Table of Contents

Advertisement

Quick Links

INSTALLATION AND OPERATION INSTRUCTION

CONDENSING and NON-CONDENSING HYBRID CONTROL

This product can be used with the following systems:

•

Hi Delta Hydronic Boilers, Models 302C-902C

•

Hi Delta SS Hydronic Boilers, Models HD101-HD401

•

MVB Modulating Vertical Hydronic Boilers 503A-2003A

•

MVB Modulating Vertical Hydronic Boilers 504A-2004A

•

MVB Modulating Vertical Water Heater 2503-4003

•

MVB Modulating Vertical Water Heaters 503A-2003A

Now with Optional

BACnet MS/TP

E

G

I

Comm

HYBRID

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

PWR

E

K

F

L

G

M

H

N

I

O

J

L N

1 2

3 4

5 6

7 8

9 10

11 12

11 12

IMPORTANT SAFETY INSTRUCTIONS. READ AND FOLLOW

ALL INSTRUCTION. SAVE THESE INSTRUCTIONS.

WARNING: The TempTracker mod+ Hybrid is strictly an operating control. It CANNOT be used as a

A

limit control. All boilers must have all safety and limit controls required by code. It is the responsibility

of the installer to verify that all the safety and limits are working properly before the TempTracker mod+

Hybrid is installed.

This control must be installed by a licensed electrician.

This manual should be maintained in legible condition and kept adjacent to the unit or in a safe place for future

use.

K

F

L

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

M

H

N

FOR ALL CIRCUITS

INPUT RATINGS:

O

J

P

115VAC 60Hz, 12VA MAX

Use Copper Conductors Only.

Power

CAUTION:

Risk of Electric Shock.

More than one disconnect switch may be required

to de-energize the equipment before servicing.

Ext A

Ext B

E

K

F

L

G

M

H

N

I

O

J

P

P

CUR / VLT

CUR / VLT

CUR / VLT

CUR / VLT

CUR / VLT

CUR / VLT

GND

mA

VLT

GND

GND

mA

VLT

GND

GND

mA

VLT

GND

GND

mA

VLT

GND

mA

VLT

GND

GND

mA

VLT

13

14

15

16

16

17

18

19

19

20

21

22

22

23

24

25

26

27

28

16

29

30

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz , 30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

ENCLOSED

ENERGY

CAUTION

: RISK OF ELECTRIC SHOCK

MANAGEMENT

More than one disconnect switch may be required

EQUIPMENT

99RA

to de-energize the equipment before servicing.

EXTENSION

MODULE

RS-485

HYBRID

SYSTEM

A

B

C

D

DO NOT APPLY ANY VOLTAGE

PROGRAM

RUN

TO INPUT TERMINALS

Effective: 03-25-22

Replaces: 02-24-12

P/N 241382 Rev. 5

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Rheem Raypak TempTracker MOD+ HYBRID

- Page 1 INSTALLATION AND OPERATION INSTRUCTION CONDENSING and NON-CONDENSING HYBRID CONTROL This product can be used with the following systems: • Hi Delta Hydronic Boilers, Models 302C-902C • Hi Delta SS Hydronic Boilers, Models HD101-HD401 • MVB Modulating Vertical Hydronic Boilers 503A-2003A •...

- Page 2 Revision 5 reflects the following changes: Reformatted and reorganized. Additional metric data added. Final paragraph added to Staging Logic Overview on page 4. Final sentence added to Wiring the Voltage Modulating or Staging Boilers on page 16. First bullet point added to Lead Boiler Rotation on page 33.

