Summary of Contents for MST YE4

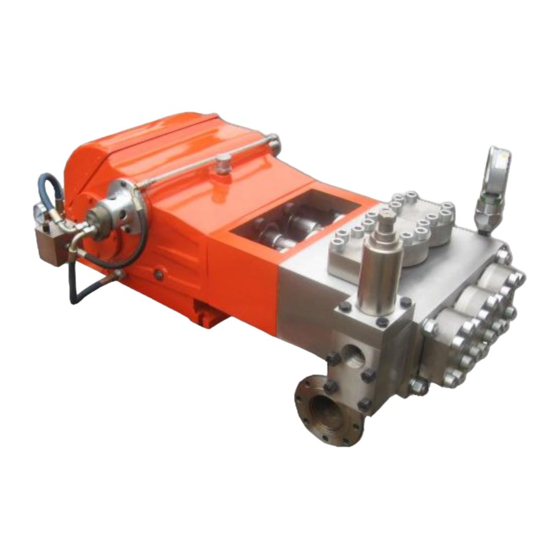

- Page 1 MILESTONE MANUFACTURING & ENGINEERING YE4 High Pressure Plunger Pump Operations Manual Mi lestone Pump...

-

Page 2: Technical Data

Application The YE4 series pump could be used as the power device of oilfield water injection and high pressure water cleaning equipment, widely used in petroleum, chemical, iron and steel metallurgy, ship transport, water conservancy and other industries. -

Page 3: Pump Structure

Pump Structure a. Pump power end (a) Structure Number Parts crankcase cover crankcase Bearing Crank assembly Number Parts Connecting-rod Cross-head Bearing Small Gear Shaft Assembly assembly The crank case is made of high strength cast iron, with good water and dust proof functions. - Page 4 b. Fluid End (a) Structure The liquid end is composed by pump head , intake liquid valve, draining valve, packing seal, plunger, pressure regulating valve, safety valve etc Part Part Part Part Valve body Cover A Valve seat Bolt Cover B Valve sleeve Bolt stud Inside...

- Page 5 c. Pressure regulator Valve The function of the valve is mainly constant pressure overflow, so that the pressure in the water system is kept in the adjusting value. The valve is used to protect the high pressure water system from overload, and the valve is closed and used as the safety valve at this time.

-

Page 6: Pump Lubrication

Pump Lubrication The pump drive end is splash lubrication and the crankcase oil storage of about 12 liters. When filling oils, remove the vent cap and fill oils through the oil hole. The Crankcase lubricating oil should be 15W/40CD at an ambient temperature of 15 ℃ ~ 40 ℃, 15W/3CD at an ambient temperature of 5 ℃... - Page 7 damaged badly. (4) Before starting, turn on all valves on the inlet and outlet pipes for preparation for no-load start. (5) Before starting, please make sure the inlet and outlet pipe fittings are tightened, to prevent the cavitation caused by air. (6) Before starting, fill the required lubricating oil to the fixed oil level in the case.

- Page 8 fully open in the system, to prevent the pump from running under pressure without liquid, which could damage the pump. Note: Due to the low ambient temperature in winter, please remember to run with this method to protect the pump head from freezing. Pump operation (1) Check the oil level before running.

- Page 9 Failure & Reasons Code Failure The capacity is not enough Discharge pressure could not reach the set value Noise The power end casing is heated The pump could not pump water Oil leakage of the middle rod at the power end Pressure gauge indicates abnormal Pressure regulator is unstable Water Leakage in the stuffing box...

- Page 10 The pressure regulating √ valve is jammed Pressure spring stuck √ Intake/draining valve is √ √ jammed Pressure regulator valve √ √ √ fails The nozzle diameter is √ too large The nozzle diameter is √ √ too small The packing seal is √...

Need help?

Do you have a question about the YE4 and is the answer not in the manual?

Questions and answers