Summary of Contents for Rivacold BEST W R290

- Page 1 BEST W R290 Wall-mounted packaged unit for coldrooms Instruction manual | v. 01 Instructions translated from the original DANGER! Anyone who uses this machine is obliged to read these instructions for their own safety.

- Page 2 Transfer the document to websites or other electronic systems. Copy the content unmodified and indicating Rivacold srl as the copyright holder. Rivacold srl reserves the right to make changes or improvements to the relative documentation without prior notice. Requests for authorizations, additional copies of this...

-

Page 3: Table Of Contents

BEST W R290 Contents Warranty and assistance 6.2 Control panel operations Conformity 6.3 Setting the date and time 6.4 Using the MY I.D. App 1. Introduction 6.5 The passwords 1.1 Identification data 6. Use 1.2 Information about the instruction manual 6.6 Setting the date and time... - Page 4 BEST W R290 9.3 Periodic maintenance 9.4 Corrective maintenance 9.5 Remove the front panel 9.6 Checking or replacing condensing unit components 9.7 Checking or replacing evaporating part components 9.8 Check or replace components of the electrical box 10. Diagnostics 10.1 Installation and operation troubleshooting 10.2 Errors indicated by the controller...

-

Page 5: Warranty And Assistance

Post-warranty assistance After the warranty time frames have elapsed, assistance will be provided by RIVACOLD srl with a charge for the replaced parts and labor and transport expenses in force at the time. Warranty invalidation... -

Page 6: Introduction

BEST W R290 1. Introduction This section includes the following topics: 1.1 Identification data 1.2 Information about the instruction manual 1.1 Identification data 1.1.1 Manufacturer's contacts RIVACOLD srl Montecchio - via Sicilia, 7 61022 Vallefoglia (PU) Italia Tel: +39 0721 919911 Fax: +39 0721 490015 e-mail: info@rivacold.com... -

Page 7: Information About The Instruction Manual

It must be stored in a clean place and kept in good condition to be accessible to the operators. If the manual is lost or damaged, contact RIVACOLD srl. If the packaged unit is sold, always attach the instruction manual. - Page 8 1. Introduction BEST W R290 1.2.6 Figures and illustrations The figures and illustrations in this instruction manual are only used for reference and may differ in detail and proportions from the actual product. 1.2.7 Updates of the instruction manual Code...

-

Page 9: Safety

BEST W R290 2. Safety This section includes the following topics: 2.1 General safety warnings 2.2 Personnel skills 2.3 Residual risks 2.4 Safety labels 2.5 Fixed guards 2.6 Noise 2.1 General safety warnings 2.1.1 Obligations for the employer The employer must select, train and appoint authorized personnel to carry out their duties. -

Page 10: Personnel Skills

2. Safety BEST W R290 2.2 Personnel skills 2.2.1 Preamble Every section of this instruction manual is preceded by the skills that the personnel in question must have. Not having these skills can: endanger the safety of personnel invalidate the warranty Note: the operator's tasks are defined by the complexity of the operations and their level of experience and skill. - Page 11 BEST W R290 2. Safety Every procedure described in this instruction manual indicates the possible risks. Always follow the instructions in the instruction manual to avoid damage or injury. Follow the warnings given in this instruction manual concerning installation. Follow the instructions for adjustment, cleaning and maintenance given in this instruction manual.

-

Page 12: Safety Labels

2. Safety BEST W R290 2.3.6 Chemical residual risks Risk When it occurs How to avoid it Follow the regulations in force and the warnings on Explosion and fire During transport and handling, adjustments and maintenance given in this installation, cleaning and instruction manual. -

Page 13: Fixed Guards

BEST W R290 2. Safety Symbol Description Do not repair moving parts Do not remove safety devices Moving parts Do not use your hands to clean the condenser Flammable gas Electrocution Disconnect the power supply before performing maintenance. 2.5 Fixed guards 2.5.1 Fixed guards of the condensing unit... -

Page 14: Noise

2. Safety BEST W R290 2.5.2 Fixed guards of the evaporating part The fixed guards of the evaporating part consist of the side panels [A] and the grid [B]. 2.6 Noise 2.6.1 Sound pressure level The sound pressure measured while the packaged unit is running is less than 70 dB(A) LEX and/or 135 dB(C) Lpeak. -