-

Page 3: Table Of Contents

TABLE OF CONTENTS 1. WARNINGS ............4 Staging Boiler Operating Settings ......35 Pay Attention to these Terms ........4 Day / Night Schedule ..........36 Maintenance............37 2. HYBRID LOGIC OVERVIEW ......... 5 Display ..............38 3. MODULATING LOGIC OVERVIEW ...... 6 Display Messages .......... -

Page 4: Warnings

1. WARNINGS Pay Attention to these Terms Indicates the presence of immediate hazards which will cause severe personal injury, death or substantial DANGER property damage if ignored. ndicates the presence of hazards or unsafe practices which could cause severe personal injury, death or WARNING substantial property damage if ignored. -

Page 5: Hybrid Logic Overview

Condensing boiler group will be the lead group and the 2. HYBRID LOGIC OVERVIEW Condensing Group will be the lag group. In response to new advancements in condensing boiler The TempTracker mod+ Hybrid will control the condensing design and size, many applications utilize both multiple group of boilers as the lead group so long as the sensed condensing boilers and multiple non-condensing boilers. -

Page 6: Modulating Logic Overview

When the Temp Tracker mod+ Hybrid PID logic foresees 3. MODULATING LOGIC that the system will overshoot, regardless of the current OVERVIEW system and target values, it will make sure that the last stage turned on/energized has elapsed a full Minimum The Modulation PID logic provides the capability of Runtime before it is turned off/ de-energized. - Page 7 Reset Ratio, Water Offset, and changes with Outdoor temperature. Reset Ratio/Outdoor Reset WITH A 0°F OFFSET, THE RESET CURVES When a building is being heated, heat escapes through the BEGIN AT 100°F WATER TEMPERA- walls, doors, and windows to the colder outside air. The TURE.

-

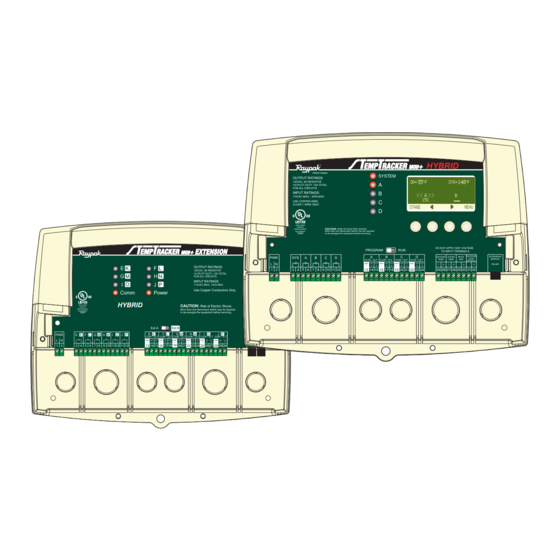

Page 8: Temptracker Mod+ Hybrid Layout

6. TEMPTRACKER MOD+ HYBRID LAYOUT The digital display shows the system status, set point, Program Switch to restrict access to lead stage <in brackets>, and status of each stage. function changes. This switch is To view and adjust settings, press the appropriate buttons. covered with Wiring Enclosure. -

Page 9: Temptracker Mod+ Extension Layout

7. TEMPTRACKER MOD+ EXTENSION LAYOUT Extension Selection Switch to determine Stage letters and LED colors. Ext-A Stages E - J and all LEDs are Green LED indicates the Ext-B Stages K - P and all LEDs are Red associated relay status. This switch is covered with the Wiring Enclosure. -

Page 10: Features

lead stage every selected time period from every hour to 8. FEATURES every 60 days. The TempTracker mod+ Hybrid has been designed with Outdoor Reset Hydronic building heating, using both condensing and non-condensing boilers, as the primary purpose. As well, The TempTracker mod+ Hybrid has a hydronic outdoor it is capable of controlling modulating or staging boilers. -

Page 11: Make Sure You Have The Right Control

BACnet settings. See "BACnet MSTP Startup Menu" BACnet MS/TP Communication on page 45. An optional BACnet Interface Module (#651735) can be used to connect the control to a BACnet MSTP network for 9. INSTALLATION remote access. Each of the TempTracker mod+ Hybrid or Extension consists of three primary enclosure components. -

Page 12: Install The Sensors

humidity. Ambient operating temperature is from feet past the boiler loop outlet on the common supply 20°F to 120°F (-7°C to 49°C). header but before any major takeoffs. The sensor must be located where it sees the output of all the •... -

Page 13: Wiring

• Do not run sensor wires in conduit with line voltage • Temperature sensors have no polarity. Connect the wiring. two wires from the sensor to the TempTracker mod+ Hybrid terminals marked SYSTEM TEMP 27, 28. NOTE: Determining the proper location of the Outdoor •... - Page 14 desirable to turn off the TempTracker mod+ Hybrid System Output. All boiler outputs will be off when the stage outputs from a remote location or another PROVE input is open. controller (i.e. EMS input). • A factory-installed jumper provides the System Prove •...

