The Pico 3000 transmitter supports burst mode. Read device variable trim points This field device does not support catch device vari- Read device variable trim guide- able and command 53 "Write device variable units". lines Device variable units can only be changed directly Write device variable trim point... - Page 61 7 Fieldbus Communication Measurement Start/Stop/Freeze (Command 122) Example: This command starts or stops the sensor and acti- Current instrument status: vates the freeze mode. instrument in operation The command response is the current state of the no freeze of data output instrument before the command is executed.

-

Page 62: Tables

Long tag: sensor specific (L-Dens 7400,..) Pico 3000 Response Status Codes • Date: Factory adjustment date Table 52: Pico 3000 Response Status Codes • Descriptor: ANTON PAAR Initializing • Message: EMPTY MESSAGE Started • Final assembly number: 6 digits sensor's serial... -

Page 63: Hart Analog Out Specifications

1. Connect the Pico 3000 Software 2. Change the polling address: different to "0" Table 57: HART capability checklist 3. Activate the multidrop mode Manufacturer, model and Anton Paar 4. Choose the application program revision Pico 3000 HART, rev. 1 5. -

Page 64: Additional Information

7 Fieldbus Communication 7.1.9 Additional Information 4. Check the measurement values and assign them via drop down box, if the ones set by default do not fit. Reset Command 42 ("Device reset") causes the device to resets its microprocessor. The resulting restart is 7.2.3 Integrating the Pico 3000 PROFIBUS identical to the normal power-up sequence. - Page 65 7 Fieldbus Communication Table 58: Input datablock PROFIBUS Table 58: Input datablock PROFIBUS Address Type, Address Type, Name, description Name, description relative No. data bits relative No. data bits NAMUR Status Measurement Real,32 Byte,8 Sensor 2 (0.1 or 4) Value 5 MSB,...,LSB Node ID Sensor 2 Byte,8...

-

Page 66: Output Datablock

7 Fieldbus Communication 7.2.3.2 Output datablock Addr. Type, Name, description rel. No. data bits Addr. Type, Name, description Requested Parame- rel. No. data bits ter Type 5 Byte,8 Product Number Word,16 See Chapter 7.2.3.3 Application ID Reserved Byte,8 See Chapter 7.2.3.5 . DWord,32 Requested Parame- Reacts on changes! -

Page 67: Parameter Types

7 Fieldbus Communication Addr. Type, Addr. Type, Name, description Name, description rel. No. data bits rel. No. data bits Send Parameter 2 Enter write-com- Channel ID 2 DWord,32 mand: The "Enter See Chapter 7.2.3.6 write" - command is recognized if the con- Send Parameter Real,32 tents of this memory... -

Page 68: Channel Ids (Decimal Numbers!)

Group A Crude Oil (ASTM): SG at 100603 ICUMSA Out of Operation 39319 Group B Refined Products (ASTM): 100701 Density at T Anton Paar Function 4096 Group B Refined Products (ASTM): 100702 User Function 8192 API at T Group B Refined Products (ASTM): 7.2.3.6 Channel IDs (decimal numbers!) - Page 69 7 Fieldbus Communication Anton Paar Function: Output 0 101000 Fruit Juice: Density @ T20 110901 Anton Paar Function: Output 1 101001 Fruit Juice: Conc. g/L 110902 User Function: Output 0 101010 Fruit Juice: Oechsle 110903 User Function: Output 1 101011...

-

Page 70: Profibus Communication Examples

7 Fieldbus Communication 7.2.3.7 PROFIBUS Communication Examples Reading "Offset" and "Gain" of Ethanol Concen- tration in %m/m Reading Measurement Values and Sensor Sta- • Sensor: L-Dens 7000 • Active Application: Ethanol • Sensor: L-Dens 7000 • Current Offset value: 0.000 •... -

Page 71: Modbus Rtu, Modbus Tcp

7 Fieldbus Communication 7.3.2 General specifications and Interface Table 62: Output Datablock Settings for Modbus RTU via Pico 3000 HMI Address Name Value relative All numbers are transferred in the selected format. Go to menu "System Setup > Field- Send Parameter bus"... -

Page 72: Holding Registers (Read/Write)

7 Fieldbus Communication Table 63: Input Registers Table 63: Input Registers Measurement Real,32 Measurement Real,32 30018 30042 Value 5 LSB,...,MSB Value 17 LSB,...,MSB Measurement Real,32 Measurement Real,32 30020 30044 Value 6 LSB,...,MSB Value 18 LSB,...,MSB Measurement Real,32 Measurement Real,32 30022 30046 Value 7 LSB,...,MSB... -