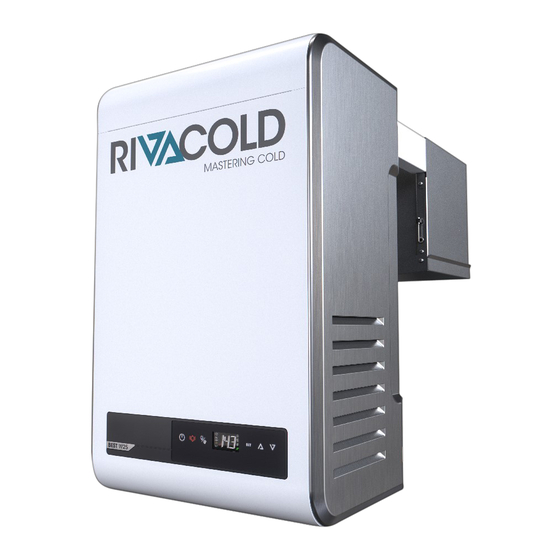

Page 15: Learning About The Packaged Unit For Coldrooms

3.4 Packaged unit operation 3.1 Limits of use 3.1.1 Intended use BEST W R290 is a packaged unit for small-sized coldrooms with electronic fan-motors and a water, air or Water Loop condenser. 3.1.2 Unintended use This packaged unit has been designed for all the uses declared in "Intended use" above. -

Page 16: Description Of The Packaged Unit

UNI EN 378-1. The amount of refrigerant for every circuit is ≤ 150 g to allow installation to take place anywhere without restrictions, as required by the reference standard. Note: Rivacold cannot be held liable for any restrictions due to national or regional regulations or laws. 3.2.3 Optional extras... - Page 17 3. Learning about the packaged unit for BEST W R290 coldrooms 3.3.2 BEST W components for installation with plug-in insulating panel removed Part Description Evaporating part Eyebolts Condensing unit Control panel Brackets Evaporator tray Plug-in insulating panel Instruction manual v. 01 | 9600-0033 ©...

- Page 18 3. Learning about the packaged unit for BEST W R290 coldrooms 3.3.3 BEST WT components for installation with the plug-in fitted Part Description Evaporating part Eyebolts Condensing unit Control panel Brackets Evaporator tray Plug-in insulating panel Instruction manual v. 01 | 9600-0033 ©...

- Page 19 3. Learning about the packaged unit for BEST W R290 coldrooms 3.3.4 Internal components Part Description Ventilation unit of the evaporating part Thermostatic valve Condenser Condensate drain tray Compressor Evaporator Condensing unit ventilation unit Electrical box 3.3.5 Components of the control panel...

- Page 20 3. Learning about the packaged unit for BEST W R290 coldrooms 3.3.6 Connections Part Description Power supply Wi-Fi IoT gateway antenna BMS (Building Management System) Refrigeration coldroom light Alarm Door heater (only for low temperature) Free position 2G IoT gateway antenna Master &...

- Page 21 3. Learning about the packaged unit for BEST W R290 coldrooms 3.3.7 USB port connection Part Description Electrical box USB micro port 3.3.8 Door switch components Part Description Door switch Retainer Instruction manual v. 01 | 9600-0033 © 2021 RIVACOLD srl Rev.

-

Page 22: Packaged Unit Operation

News: to know the news and events of the Rivacold world. Select: to know all the Rivacold products. Documents: to download the sales and technical documentation relating to Rivacold products. My Vision: to have access to the cloud through which it is possible to monitor and control the operation of every packaged unit. -

Page 23: Transport And Handling

BEST W R290 4. Transport and handling This section includes the following topics: 4.1 Handling warnings 4.2 Transport and handling 4.1 Handling warnings 4.1.1 Required skills Driver 4.1.2 Safety DANGER! Explosion/Burn. Presence of flammable gas. During transport and handling, adopt all the precautions required by the legislation in force. -

Page 24: Transport And Handling

4. Transport and handling BEST W R290 4.1.6 Lifting angle The angle between the tie rods changes the applied load according to the following diagram: Note: we recommend using angles less than 60°. 4.2 Transport and handling 4.2.1 Transport conditions The packaged unit is secured and packed in such a way as to prevent movement, impact and damage during transport. -

Page 25: Installation

5.8 Connect the packaged unit to the electrical mains 5.9 Work area and operational tasks 5.1 Installation warnings 5.1.1 Preamble Always refer to the information provided when ordering the packaged unit. Contact Rivacold technical assistance to receive specific information for the installation. 5.1.2 Required skills Manufacturer's personnel... -

Page 26: Setting The Packaged Unit In Place

5.2.4 Inspections and checks on the packaged unit Visually inspect the packaged unit to look for any damage caused during transport that could compromise normal operation. Transport damage must be attributed to the carrier and immediately reported to RIVACOLD srl. -

Page 27: Installation Requirements

BEST W R290 5. Installation Position the packaged unit so that there is sufficient space to pick it up, lift it and move it safely. Place the packaged unit indoors and covered with sheets so as to avoid exposure to atmospheric agents. - Page 28 5. Installation BEST W R290 5.4.3 Procedure 1. Make the grooves [A] and a hole [B] in the wall to 2. Undo the screws of the tray [C] and remove it drain water, using the packaging template. from the evaporating part [D].