- Page 15 Wiring the System Output (Terminals 3, 4) • The SYS output relay will energize and remain constantly energized whenever outdoor temperature is below the Outdoor Cutoff. • When the outdoor temperature rises 2°F (1°C) above the Outdoor Cutoff, the SYS output will remain energized for the period set by the System Run-On then de-energize.

- Page 16 Wiring to Modulating Boilers Wiring the Voltage Modulating or Staging Boilers WARNING: The Modulating Output Type must be set (A Terminals 13, 15), (B Terminals 16, 18),... to match the boiler modulating signal prior to wiring the boiler signal to avoid control or equipment damage. •...

- Page 17 • Only the 6-wire RJ11 cable supplied with the NOTE: To set the Extension to a specific letter, remove extension must be used for proper operation. the wiring cover and switch the Ext A/Ext B to the desired • RJ11 cables must be of a 6-wire with 6-pin terminals. letter.

-

Page 18: Startup Settings

RJ45 socket (RS485) to connect to communicate to Connecting to BACnet Interface Module each other. • The TempTracker mod+ Hybrid can communicate • The Interface BACnet Module must be wired to the to BACnet MSTP networks when used the BACnet BACnet MSTP network using the RS485 terminals A, Interface Module (#651735). - Page 19 • On the first power up, the System Startup screen will • If Reset °C is selected, all temperatures and settings appear after the initialization is complete. If it doesn’t, will be displayed in degrees Celsius and the control the TempTracker mod+ Hybrid has already been will use Reset Ratios to adjust the system setpoint.

-

Page 20: Hybrid Startup Menu

11. HYBRID STARTUP MENU page 19 -------- SETTINGS ---- --- BOILER TYPE --- -- ARE YOU SURE? -- Season Winter Modulation System Target 140 Staging <System Settings> Hybrid <Maintenance> ▲ ▼ BACK SAVE <System Startup> ▲ ▼ BACK SAVE page 22 page 19 ▲... -

Page 21: Modulating & Staging Startup Menu

12. MODULATING & STAGING STARTUP MENU page 19 --- BOILER TYPE --- -- ARE YOU SURE? -- -------- SETTINGS ---- Modulation Season Winter Staging System Target 140 Hybrid <System Settings> ▲ ▼ BACK SAVE <Maintenance> ▲ ▼ BACK SAVE <System Startup> page 19 ▲... -

Page 22: Hybrid Startup Settings

• It is the setpoint at which the TempTracker mod+ EMS 4mA and 20mA Setpoints Hybrid will switch between the Condensing Boiler 4mA: can be set from 50°F/ 10°C to 200°F/ 93°C Group and Non-Condensing Boiler Group. (Default: 70°F/ 21°C) •... -

Page 23: Hybrid Modulating Boiler Settings

• To switch the lead group when the temperature is Stage-A. rising, the Target Temperature must rise above the • Then, select the number of non-condensing boilers Switch Setpoint for the complete Switch Delay period later in the Startup menu. See "HYBRID Startup before the switching of the lead group could take Menu"... -

Page 24: Hybrid Staging Boiler Settings

Modulating Mode NON-CONDENSING -- OUTPUT TYPE -- On/Off Normal, Parallel (Default: Normal) 2-Stage 3-Stage Button: MENU/<System Startup>/../Output A Type/ 4-Stage Condensing Modulating Mode ▲ ▼ BACK SAVE • Some modulating boilers perform better at higher Figure 41. Staging Output Type modulation. -

Page 25: Staging Boiler Settings

the boiler multiplied by 2. That is, if the lowest firing Modulating Output Type of the boiler was 20%, set your Modulation Start% to 4-20mA, 0-10V, 1-10V (Custom) Outputs (Default: 1-10v 40%. See "Modulation Start %" on page 42. Custom) •... - Page 26 relay will continue to run for the System Run-On Staging period before turning off. -- OUTPUT TYPE -- On/Off • Domestic Hot Water No Priority (Summer) behaves 2-Stage the same as the DHW No Priority. The only difference 3-Stage is that in Summer, Shutdown, No Tstat call for heat, or 4-Stage when outdoor temperature is above Outdoor Cutoff, ▲...