Page 73: Coils (Read/Write)

7 Fieldbus Communication Table 64: Holding Registers Table 65: Coils Gain Application Not Used bit,1 Output 2 Real,32 40056 Not Used bit,1 See Chapter LSB,...,MSB Chapter 7.3.7 Not Used bit,1 Offset Applica- Not Used bit,1 tion Output 3 "Real, 32; 40058 See Chapter LSB,...,MSB"... -

Page 74: Application Outputs

7 Fieldbus Communication 7.3.7 Application Outputs Table 67: Application Outputs Application Name, Output Value Output Value Output Value Output Value Output Value Sensor Type (decimal ID) Extract Con- Extract of wort Density at centration in L-Dens (1) 20°C °Plato Concentra- Density at Concentra- Concentra-... - Page 75 Extract of Wort - S centration at hot wort at centration of L-Sonic (16) the Lauter the brewing cold wort kettle Anton Paar Function L-Dens / L-Sonic Output 0 Output 1 (4096) User Function L-Dens / L-Sonic Output 0 Output 1...

-

Page 76: Profinet Io

7 Fieldbus Communication Table 67: Application Outputs Conc. Sugar Pack- L-Rix Beverages (34) Beer Fermentation Ri App. Extr. Alcohol- Orig.Extract Conc. Sugar Real Extract (36) Dens V20 °C Concentra- ICUMSA (37) Conc. Sugar tion Out of Operation (39319) 7.4 PROFINET IO The datablocks and all functions available via field- bus are equal to PROFIBUS DP. -

Page 77: Input Datablock

7 Fieldbus Communication 7.4.3.1 Input Datablock TIP Changing these settings doesn’t require a re- start of the instrument. The input datablock is 128 bytes long and is used to The datablocks and all functions available via field- transfer information from Pico 3000 to the PLC. bus are equal to PROFIBUS DP. -

Page 78: Troubleshooting

8 Troubleshooting 8 Troubleshooting This chapter describes possible problems with the sensor, possible causes for a problem and how to solve it. CAUTION A problem can be caused by Pico 3000, by the sen- Risk of injury and damage to property sor (L-Dens 7000, L-Sonic, ...) or by operating con- Maintenance and service work must only be car- ditions which are outside specification. -

Page 79: Logging

8 Troubleshooting 8.2 Logging 8.2.3 Data Log For diagnosis purpose in case of problems with the Pico 3000 provides three types of logging. sensor, measured parameters can be stored direct- ly in the Pico 3000 data memory. The parameters 8.2.1 System Log can be measured and calculated sample parame- A system log entry is generated upon the following... -

Page 80: Analog Output Signal For Out-Of-Specification And Error Conditions

8 Troubleshooting 8.3.1 Analog Output Signal For Out-of-Specification and Error Conditions Condition Code* Output Error various The error current can be selected in the menu "System Setup > Analog Outputs". You can select between 2/3.6/4/22 mA Channel not found or NaN 23x2 4 mA on affected AO Measured value below specified range... - Page 81 The current of the analog nected. Check external sensor. input is less than 3.8 mA, External sensor defective. Contact your Anton Paar rep- but it is not equal to the Pico 3000 defective. resentative. error current of 2 mA. 2101 AI current >...

-

Page 82: Pico 3000 Errors (Failure) Codes

The PROFIBUS configu- FIBUS master e.g. wrong file on USB flash drive or con- ration for the device is GSD file tact Anton Paar representa- invalid tive for the latest GSD file 6150 Fieldbus: No phys. conn. Cable not connected... -

Page 83: Sensor Specific Error Codes

Pico is not able to estab- sensor board. and on). If the problem per- lish a connection to a sen- sists or occurs again, contact sor. your Anton Paar representa- tive. 7001 Sensor connection lost Hardware or firmware prob- Restart the sensor (power off The connection between lem on the sensor board. - Page 84 Pressure sensor expected but and hardware configuration. no pressure sensor connected • Output current of pressure sen- • Contact Anton Paar for replace sor < 3.8 mA due to malfunction pressure sensor. 8449 p AI: Current Output current of pressure sensor...

- Page 85 > +147 °C the specified range. • Density and temperature readout inaccurate Temperature • Connection between sensor Contact Anton Paar for replace- 16387 sensor error board and temperature sensor ment of the sensor board (4003) defective • Electronics error...

- Page 86 Defective sound sensor or sound signal • Reset instrument (1002) too low doesn‘t get through medium • Fill water to check sensor • Contact Anton Paar Ser- vice 4099 Sound signal Defective sound sensor • Reset instrument (1003) too high •...