-

Page 29: Install The Best W (With Plug-In Insulating Panel)

BEST W R290 5. Installation 7. Secure the tray [C] to the evaporating part [D] by 8. Connect the overflow tube to drain the inserting the tube in the hole [B] of the wall. condensate. 9. Install the door switch (see "Secure the door switch"... - Page 30 5. Installation BEST W R290 5.5.2 Dimensions of the window to be made in the wall Depending on the dimensions of the packaged unit, cut a window with the following dimensions in the coldroom wall. Use the packaging template to proceed more quickly.

- Page 31 BEST W R290 5. Installation 7. Lift the packaged unit using the eyebolts [H]. 8. Insert the evaporating part [I] and recess the plug-in insulating panel [E] in the window [A] of the wall. 9. Secure the packaged unit to the wall by inserting 10.

-

Page 32: Install The Best Wt (With The Pre-Fitted Plug-In Insulating Panel)

5. Installation BEST W R290 5.6 Install the BEST WT (with the pre-fitted plug-in insulating panel) 5.6.1 Result 5.6.2 Dimensions of the window to be made in the wall For this type of installation, depending on the dimensions of the packaged unit, a window with the following... -

Page 33: Secure The Door Switch

BEST W R290 5. Installation 3. Insert the evaporating part [C] and recess the 4. Secure the packaged unit with the screws [E]. plug-in insulating panel [D] in the window [A] of the wall. 5. Seal the parts of the packaged unit in contact with 6. -

Page 34: Connect The Packaged Unit To The Electrical Mains

5. Installation BEST W R290 CAUTION!: the installation of electrical components inside the refrigeration coldroom falls entirely under the responsibility of the end user. Only use suitable materials for the types of risks, in compliance with the laws in force. - Page 35 BEST W R290 5. Installation 5.9.2 Work area The work area for the operator is that in front of the control panel. 5.9.3 Operating tasks The operator sets the packaged unit and checks that is functions correctly. The operator periodically cleans the packaged unit (see "Maintenance and cleaning performed by the operators"...

-

Page 36: Start-Up

BEST W R290 6. Start-up This section includes the following topics: 6.1 Control panel 6.2 Control panel operations 6.3 Setting the date and time 6.4 Using the MY I.D. App 6.5 The passwords 6.1 Control panel 6.1.1 Control elements supplied with the packaged unit It is possible to control the packaged unit via the control panel or via mobile devices connected to the packaged unit via Bluetooth. -

Page 37: Control Panel Operations

BEST W R290 6. Start-up Button Function Steady on Flashing on Press briefly: scrolls through the menu items or Setpoint or active increases the displayed value. parameters menu Pressing simultaneously (3 seconds): accesses the parameters menu. Press briefly: scrolls through the menu items or Setpoint or active decreases the displayed value. -

Page 38: Setting The Date And Time

6. Start-up BEST W R290 6.2.2 Switch the coldroom light on and off Switch on: press and hold the button for 3 seconds and release. The coldroom pilot light lights up on the display. Switch off: press and hold the button for 3 seconds and release. - Page 39 BEST W R290 6. Start-up 6.3.2 Menu structure with Installer access 1st level 2nd level Menu Description Menu Description Configuration Service Installer Cloning Regulation Cooling Neutral Zone Humidity Compressor Pressure Times Compressor analog output Condenser Regulation Condenser analog output Defrost...

- Page 40 6. Start-up BEST W R290 Step Button Action Result Enter the password. Access enabled. Press and hold simultaneously for 3 seconds and release. "CnF" appears on the display. Press to view the rEG item. Press briefly. "Cld" appears on the display.

-

Page 41: Using The My I.d. App

BEST W R290 6. Start-up Step Button Action Result The value of the current time zone set appears fixed. Press UP/DOWN to select the desired value. Press SET to confirm and switch to the next value. The letter d (day) appears, followed by two digits indicating the number of the day. - Page 42 1. Download the free MY I.D. App from the Apple App Store or the Google Play Store. 2. Create your Rivacold account. 3. Pair the App with the packaged unit, see "Register the packaged unit using the QR code" below or "Register the packaged unit using the numeric code"...

- Page 43 BEST W R290 6. Start-up 6.4.4 Register the packaged unit using the numeric code 1. Select the menu 2. Select Units. 3. Select + 4. Select Manual. 5. Enter the packaged unit 6. Choose the option to share code next to the the position.