-

Page 27: Setting The Control To Factory Defaults

allows an external device or control to provide the Cutoff. However, when the Outdoor sensor reads setback signal. No scheduling or boost menu options Short or Open, the control will try to maintain the will be available with Setback. Maximum Water Temperature. •... -

Page 28: Hybrid Operating Menu

13. HYBRID OPERATING NOTE: To be able to change the TempTracker mod+ Hybrid settings the Program/Run Switch must be set MENU to Program. The switch is located under the Enclosure Wiring Cover for security. The Enclosure Wiring Cover can be secured using a lock. ----- SEASON ----- -------- SETTINGS ---- Winter... -

Page 29: Modulating And Staging Operating Menu

14. MODULATING AND NOTE: To be able to change the TempTracker mod+ Hybrid settings the Program/Run Switch must be set STAGING OPERATING to Program. The switch is located under the Enclosure MENU Wiring Cover for security. The Enclosure Wiring Cover can be secured using a lock. -

Page 30: Operating Settings

the setpoint depends on the Modulation Mode, 15. OPERATING SETTINGS System Settings, and Stage Settings. Program Change Switch Setting ----- SET POINT ----- To be able to change the TempTracker mod+ Hybrid settings, the Program/Run Switch must be set to Program. ▲... - Page 31 -- SYSTEM TARGET -- ------- OFFSET ------ 1.00 OD = 4.00 1.00 OD = 3.00 1.00 OD = 2.00 1.00 OD = 1.50 ▲ ▼ BACK SAVE 1.00 OD = 1.25 1.00 OD = 1.00 Figure 60. Offset 1.25 OD = 1.00 1.50 OD = 1.00 2.00...

-

Page 32: System Settings

Minimum Water Temp ----- SETTINGS 1 ---- Setback Adjustable from 50ºF/ 10ºC to 180ºF/ 82ºC (Hybrid Purge Delay 1.0min System Run-On 0min Default: 70ºF/ 21ºC) (Staging or Modulation Default: Lead Rotation Time 120ºF/ 49ºC) <More Settings> ▲ ▼ SELECT BACK Button: MENU/System Target/Offset/Outdoor Cutoff/ Minimum Water Temp ----- SETTINGS 2 ----... - Page 33 • The System Run-On time should be set based on ------- SETBACK ------- the size and type of the boilers and pumps used. In general, when setting the System Run-On consult the boiler and pump manufacturers for the best setting. ▲...

-

Page 34: Modulating Boiler Operating Settings

• When Soft-Off is set to other than 0 seconds, the Standby Time Lead Boiler will need to remain at or exceed the Last Adjustable from 1 min to 60 min (Default: 10 min) Stage Hold for the Soft-Off period before turning off. Button: MENU/<System Settings>/<More Settings>/ LAST STAGE HOLD Standby Time... -

Page 35: Staging Boiler Operating Settings

0 to 2). Wait for at least 15 minutes before evaluating Soft-Off Delay how the change has affected the system. Adjustable from 0sec to 60sec Default: 10 sec MODULATION SETTINGS Button: MENU/<System Settings>/<More Gain Settings>/<Modulating Settings>/Soft-Off Delay Lag Delay 0min Soft-Off Delay 45sec •... -

Page 36: Day / Night Schedule

Day / Night Schedule Minimum Runtime Adjustable from 1 to 60 minutes (Default: 2 minutes) (Available when "Shutdown or Tstat" is selected from the Shutdown/Tstat/ Setback Startup menu option Button: MENU/<System Settings>/<More only) Settings>/<Stage Settings>/Min Runtime Button: MENU/<System Settings>/<More Settings>/ •... -