- Page 87 Table 72: Error codes - L-Sonic 5500/5600 Code decimal Condition Cause Solution (hexadec.) 16387 Temperature • Connection between sensor Contact Anton Paar for replace- (4003) sensor error board and temperature sensor ment of the sensor board defective • Electronics error 16388 Process temp. Maximum allowed temperature •...

- Page 88 4147 RI out of Range! Measured RI is out of range Check sample (1033) 8739 LED Error! LED Hardware error Contact Anton Paar Service (2223) 12896 Voltage below Supply voltage out of specified Check power supply! DC 20V range (3260)

-

Page 89: Resetting The Sensor After Errors

Table 74: Error codes - L-Rix 5X00 Code decimal Condition Cause Solution (hexadec.) LED Tempera- LED temperature could not be Contact Anton Paar Service 20563 ture Sensor measured (5053) Error! Lens Tempera- Lens temperature could not be Contact Anton Paar Service... -

Page 90: Appendix A: Menu Structure Of The Pico 3000

Appendix A: Menu Structure of the Pico 3000 Appendix A: Menu Structure of the Pico 3000 The available In-/Outputs depend on the Pico 3000 model. Main Adjustment Measurand 1 Offset menu Gain Filter size MinMax Removal Measurand 2 Offset Gain Filter Size MinMax Removal Product Settings/... - Page 91 Appendix A: Menu Structure of the Pico 3000 Application Config In-/Outputs Measurand Analog Output 1 cont. Assignment Scaling Current Value Value for 4 mA Value for 20 mA Fixed Value Measurand Analog Output 2 Assignment Scaling Current Value Value for 4 mA Fixed Value Value for 20 mA Measurand...

- Page 92 Appendix A: Menu Structure of the Pico 3000 Application Config Parameters Parameter 1 cont. Parameter 2 ..Formula Type Coefficients Ref. x1 Ref. x2 Ref. x3 Coeff 1 ..Coeff n x-Axis y.-Axis Table Values System Setup Product Selection Channel 1 (Start/ Digital Inputs Stop) Channel 2 (Hold)

- Page 93 Appendix A: Menu Structure of the Pico 3000 System Setup Date and Time Set Date & Time Set Date cont. Set Time Set Date & Time Set Date Format Format Set Time Format Automatic Log Out Duration Brightness Active Level Inactive Level Password Protection Select User Enter New PIN...

- Page 94 Appendix A: Menu Structure of the Pico 3000 Table A-1: User rights User Type Read only Operator Administrator Allowed action NO PIN PIN: 3333 PIN: 2222 Read Live Values Read Service Values Read System Information Create Diagnostics Package Change Displayed Values Load &...

-

Page 95: Appendix B: Technical Specifications

-25 to 55 °C -25 to 50 °C with Pico 3000 and HMI -20 to 55 °C -20 to 50 °C Temperature Pico 3000 RC housing (Ex d) -20 to 60 °C Temperature Class Pico 3000 Ex d housing T1 to T5 Humidity... - Page 96 Appendix B: Technical Specifications Table B-2: Electrical specifications Supply voltage DC 24 V (range DC 20 - 28 V) Power consumption max. 3 W Clamping terminals Push-in spring connection 0.2 to 1.5 mm² / AWG 24 to 16 Cable gland type M16x1.5 (optionally supplied) EMC cable glands, metric, earthing cones acc.

-

Page 97: Appendix B.2: Dimensions And Weight Of The Pico 3000 Rc

2.9 kg Fig. B-1: Dimensions Pico 3000 RC 179380 Pico 3000 RC Ex d remote control housing Version wall mounting with TFT-display 191812 Pico 3000 RC NPT Ex d remote control housing Version wall mounting with TFT-display Weight 2.4 kg Fig. - Page 98 Appendix B: Technical Specifications 179382 Pico 3000 RC remote control housing Version cabinet mounting with TFT-display Weight 2.4 kg plate thickness 1-3mm Cutout Fig. B-3: Dimensions Pico 3000 RC Cabinet Mounting E22IB001EN-I...