- Page 44 6. Start-up BEST W R290 6.4.5 Access the packaged unit via Bluetooth 1. Select Smart Control. 2. Select the packaged unit to 3. Select the profile you want to be controlled. log in with. 4. Enter the control panel login 5.

-

Page 45: The Passwords

BEST W R290 6. Start-up 6.5 The passwords 6.5.1 Levels of access to the parameters Access to the parameters menu and control of the packaged unit from the App are password protected. There are two levels of access: one for the installer and one for the end user. -

Page 46: Use

6. Use BEST W R290 6. Use This section includes the following topics: 6.6 Setting the date and time 6.6 Setting the date and time 6.6.1 Enter the password Step Button Action Result Press and hold simultaneously for 3 seconds and release. - Page 47 BEST W R290 6. Use 1st level 2nd level Menu Description Menu Description Evaporator Fans Electronic Valve Regulation Protections Coldroom Door and Light Alarms Alarms from inputs Alarms from operations HACCP Alarms Alarm setting General functions General alarms Settings Clock...

- Page 48 6. Use BEST W R290 Step Button Action Result Press briefly. "Cld" appears on the display. Press briefly. "SEt" appears on the display. Press the arrows to view the parameter. Press briefly. The parameter value appears on the display. Press to set the desired value.

- Page 49 BEST W R290 6. Use Step Button Action Result The letter m (month) appears, followed by two digits indicating the number of the month. Press UP/DOWN to set the month. Press SET to confirm and switch to the next value.

-

Page 50: Quick Menu

BEST W R290 7. Quick menu This section includes the following topics: 7.1 Description of the Quick menu 7.2 View the input and output state 7.3 Download and upload 7.4 Alarm log 7.5 HACCP alarm log 7.6 System information 7.7 Lock and unlock the control panel 7.1 Description of the Quick menu... - Page 51 BEST W R290 7. Quick menu Function code Description View the values of the analog outputs. View the values of the digital outputs. 7.2.2 View the state of input T21 (evaporator temperature probe) IOS > AI Step Button Action Result Press and hold for 3 seconds and release.

- Page 52 7. Quick menu BEST W R290 7.2.3 Input and output table Unit descriptions Unit I/O Description Analog inputs Coldroom temperature probe Evaporator temperature probe Coldroom 2 temperature probe Evaporator 2 temperature probe Circuit 1 low pressure probe Circuit 1 high pressure probe...

-

Page 53: Download And Upload

BEST W R290 7. Quick menu Unit descriptions Unit I/O Description Digital outputs Compressor 1 Compressor 2 Compressor 3 Condenser fans Evaporator defrost Evaporator 2 defrost Evaporator fans Evaporator 2 Fans On/Off from digital output Alarm Evaporator discharge heater Evaporator 2 discharge heater... -

Page 54: Alarm Log

7. Quick menu BEST W R290 d/L > dnL Step Button Action Result Press and hold for 3 seconds and release. The first item of the Quick menu appears on the display. Press briefly to display the desired menu item. -

Page 55: Haccp Alarm Log

BEST W R290 7. Quick menu Step Button Action Result Press briefly to display the desired menu item. Press briefly. "ALL" appears on the display. Press briefly. The display shows the code of the last logged alarm. Press briefly to view the alarm codes in the log. - Page 56 7. Quick menu BEST W R290 Quick menu > HCP > ALL Step Button Action Result Press and hold for 3 seconds and release. The first item of the Quick menu appears on the display. Press briefly to display the desired menu item.

-

Page 57: System Information

BEST W R290 7. Quick menu 7.6 System information Quick menu > InF 7.6.1 Available functions Function code Description View the version of the software installed on the controller. View the version of the operating system installed on the controller. - Page 58 7. Quick menu BEST W R290 Step Button Action Result Press briefly. "LOC" appears on the display for a few seconds. 7.7.2 Unlock the control panel Step Button Action Result Press simultaneously for 3 seconds. "unL" and the value of the variable set in parameter /t1 appear on the display for a few seconds, see "Configuration...

