Table of Contents

Advertisement

Quick Links

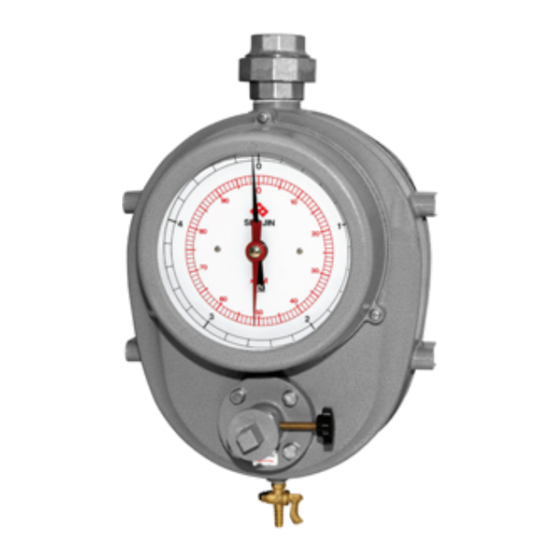

TANK LEVEL GAUGE (SLT)

(Gunja- - - - Dong) No.288 Dongil

(Gunja

Dong) No.288 Dongil- - - - Ro Gwangjin

(Gunja

(Gunja

Dong) No.288 Dongil

Dong) No.288 Dongil

Tel: 02-2204-8500

http:// www.seojin.biz

Ro Gwangjin- - - - Ku

Ku

Ro Gwangjin

Ro Gwangjin

Ku

Ku

Fax: 02-2204-8505

MAR.2012

LT-10120100514-SBL

Rev.2.0

Advertisement

Table of Contents

Summary of Contents for Seojin Instech SLT Series

- Page 1 TANK LEVEL GAUGE (SLT) MAR.2012 (Gunja (Gunja- - - - Dong) No.288 Dongil Dong) No.288 Dongil- - - - Ro Gwangjin Ro Gwangjin- - - - Ku (Gunja (Gunja Dong) No.288 Dongil Dong) No.288 Dongil Ro Gwangjin Ro Gwangjin Tel: 02-2204-8500 Fax: 02-2204-8505 http:// www.seojin.biz LT-10120100514-SBL...

-

Page 2: Table Of Contents

TABLE OF CONTENTS TABLE OF CONTENTS TABLE OF CONTENTS TABLE OF CONTENTS Chapter Contents Page Instruction Features Principles of operation Specifications Installation Adjustment Zero Calibration Procedures Mounting Component of system Checking before service... -

Page 3: Instruction

1. Instruction 1. Instruction 1. Instruction 1. Instruction MODEL SLT-1100〜4400 Tank Level Gauge for liquid level measuring system has robust function over local and remote indicating, alarming output, continuous display signal. So we may apply this instrument to not only level measurement but also monitoring, controlling of liquid level such as water, oil, chemical solvent, etc. - Page 4 4. Specification 4. Specification 4. Specification 4. Specification 4 4 4 4 ..1 1 1 1 SLT SLT- - - - 1100 Type 1100 Type 1100 Type 1100 Type Mechanical Specification Mechanical Specification Mechanical Mechanical Specification Specification Output : Analog Display...

-

Page 5: Specifications

4 4 4 4 ..5 5 5 5 Physical Specification Physical Specification Physical Specification Physical Specification Marking Marking ATEX Marking Marking ATEX ATEX (Flameproof Enclosure) ATEX (Flameproof Enclosure) (Flameproof Enclosure) (Flameproof Enclosure) All units have a rating label, which carries the following important information: TANK LEVEL GAUGE Model : SLT (Except SLT-1100) Code : Ex d IIC T6... -

Page 6: Installation

5. Installation 5. Installation 5. Installation 5. Installation 5 5 5 5 ..1 1 1 1 Checking before installation Checking before installation Checking before installation Checking before installation - Before starting a work for installation, you shall prepare or arrange each component as shown figure 1. - Page 7 5 5 5 5 ..2 2 2 2 Install Transmit Install Transmit Install Transmit Install Transmitter — Before mounting remove transmitter cover. Turn drive shaft (6. Fig. 1) until both worm wheel screws are accessible. — Flange the transmitter to the tank level gauge using the accessories shown in Fig.

- Page 8 5 5 5 5 ..4 4 4 4 Cable Selection Cable Selection Cable Selection Cable Selection When using the external earth terminal a cable crimp lug must be used. The cable lug should be located between the two M4 stainless steel flat washers, The M4 stainless steel spring washer must be fixed between the outer flat washer and the M4 stainless steel nut to ensure that the cable lug is secured against loosening and twisting.

- Page 9 5 5 5 5 ..7 7 7 7 M M M M easuring Tape easuring Tape easuring Tape easuring Tape — Don’t loosen fix screw ⓧ which is located on the lower end of indicator body before float is combined with measuring tape.

- Page 10 5.8.2 Guide Wire Knob and Bottom Piece The distance which should be assembled between both guide wire knobs, or both bottom pieces, shall be 440±2 ㎜ and the wire knobs and bottom pieces shall be combined on the same vertical axis.

- Page 11 ④ Put the measuring tape through guide wire figure 7 pipe of indication with the same tying a rope or wire on the end of it at this time. You shall put out carefully the rope or wire not to be the measuring tape twisted (Refer to the fig.

- Page 12 ⑧ Disassemble screw from bracket attached on the both side of float, and separate guide fix bracket from it. Then, put the end of wire into a hole on the bracket and tighten the set screw again (Refer to fig. 14). Fig.

-

Page 13: Adjustment

6. Adjustment 6. Adjustment 6. Adjustment 6. Adjustment 6.1 Checking Checking Checking Checking the operating condition in manual the operating condition in manual the operating condition in manual. the operating condition in manual - Push hoist lever knob, put lever to knob and turn counter in clockwise direction. - Float will be raised and the dial will be moved. -

Page 14: Zero Calibration Procedures

7 7 7 7 . Zero Calibration Procedures . Zero Calibration Procedures . Zero Calibration Procedures . Zero Calibration Procedures If you can measure fluid level manually before calibration, fix point position after remove indicator cover and loosen fixture screw Calibration that measuring range 300~16800㎜... -

Page 15: Mounting

8. Mounting 8. Mounting 8. Mounting 8. Mounting SIDE MOUNT TYPE U-SEAL POT & SIDE MOUNT TYPE TOP MOUNT TYPE FLOATING ROOF & SIDE MOUNT TYPE... -

Page 16: Component Of System

9. 9. 9. 9. Components of system Components of system Components of system Components of system Component External form and Dimension Material Q,TY Body: ADC9 Indicator Back Cover: ADC9 Body Scale Cover: ADC9 Std.: 304SS Float Option: 316SS Knob: AC2B Guide Wire Knob Nipple: SS41... - Page 17 Component External form and Dimension Material Q,TY Body Mount SS41 Bracket Pipe SS41 Supporter Flange: 304SS Flange & Union Union: SS41 (Option) Option: 304SS 304SS Bottom Piece Option: 316SS Elbow: AC2B U-Type Pipe: 304SS Seal Pot Oil: Silicon (10,000cs)

-

Page 18: Checking Before Service

11. Checking before service . Checking before service . Checking before service . Checking before service Touble Cause applicable - Check power supply (DC 13V〜32V) - Check if measuring tape is broken or its way is drifted a way from tape winding pulley Indicating scale is not worked - Chock if constant spring is broken - Check if float is untied from tape and is on the...

Need help?

Do you have a question about the SLT Series and is the answer not in the manual?

Questions and answers