Page 37: Maintenance

Set Time System & Outdoor Sensor Trim Button: MENU/<System Settings>/<More Settings>/Set Adjustable from -5F°/ -3C° to +5F°/ +3C° (Default: Time 0°F/C) • Adjust the time by selecting Set Time from the menu and Button: MENU/<Maintenance>/System Trim then scrolling through the hours then select Save. If the Button: MENU/<Maintenance>/Outdoor Trim hours are to be set to PM, scroll through the AM hours to •... -

Page 38: Display

Outdoor and System Configuration F SYS= Temperature Messages Prepurge Delay 15 Button: MENU/<Maintenance>/<Configuration> Boilers and <<A>> Their Status • This menu option provides a consolidated view of the TempTracker mod+ Hybrid's Startup and Stage Button Functions STAGE ◄ ► MENU settings. -

Page 39: Display Messages

Display Messages The TempTracker mod+ Hybrid display layout reserved the second line for message indications. The following is a list of the most common Message Display Line information: Message Display Message Information The Boost has started 30 minutes before the Day Schedule setting and the Boost temperature is Boost To 170˚F (77°C) 170˚F (77°C). -

Page 40: Boiler Stage Menu

16. BOILER STAGE MENU F SYS= <<A>> STAGE ◄ ► MENU STAGE A - IGNITION POINT - Staging Modulation STAGE A SETTINGS STAGE A SETTINGS ▲ ▼ Mode Auto Mode Auto BACK SAVE <Prev Stage> Ignition % <Next Stage> Mod Start % <Prev Stage>... -

Page 41: Boiler Stage Settings

Sequencing Boiler Stage Menu Boiler Stage Settings STAGE A SETTINGS Mode Auto Button: STAGE/ <Prev Stage> <Next Stage> The Stage menu provides adjustment for each of the ▲ ▼ individually boiler operations. BACK SELECT • In most installations, all active boiler adjustments are Figure 89. - Page 42 (Modulating Boilers Only) boilers to run at the lowest modulation. See "Modulating Logic Overview" on page 6. 0-10VDC Adjustable from 1% to 50% (Default: 1%) STAGE A 1-10VDC Custom Adjustable from 5% to 70% (Default: MODULATION START 25%) Button: STAGE/Ignition % •...

-

Page 43: Troubleshooting

NOTE: The Mode MUST be set for each boiler. The Display shows an Incorrect Temperature Copy Settings command will not set the Mode for the Remove the wires from the sensor terminals. The remaining boilers. Only Ignition % and Modulation Start display should change to read OPEN. - Page 44 • Control Settings - The Last Stage Hold will allow only the Lead boiler to stay on for an additional number of degrees. If the setting is too high, and only the Lead boiler is on, the system can over heat. Reduce the Last Stage Hold setting. See "Last Stage Hold"...

-

Page 45: Bacnet Mstp Startup Menu

required (#651735). In addition, each of the Boiler Type 18. BACNET MSTP STARTUP and Sensor Type Startup menu option will offer a different MENU list of BACnet variables. See "Boiler Type" on page 19, "Sensor Type" on page 19, and "Hybrid - Outdoor Reset When using the TempTracker mod+ Hybrid in a BACnet - BACnet Variable List"... -

Page 46: Bacnet Pics Statement

19. BACNET PICS STATEMENT Product Model Number Protocol Revision Software Version Firmware Version TempTracker mod+ Hybrid BACnet Control Varies Vendor Vendor ID Address and Phone Raypak, Inc. 2151 Eastman Ave., Oxnard, CA 93030 - (805)278-5300 Product Description TempTracker mod+ Hybrid control for hot water heating applications. (See http://www.raypak.com for more information) BACnet Standardized Device Profile (Annex L) Product... -

Page 47: Hybrid - Outdoor Reset - Bacnet Variable List

20. HYBRID - OUTDOOR RESET - BACNET VARIABLE LIST... - Page 48 Hybrid - Outdoor Reset - BACnet Variable List (continued)

-

Page 49: Modulation - Outdoor Reset - Bacnet Variable List

21. MODULATION - OUTDOOR RESET - BACNET VARIABLE LIST... - Page 50 Modulation - Outdoor Reset - BACnet Variable list (continued)

-

Page 51: Staging - Outdoor Reset - Bacnet Variable List

22. STAGING - OUTDOOR RESET - BACNET VARIABLE LIST... - Page 52 Staging - Outdoor Reset - BACnet Variable list (continued)