-

Page 59: Parameters

BEST W R290 8. Parameters This section includes the following topics: 8.1 Connecting to the micro USB port 8.2 Structure of the parameters menu 8.3 Changing a parameter 8.4 Configuration parameters 8.5 Service parameters 8.6 Regulation parameters 8.7 Compressor parameters 8.8 Condenser parameters... -

Page 60: Structure Of The Parameters Menu

8. Parameters BEST W R290 8.2 Structure of the parameters menu 8.2.1 Menu structure with Installer access 1st level 2nd level Menu Description Menu Description Configuration Service Installer Cloning Regulation Cooling Neutral Zone Humidity Compressor Pressure Times Compressor analog output... -

Page 61: Changing A Parameter

BEST W R290 8. Parameters 8.3 Changing a parameter 8.3.1 Enter the password Step Button Action Result Press and hold simultaneously for 3 seconds and release. "PSS" appears on the display. Press briefly. "P 0" appears on the display. Press briefly to display the relevant number (e.g. - Page 62 8. Parameters BEST W R290 1st level 2nd level Menu Description Menu Description General functions General alarms Settings Clock Supervision Master/Slave Password Initialization Unit of measurement Logout 8.3.3 Menu structure with user access 1st level 2nd level Menu Description Menu...

-

Page 63: Configuration Parameters

BEST W R290 8. Parameters Step Button Action Result Press briefly. The parameter value appears on the display. Press to set the desired value. Press briefly. The value is stored. The parameter name appears on the display. 8.4 Configuration parameters 8.4.1 List of parameters... - Page 64 8. Parameters BEST W R290 Unit of Parameter Description Options measure Range Default Select the Refrigerant Gas 1 - R22 1…40 2 - R134a 3 - R404A 4 - R407C 5 - R410A 6 - R507A 7 - R290 8 - R600...

- Page 65 BEST W R290 8. Parameters Unit of Parameter Description Options measure Range Default Select the stepper valve model 0 - User Defined 0…8 1 - Carel E2Vu 2 - Danfoss/Saginomya KV 3 - Sporlan ESX 4 - Alco EXM/EXL 5 - Sanhua L Series...

-

Page 66: Service Parameters

8. Parameters BEST W R290 8.5 Service parameters 8.5.1 List of installer parameters SEr > InS Unit of Parameter Description Options measure Range Default Enable Vacuum function Select the HMI type 0 - pLed 0…1 1 - pGD 8.6 Regulation parameters 8.6.1 List of cooling parameters... -

Page 67: Compressor Parameters

BEST W R290 8. Parameters Unit of Parameter Description Options measure Range Default Differential for Heating °C/°F 0…99.9 8.6.5 Parameter dnZ It defines the interval around the Set temperature, within which the cooling demand and the heating demand are reset. -

Page 68: Condenser Parameters

8. Parameters BEST W R290 8.7.2 List of timing parameters CMP > tME Unit of Parameter Description Options measure Range Default Delay Unit at start up and after blackout 0…999 8.7.3 List of cooling parameters CMP > CLd Unit of... -

Page 69: Defrost Parameters

BEST W R290 8. Parameters 8.8.3 List of analog output parameters Cnd > AOM Unit of Parameter Description Options measure Range Default Minimum value for Compressor Analog 0…100 output Speed Up time for Condenser fans 0…999 Analog output 8.8.4 Parameter Sut Useful in the case of traditional fans which need more electric current at start-up. - Page 70 8. Parameters BEST W R290 Unit of Parameter Description Options measure Range Default Enable and set time for Defrost 6 Enable and set time for Defrost 7 Enable and set time for Defrost 8 Enable and set time for Defrost 9...

-

Page 71: Evaporator Fan Parameters

BEST W R290 8. Parameters 8.9.3 Parameter dOH When the packaged unit starts, the controller cancels a defrost cycle if it is set to start in a shorter time than that set by parameter dOH. 8.9.4 Parameter tdc Defrosting is subject to conditions which prevent it from starting if not fully met. If the defrost is not started, the controller waits for the operation to start within a time defined by parameter tdc. -

Page 72: Electronic Valve Parameters

8. Parameters BEST W R290 8.11 Electronic valve parameters 8.11.1 List of regulation parameters EEV > REG Unit of Parameter Description Options measure Range Default Superheat setpoint 99.9…99.9 PID: Proportional gain 0.0…999.0 PID: Integral time 0.0…999.0 PID: Derivative time 0.0…999.0 Delay time after Defrost status 0…999... -

Page 73: Electronic Valve Protections

BEST W R290 8. Parameters Unit of Parameter Description Options measure Range Default Low Operating Pressure Protection: 1…999 Alarm Delay Max Operating Pressure Protection: °C/°F Threshold 99.9…99.9 Max Operating Pressure Protection: 0.0…999.0 Integral Time Max Operating Pressure Protection: 1…999 Alarm Delay 8.12 Electronic valve protections... - Page 74 8. Parameters BEST W R290 Quantity Description Parameter Alarm Alarm delay Time 8.12.2 Low evaporation pressure protection The low evaporation pressure protection (LOP) trips when the evaporation temperature is too low, to prevent the compressor from stopping due to the tripped low pressure switch.