-

Page 99: Appendix B.3: I/O Overview

Appendix B: Technical Specifications Appendix B.3: I/O Overview Table 75: Input and output interfaces Transmitter Analog Analog Digital Relay Frequency HART Fieldbus type Analog/Digital Analog (AO Eco)** Frequency*** HART Modbus RTU PROFIBUS DP PROFINET IO EtherNet/IP Modbus TCP * replaced by version Analog/Digital ** renamed AO Eco (as of September 2018). -

Page 100: Appendix B.5: Analog And Digital Input Specifications

Appendix B: Technical Specifications Appendix B.5: Analog and Digital Input Specifications Table B-5: Analog current input Galvanically isolated input for active and passive transmitters Signal input current range 4 to 20 mA Full input current range (incl. fault current) 0 to 23 mA Accuracy 0.1 % FS (=0.02 mA) at 25 °C Resolution... -

Page 101: Appendix B.6: Frequency Output Specifications

Appendix B: Technical Specifications Appendix B.6: Frequency Output Specifications for L-Dens 7000 only Table B-7: Frequency output Frequency modulated current output proportional to the temperature corrected and (optional) pressure corrected density value Galvanically isolated, passive current output Supply voltage DC 12 to 26 V Frequency range 750 to 2000 Hz Frequency signal shape... -

Page 102: Appendix B.8: Modbus Rtu Interface Specifications

Appendix B: Technical Specifications Appendix B.8: Modbus RTU Interface Specifications Table B-9: Modbus RTU Interface Externally powered RS485 interface according to "Modbus over Serial Line Specification & Implementa- tion guide V1.02" Interface RS485 (EIA-485) Protocol Modbus Application Protocol Specification V1.1b Data transfer rates 19200, 9600 Baud Numbers of devices... -

Page 103: Appendix B.10: Profinet Io, Ethernet/Ip, Modbus Tcp Interface Specifications

Appendix C: Label on Pico 3000 RC Ex d Appendix B.10: PROFINET IO, EtherNet/IP, Modbus TCP Interface Specifications Transfer rate 100 MBit/s Max. cable length 100 m Cable specifications shielded 4-wire cable CAT5 ("Twisted pair") or optical fibre Switches Full duplex transfer, auto crossover, auto negotiation Appendix C: Label on Pico 3000 RC Ex d Fig. -

Page 104: Appendix D: Certificates

Appendix D: Certificates Appendix D: Certificates Appendix D.1: EU Declarations of Conformity E22IB001EN-I... - Page 105 Appendix D: Certificates E22IB001EN-I...

-

Page 106: Appendix D.2: Eu-Type Examination Certificate Atex

Appendix D: Certificates Appendix D.2: EU-Type Examination Certificate ATEX NOTICE Pico 3000 versions for ATEX Only the following Pico 3000 versions can be used in combination with ATEX certified sensor models: Analog/Digital, Analog, HART, Modbus RTU, Frequency E22IB001EN-I... - Page 107 Appendix D: Certificates E22IB001EN-I...

- Page 108 Appendix D: Certificates E22IB001EN-I...

-

Page 109: Appendix D.3: Iecex Certificate Of Conformity

Appendix D: Certificates Appendix D.3: IECEx Certificate of Conformity E22IB001EN-I... - Page 110 Appendix D: Certificates E22IB001EN-I...

- Page 111 Appendix D: Certificates E22IB001EN-I...

- Page 112 Appendix D: Certificates E22IB001EN-I...

-

Page 113: Appendix D.4: Csa/Ul/Fm Certificate Of Compliance

Testing, Certification and Field Evaluation Body Accredited in Canada, the USA, and Internationally File LR1437 CERTIFICATE OF COMPLIANCE (ISO TYPE 3 CERTIFICATION SYSTEM) Issued to Anton Paar GmbH Address Anton-Paar-Strasse 20 Graz, Austria, 8054 Project Number LR1437-1 Product Density Sensors... - Page 114 Appendix D: Certificates QPS Evaluation Services Inc Testing, Certification and Field Evaluation Body Accredited in Canada, the USA, and Internationally File LR1437 Model Markings L-Dens 7400 AAA Ex d Class I Division 1 Gr CD T4/T5 L-Dens 7400 AAA NPT Ex d Ex db IIB T4/T5 Gb Class I Zone 1, AEx db IIB T4/T5 Gb Where AAA denotes material options:...

- Page 115 IP66/Enclosure Type 4X Pico 3000 RC Ex d (with HMI) Class I Division 1 Gr CD T5 Pico 3000 RC NPT Ex d (with HMI) Ex db IIB T5 Gb Class I Zone 1, AEx db IIB T5 Gb Ta= -20°C to +60°C...

-

Page 116: Appendix E: Document Numbers

Appendix E: Document Numbers Appendix E: Document Numbers Document Number Date Comment E22IB001EN-A August 2017 First version E22IB001EN-B December 2017 PROFIBUS and Modbus added E22IB001EN-C January 2018 Manual renamed: Reference Guide E22IB001EN-D June 2018 Ex-version included Update: Technical data (FW 1.1.8) E22IB001EN-E June 2018 Layout adapted to newest template...

Need help?

Do you have a question about the Pico 3000 RC and is the answer not in the manual?

Questions and answers