-

Page 53: Modulation - Setpoint - Bacnet Variable List

23. MODULATION - SETPOINT - BACNET VARIABLE LIST... - Page 54 Modulation - Setpoint - BACnet Variable list (continued)

-

Page 55: Staging - Setpoint - Bacnet Variable List

24. STAGING - SETPOINT - BACNET VARIABLE LIST... - Page 56 Staging - Setpoint - BACnet Variable list (continued)

-

Page 57: Piping And Wiring Diagrams

The TempTracker mod+ Hybrid operates four modulating 25. PIPING AND WIRING boilers and two 4-stage Boilers. The boilers are piped in DIAGRAMS Reverse Return on the primary loop. The System output is controlling the System Pump. Hybrid Piping Diagram Raypak, Inc. is aware that each installation is unique. Thus, Raypak, Inc. -

Page 58: Hybrid Wiring Diagram

Hybrid Wiring Diagram Two 4-20mA Modulating Condensing Boilers HYBRID and Two 4-Stage Non- SYSTEM OUTPUT RATINGS: Condensing Boilers 120VAC, 6A RESISTIVE 1A PILOT DUTY, 15A TOTAL FOR ALL CIRCUITS INPUT RATINGS: 115VAC 60Hz , 30VA MAX USE COPPER WIRE, CLASS 1 WIRE ONLY. ENCLOSED ENERGY CAUTION... -

Page 59: Modulating Piping Diagram

Raypak, Inc. is aware that each installation is unique. Modulating Piping Diagram Thus, Raypak, Inc. is not responsible for any installation System: related to any electrical or plumbing diagram generated by Raypak, Inc. The provided illustrations are to demonstrate The TempTracker mod+ Hybrid operates four modulating Raypak, Inc.’s control operating concept only. -

Page 60: Modulating Wiring Diagram

Modulating Wiring Diagram Four 4-20mA Modulating Boilers HYBRID SYSTEM OUTPUT RATINGS: 120VAC, 6A RESISTIVE 1A PILOT DUTY, 15A TOTAL FOR ALL CIRCUITS INPUT RATINGS: 115VAC 60Hz , 30VA MAX USE COPPER WIRE, CLASS 1 WIRE ONLY. STARTUP SETTINGS Boiler Type = Modulation ENCLOSED ENERGY CAUTION... -

Page 61: Staging Piping Diagram

Raypak, Inc. is aware that each installation is unique. Staging Piping Diagram Thus, Raypak, Inc. is not responsible for any installation System: related to any electrical or plumbing diagram generated by Raypak, Inc. The provided illustrations are to demonstrate The TempTracker mod+ Hybrid operates two 2-stage Raypak, Inc.’s control operating concept only. -

Page 62: Staging Wiring Diagram

Staging Wiring Diagram Two 2-Stage Boilers HYBRID SYSTEM OUTPUT RATINGS: 120VAC, 6A RESISTIVE 1A PILOT DUTY, 15A TOTAL FOR ALL CIRCUITS INPUT RATINGS: 115VAC 60Hz , 30VA MAX STARTUP SETTINGS USE COPPER WIRE, CLASS 1 WIRE ONLY. Boiler Type = Staging Boiler Number = 2 Output Type = 2-Stage ENCLOSED... -

Page 63: Specifications

26. SPECIFICATIONS (1:4) to (4:1) (Outdoor : System Reset Ratio Range Water) General minus -40°F°/-22°C° to plus Offset Adjustment Item Specification 40°F°/22°C° Voltage Input: 120 VAC 60 Hz Minimum Water 50°F/10°C to 170°F/77°C Temperature Power Consumption 12 VA Max Maximum Water Operating Temperature 20°F/-6°C to 130°F/54°C 90°F/32°C to 240°F/116°C... - Page 64 NOTES Raypak, Inc., 2151 Eastman Avenue, Oxnard, CA 93030 (805) 278-5300 www.raypak.com...

Need help?

Do you have a question about the Raypak TempTracker MOD+ HYBRID and is the answer not in the manual?

Questions and answers