-

Page 75: Coldroom Light And Door Switch Parameters

BEST W R290 8. Parameters The value of PM1 must be higher than the nominal evaporation temperature of the machine to avoid unwanted high evaporation pressure protection actions. The action on the electronic valve is not intended to eliminate the failure, but to keep the evaporation temperature below the threshold value. -

Page 76: Parameters Of The Alarms

8. Parameters BEST W R290 Unit of Parameter Description Options measure Range Default Enable Coldroom Light ON from Door 0 - No 0…1 Switch 1 - Yes Delay Compressor switch OFF when the 0…999 Door is open Delay Evap. fans switch OFF when the 0…999... - Page 77 BEST W R290 8. Parameters Alarm parameters from digital inputs Unit of Parameter Description Options measure Range Default Max number of PSH Alarms from DI 0…999 during PEI time Interval time for counter PSH Alarms from 0…180 Delay EXTERNAL ALARM Alarm from DI 0…999...

- Page 78 8. Parameters BEST W R290 Unit of Parameter Description Options measure Range Default Select High Regulation Temp. Alarm 0 - Disable 0…2 mode 1 - Relative 2 - Absolute Differential for return to High Regulation °C/°F 0...99.9 Temp. Alarm Threshold (Absolute)/ Differentilal °C/°F...

- Page 79 BEST W R290 8. Parameters Unit of Parameter Description Options measure Range Default Select the Alarm Threshold type for High 0 - Relative 0…1 Temperature HACCP 1 - Absolute Delay for HACCP High Temperature 0…120 Alarm Threshold for Absolute Alarm HACCP °C/°F...

- Page 80 8. Parameters BEST W R290 HSP= 3: average between the HACCP probe and the coldroom regulation probe. With HSP = 3, the temperature value that triggers the alarm is obtained by finding the average between the value detected by the HACCP probe and that of the coldroom regulation probe. The delay time is set with HC2.

-

Page 81: General Function Parameters

BEST W R290 8. Parameters 8.15 General function parameters 8.15.1 List of general alarm parameters GEF > ALF Unit of Parameter Description Options measure Range Default Enable Generic Alarm 1 0 - No 0…1 1 - Yes Select the variable for the regulation of 1 - Coldroom Temperature 1…40... - Page 82 8. Parameters BEST W R290 Unit of Parameter Description Options measure Range Default 28 - Safety High Pressure Switch from DI 29 - Safety Low Pressure Switch from DI 30 - Pump-Down Pressure Switch from DI 31 - Thermal Protection...

- Page 83 BEST W R290 8. Parameters Unit of Parameter Description Options measure Range Default Select the variable for the regulation of 1 - ST1.1 1…40 Generic Alarm 1 2 - ST2.1 3 - ST1.2 4 - ST2.2 5 - BPL1 6 - BPH1...

-

Page 84: General Setting Parameters

8. Parameters BEST W R290 Unit of Parameter Description Options measure Range Default Select Direct/Reverse regulation for 0 - Direct 0…1 Generic Alarm 2 1 - Reverse Threshold for Generic Alarm 2 99.9…99.9 Differential for Generic Alarm 2 0…99.9 Delay for Generic Alarm 2 0…999... - Page 85 BEST W R290 8. Parameters Unit of Parameter Description Options measure Range Default Baudrate for BMS port 0 - 1200 0…9 1 - 2400 2 - 4800 3 - 9600 4 - 19200 5 - 38400 6 - 57600 7 - 76800...

- Page 86 8. Parameters BEST W R290 Unit of Parameter Description Options measure Range Default Select the Defrost management for 1 - No Management 1…5 Master/Slave 2 - Contemporary Start/ Individual End 3 - Contemporary Start and 4 - Sequential Start 5 - Sequential Start and No...

- Page 87 BEST W R290 8. Parameters 8.16.4 Password change parameters StG > PWd Unit of Parameter Description Options measure Range Default Set new Password for User profile 0…9999 2201 Set new Password for Installer BEST 0…9999 2300 8.16.5 Initialization parameters StG > InI...

-

Page 88: Maintenance

BEST W R290 9. Maintenance This section includes the following topics: 9.1 Maintenance warnings 9.2 Maintenance and cleaning performed by the operators 9.3 Periodic maintenance 9.4 Corrective maintenance 9.5 Remove the front panel 9.6 Checking or replacing condensing unit components 9.7 Checking or replacing evaporating part components... -

Page 89: Maintenance And Cleaning Performed By The Operators

9.1.4 Maintenance on equipment components Perform maintenance by following the instructions, frequencies and all indications in the manuals and in the attached documentation. If necessary, contact RIVACOLD srl assistance. 9.2 Maintenance and cleaning performed by the operators 9.2.1 Required skills Operator 9.2.2 Safety... -

Page 90: Periodic Maintenance

Check that the refrigeration circuit is in good condition and that there are NO refrigerant gas leaks. Usually, the presence of lubricating oil indicates leaking refrigerant from the circuit. If in doubt, before carrying out any operation, contact RIVACOLD srl. Clean as follows: Cleaning Evaporator and... -

Page 91: Corrective Maintenance

9.4.1 Required skills Mechanical maintenance engineer Electrical maintenance engineer 9.4.2 Safety If in doubt, before carrying out any operation, contact RIVACOLD srl. Always wear helmets, footwear and protective gloves. Always wear the mask and protective goggles. 9.4.3 What to do In case of damage or a malfunction, consult "Installation and operation troubleshooting"... -

Page 92: Checking Or Replacing Condensing Unit Components

9.6.3 Warning Check or replace the components following the instructions, frequency and all indications in this manual and in the attached documentation. If necessary, contact RIVACOLD srl assistance. 9.6.4 Checking or replacing internal components of the condensing unit 1. Remove the side panels [A]. - Page 93 BEST W R290 9. Maintenance 9.6.5 Checking or replacing the condensing fan unit 1. Remove the top panel [A]. 2. Check or replace the fan unit of the evaporating part [B]. 3. If you need to replace the unit, replace and...

- Page 94 9. Maintenance BEST W R290 9.6.8 Replace the compressor 1. Remove the side panels [A]. 4. Undo the screws [D] and remove the compressor [E], removing all the components 2. Remove the front panel [B] (see "Remove the front that prevent its removal.

-

Page 95: Checking Or Replacing Evaporating Part Components

9.7.3 Warning Check or replace the components following the instructions, frequency and all indications in this manual and in the attached documentation. If necessary, contact RIVACOLD srl assistance. 9.7.4 Checking or replacing the fan unit 1. Remove the la grid [A]. -

Page 96: Check Or Replace Components Of The Electrical Box

9.8.3 Warning Check or replace the components following the instructions, frequency and all indications in this manual and in the attached documentation. If necessary, contact RIVACOLD srl assistance. Instruction manual v. 01 | 9600-0033 © 2021 RIVACOLD srl Rev. - Page 97 BEST W R290 9. Maintenance 9.8.4 Access the electrical box 1. Access the electrical box components [A] by removing the right side panel [B] and the electrical box panel [C]. 2. Check or replace the component. Instruction manual v. 01 | 9600-0033 ©...

-

Page 98: Diagnostics

10.1.2 Safety warnings If maintenance is required, follow the instructions and all indications in this manual and in the attachments. If necessary, contact RIVACOLD srl assistance. In case of maintenance, wear helmets, footwear and protective gloves. 10.1.3 Causes and solutions... - Page 99 BEST W R290 10. Diagnostics Cause Solution Personnel No controller consent to the Check the Setpoint (Set) and the differential (diF). compressor Load the default setting of the unit. Controller consent is present Check the wiring of the compressor relay on the circuit board but the compressor is off (OFF) and its activation state.

-

Page 100: Errors Indicated By The Controller

10. Diagnostics BEST W R290 The suction pipe and the compressor are frosted Cause Solution Personnel There is a liquid return and the If there is NO controller consent, check the evaporator fan evaporator fans are NOT parameters and, if necessary, load the default setting. - Page 101 BEST W R290 10. Diagnostics Reset Description Cause Impact Resolution Relay Evaporator Value measured Visual indication Check wiring and temperature probe outside the only integrity of the probe alarm operating ranges and replace it if necessary Faulty or disconnected sensor...

- Page 102 10. Diagnostics BEST W R290 Reset Description Cause Impact Resolution Relay Evaporation Value measured Visual indication Check wiring and temperature probe outside the only integrity of the probe alarm operating ranges and replace it if necessary Faulty or disconnected sensor...

- Page 103 BEST W R290 10. Diagnostics Reset Description Cause Impact Resolution Relay Compressor 1 alarm Compressor 1 alarm Circuit 1 block Check the condition triggered, possible of the compressor causes: circuit breaker or dedicated thermal protector tripped Compressor overheating or short...

- Page 104 10. Diagnostics BEST W R290 Reset Description Cause Impact Resolution Relay Value measured Visual indication Check wiring and Circuit 2 condensing outside the only integrity of the probe pressure probe operating ranges and replace it if alarm necessary Faulty or...

- Page 105 BEST W R290 10. Diagnostics Reset Description Cause Impact Resolution Relay Evaporating The valve opening Check that the Evaporation temperature too low, intensity is thermostatic valve temperature low below threshold PL1 increased. The and evaporator fans protection for longer than PL3 further the function properly.

- Page 106 10. Diagnostics BEST W R290 Reset Description Cause Impact Resolution Relay Error in EEV Driver Visual indication Check parameters EEV valve ID error parameterization only PVt and PVM Probable refrigerant Circuit 1 block Check the circuitry Circuit 1 gas leak...

- Page 107 BEST W R290 10. Diagnostics Reset Description Cause Impact Resolution Relay Probable refrigerant Stopped machine Check the circuitry General gas leak leak in the unit and whether there is alarm circuitry or a leak or check the evaporator blocked condition of the...

- Page 108 10. Diagnostics BEST W R290 Reset Description Cause Impact Resolution Relay Probe(s) used for Deactivation of the Check probe alarms General alarm probe the generic function generic function and verify their state 2 alarm in alarm state and connections Probe(s) used for...

- Page 109 BEST W R290 10. Diagnostics Reset Description Cause Impact Resolution Relay Probable incorrect Slave unit in alarm Check the Slave unit 1 offline connection or state not considered connection of the disconnection of the by the master in the master/slave line or...

- Page 110 10. Diagnostics BEST W R290 Reset Description Cause Impact Resolution Relay Evaporator defrost Visual indication Check the defrost Evaporator defrost ended due to only end value dT1 or the timeout alarm maximum time and maximum duration not due to value dS1...

- Page 111 BEST W R290 10. Diagnostics Reset Description Cause Impact Resolution Relay Defrost cycle Defrost not Check the Sequential defrost skipped on slave 6 performed, only conditions of the skipped on slave 6 during the visual indication unit and if alarm...

- Page 112 10. Diagnostics BEST W R290 Reset Description Cause Impact Resolution Relay 106 General alarm on At least one slave Visual indication Check the slave unit unit has a serious only in alarm state and slave unit alarm check the alarm in...

-

Page 113: Appendix

BEST W R290 11. Appendix This section includes the following topics: 11.1 Decommissioning 11.2 Technical features 11.3 Basic configurations 11.4 Attachments 11.5 Time zones 11.1 Decommissioning 11.1.1 Required skills Mechanical maintenance engineer Electrical maintenance engineer Driver 11.1.2 Safety Always wear protective goggles, footwear, protective gloves and tight- fitting clothes. - Page 114 11. Appendix BEST W R290 11.1.4 Dismantling the machine If the machine is to be relocated or has reached the end of its technical and operational life cycle, it must be dismantled. Dismantling procedure 1. Disconnect the energy sources. 2. Disassemble the various components.

- Page 115 BEST W R290 11. Appendix Instruction manual v. 01 | 9600-0033 © 2021 RIVACOLD srl Rev. | ...

- Page 116 11. Appendix BEST W R290 Instruction manual v. 01 | 9600-0033 © 2021 RIVACOLD srl Rev. | ...

- Page 117 BEST W R290 11. Appendix Instruction manual v. 01 | 9600-0033 © 2021 RIVACOLD srl Rev. | ...

-

Page 118: Basic Configurations

11. Appendix BEST W R290 11.3 Basic configurations The table shows the complete list of parameters with the relative settings for each of the four basic configurations. Parameters BEST WALL BEST WALL BEST WALL BEST WALL 2 COMPRESSORS 2 COMPRESSORS 1 COMPRESSOR NT 1 COMPRESSOR LT 99.9... -

Page 119: Attachments

BEST W R290 11. Appendix 11.4 Attachments 11.4.1 Documents attached to the manual Declaration of conformity Wiring diagram of the packaged unit Refrigerating diagram 11.5 Time zones 11.5.1 Time zones table Time zone Territory UTC -12:00 Baker Island, Howland Island... - Page 120 11. Appendix BEST W R290 Time zone Territory UTC +0:00 Burkina Faso, Canary Islands* (Spain), Ivory Coast, Gambia, Ghana, Guinea, Guinea-Bissau, Ireland*, Iceland, Faroe Islands*, Liberia, Mali, Mauritania, North Pole, Portugal*, United Universal time Kingdom*, Sant'Elena, São Tomé and Príncipe, Senegal, Sierra Leone, Togo...

- Page 122 RIVACOLD srl Montecchio - via Sicilia, 7 61022 Vallefoglia (PU) Italia www.rivacold.com info@rivacold.com Tel. +39 0721 919911 BEST W R290 Fax +39 0721 490015 © 2021 RIVACOLD srl...

Need help?

Do you have a question about the BEST W R290 and is the answer not in the manual?

Questions and answers